Looseness detection method of bolt

A detection method and technology of bolt looseness, applied in image data processing, instrumentation, calculation, etc., can solve problems such as low bolt efficiency, bolt looseness, time-consuming and labor-intensive problems, and achieve improved pertinence, improved evaluation and monitoring, improved safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

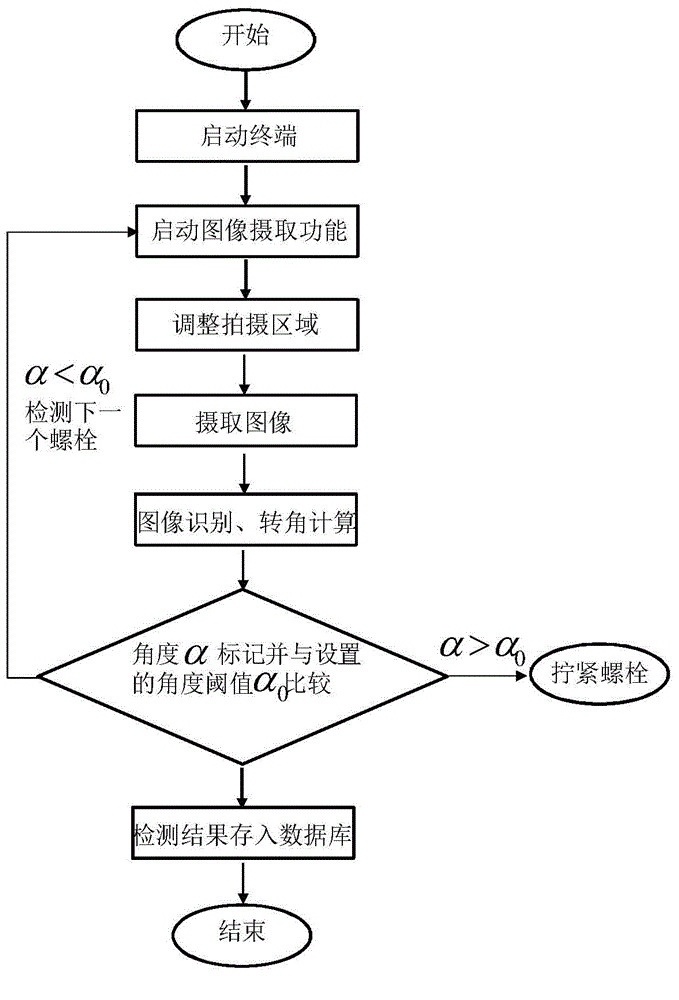

[0018] The detection method of bolt looseness that the present invention proposes, its flow chart is as figure 1 shown, including the following steps:

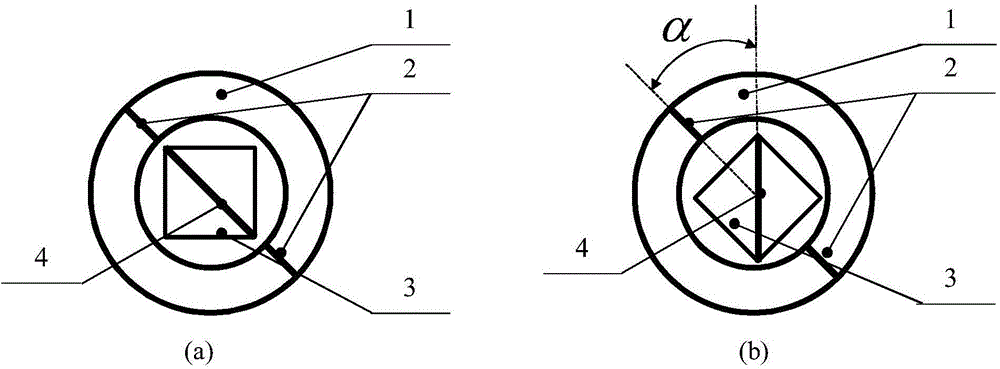

[0019] (1) Mark the bolts to be tested after tightening, such as figure 2 As shown, the first mark 2 is made on the fixed part 1 of the bolt, the second mark 4 is made on the rotating part 3 of the bolt, the first mark 2 and the second mark 4 are on a straight line, and the symbol of the mark is a straight line or a dot , in one embodiment of the present invention, the first mark and the second mark are straight lines;

[0020] (2) After the bolt to be tested is loosened, take a photo of the bolt, the photo includes the first mark, the second mark and the complete image of the bolt to be tested;

[0021] (3) After capturing the image, use the calculation algorithm of the image angle to recognize the coordinate positions of the first mark and the second mark in the photo through image grayscale, image binarization, edge dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com