End face oil configuration for journal bearings

A technology of journal bearings and end faces, which is applied in the field of journal bearings, can solve the problems of increased leakage, etc., and achieve the effect of reducing oil flow rate and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

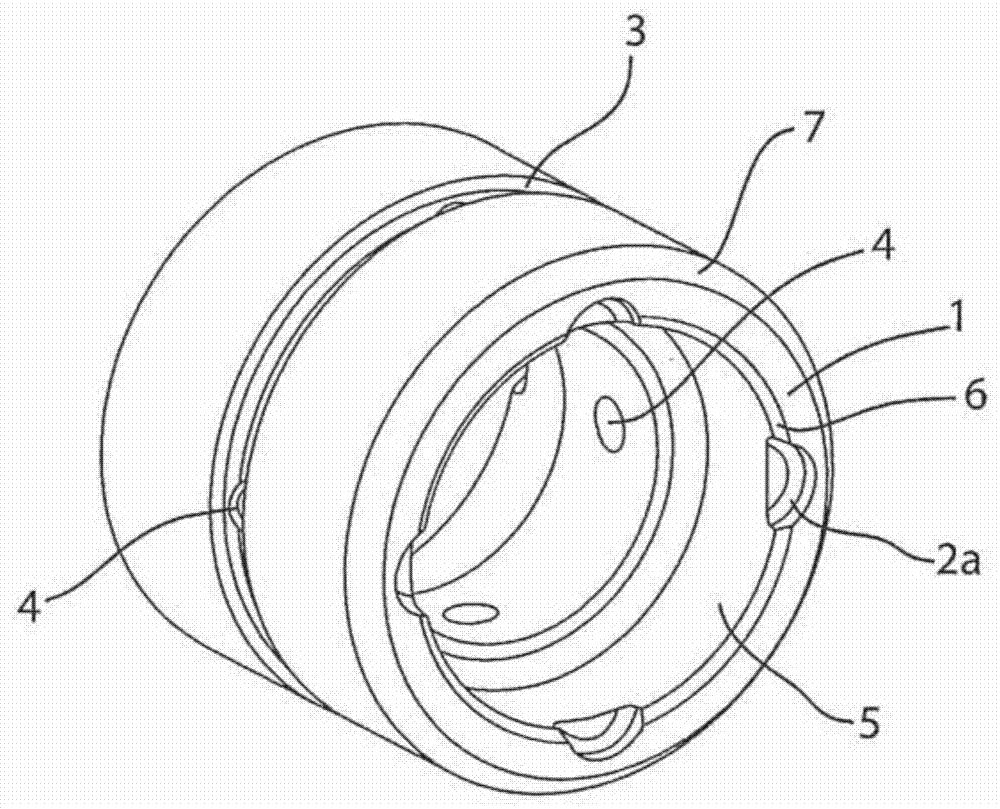

[0018] figure 1 A first embodiment of the inventive journal bearing end face of the present invention is depicted;

