Powder supply device

A supply device and powder technology, applied in the direction of transportation and packaging, loading/unloading, conveying bulk materials, etc., can solve problems such as changes in supply valve powder supply, and achieve the effect of improving quality or productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

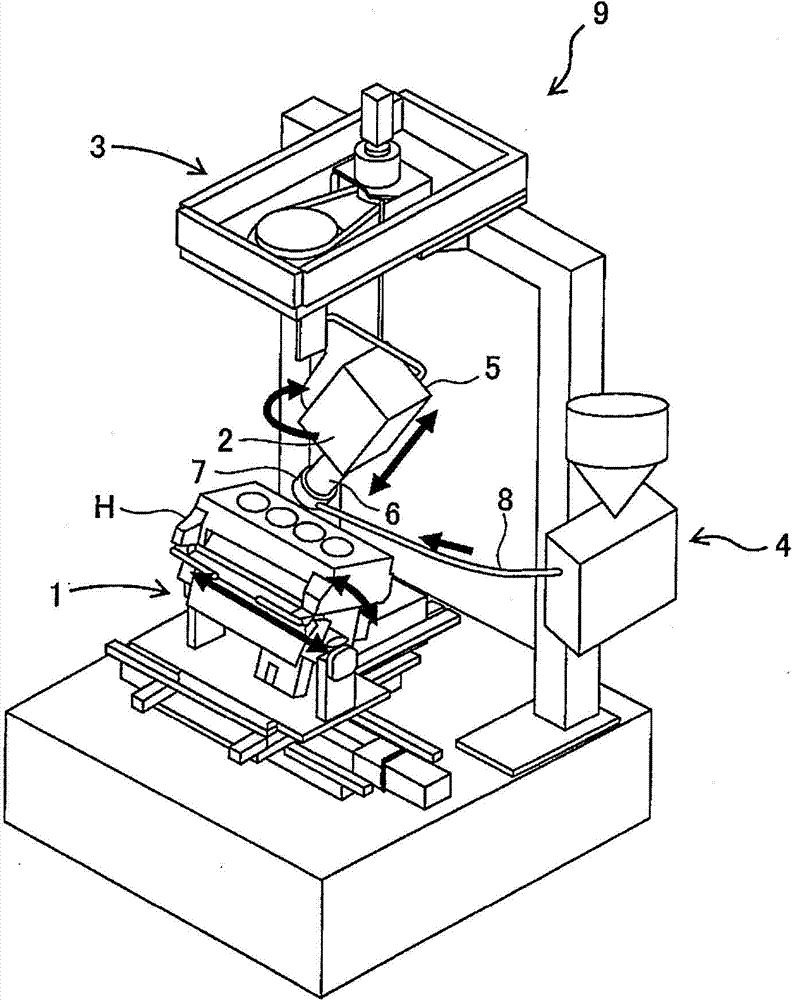

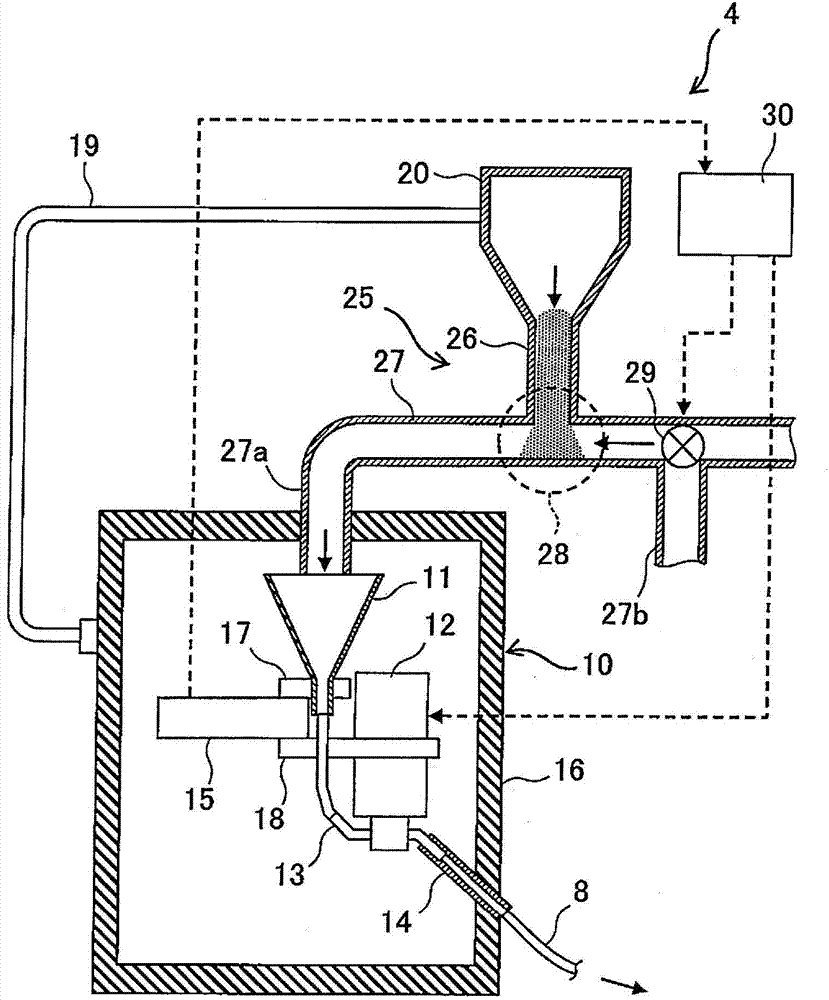

[0024] figure 1 It is a perspective view schematically showing the main configuration of a laser welding processing apparatus to which Embodiment 1 of the powder supply apparatus of the present invention is applied.

[0025] The illustrated laser welding processing device 9 is, for example, a device that performs laser welding processing on the valve seat portion of the cylinder head H, and includes: a cylinder head holding device 1 that deflects and holds the cylinder head H; A laser processing head 2 that discharges powdered metal (powder) (such as a material mainly composed of copper); the laser processing head 2 is tilted and held relative to the vertical direction, and the laser processing head 2 is rotated around the vertical axis a rotating rotating device 3; and a powder supplying device 4 for supplying powdered metal toward the laser processing head 2.

