A twist-resistant fire-resistant power cable

A power cable and twist-resistant technology, which is applied in the field of twist-resistant fire-resistant power cables, can solve the problems of power cable twist, shorten the service life of the cable, and break the core of the cable, so as to increase the tensile capacity, improve the anti-torsion capacity, and enhance the stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the technical solution of the present invention will be described in detail through specific examples.

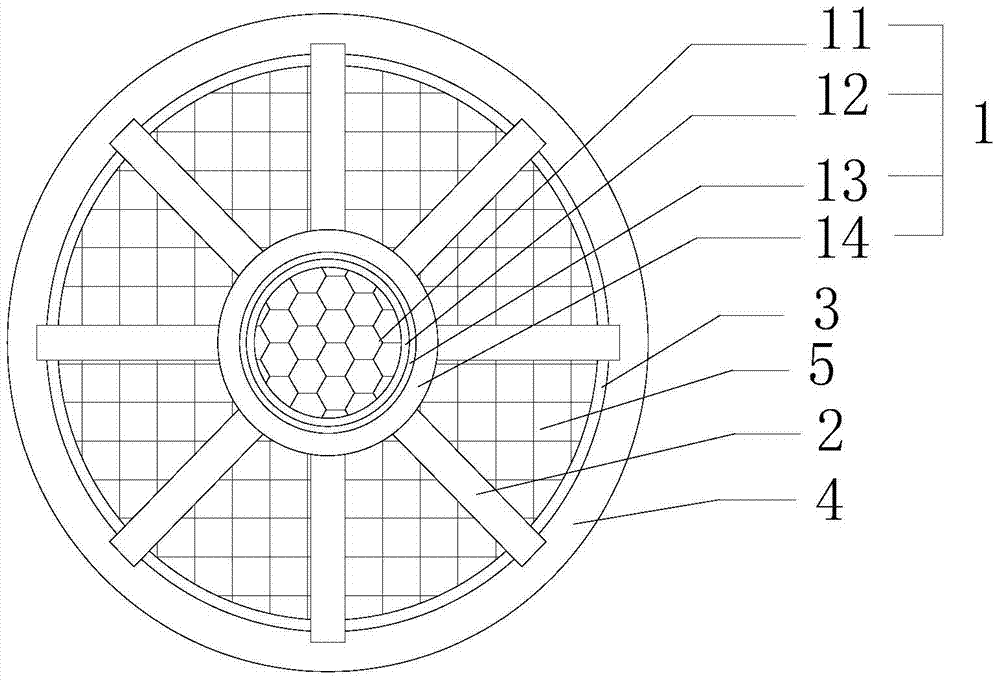

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a torsion-resistant and fire-resistant power cable proposed by the present invention.

[0013] refer to figure 1 , a twist-resistant and fire-resistant power cable proposed by the embodiment of the present invention, including: a cable core 1, a cable core 1 is composed of a conductor 11 and an insulating layer 12 that is coated on the outer periphery of the conductor 11 from the inside to the outside, and a mica tape wrapping layer 13 and the inner extrusion cladding layer 14, wherein the conductor 11 is formed by twisting multiple soft copper wires, the inner extrusion cladding layer 14 is formed with elastic connectors 2 at one time during the extrusion process, and the elastic connectors 2 are provided with multiple groups and parallel Evenly distributed along the outer r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap