Drive device for automobile engine variable valve lift

A technology of automobile engine and valve lift, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of complex structure, difficult installation of connecting shaft, etc., and achieve the effect of ensuring adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

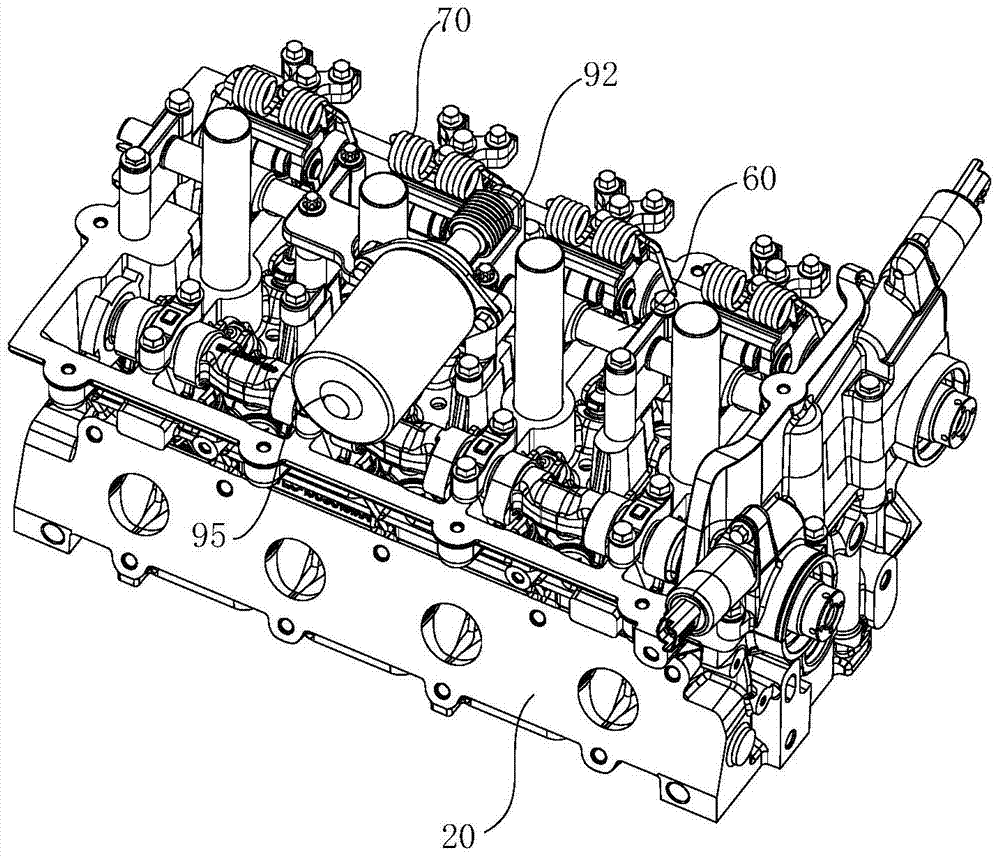

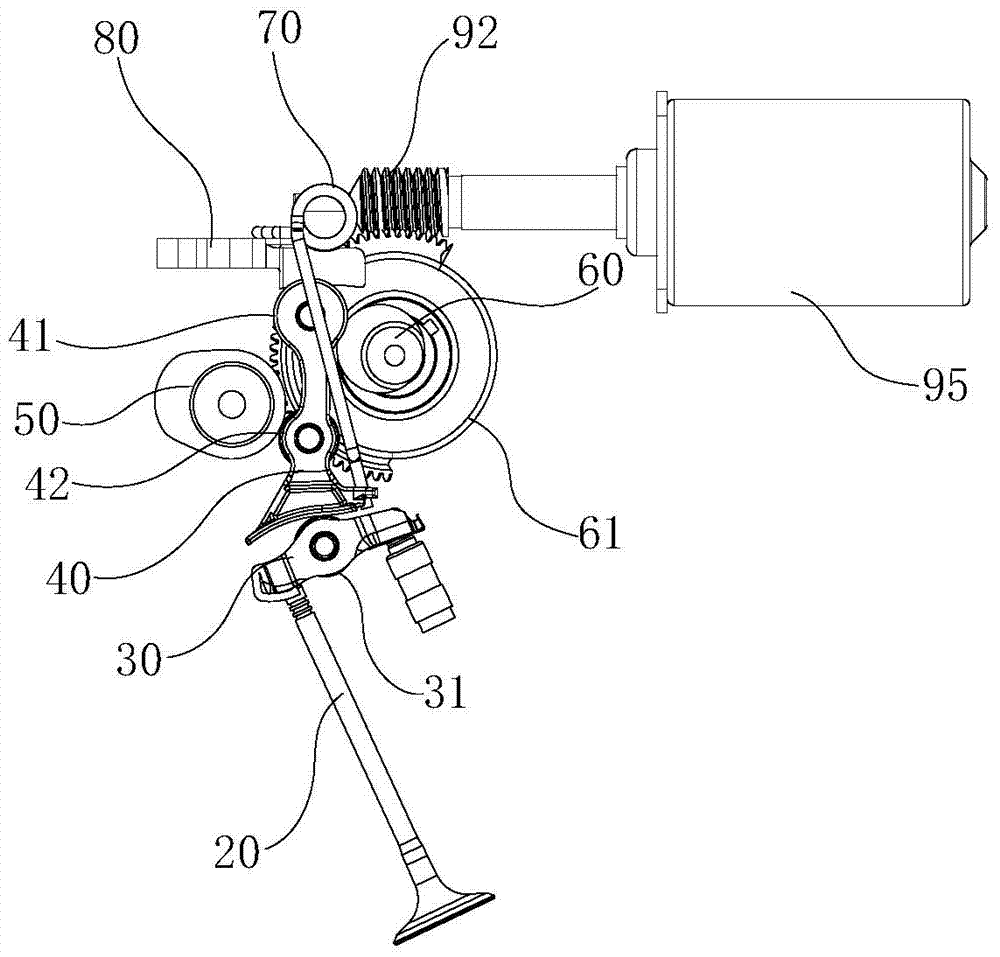

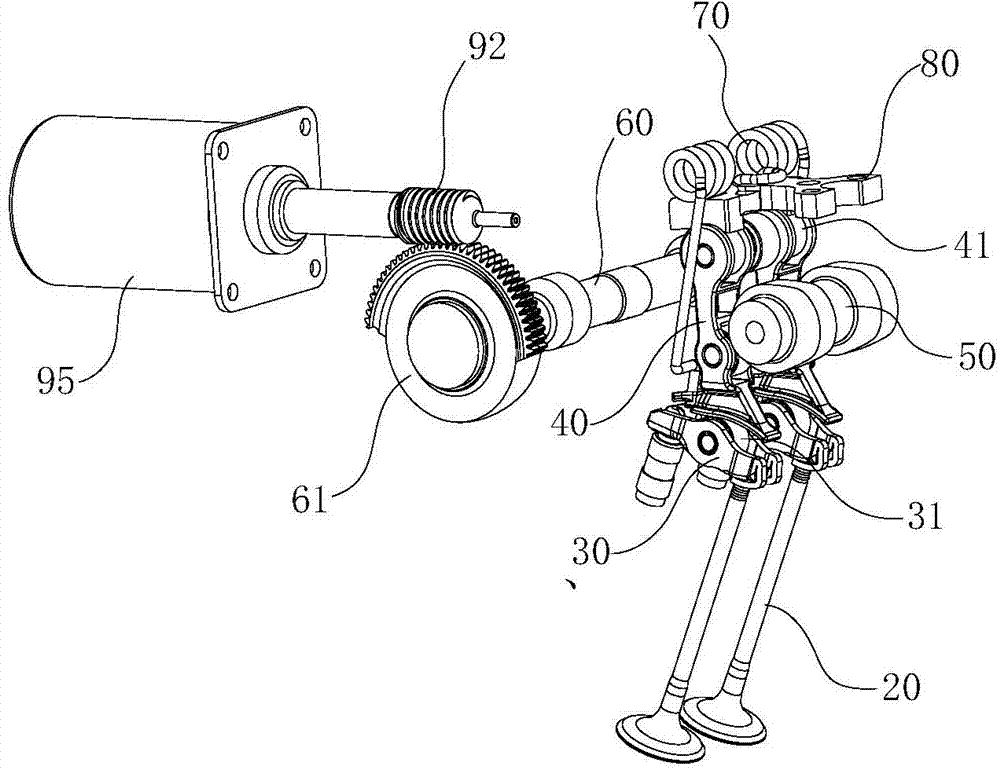

[0013] combined with Figures 1 to 6 , the present invention is described in further detail:

[0014] combine image 3 , a driving device for a variable valve lift of an automobile engine, comprising a valve 20 arranged on the cylinder head 10, one end of the valve rocker arm 30 is connected with the rod end of the valve 20, and the other end of the valve rocker arm 30 is also connected with the valve lifter It is characterized in that: the device also includes an intermediate rocker arm 40, the lower end of the intermediate rocker arm 40 forms a press fit with the middle section of the valve rocker arm 30, the upper end of the intermediate rocker arm 40 abuts against the curved surface of the guide rail of the upper support 80, and the middle The left and right sides of the rocker arm 40 are respectively abutted against the eccentric shaft 60 and the camshaft 50, and the middle rocker arm 40 is also connected with a spring 70, which provides elastic force to drive the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com