Exposed steel wire detection device of tire forming machine

A technology of tire building machine and detection device, applied in the direction of measurement device, material analysis by electromagnetic means, instrument, etc., can solve the problems of waste of resources, leakage of tire steel wire, non-compliance with environmental protection and saving, etc., and achieves high safety and economical efficiency. resources, the effect of avoiding product quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

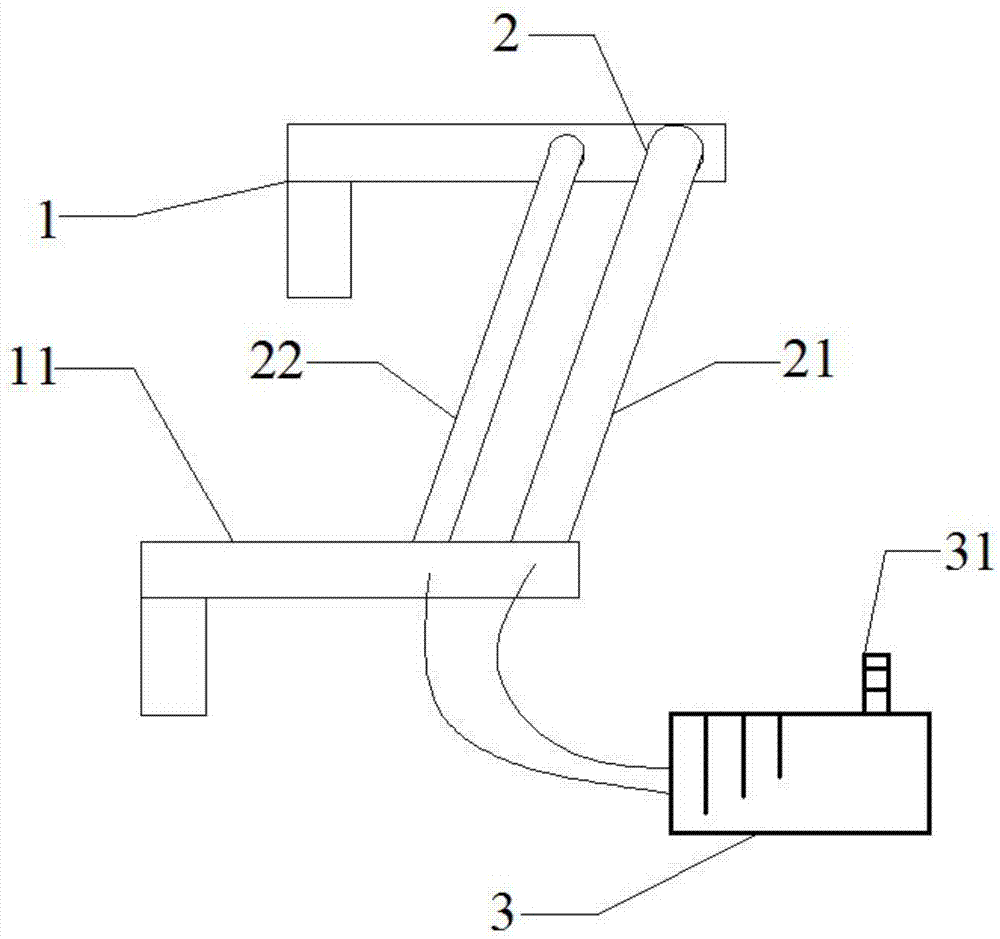

[0011] The steel wire leakage detection device of a tire building machine includes a bracket 1, a pressure roller 2, and a controller 3. The bracket 1 is provided with a suspension beam 11, and the pressure roller 2 includes a first pressure roller 21 and a second pressure roller 22. The length of the first pressure roller 21 is the same as the length of the second pressure roller 22, the outer diameter of the first pressure roller 21 is greater than the outer diameter of the second pressure roller 22, the first pressure roller 21 and the second pressure roller Both ends of the two pressure rollers 22 are insulated, the first pressure roller 21 and the second pressure roller 22 are installed side by side on the suspension beam 11, and the controller 3 is connected to one end of the pressure roller 2 through a wire.

[0012] The ends of the first pressing roller 21 and the second pressing roller 22 are all insulated, the distance between the first pressing roller 21 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com