Semiconductor device and method of making the same

A semiconductor and device technology, applied in the field of semiconductor devices and their preparation, can solve the problems of carrier mobility reduction, affecting device linearity, degradation, etc., and achieve the effect of improving interface scattering effect, improving linearity and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

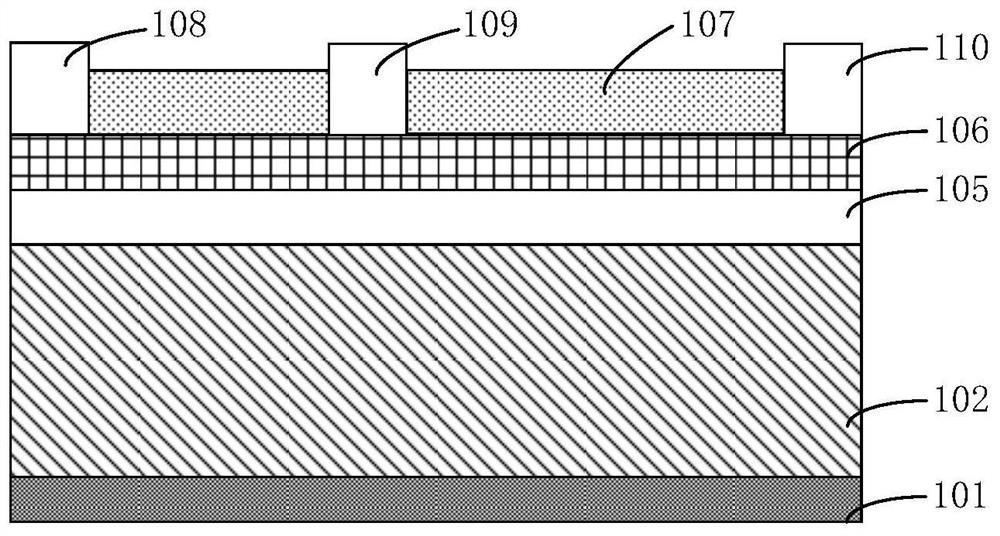

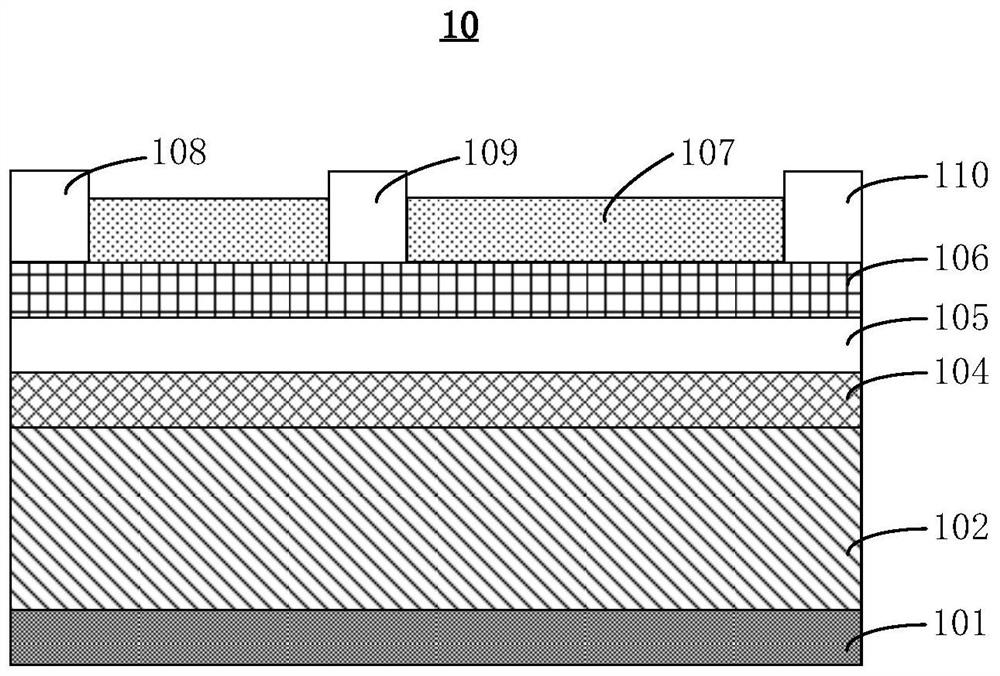

[0046] In order to solve the above problems, embodiments of the present application provide a semiconductor device 10, such as image 3 As shown, the semiconductor device 10 includes a substrate 101 , a buffer layer 102 , a transition layer 104 , a channel layer 105 , a barrier layer 106 , a passivation layer 107 , a source electrode 108 , a gate electrode 109 and a drain electrode 110 .

[0047] In detail, the substrate 101 may be made of sapphire (Sapphire), silicon carbide (SiC), silicon (Si), lithium niobate, rare earth oxide or any other suitable material. Optionally, the substrate 101 may be made of silicon carbide with good heat dissipation properties.

[0048] The material of the buffer layer 102 can be nitride, specifically GaN or AlN or other nitrides, and the buffer layer 102 can be used to match the material of the base substrate 101 and the epitaxial transition layer 104 and the channel layer 105 .

[0049]Generally speaking, the semiconductor layer includes a ch...

Embodiment 2

[0055] In another embodiment, in order to improve the confinement of electrons in the channel, the linearity is further improved, such as Figure 5 As shown, the back barrier layer 103 is formed on the side of the transition layer 104 close to the substrate 101. In the embodiment of the present application, the back barrier layer 103 is formed between the transition layer 104 and the nitride buffer layer 102. The barrier layer 103 is used to increase the energy level difference between the transition layer 104 and the buffer layer 102, thereby forming a square-like electron moving channel with a certain width. The forbidden band width of the back barrier layer 103 is larger than that of the transition layer 104 . The back barrier layer 103 may be made of at least one of aluminum gallium nitride (AlGaN), aluminum nitride (AlN), gallium nitride (GaN), and other semiconductor materials. Because the back barrier layer 103 forms the sidewall of the energy band of the semiconductor...

Embodiment 3

[0058] Embodiments of the present application also provide a method for fabricating a semiconductor device, such as Figure 7 shown, including the following steps.

[0059] Step S101, providing a substrate.

[0060] Step S102, fabricating a buffer layer based on the substrate.

[0061] The embodiments of the present application do not limit the material of the substrate, and a buffer layer may be formed by depositing materials such as GaN or InGaN on the surface of the substrate.

[0062] Step S103, forming a transition layer on the side of the buffer layer away from the substrate.

[0063] In the embodiment of the present application, after the buffer layer is formed, gallium nitride or indium gallium nitride can also be deposited on the surface of the buffer layer to form a transition layer. The transition layer can be heavily doped with n-type, and its doping concentration can be greater than 1e17cm -3 .

[0064] Preferably, in step S104, before forming the transition l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com