Hollow ultra-wide angle nozzle

An ultra-wide-angle, nozzle technology, applied in the direction of spraying device, spraying device, etc., can solve the problem of nozzle service life reduction, affecting product quality, difficult to clean, etc., to save installation time, improve installation efficiency, and reduce installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

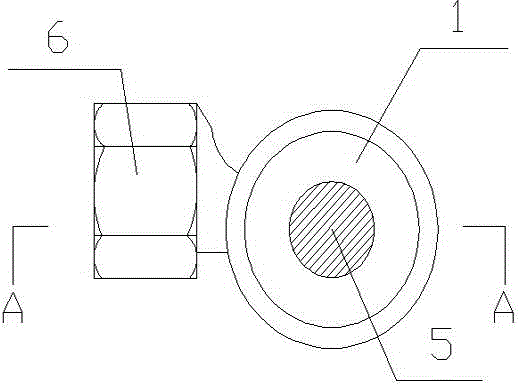

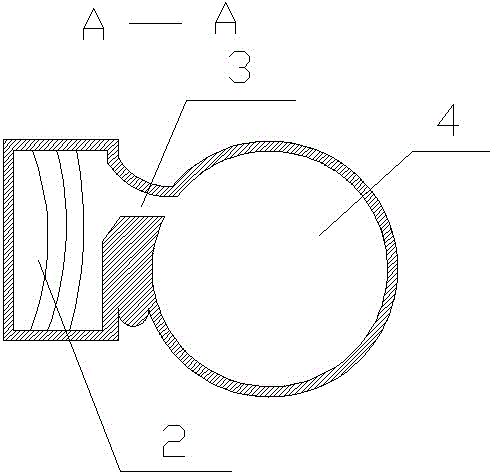

[0010] A hollow super wide-angle nozzle, comprising a nozzle 1, a connecting port 2, a diversion groove 3 and a mixing chamber 4. The nozzle 1 is located on the upper part of the mixing chamber 4, the mixing chamber 4 and the diversion groove 3 are connected, and the tail of the diversion groove 3 is provided There is a connection port 2. The nozzle 1 is a round hole nozzle, and the inside of the round hole nozzle is equipped with a filter screen 5. The filter screen 5 is a fine stainless steel filter screen. The connection port 2 is provided with a connection thread 6, which is located at the connection port 2. At the tail, the diversion groove 3 is located between the mixing chamber 4 and the connecting port 2, and the diversion groove 3 is a thin diversion groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com