A phase-changing power socket

A technology of plugging and plugging power supply, which is applied in the direction of circuits, electrical components, and two-component connection devices, which can solve the problems of electrical safety hazards, inconvenience, and large storage space, and achieve aesthetic improvement, easy processing, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

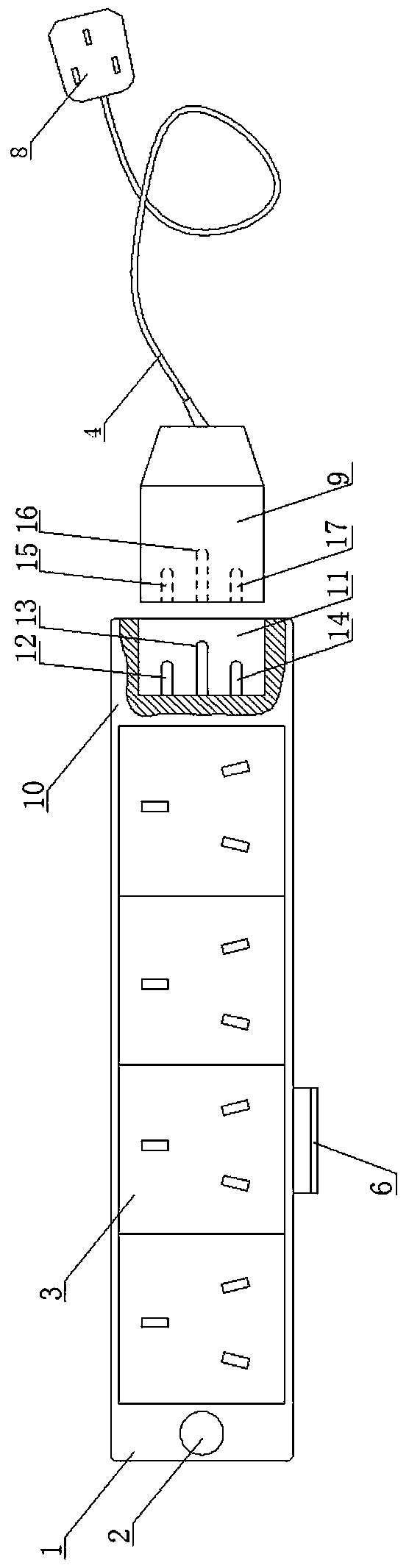

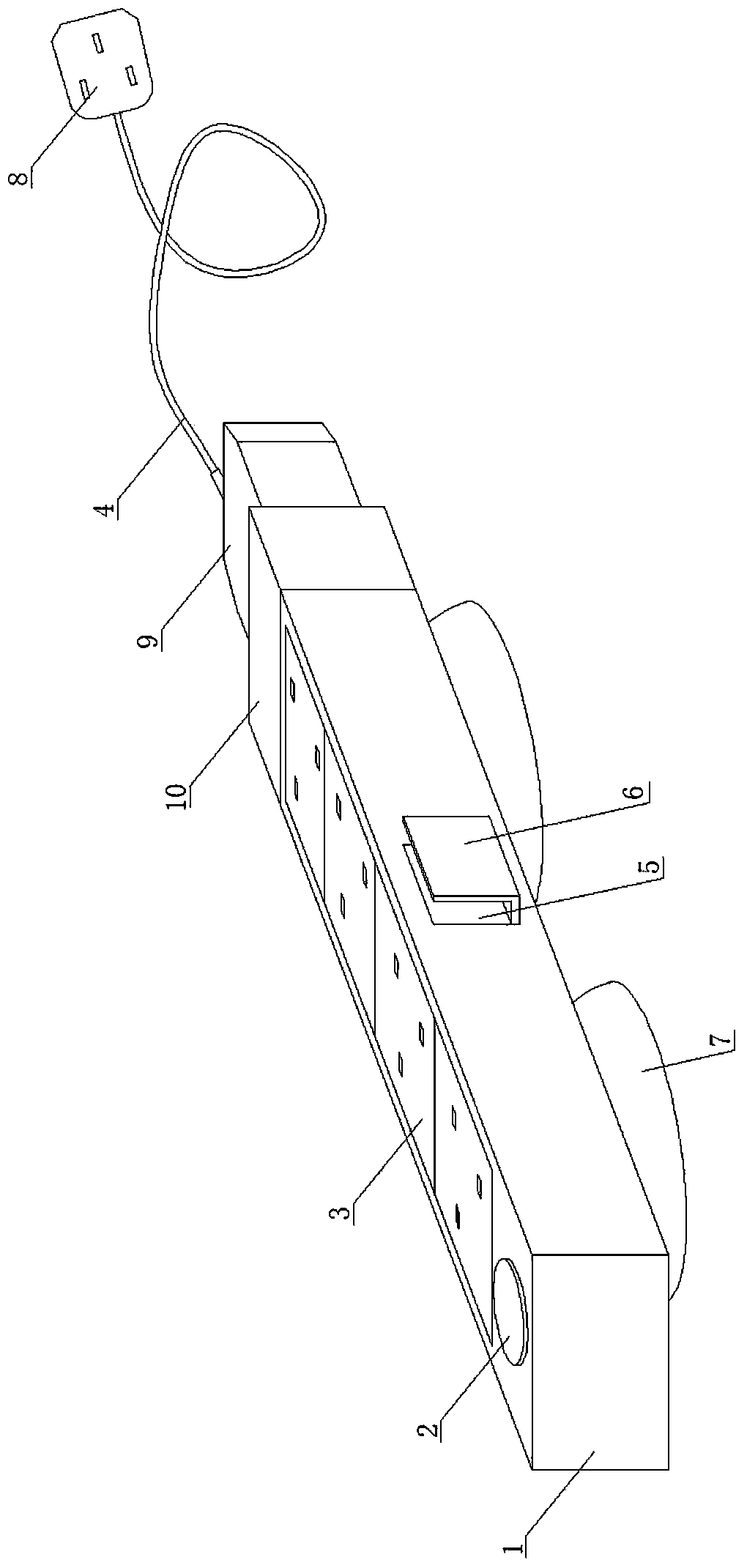

[0016] The phase-changing power supply strip includes a housing 1, a switch 2, a socket area 3 and a power cord 4. A suction cup 7 for positioning is arranged in the middle of the bottom of the housing 1; 5 is provided with a drawable winding button 6; the surface of the other side of the housing 1 opposite to the power cord 4 is provided with a switch 2, and the middle part of the surface of the housing 1 is provided with a jack area 3, and the housing 1 is connected to the power cord 4 One end of the power cord 4 is provided with a reversing socket 10; one end of the power cord 4 is connected to the power plug 8, and the other end of the power cord 4 is connected to the reversing plug 9, and the reversing plug 9 is provided with a live wire hole 15, a grounding hole 16 and a neutral wire hole 17 , the live wire hole 15, the ground hole 16 and the neutral wire hole 17 are on the same horizontal plane, and the distance between the live wire hole 15 and the ground hole 16 is the...

Embodiment 2

[0018] The phase-changing power strip includes a housing 1, a switch 2, a socket area 3 and a power cord 4, and a suction cup 7 for positioning is provided on the front and rear sides of the bottom of the housing 1; a dark groove 5 is provided on the side of the housing 1 , the dark