Single-plate plugging mechanism, single-plate case, case frame and single-plate installation device

A plug-in mechanism and single-board technology, which is applied in the field of single-board plug-in mechanism, machine frame and single-board installation device, and single-board chassis, can solve the problems of inconvenient plug-in and pull-out of single boards, and reduce the risk of backstitching , the effect of direction stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present application, and to make the above-mentioned purposes, features and advantages of the embodiments of the present application more obvious and understandable, the following describes the technical solutions in the embodiments of the present application in conjunction with the accompanying drawings For further detailed explanation.

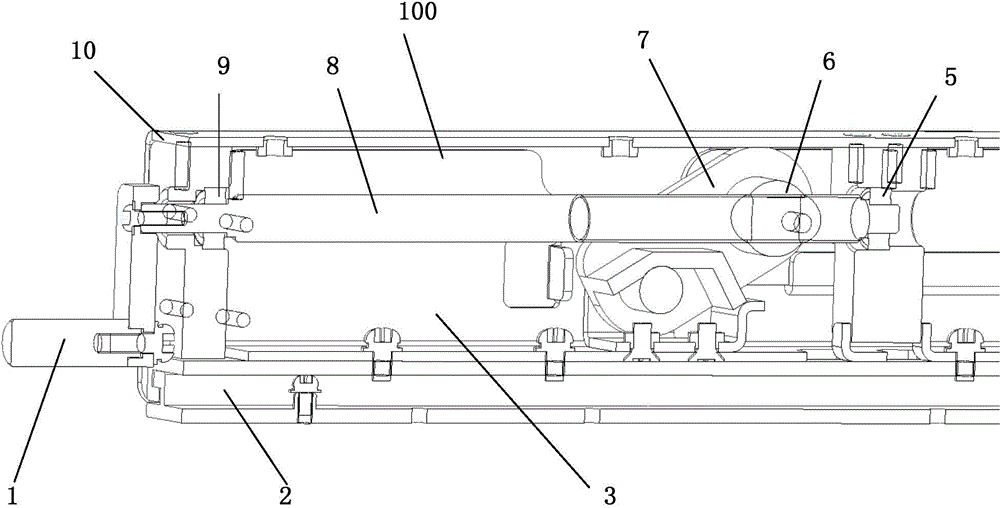

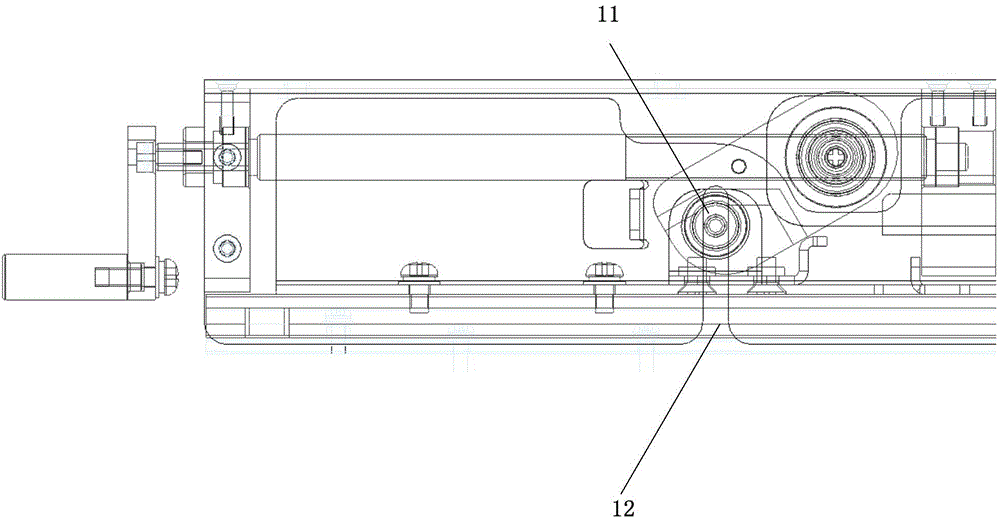

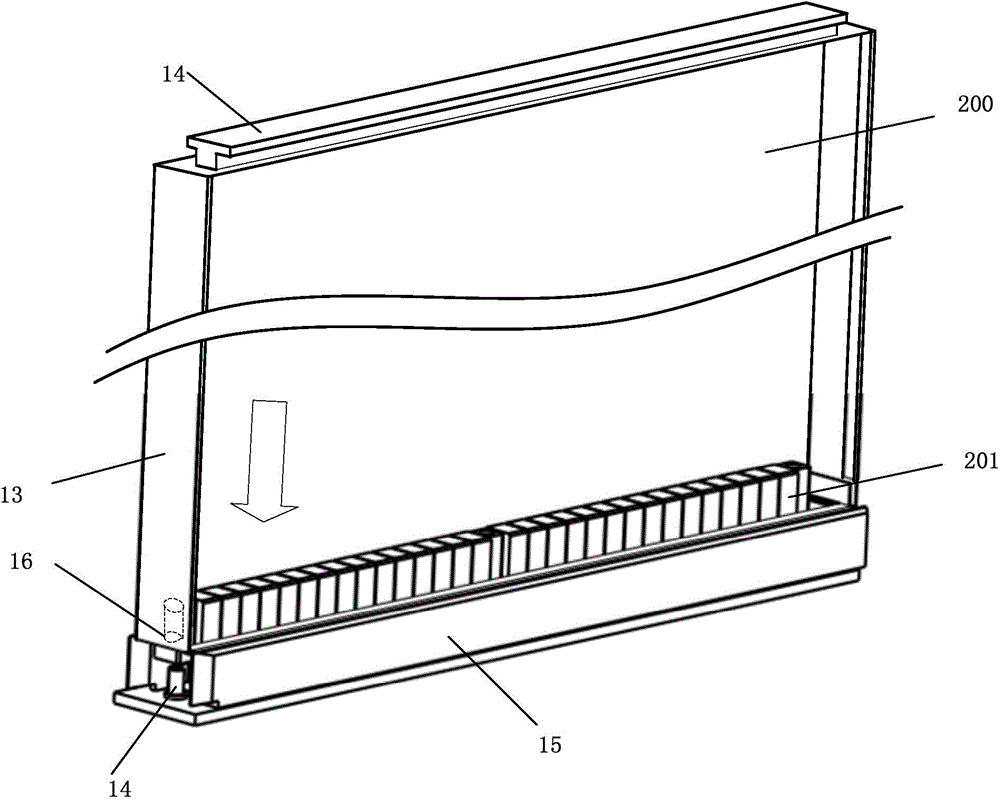

[0031] see figure 1 , is a schematic cross-sectional structure diagram of a single-board plug-in mechanism provided in the embodiment of the present application, 100 in the figure is a single-board plug-in mechanism, including: a fixed bracket 10, an operating handle 1, a screw 8, a turntable 6, and a transmission member 7 and the kinematic support 3, wherein the fixed bracket 10, as the load-bearing structure of the entire single-board plug-in mechanism, can be the shell of the single-board plug-in mechanism. on the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com