Novel filter with replaceable filtration core

A technology for replacing filter elements and filters, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., and can solve problems such as increased use costs, troublesome removal, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

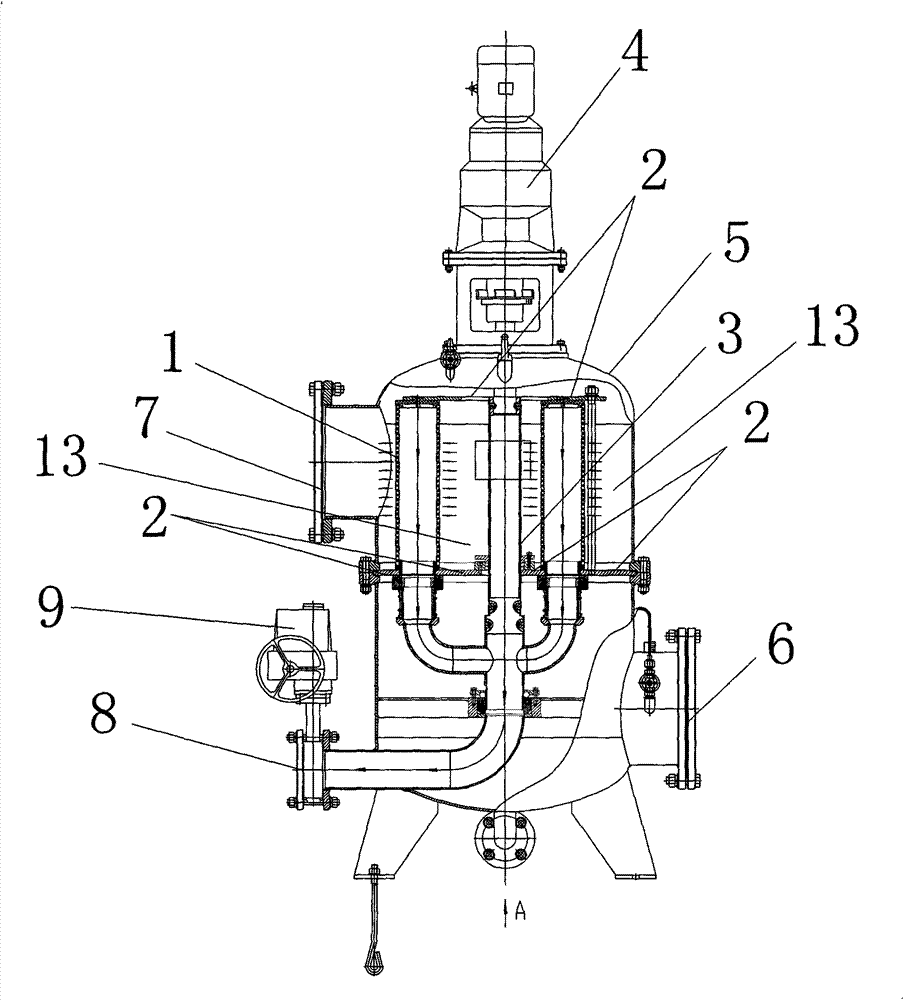

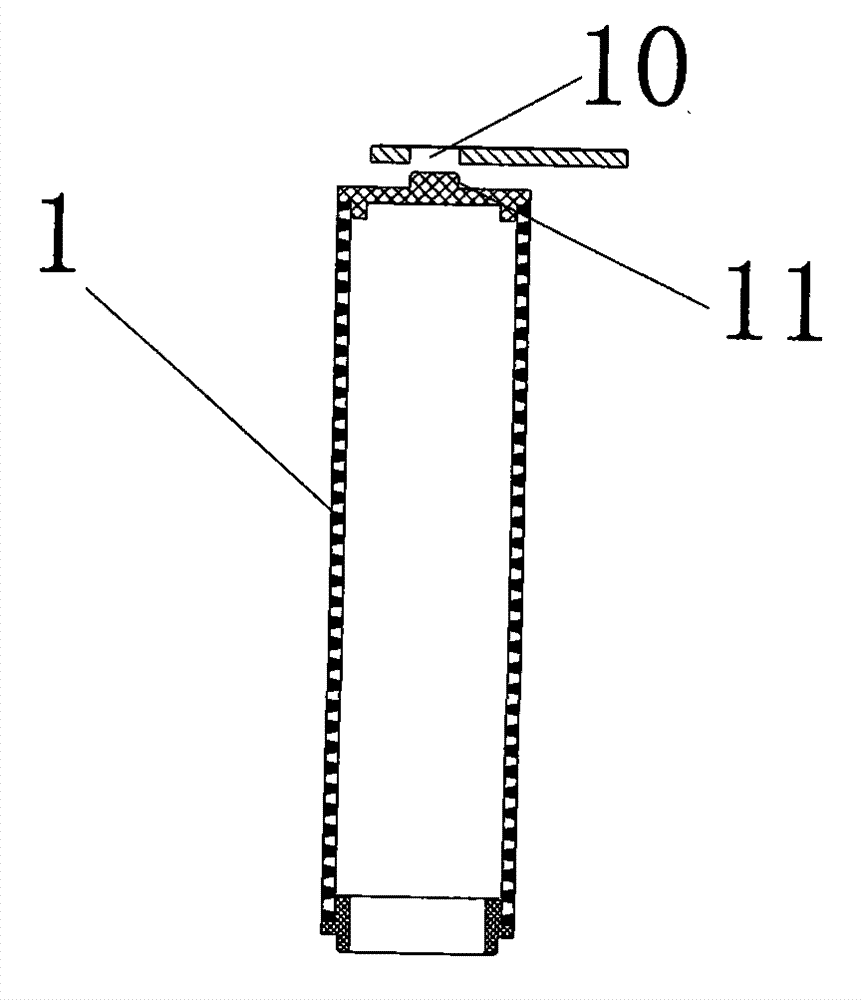

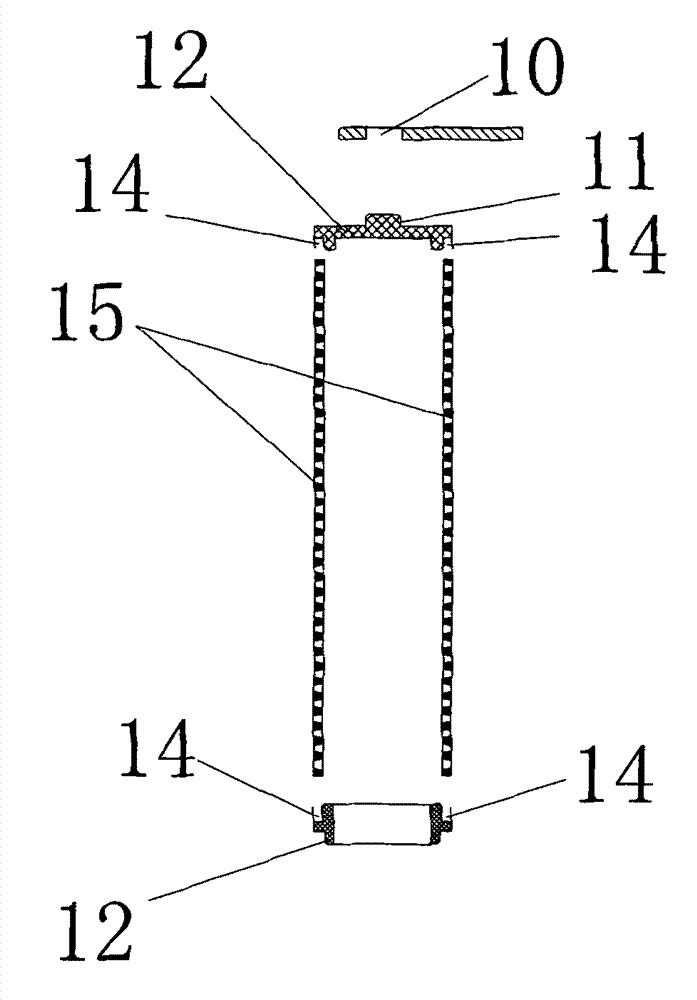

[0013] like figure 1 , figure 2 , image 3 Shown is a new type of filter with a replaceable filter element, which has a filter element 1, and a gap is provided between the filter element 1, the side wall of the housing 5 and the middle plate 2, and the gap is connected to form a filtrate chamber 13, and the upper part of the housing 5 is provided with a filtrate Outlet 7, the filtrate outlet 7 is connected with the filtrate chamber 13, the filter element 1 is fixed on the middle disc 2 of the filter, the middle disc 2 is set on the main shaft 3, the main shaft 3 is connected to the driving device 4, and the driving device 4 is set on the filter housing 5, the bottom of the housing 5 is provided with a filtrate inlet 6, the filtrate inlet 6 communicates with the filter element 1, the sewage outlet 8 is located at the bottom of the housing 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com