Radiating structure of display module

A technology of heat dissipation structure and display module, which is applied to the structural parts of electrical equipment, cooling/ventilation/heating transformation, optics, etc., can solve the problem of poor heat dissipation and cannot display module heat dissipation, etc. The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

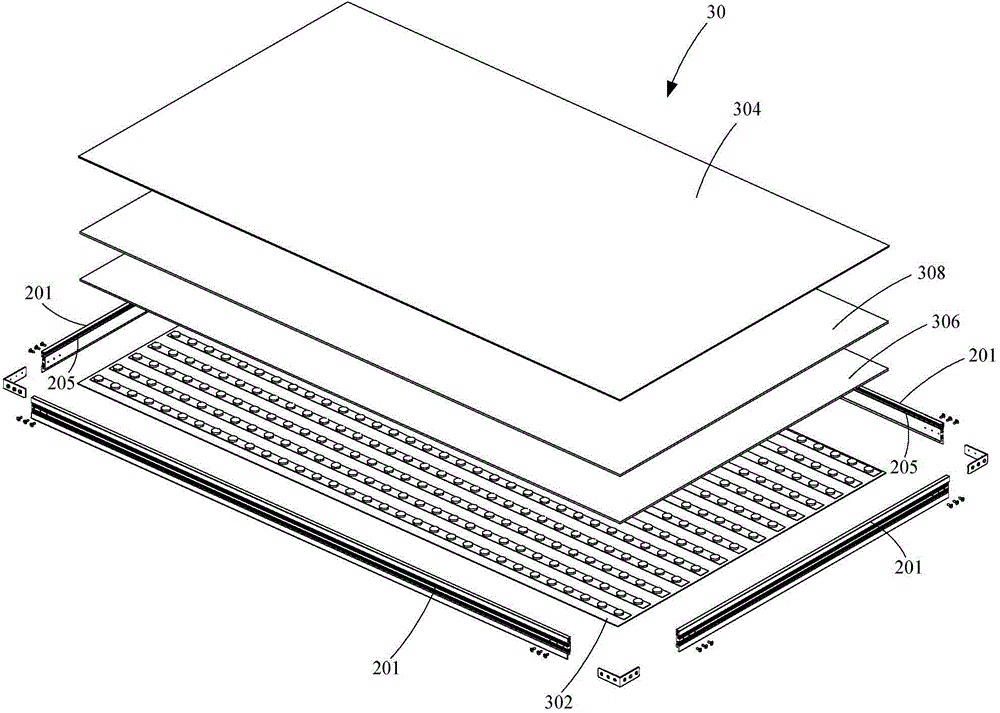

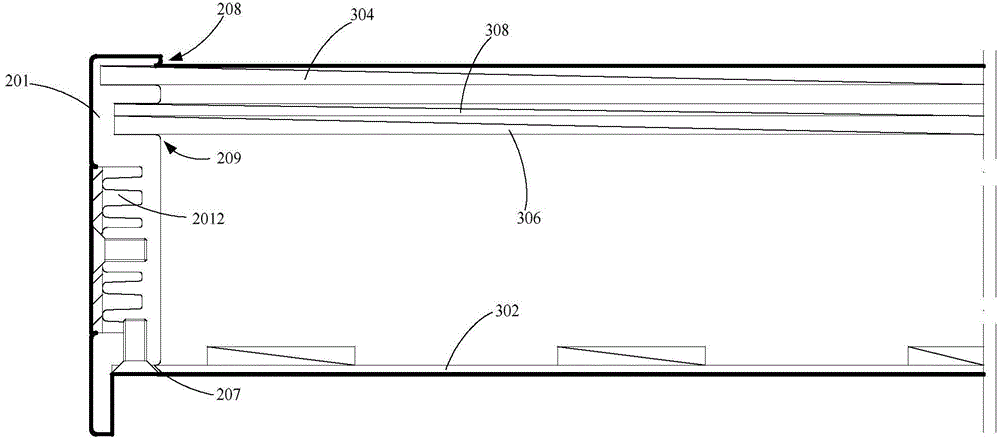

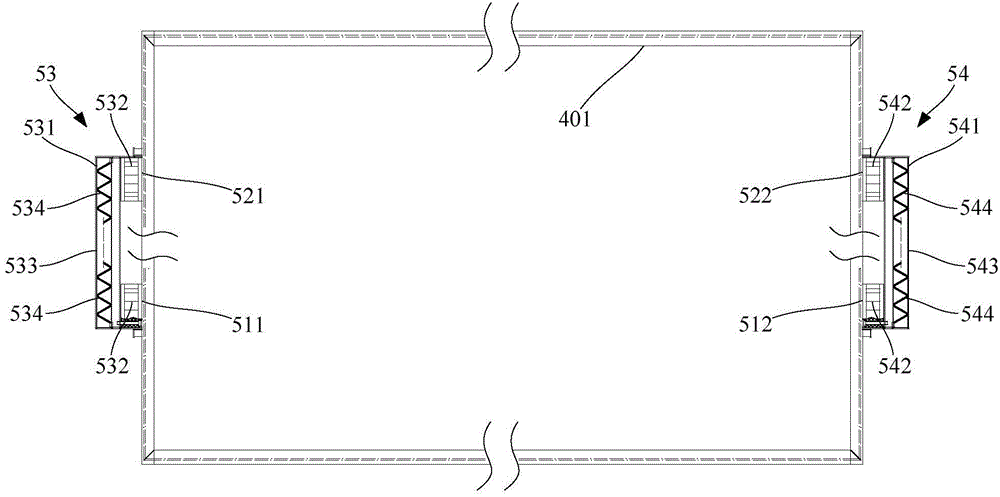

[0024] The invention provides a heat dissipation structure of a display module, which adopts a method of setting ventilation channels to form air convection to dissipate heat from the display module, thereby ensuring the display effect and rapidly dissipating heat from the display module. The existing heat conduction heat dissipation has better heat dissipation effect. The present invention forms a ventilation channel by opening an air inlet and an air outlet on the outer frame, overcomes the existing technical prejudice that the air-cooled heat dissipation cannot be applied to the liquid crystal display module, and ensures that the air inside the display module is clean. Air-cooled air convection dissipates heat from the display module. The heat dissipation structure of the display module of the present invention will be described below with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com