Oil cylinder connection device

A technology for connecting devices and oil cylinders, which is applied to fluid pressure actuating devices, mechanical equipment, etc. It can solve the problems that the oil cylinder is not easy to change the driving direction, damage the oil cylinder and fixed seat, shorten the service life of the oil cylinder, etc., and achieve simple structure and reduce impact force , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

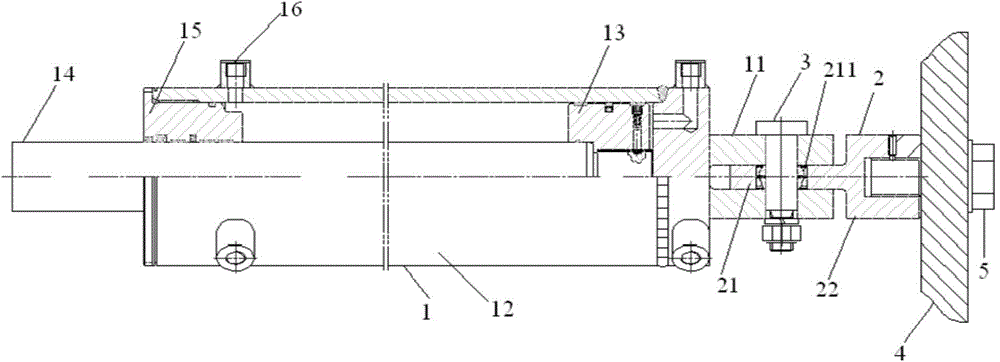

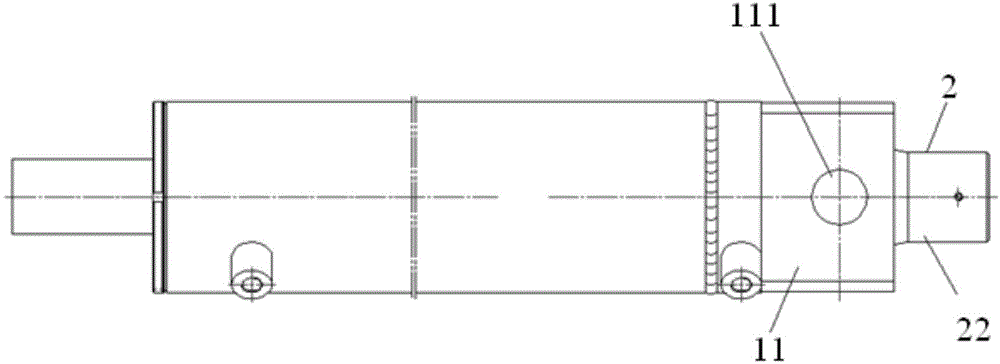

[0020] In order to understand the present invention better, below in conjunction with specific embodiment and Figure 1-Figure 3 The present invention is further described.

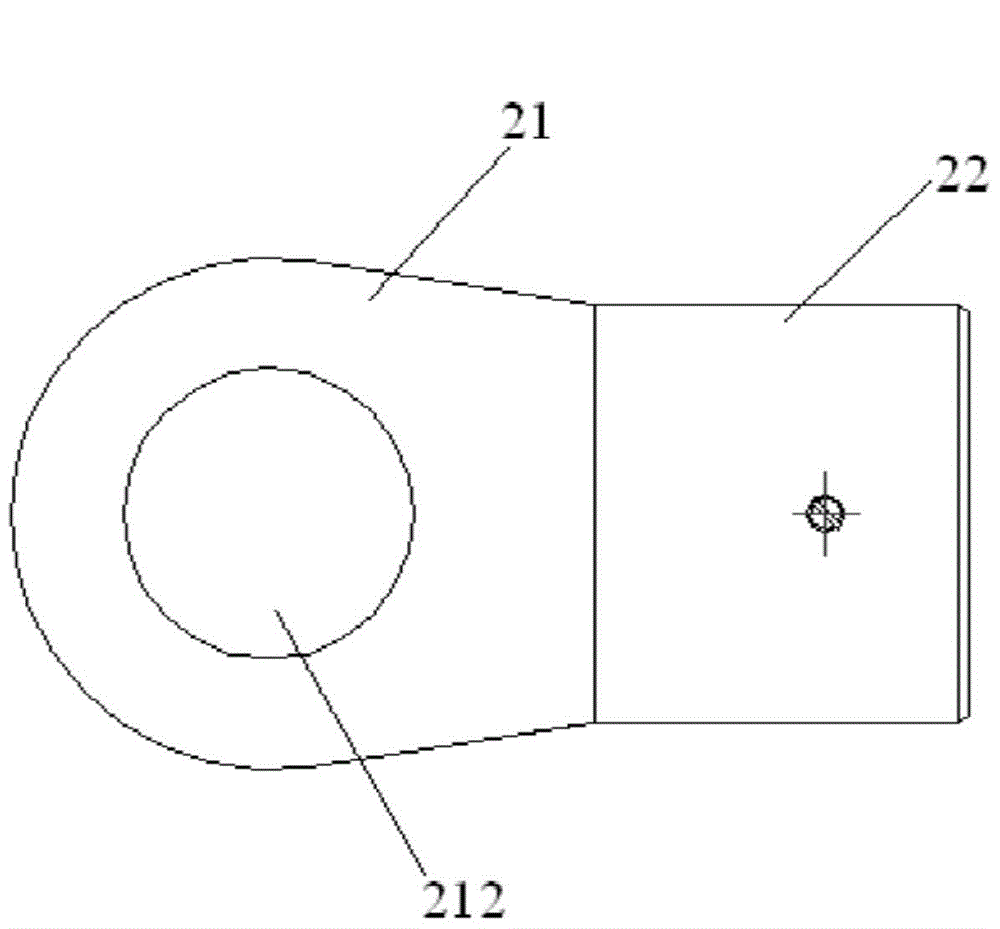

[0021] The oil cylinder connecting device is arranged on the oil cylinder 1 and includes earrings 11 arranged on the oil cylinder 1 and a connecting seat 2 . The connecting seat 2 includes a connecting end 21 and a fixed end 22 .

[0022] In this embodiment, the oil cylinder 1 has a double clevis structure, and the two clevis are arranged symmetrically along the axial direction of the oil cylinder 1 . Two earrings are provided on the cylinder at the opposite end to the end where the piston rod of the cylinder is located. The earring 11 in this embodiment is one of them. The gap between the two earrings matches the connecting end 21 . The earring 11 is provided with a first hole 111 for connecting the earring 11 and the connecting base 2 .

[0023] The connecting end 21 is provided with a second hole 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap