Device And Method For Manufacturing Of Plastic Articles By Extrusion Blow Moulding

A technology for plastic products and extrusion devices, applied in the field of devices for manufacturing plastic products by extrusion blow molding and in the field of manufacturing plastic products, can solve the problems of lack of flexibility of adjustment rods, variability restrictions, production restrictions, etc., and achieve considerable material savings , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

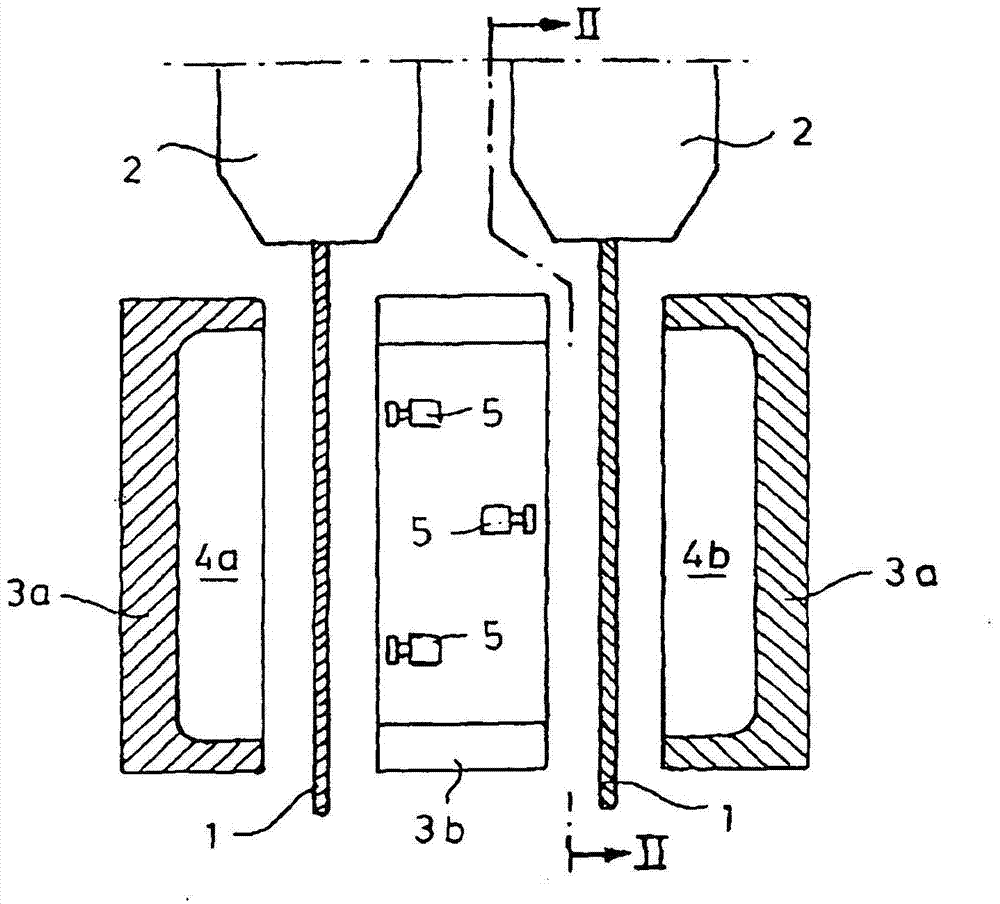

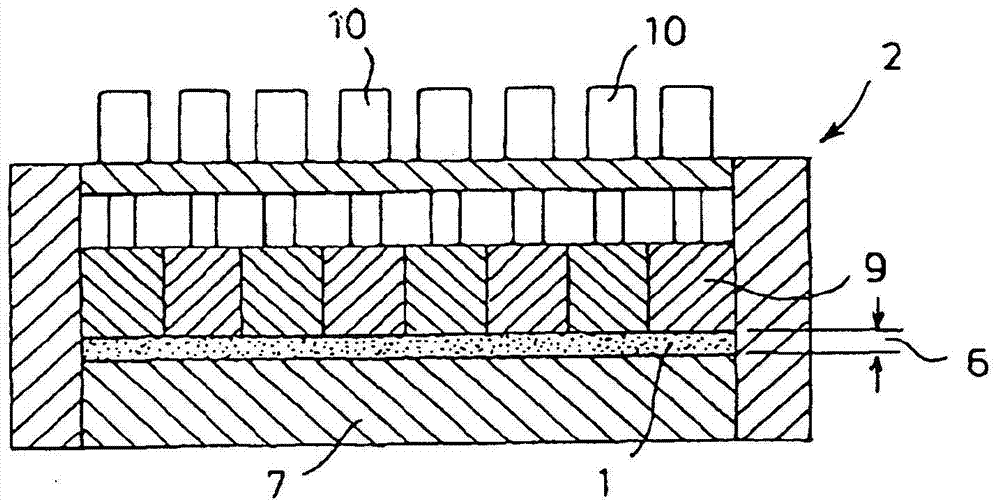

[0038] exist figure 1 A part of a method for producing an extrusion-blown article from a web-shaped preform 1 is schematically shown in FIG. Each preform 1 is extruded pendulously from two wide-slit nozzles 2 . The slot nozzles 2 are part of an extrusion head, not shown, which is supplied with molten liquid thermoplastic in a known manner from the extruder.

