A two-stage compressor

A two-stage compressor, one-stage technology, applied in the direction of mechanical equipment, machine/engine, pump combination for elastic fluid rotary piston type/oscillating piston type, etc., can solve the problem of insufficient air intake of high-pressure stage cylinders, compressors Problems such as limited displacement and reduced performance of the compressor achieve the effect of keeping the suction and exhaust process smooth and avoiding pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

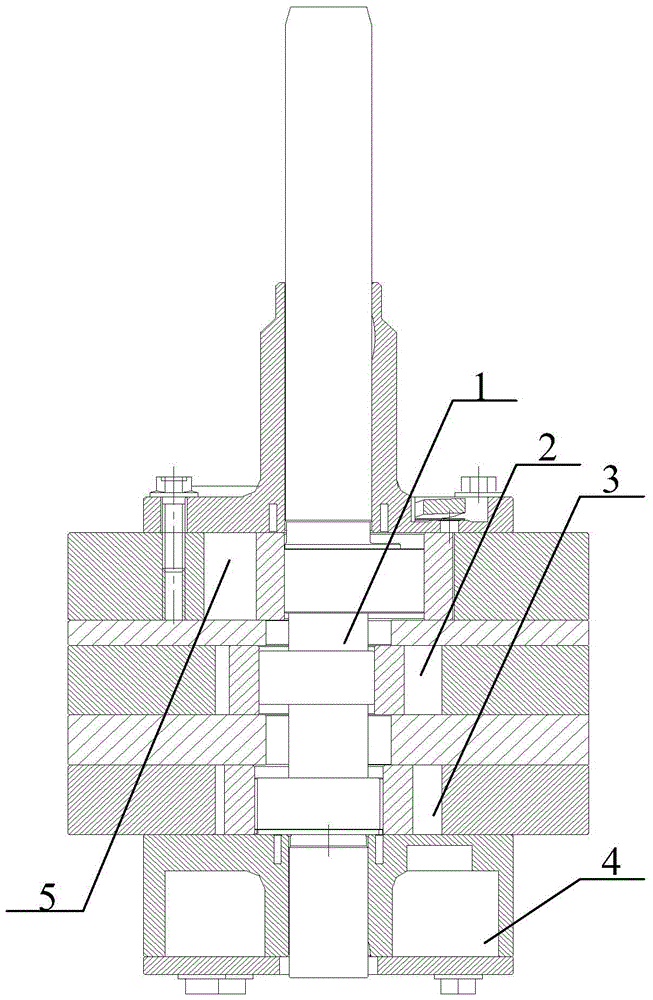

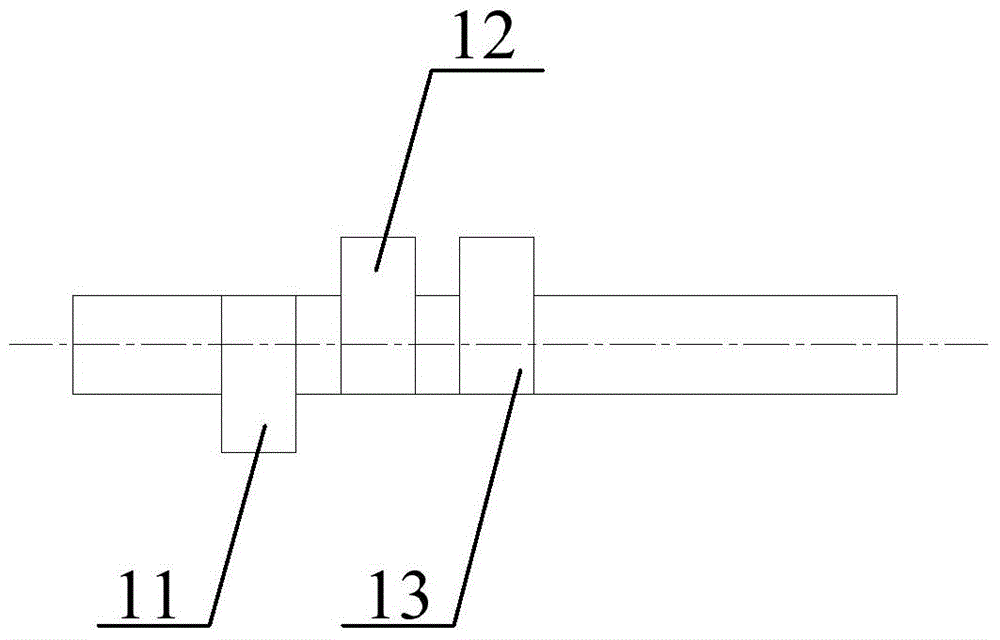

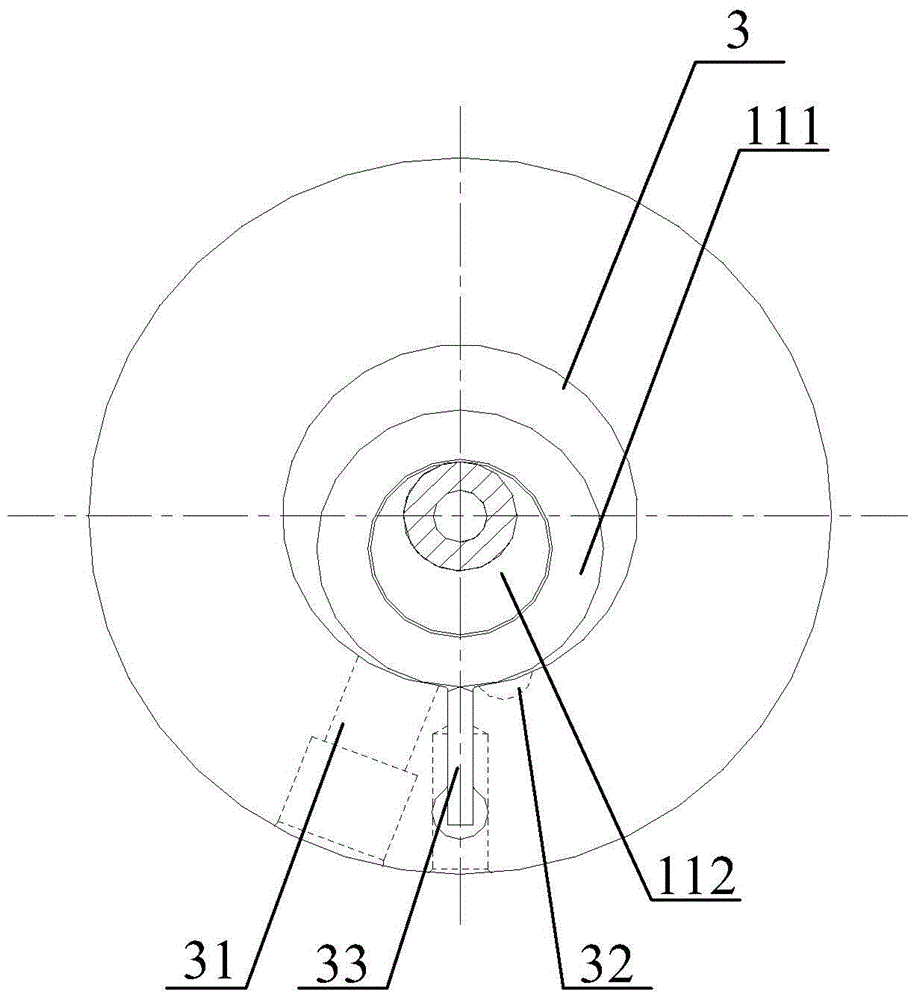

[0048] Please refer to Figure 1 to Figure 5 , figure 1 It is a partial cross-sectional schematic diagram of a two-stage compressor, figure 2 It is a structural schematic diagram of the crankshaft in the first embodiment, image 3 is a schematic top view of the first cylinder in the first embodiment, Figure 4 It is a schematic top view of the second cylinder in the first embodiment, Figure 5 It is a schematic plan view of the high-pressure stage cylinder in the first embodiment.

[0049] In the embodiment of the present invention, for convenience of description, the eccentric portion in the first eccentric assembly 11 in the first cylinder 3 is named as the first eccentric portion 112, and the eccentric portion in the second eccentric assembly 12 in the second cylinder 2 is named The eccentric part is named the second eccentric part 122, and the eccentric part in the high-pressure eccentric assembly 13 in the high-pressure stage cylinder 5 is named the high-pressure ecc...

Embodiment 2

