Boiler container of automatic cooker

A cooking machine and cooking pot technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of poor heating effect, easy to scrape off the coating, poor heating effect, etc., to avoid coating peeling off, high thermal efficiency, prevent Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

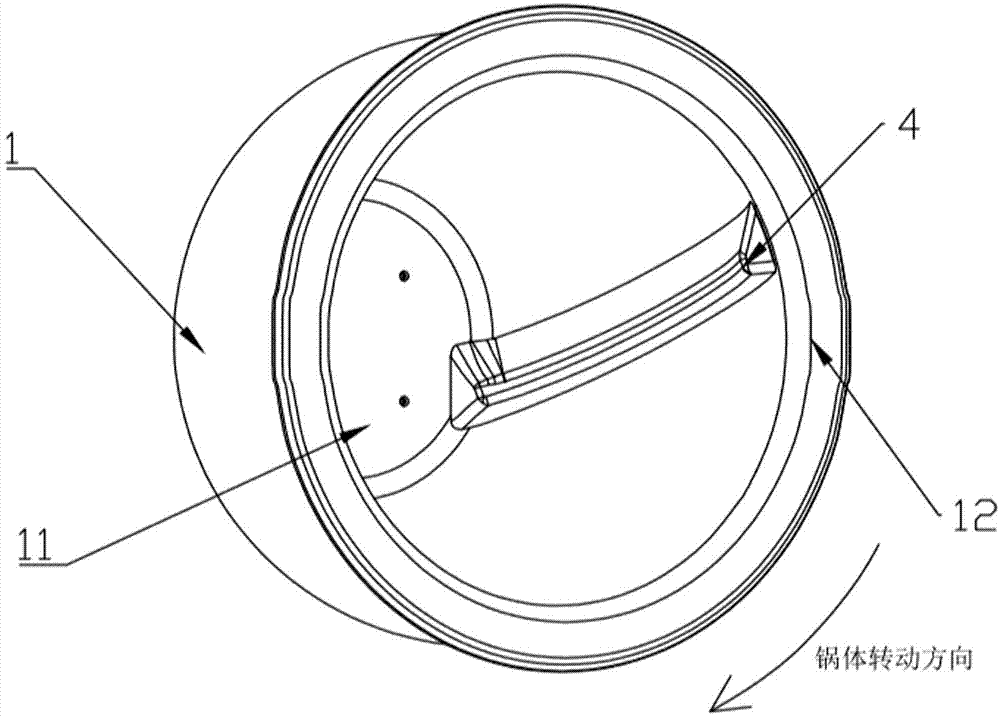

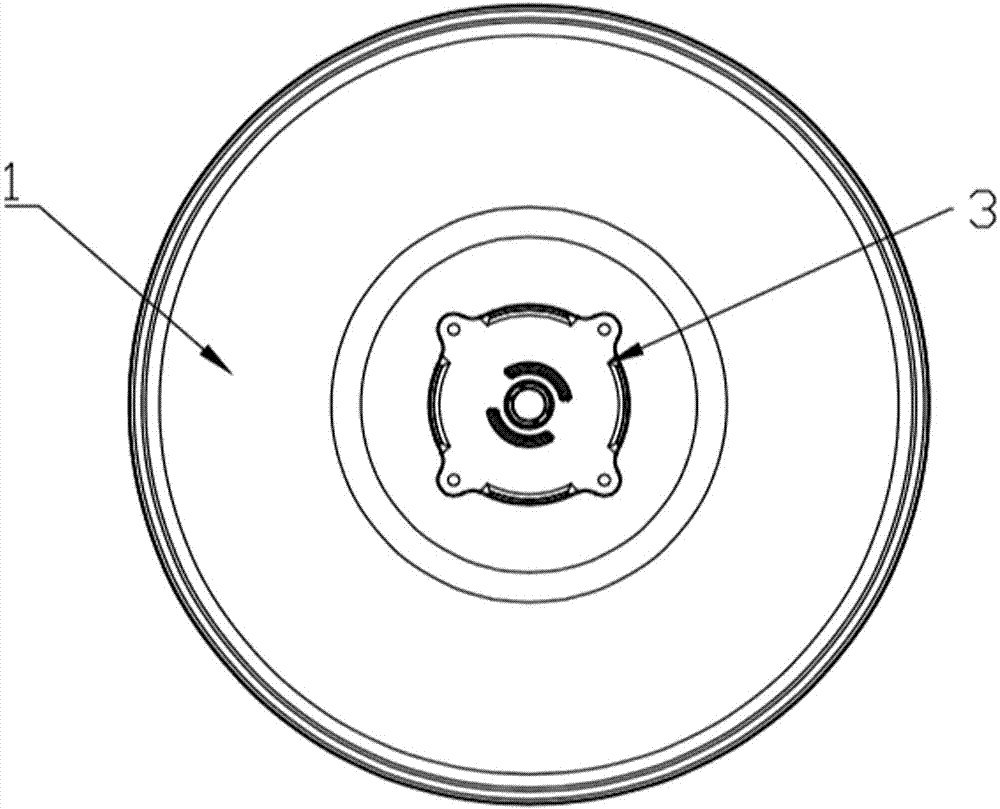

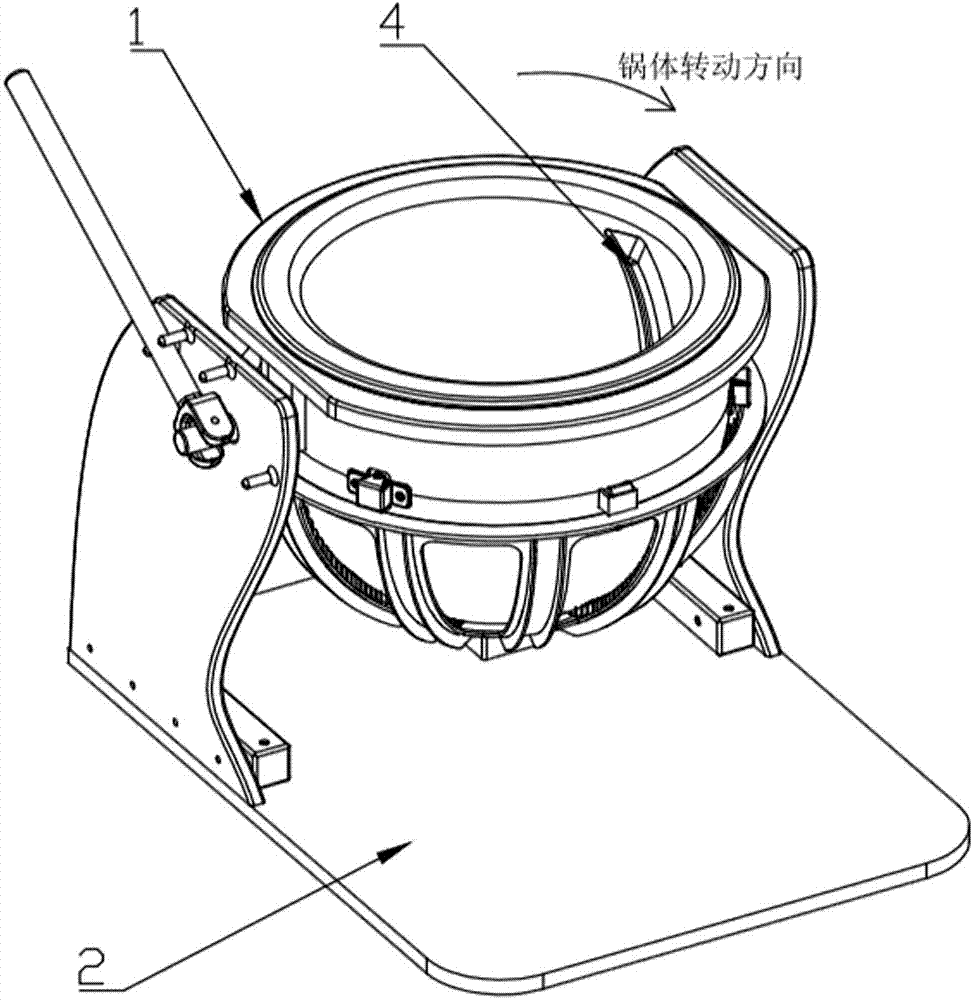

[0028] Embodiment one: if figure 1 , 3 As shown, the main structure of this embodiment is a pot body 1 for holding ingredients for processing, and the pot body 1 can rotate with the drive of the cooking machine host 2 . like figure 2 As shown, the bottom surface of the pot body 1 is provided with a connector 3 for cooperating with the host 2 of the cooking machine. like figure 1 , 3 As shown, the inner wall of the pot body 1 is provided with elongated tendons 4 for stir-frying ingredients, and the ribs 4 are from the bottom surface 11 of the pot body 1 to the opening 12 of the pot body 1 and along the direction of the pot body 1. Body 1 extends in the opposite direction of rotation. The pot body 1 forms an acute angle with the horizontal plane and is installed on the main unit 2 of the cooking machine to rotate and heat. , when the ingredients reach a certain height, they will fall.

[0029] like Figure 4 As shown, it is assumed that the main storage area of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com