Combined type screw nut

A combination and nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of frequent adjustment, long thread adjustment distance, long time, etc., and achieve the effect of saving time, fast locking and fast moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

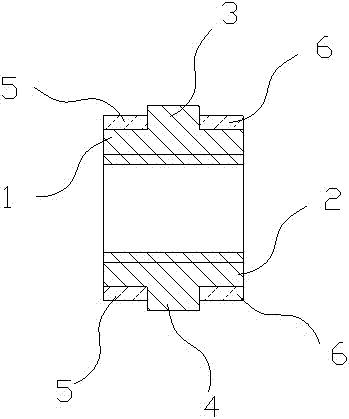

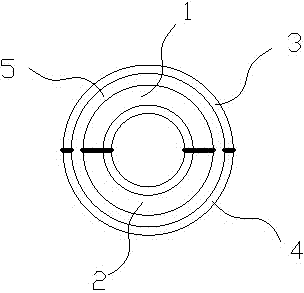

[0012] Such as figure 1 , figure 2 As shown, a combined nut includes a first half nut 1 , a second half nut 2 , a first casing 5 and a second casing 6 . The middle part of the first half nut 1 has a first half nut boss 3, and the middle part of the second half nut 2 has a second half nut boss 4. After the first half nut 1 and the second half nut 2 are combined, the inner cavity forms a complete Internal thread, the first half nut boss 3 and the second half nut boss 4 form a complete nut boss, the first outer sleeve 5 is set on the left outer surface of the first half nut 1 and the second half nut 2, the second The second outer sleeve 6 is fitted on the right outer surfaces of the first half nut 1 and the second half nut 2 to limit the radial separation of the first half nut 1 and the second half nut 2 .

[0013] The first cover 5, the second cover 6, the first half nut 1 and the second half nut 2 form a complete combined nut, and the first half nut boss 3 and the second hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com