Grain drying device

A drying device and grain drying technology, applied in the direction of preserving seeds through drying, can solve the problems of low efficiency, impossibility, and easy damage of natural drying, and achieve the effects of long service life, convenient use, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

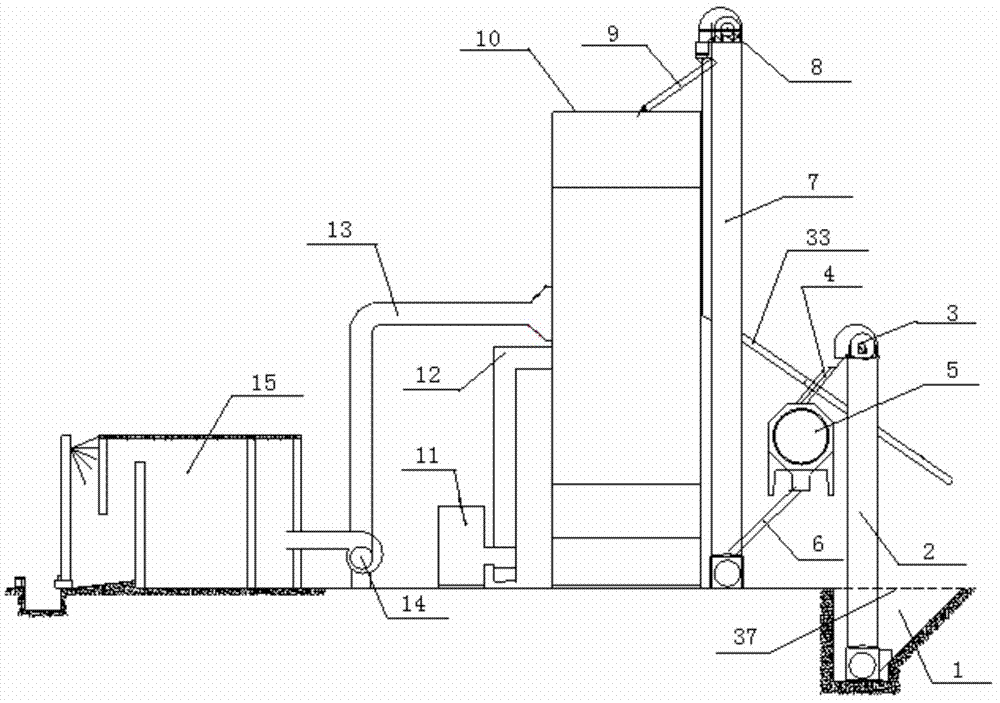

[0029]This embodiment provides a grain drying device, including a grain feeding system, a grain drying system, and an exhaust system. The grain feeding system includes a grain pit 1 for storing grain, a first grain feeding pipeline 2, a first reduction motor 3, The first glide track 4, the initial cleaning screen 5, the second glide track 6, the second grain feed pipeline 7, the second reduction motor 8 and the third glide track 9, the first grain feed pipeline 2 and the second grain feed pipeline 7 are all Vertically set, the first glide track 4, the second glide track 6 and the third glide track 9 are all inclined;

[0030] The entrance of the lower end of the first grain feeding pipeline 2 extends into the inside of the grain pit 1, the upper end of the first grain feeding pipeline 2 is provided with a first reduction motor 3, the upper end outlet of the first grain feeding pipeline 2 is connected with the first glide track 4, and the first glide track The lower end of 4 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap