Preparation method of lightweight composite board

A composite board, lightweight technology, applied in the field of architectural decoration, can solve the problems of resin curing, large amount of resin, high temperature resistance, etc., to achieve the effect of dense and uniform material, high natural texture and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

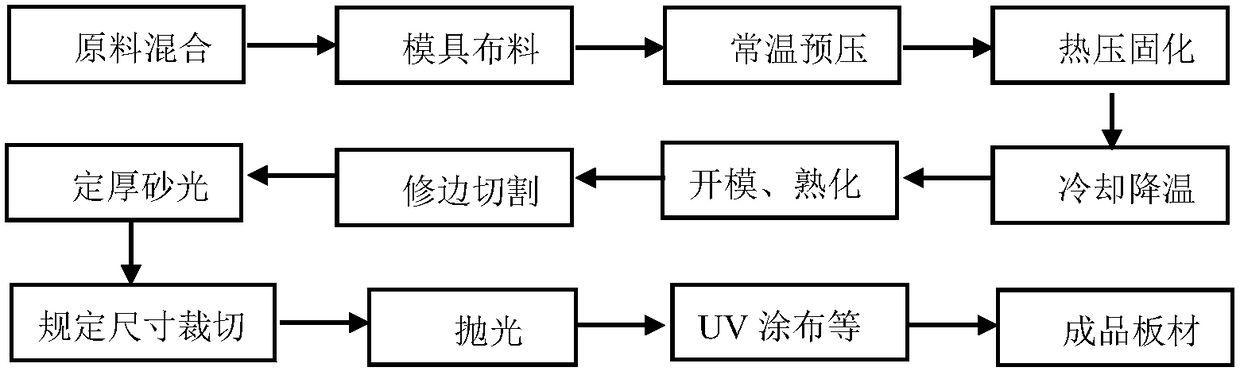

Method used

Image

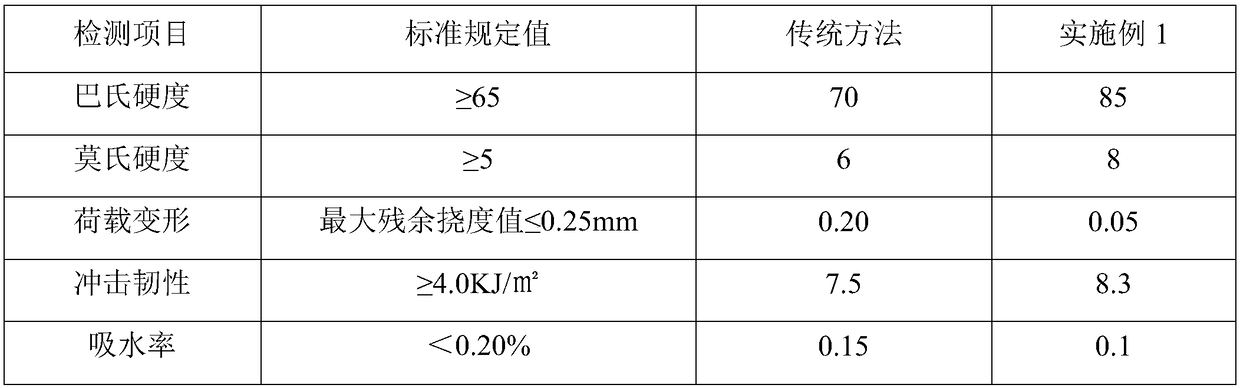

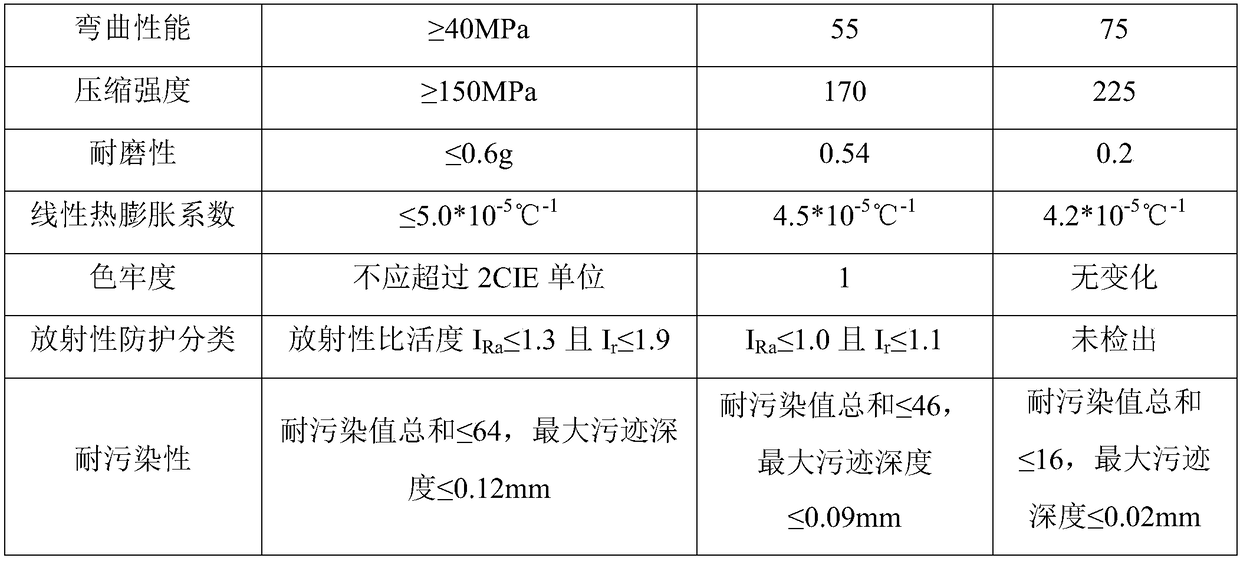

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of lightweight composite board, and the steps include:

[0036] 1) According to the number of parts by weight, select 10 parts of crushed 40-mesh stone powder; choose a mesh number of 100 and a density of 300KG / m 3 50 parts of fly ash-based microbead particles; choose 10 parts of ordinary Portland cement P.O 32.5; choose 6 parts of thermosetting phenolic resin powder;

[0037] 2) First put 10 parts of stone powder into the stirring tank, and the rotation speed of the stirring tank is 600r / min; then put 3 parts of resin powder into the stirring tank, and the stirring time is 10min; then put 50 parts of fly ash-based microbeads The particles are put into the stirring tank, and the stirring time is 15 minutes; finally, 10 parts of ordinary Portland cement P.O 32.5 and 3 parts of resin powder are put into the stirring tank, and the stirring time is 10 minutes;

[0038] 3) Lay one deck of wheat flake paper on the ...

Embodiment 2

[0063] The present embodiment provides a kind of preparation method of lightweight composite board, and the steps include:

[0064]1) According to the number of parts by weight, select 20 parts of crushed 200-mesh stone powder; choose a mesh number of 150 and a density of 400KG / m 3 70 parts of fly ash-based microbead particles; choose 20 parts of white Portland cement P.W 32.5; choose 8 parts of thermosetting phenolic resin powder;

[0065] 2) First put 20 parts of stone powder into the stirring tank, and the rotation speed of the stirring tank is 800r / min; then put 4 parts of resin powder into the stirring tank, and the stirring time is 10min; then put 70 parts of fly ash-based microbeads The particles are put into the stirring tank, and the stirring time is 20 minutes; finally, 20 parts of white Portland cement P.W 32.5 and 4 parts of resin powder are put into the stirring tank, and the stirring time is 20 minutes;

[0066] 3) Lay a layer of kraft paper on the bottom plate ...

Embodiment 3

[0091] The present embodiment provides a kind of preparation method of lightweight composite board, and the steps include:

[0092] 1) According to the number of parts by weight, select 15 parts of crushed 100-mesh stone powder; choose a mesh number of 120 and a density of 350KG / m 3 60 parts of fly ash-based microbead particles; choose 15 parts of white Portland cement P.W 32.5; choose 7 parts of thermosetting phenolic resin powder;

[0093] 2) First put 15 parts of stone powder into the stirring tank, and the rotation speed of the stirring tank is 700r / min; then put 3 parts of resin powder into the stirring tank, and the stirring time is 15 minutes; then put 60 parts of fly ash-based microbeads The particles are put into the stirring tank, and the stirring time is 18 minutes; finally, 15 parts of white Portland cement P.W 32.5 and 4 parts of resin powder are put into the stirring tank, and the stirring time is 15 minutes;

[0094] 3) Lay a layer of kraft paper on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com