Argon blowing gun for molten steel refining

A technology for blowing argon guns and molten steel is applied in the field of molten steel refining devices, which can solve the problems of excessive erosion, shortening the service life of the gun body, and cracking at the slag line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1

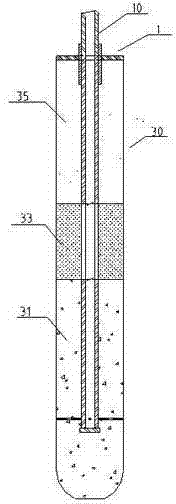

[0031] Such as figure 1 As shown, according to Embodiment 1 of the present invention, an argon blowing gun 1 for molten steel refining is provided. The argon blowing gun is configured to include a gun core 10 and a gun body 30. The gun core 10 is used as an argon blowing tube of the gun body, and the gun body 30 is wrapped around the gun core 10 and used as a refractory layer of the argon blowing gun. by figure 1 It can be seen that the gun body 30 includes three parts from bottom to top, namely: the molten steel immersion part 31, the slag line part 33 and the uppermost part 35, wherein the three parts form the gun body 30 by compound casting.

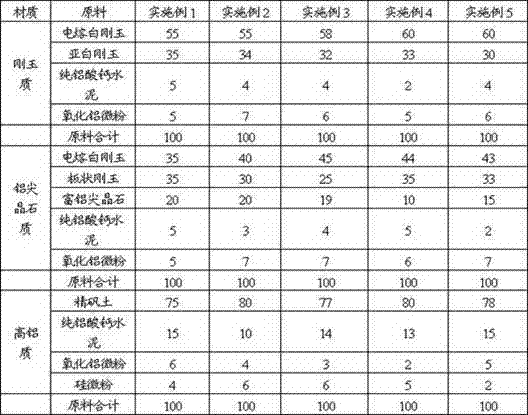

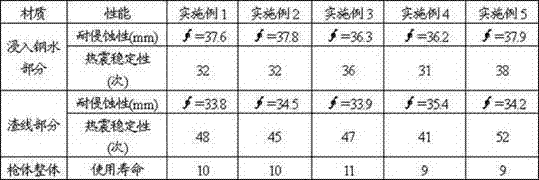

[0032] In this embodiment, the part 31 immersed in molten steel is made of corundum, and the material of the slag line part 33 is different from that of the part immersed in molten steel 31. It uses a material with good thermal shock resistance-aluminum spinel, and is located at the most The upper part 35 above is mad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap