Equipment for processing wall blocks

A block and equipment technology, applied in the direction of pressing rollers, etc., can solve the problems of increasing labor intensity, uneven injection, and high resilience of polystyrene foam particles, reducing labor intensity, eliminating loose shrinkage cavities, and uniform and dense material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the examples given are only used to explain the present invention, and do not constitute a specific limitation to the protection scope of the present invention.

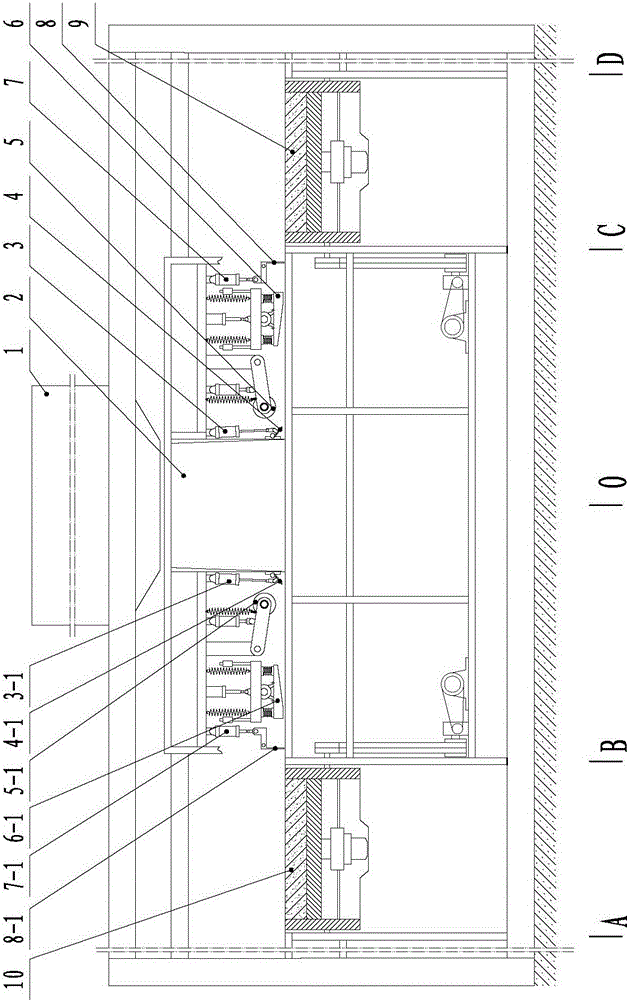

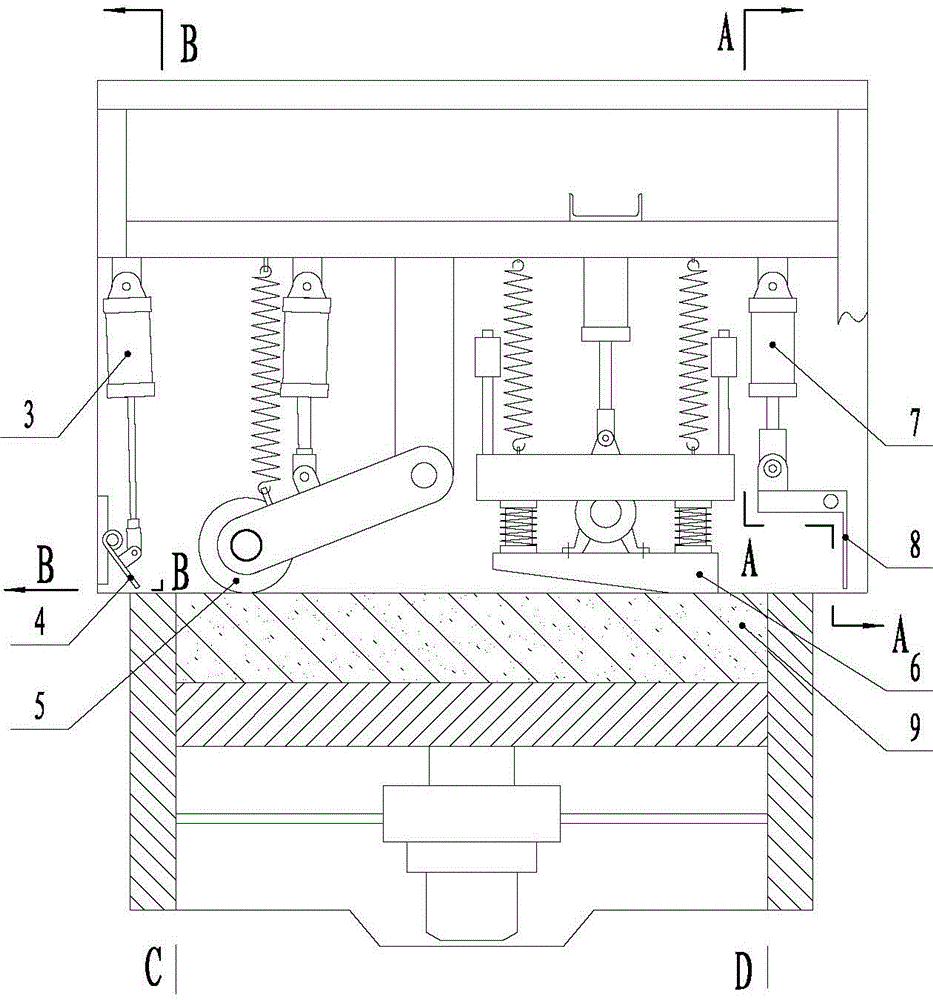

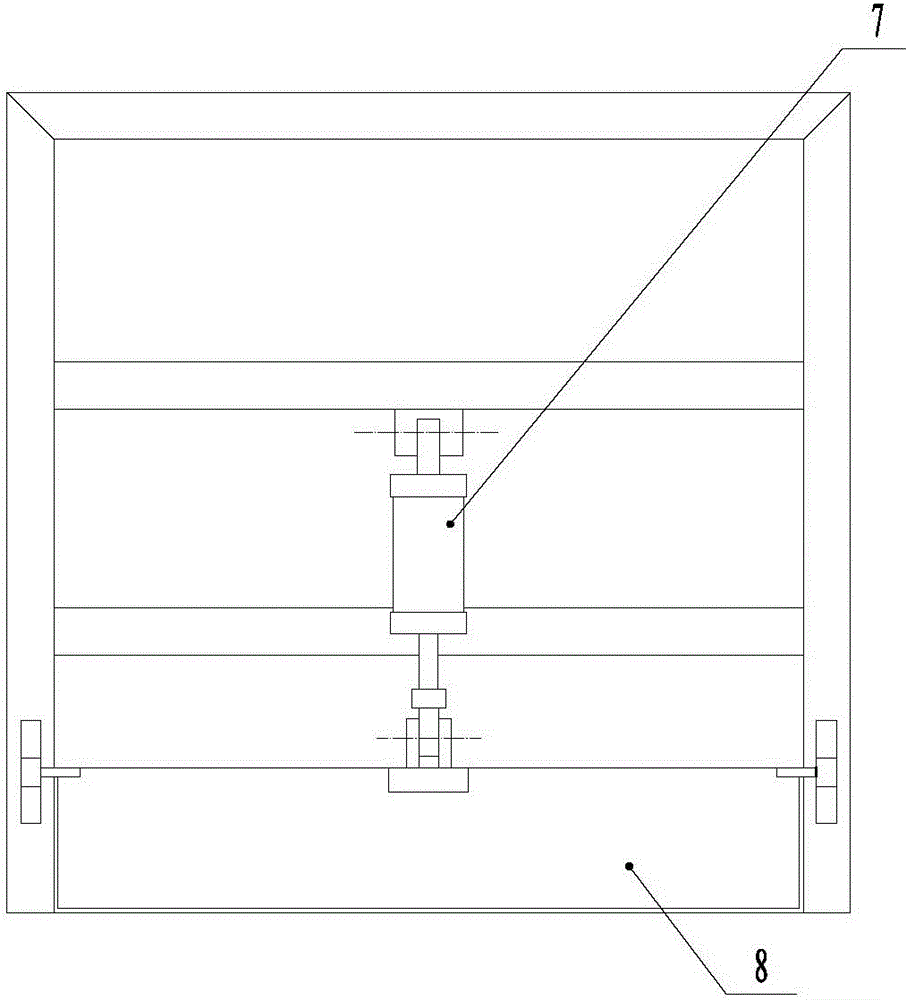

[0013] This equipment for processing wall blocks ( Figure 1-Figure 4 shown), including the silo connected to the mobile frame; it is connected with a vibrating device on the mobile frame on both sides of the silo 2; the pressure roller 5 of the vibrating device is located in the silo The side of the side; the lower end of the mobile frame on the outside of the vibrator of the rolling vibration device is provided with two supports at intervals, and the horizontal axis rotation at both ends of the scraper 8 is connected to the supports. The scraper and the scraper The piston rod front ends of the scraper cylinder block 7 that are vertically hinged and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com