Card storage box, automatic card issuer and method for increasing card storage capacity of the automatic card issuer

An automatic card issuing and card storage box technology, which is applied to computer parts, instruments, transmission record carriers, etc., can solve the problems of increasing the friction resistance of the bottom card, limited rated load of the drive motor, and hindering the normal operation of the parking lot, etc., to achieve reduction The effect of daily maintenance workload, reduced maintenance workload, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

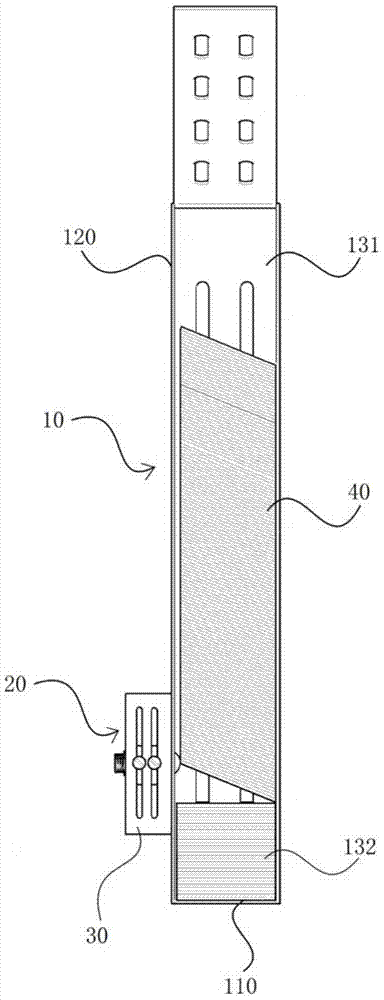

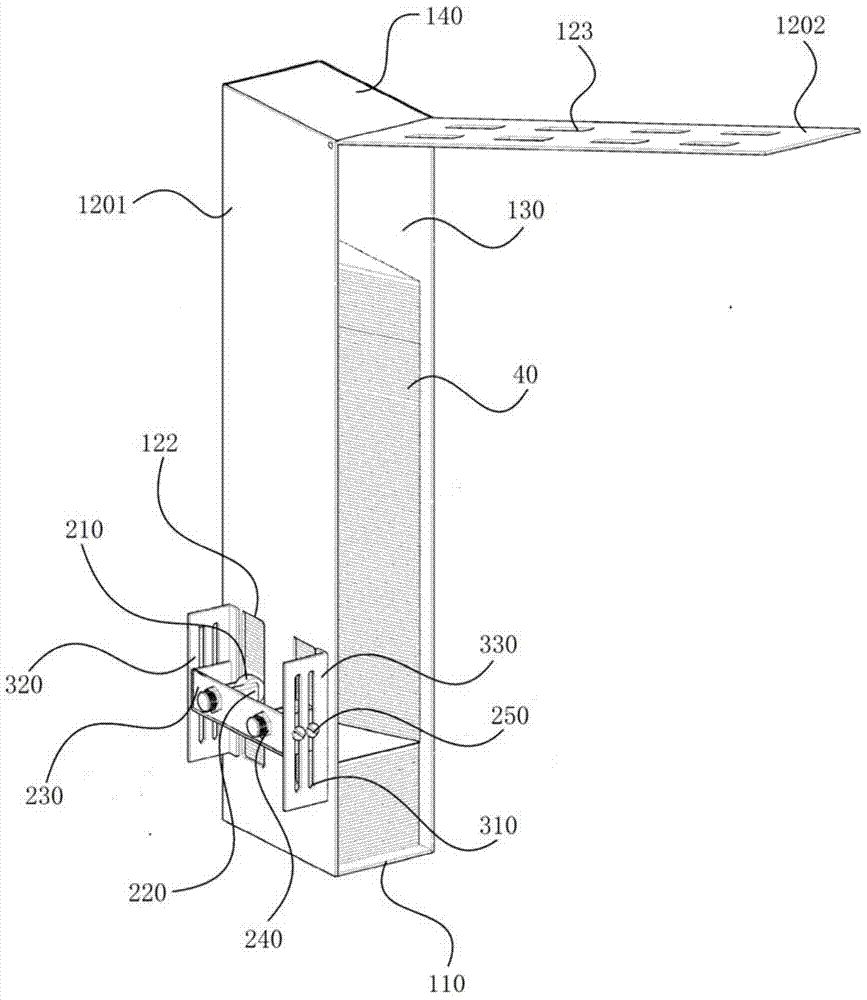

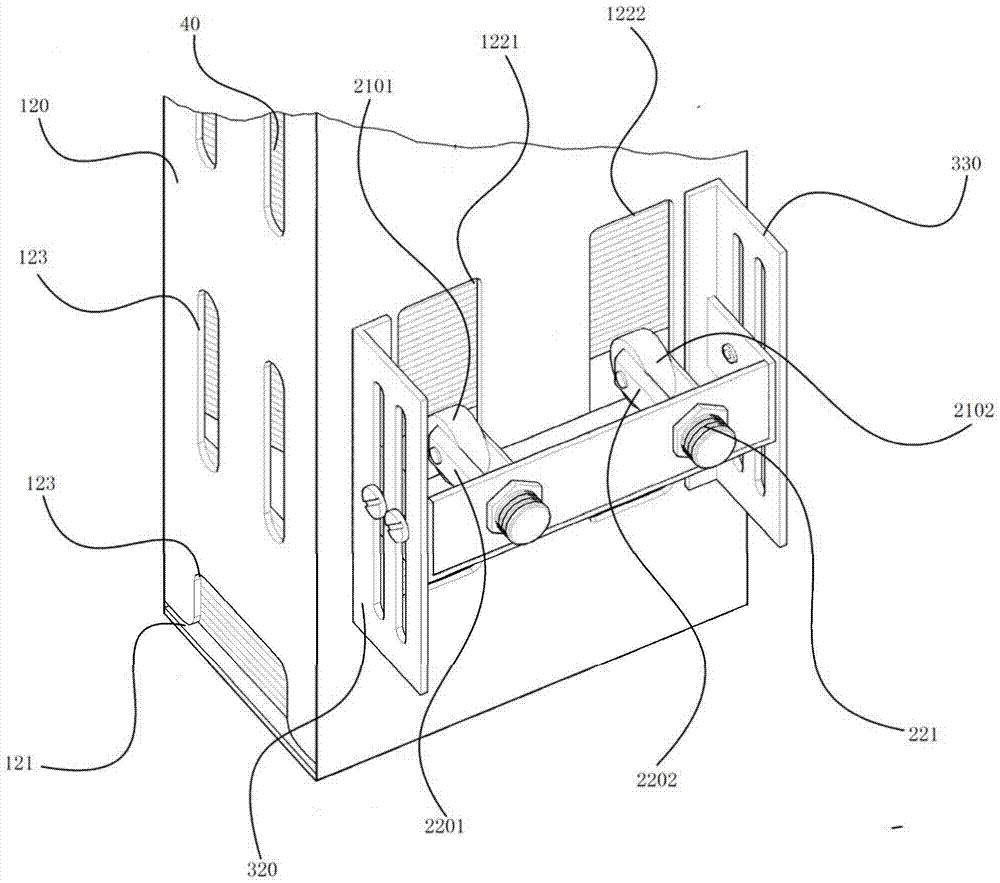

[0032] like Figure 1 to Figure 3 As shown, a card storage box includes a box body 10 and a roller mechanism 20. The box body 10 is provided with an accommodating cavity 130. The box body 10 is provided with a card outlet 121 and a through hole 122 communicating with the accommodating cavity 130. The through hole 122 is located at Above the bayonet outlet 121, the roller mechanism 20 includes a roller 210, a connector 220, and a fixed seat 230 fixed on the outer periphery of the casing 10. One end of the connector 220 is fixedly connected to the fixed seat 230, and the other end is movably connected to the roller 210. 210 passes through the through hole 122 and extends into the receiving cavity 130 , the cards 40 above the rollers 210 are stacked horizontally and obliquely, and the cards 40 below the rollers 210 are stacked horizontally.

[0033]The card stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com