Device for adjusting bearing gap

A technology for adjusting device and bearing clearance, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of bearing damage, difficult maintenance and disassembly, etc., to achieve easy maintenance, convenient installation and disassembly, and convenient disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

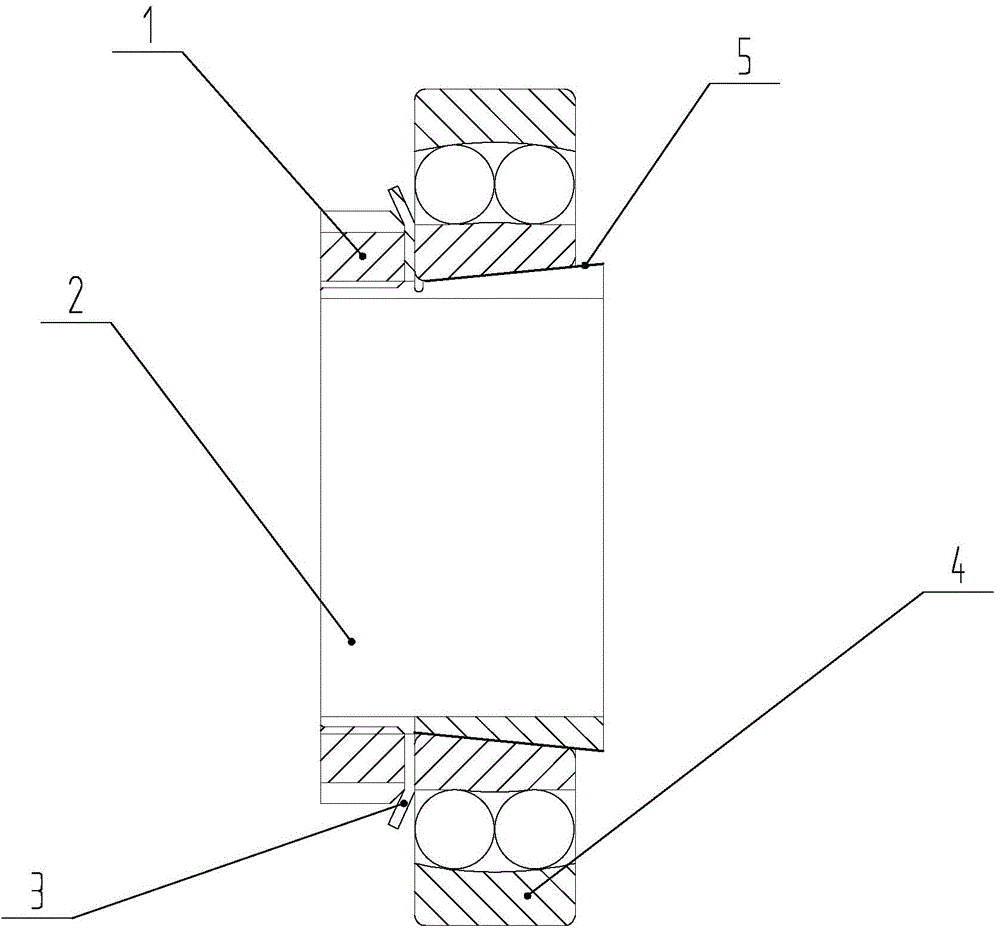

[0012] like figure 1 As shown, the present invention includes an adapter sleeve 2, a lock nut 1, a tapered hole self-aligning bearing 4, and a lock washer 3. It is characterized in that a conical surface 4 is provided on the right periphery of the adapter sleeve 2, and the cone A self-aligning bearing 4 with a tapered hole is provided on the periphery of the surface 4, and a locking washer 3 is provided on the left side of the self-aligning bearing 4 with a tapered hole. A lock nut 1 is provided on the side, and the lock nut 1 is connected with an adapter sleeve 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com