[0039] For example figure 1 As shown, a preform 1 in the form of a web or sheet can be extruded between the open parts of the forming die 3 .

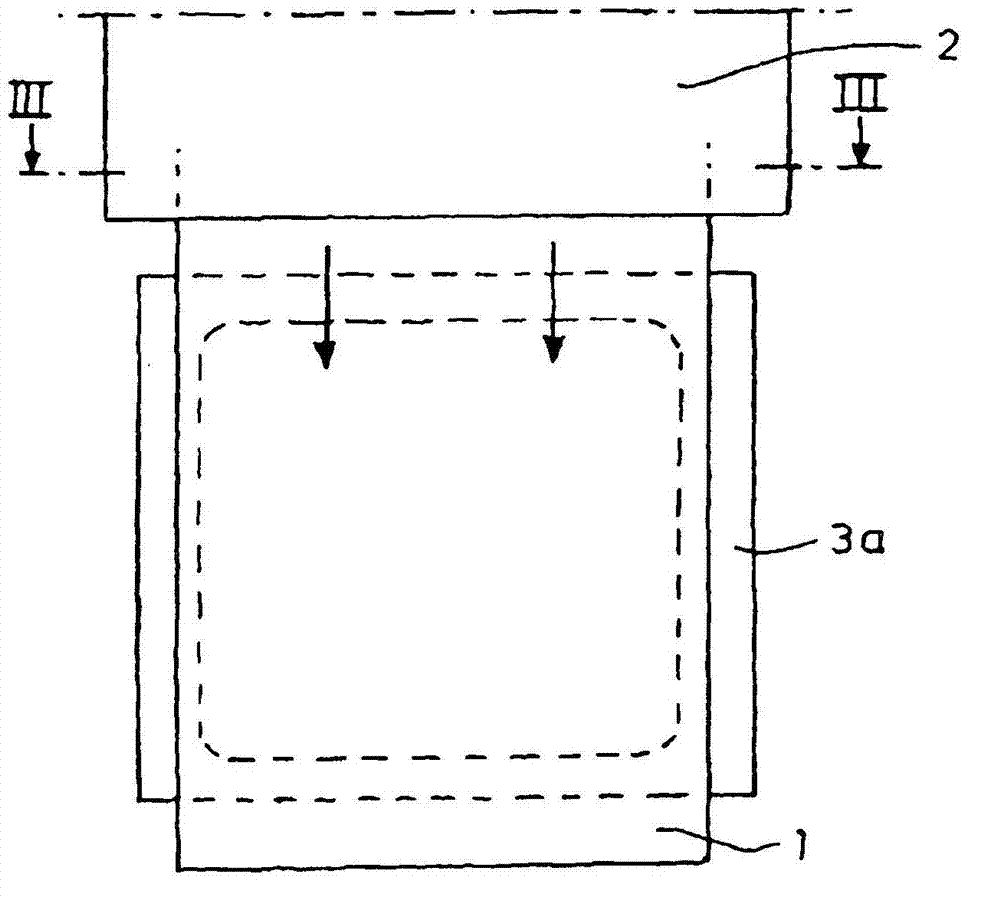

[0040]The molding die 3 includes two outer dies 3a and one middle die 3b. The outer molds 3 a each form a sub-cavity into which the pre-forms 1 are drawn or pressed and which respectively determine the later outer shape of the finished article. The manufacture of the article can take place, for example, by first extruding the individual preforms 1 between the open outer molds 3 a and the middle mold 3 b. The respective outer mold 3a is then closed relative to the central mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com