Coal quality characteristic detection method suitable for storage pulverizing system

A technology of a pulverizing system and a detection method, which is applied in the direction of thermal development of materials, etc., can solve the problems of unstable combustion of boilers, great differences in ignition stability, and fire extinguishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

[0025] A new method for comprehensively judging the ignition stability of coal based on industrial analysis of coal is provided.

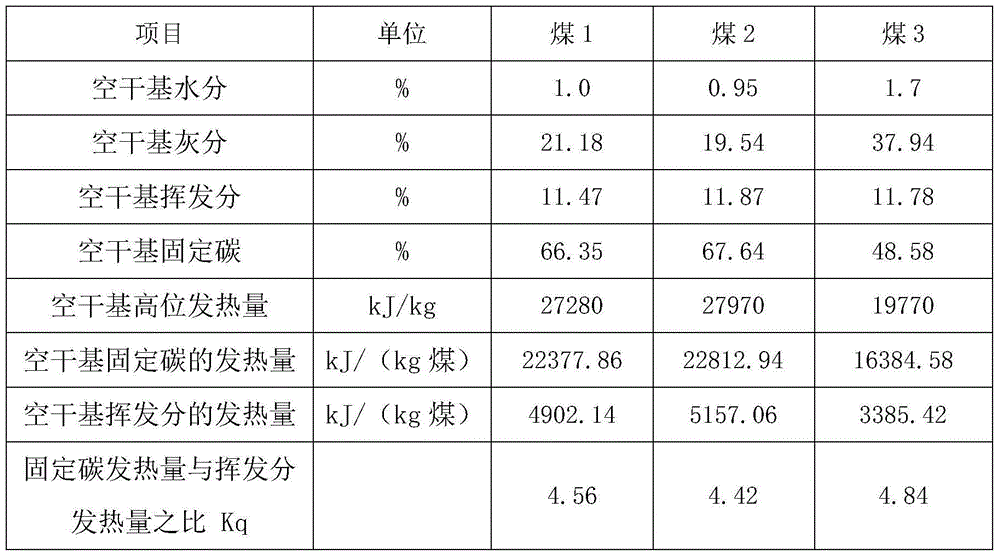

[0026] The industrial analysis of coal includes items such as air-dry basis moisture, air-dry basis ash, dry ash-free volatile matter (or air-dry basis volatile matter), air-dry basis fixed carbon, air-dry basis high calorific value, etc., general coal quality analysis Laboratories can perform these tests. Air-dry basis volatile matter, air-dry basis ash, air-dry basis fixed carbon and air-dry basis moisture are basically close to all components of coal powder in the storage bin, and the sum of their values is 100. Therefore, the air-dry calorific value of coal is the sum of the calorific value of the above four items. Moisture and ash have no calorific value, only fixed carbon and volatile matter can be burned to generate heat. The calorific value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com