Reaction kettle

A technology of reactor and kettle body, which is applied in the field of reactors with cleaning and heat dissipation functions, can solve the problems of leaving residues, cleaning, poor heat dissipation of reactors, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

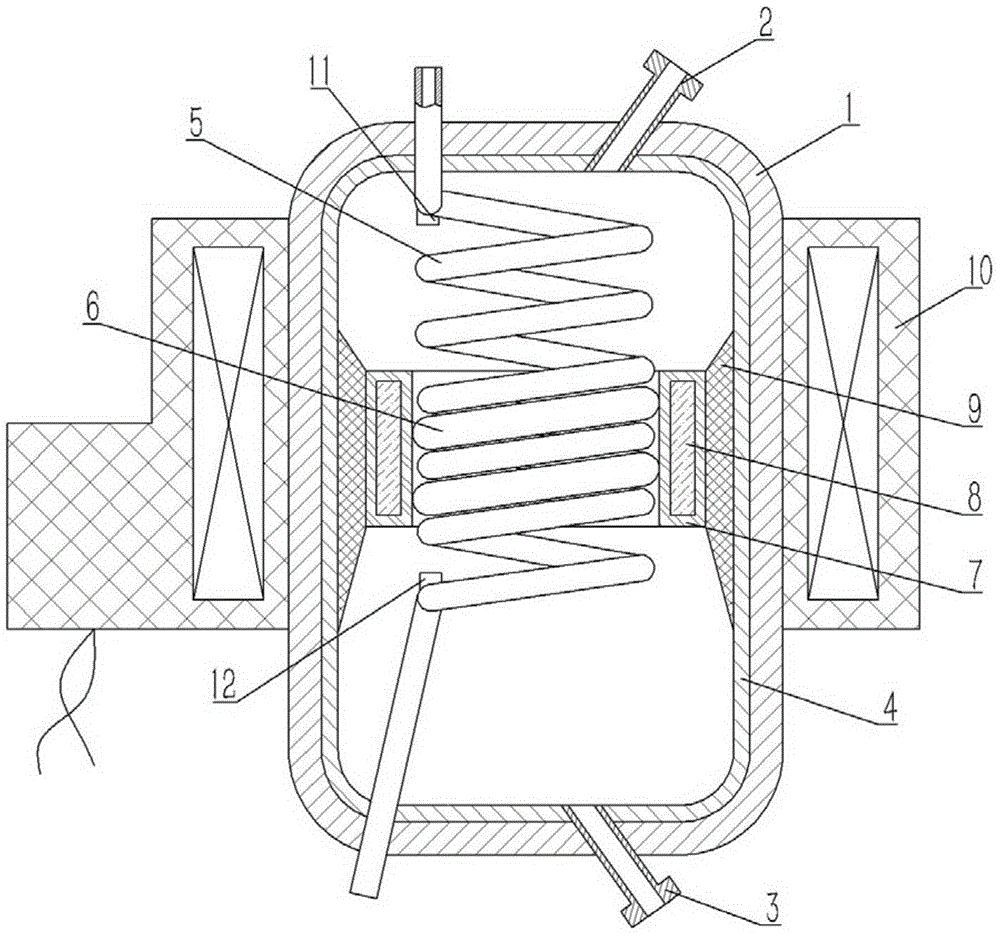

[0015] Example: see figure 1 Shown, a kind of reactor, comprises the reactor body 1 of reactor, feed pipe 2 and discharge pipe 3, and feed pipe 2 and discharge pipe 3 are respectively fixed on the upper and lower end of kettle body 1, and still body 1 is equipped with There is a vertical spring guide rail 5, the two ends of the spring guide rail 5 are fixed on the upper and lower ends of the kettle body 1 and expose the outside of the kettle body 1, the spring guide rail 5 is provided with a spring 6, the spring 6 is fixed on the annular shell 7, and the annular shell The body 7 is inserted and sleeved on the spring guide rail 5, and a number of scrapers 9 are fixed on the outer wall of the annular housing 7, and the scrapers 9 lean against the inner wall of the kettle body 1, and the annular housing 7 is fixed with an annular A magnetic rotor 8, and an electromagnetic coil 10 is fixed on the outer wall of the kettle body 1 at the magnetic rotor 8.

[0016] The spring guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com