[0053] Such as Figure 6 As shown in , taking the first eccentric part 112 as a reference, the included angle between the second eccentric part 122 and the first eccentric part 112 is 180°, and the included angle between the high-voltage eccentric part 132 and the second eccentric part 122 is 180° °. It should be noted that the top view diagram of the first cylinder 3 and the top view diagram of the second cylinder 2 in this embodiment are the same as those in Embodiment 1, so please refer to the top view diagram of the first cylinder 3 in this embodiment image 3 , please refer to the schematic diagram of the top view of the second cylinder 2 Figure 4 .

[0054] Please also refer to Figure 7 , Figure 7 It is a schematic plan view of the high-pressure stage cylinder in the second embodiment. Because the angle between the second eccentric part 122 and the first eccentric part 112 is 180°, in order to ensure the timing of the first cylinder 3 and the second cylinder 2 air...

Embodiment 3

[0057] Such as Figure 8 As shown in , taking the first eccentric part 112 as a reference, the included angle between the second eccentric part 122 and the first eccentric part 112 is 0°, and the included angle between the high-voltage eccentric part 132 and the first eccentric part 112 is 180° °. It should be noted that the top view schematic diagram of the first cylinder 3 in this embodiment is the same as that in Embodiment 1, and the top view schematic diagram of the high-pressure stage cylinder 5 is the same as that in Embodiment 1, so the first cylinder 3 in this embodiment Please refer to the top view diagram image 3 , please refer to Figure 5 .

[0058] Please also refer to Figure 9 , Figure 9It is a schematic plan view of the second cylinder in the third embodiment. Since the angle between the second eccentric part 122 and the first eccentric part 112 is 0°, in order to ensure the timing of the intake start of the first cylinder 3 and the second cylinder 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com