Integrated bulking machine

A bulk machine, integrated technology, applied in the field of machinery, can solve the problems of the expansion joint and the unloading equipment can not be well connected and sealed, can not discharge continuously and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

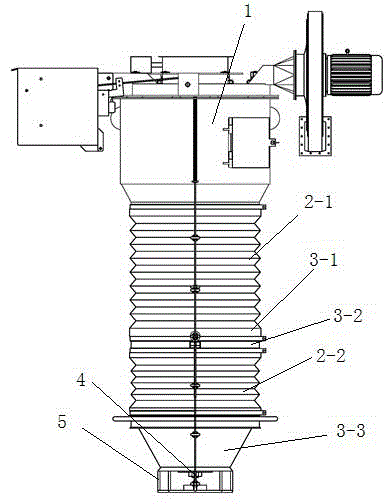

[0015] Such as figure 1 As shown, the integrated bulk packing machine of the present invention includes the following components: a housing (1), a long-section telescopic cloth bag (2-1) connected to the lower end of the housing (1), and a long-section telescopic cloth bag (2-1) The upper cone bucket (3-1) connected to the bottom, the lower cone bucket (3-2) connected to the bottom of the upper cone bucket (3-1), the short joint telescopic bag connected to the bottom of the lower cone bucket (3-2) ( 2-2), the unloading cone (3-3) connected to the bottom of the nipple telescopic bag (2-2), the material level gauge (4) connected to the unloading cone (3-3) and the The material level indicator shield (5) on the outside of the material level indicator (4), and the discharge cone (3-3) are inverted conical. Both the long-section stretchable cloth bag (2-1) and the short-section stretchable cloth bag (2-2) are double-layer stretchable cloth bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com