An anti-leakage oil pipe filter

A technology of oil leakage prevention and filter, which is applied in the field of oil transportation, can solve the problems of potential safety hazards, inconvenient use, waste, etc., and achieve the effects of eliminating potential safety hazards, ensuring safety, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

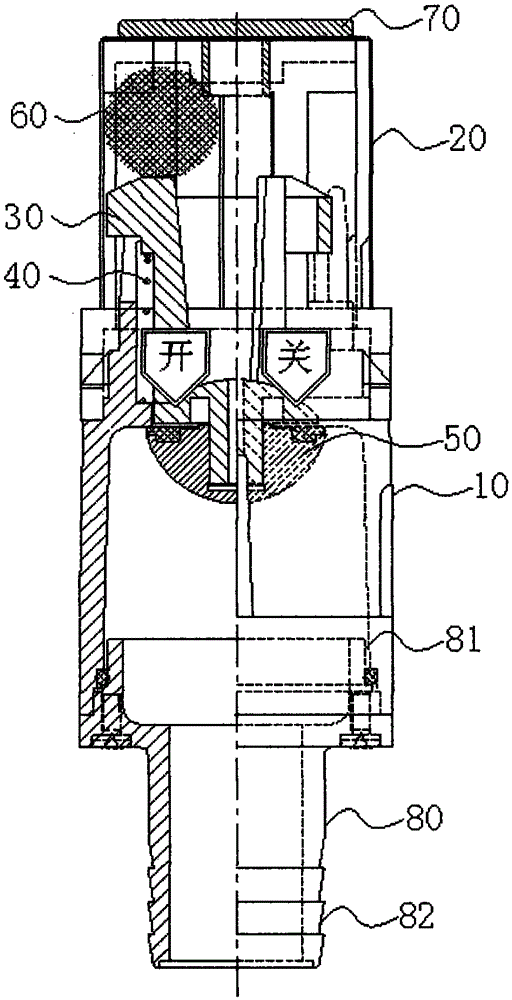

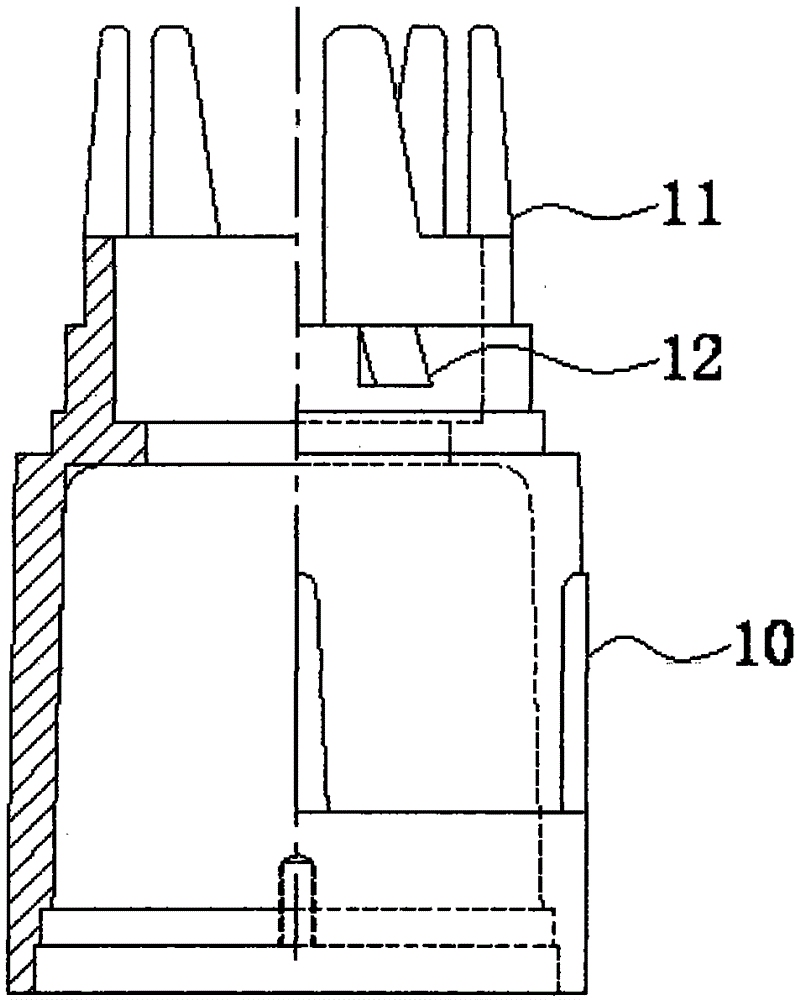

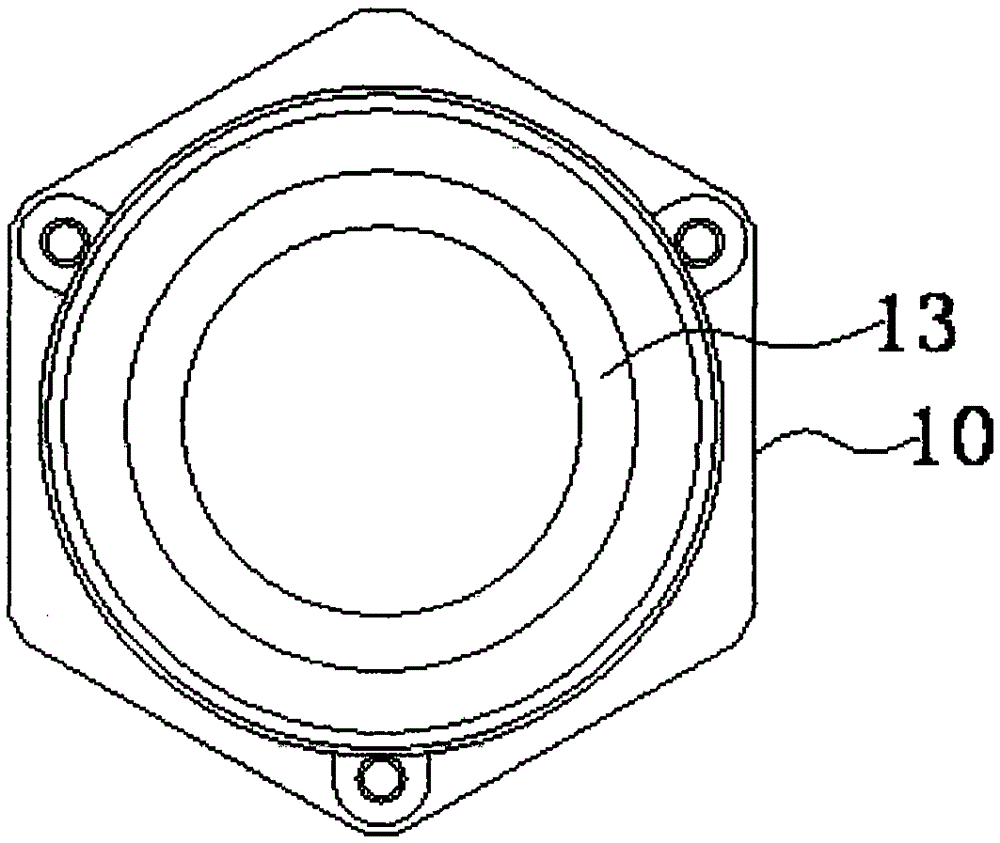

[0031] Such as Figure 1-7 As shown, in an embodiment of the present invention, the anti-leakage oil pipe filter generally includes a valve body 10 , a regulating switch 30 , a positioning sleeve 20 , a spring 40 and a filter screen 60 . The valve body 10 is a hollow tubular structure, one end is a connection end connected with the oil pipe and the other end is a closed end provided with a valve core. One end of the regulating switch 30 passes through the closed end of the valve body 10 and is connected to the valve core 50 , and the other end is located outside the valve body 10 and is provided with a radially protruding positioning block 32 . The positioning sleeve 20 is a hollow tubular structure, which is movably connected to the closed end of the valve body 10 through one end and the regulating switch 30 is set inside, and an axial sliding groove 21 is arranged on the tube body of the positioning sleeve 20, which is sleeved inside The positioning block 32 of the adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com