[0026] The cylinder head holding device 1 deflects the cylinder head H so that the central axis of the valve seat ...

Embodiment approach 2

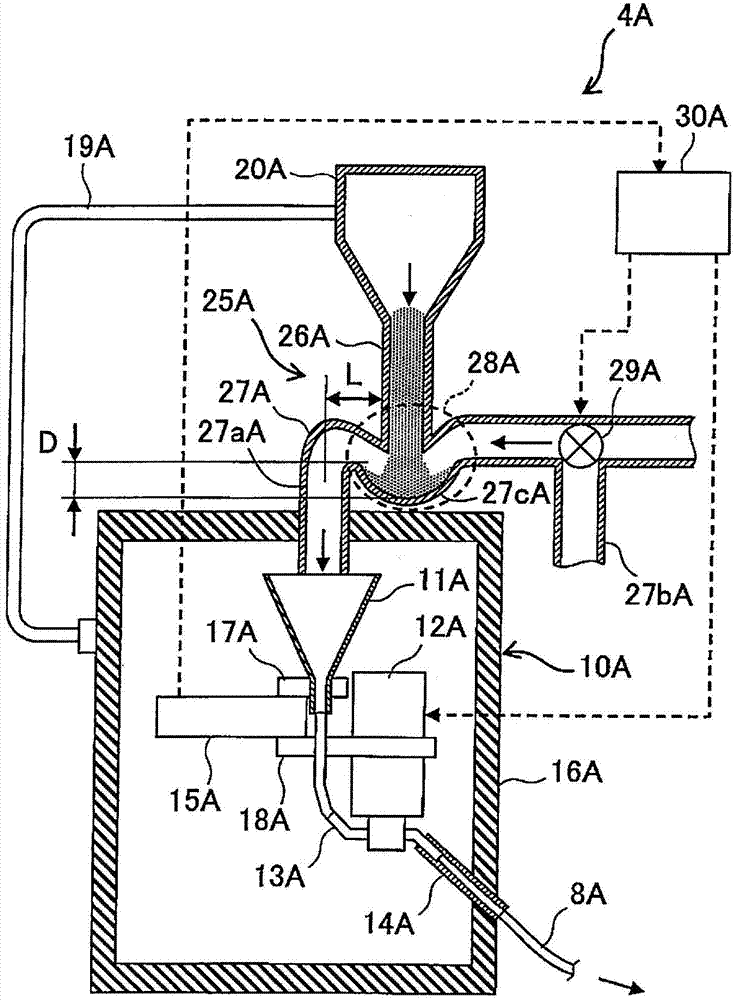

[0040] image 3 It is an overall configuration diagram showing the overall configuration of Embodiment 2 of the powder supply device of the present invention. image 3 The powder supply device of Embodiment 2 shown is compared to figure 2 The shown powder supply device according to Embodiment 1 is mainly different in the structure of the intersection between the first pipe and the second pipe, and the other structures are the same as those of the powder supply device according to Embodiment 1. Therefore, the same reference numerals are assigned to the same structures as those in Embodiment 1, and detailed description thereof will be omitted.

[0041] exist image 3 In the illustrated powder supply device 4A, the second pipe 27A has a bent portion 27cA protruding downward at an intersection 28A between the first pipe 26A and the second pipe 27A.

[0042] As described above, by providing the curved portion 27cA protruding downward at the crossing portion 28A, the powder guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com