Sealant for concrete anti-permeability performance detection, preparation method thereof and concrete anti-permeability performance detection method

A detection method and sealant technology, which are applied in the directions of sealing devices, chemical instruments and methods, measuring devices, etc., can solve the problem of being easily squeezed out between the test block and the steel die by water pressure, poor temperature applicability of the sealant, and influence of Sealant sealing effect and other issues, to achieve the effect of wide temperature applicability, good sealing effect, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

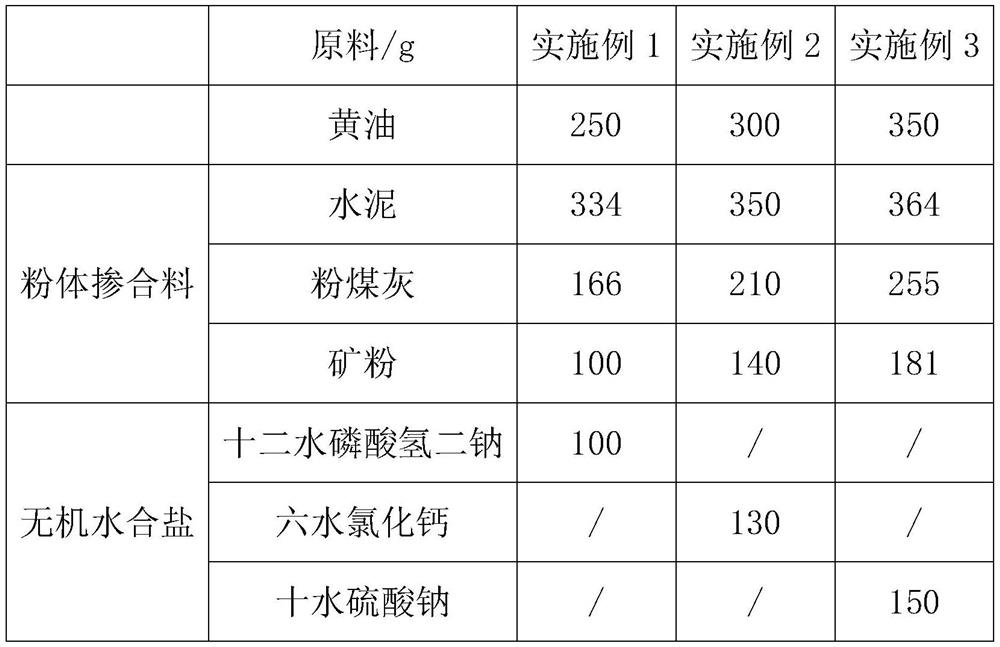

[0039]A sealant for testing the impermeability of concrete, the components of its raw materials and their corresponding weights are shown in Table 1. A preparation method of a sealant for concrete impermeability testing is as follows:

[0040] Put butter, admixture, inorganic hydrated salt and thickener into the mortar mixer, and stir at 150r / min for 3min to obtain a sealant.

Embodiment 2

[0042] A sealant for testing the impermeability of concrete, the components of its raw materials and their corresponding weights are shown in Table 1. A preparation method of a sealant for concrete impermeability testing is as follows:

[0043] Add butter, admixture, inorganic hydrated salt and thickener to the mortar mixer, and stir at 150r / min for 4min to obtain a sealant

Embodiment 3

[0045] A sealant for testing the impermeability of concrete, the components of its raw materials and their corresponding weights are shown in Table 1. A preparation method of a sealant for concrete impermeability testing is as follows:

[0046] Put butter, admixture, inorganic hydrated salt and thickener into the mortar mixer, and stir at 150r / min for 5min to obtain a sealant.

[0047] Each component and consumption of the sealant of table 1 embodiment 1-3

[0048]

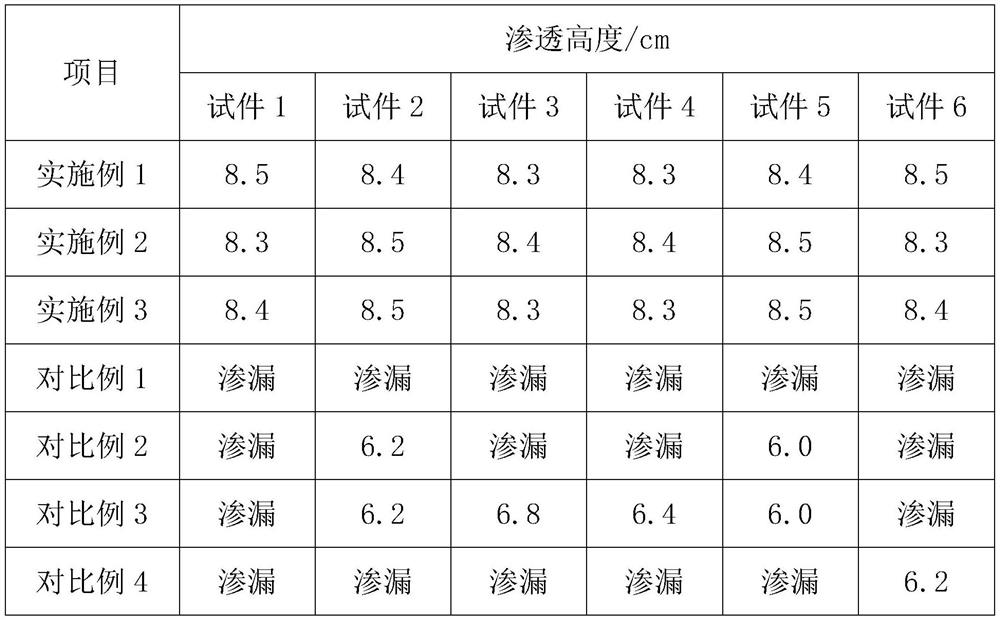

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com