groove 5 is provided with a drawable wire wrap 6; the surface of the other side of the housing 1 opposite to the power cord 4 is provided with a switch 2, and the middle part of the surface of the housing 1 is provided with a jack area 3, and the housing 1 is connected to the One end of the power cord 4 is provided with a phase-changing socket 10; one end of the power cord 4 is connected to a power plug 8, and the other end of the power cord 4 is connected to a phase-changing plug 9, and the phase-changing plug 9 is provided with a live wire hole 15, a grounding hole 16 and a neutral pin. The wire hole 17, the live wire hole 15, the ground hole 16 and the neutral wire hole 17 are on the same horizon...

Embodiment 3

[0020] The phase-changing power supply strip includes a housing 1, a switch 2, a socket area 3 and a power cord 4. Three suction cups 7 for positioning are uniformly arranged on the bottom of the housing 1; 5 is provided with a drawable winding button 6; the surface of the other side of the housing 1 opposite to the power cord 4 is provided with a switch 2, and the middle part of the surface of the housing 1 is provided with a jack area 3, and the housing 1 is connected to the power cord 4 One end of the power cord 4 is provided with a reversing socket 10; one end of the power cord 4 is connected to the power plug 8, and the other end of the power cord 4 is connected to the reversing plug 9, and the reversing plug 9 is provided with a live wire hole 15, a grounding hole 16 and a neutral wire hole 17 , the live wire hole 15, the ground hole 16 and the neutral wire hole 17 are on the same horizontal plane, and the distance between the live wire hole 15 and the ground hole 16 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com