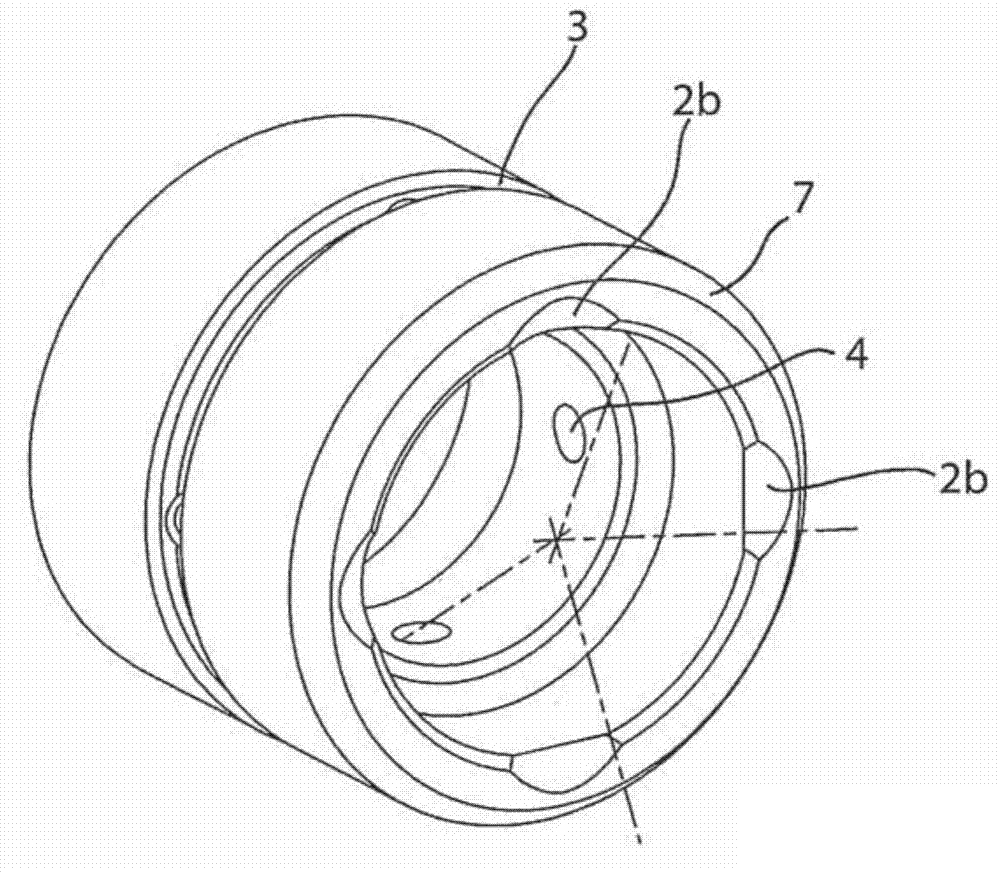

[0019] figure 2 depicts a second embodiment of an end face of a journal bearing of the present invention; and

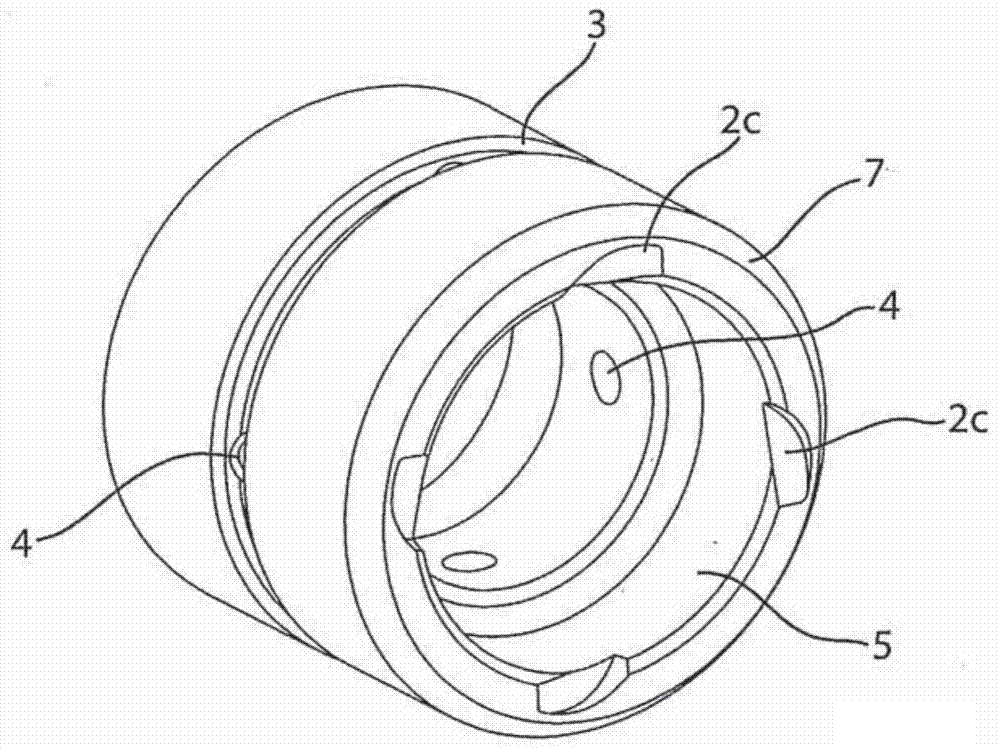

[0020] image 3 A third embodiment of an end face of a journal bearing of the present invention is depicted.

[0021] Detailed Description of the Invention

[0022] A journal bearing with a face according to the invention is improved especially in terms of guaranteeing the oil flow in the case of axial thrust, without requiring modification of the turbocharger except for the replacement of the conventional journal bearings by the inventive journal bearings. Revise. The journal bearing can be a "floating" journal bearing with a three-piece design, where the two journal bearings are separated by a bearing spacer, or it can be a "fixed" journal bearing with a one-piece design or a three-piece design. "Journal bearings. Therefore, the operation of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap