Fixing rack for supporting oil pipeline

An oil pipeline and fixing frame technology, applied in the field of support frame, can solve the problems of large contact surface between the pipe groove and the oil pipeline, unstable placement of the oil pipeline, unadjustable height of the pipeline support frame, etc., so as to avoid distortion and strengthen the L The effect of the type bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

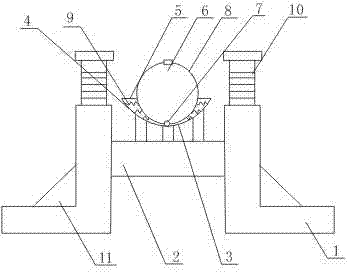

[0014] Such as figure 1 , figure 2 As shown, a fixed frame for supporting oil pipelines includes an L-shaped bracket 1, a base 2 arranged between two L-shaped brackets 1, and a support device 3 fixed on the base 2; the support device 3 includes an arc-shaped shell 4 and the horizontal plates 5 respectively connected to the two ends of the arc-shaped shell 4, one side of the horizontal plate 5 has a cuboid groove; it also includes a hoop 6, which includes two semicircular shells connected by hinges 7 8. The hoop 6 is located in the arc-shaped shell 4, and the hinge 7 is fixed on the bottom of the arc-shaped shell 4; wherein, the two semicircular shells 8 connected by the hinge 7 are respectively slidably arranged in the cuboid concave of the horizontal plate 5. In the groove; Also comprise some springs 9 that are respectively arranged on both sides inside the arc shell 4, one end of the spring 9 is connected on the inner wall of the arc shell 4, and the other end is connected...

Embodiment 2

[0017] In this embodiment, on the basis of Embodiment 1, the L-shaped bracket 1 is composed of a horizontal section and a vertical section. It has internal threads; it also includes a screw rod 10 set in the groove of the cylinder through threaded connection; it also includes a connecting rod connected to the screw rod 10 through a bearing, a slit is opened on the side of the vertical section, and the base 2 is fixed on the connection through the slit on the pole.

[0018] In this embodiment, the connecting rod is fixed on the screw rod 10 through a bearing, the base 2 is fixed on the connecting rod through a slit, and the screw rod 10 is slidably arranged in the vertical section through screw connection. Therefore, fine adjustment of the height of the oil pipeline support frame can be realized by rotating the screw rod 10 .

Embodiment 3

[0020] On the basis of Embodiment 2, this embodiment also includes a rib 11 connected to the L-shaped bracket 1. The rib 11 is a triangular column structure, and the two sides of the rib 11 are respectively fixed on the vertical section and the horizontal section of the L-shaped bracket 1. superior.

[0021] The rib plate 11 in this embodiment plays a role of strengthening the L-shaped bracket 1 and at the same time prevents the L-shaped bracket 1 from twisting and deforming under the action of external pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com