A heat-supplementing ultra-high pressure/subcritical back pressure heating unit thermal system

A heating unit and thermal system technology, applied in the field of thermal systems, can solve the problem that the main steam pressure of the back pressure unit cannot be further greatly increased, and achieve the effect of increasing the degree of freedom, obvious direct economic benefits, and improving the working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

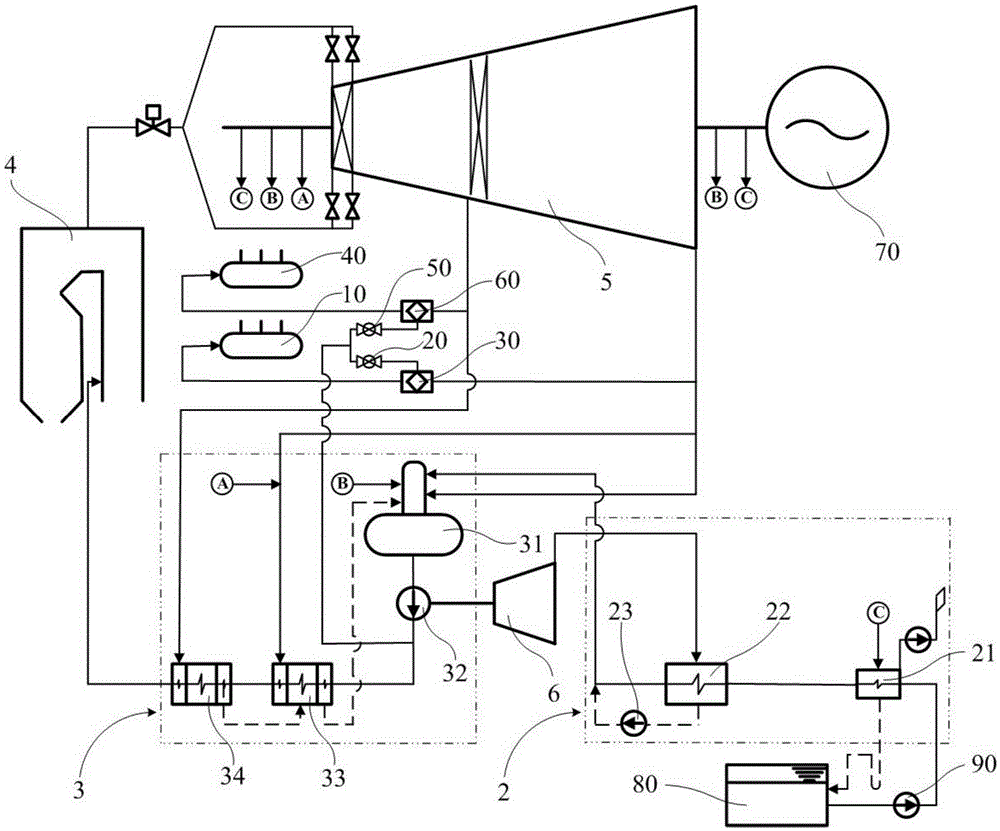

Embodiment 1

[0037] figure 2 The main steam parameter in the thermal system shown is 13.24MPa / 535°C. The system flow is generally similar to the existing technology, but under the condition of ensuring the rated pressure of the heating supply, the temperature of the exhaust steam and / or extraction steam of the steam turbine is already lower than that of the heating supply. Rated temperature, so a supplementary heating system was added. The supplementary heat system is connected after the exhaust port and / or steam extraction port of the steam turbine and before the heat supply sub-cylinder, including the first supplementary heater, the first supplementary heat bypass valve, the second supplementary heater, and the second supplementary heat bypass Valve, together with the first desuperheater, the first desuperheater, the second desuperheater, and the second desuperheater, adjust the temperature of exhaust steam and / or extraction steam of the steam turbine, so that the quality of the heating...

Embodiment 2

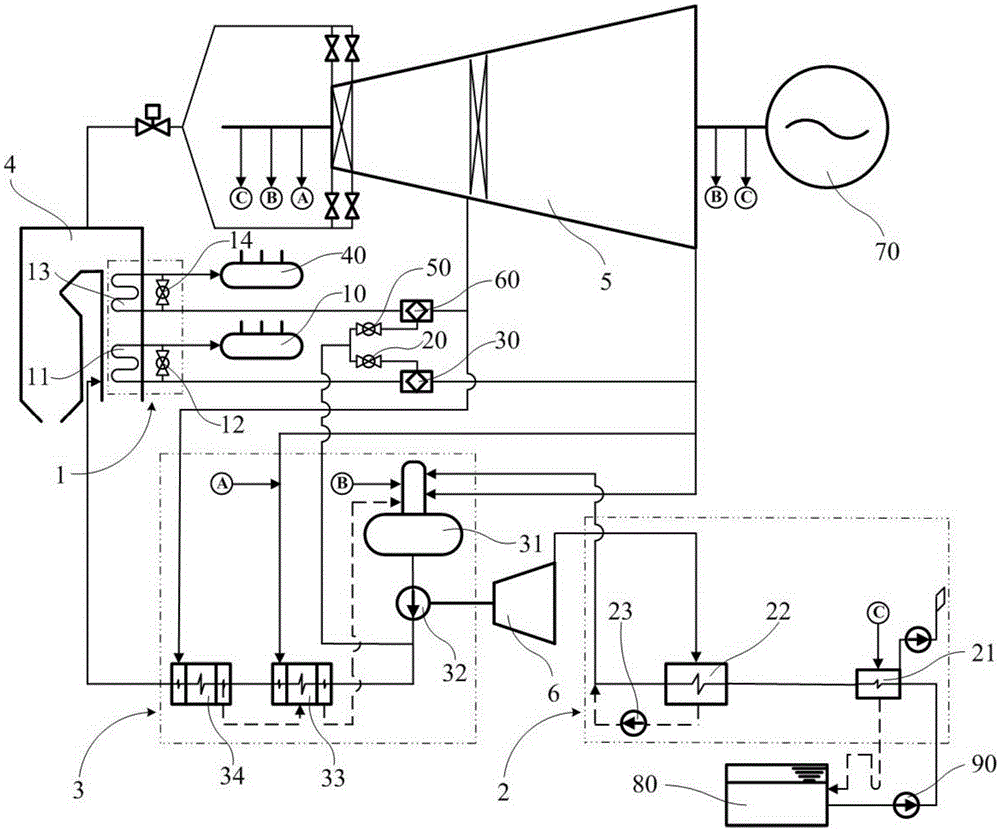

[0039] image 3 The main steam parameter in the thermal system shown is 13.24MPa / 555°C. The system flow is basically similar to that of Embodiment 1 of the present invention, the difference is that a low-pressure deaerator and a low-pressure feed water pump are added to the low-pressure recuperation system, arranged on the shaft between the seal heater and the desalinated water heater. The low-pressure deaerator and the high-pressure deaerator operate in series. The low-pressure deaerator pre-removes the main or part of oxygen and other non-condensable gases in the brine, reduces the corrosion of the desalinated water heater, and reduces the deaerator higher than the deaerator. Oxygen load, the high-pressure deaerator further reduces the dissolved oxygen and non-condensable gas in the demineralized water, ensuring the long-term safe and stable operation of the subsequent equipment of the thermal system.

Embodiment 3

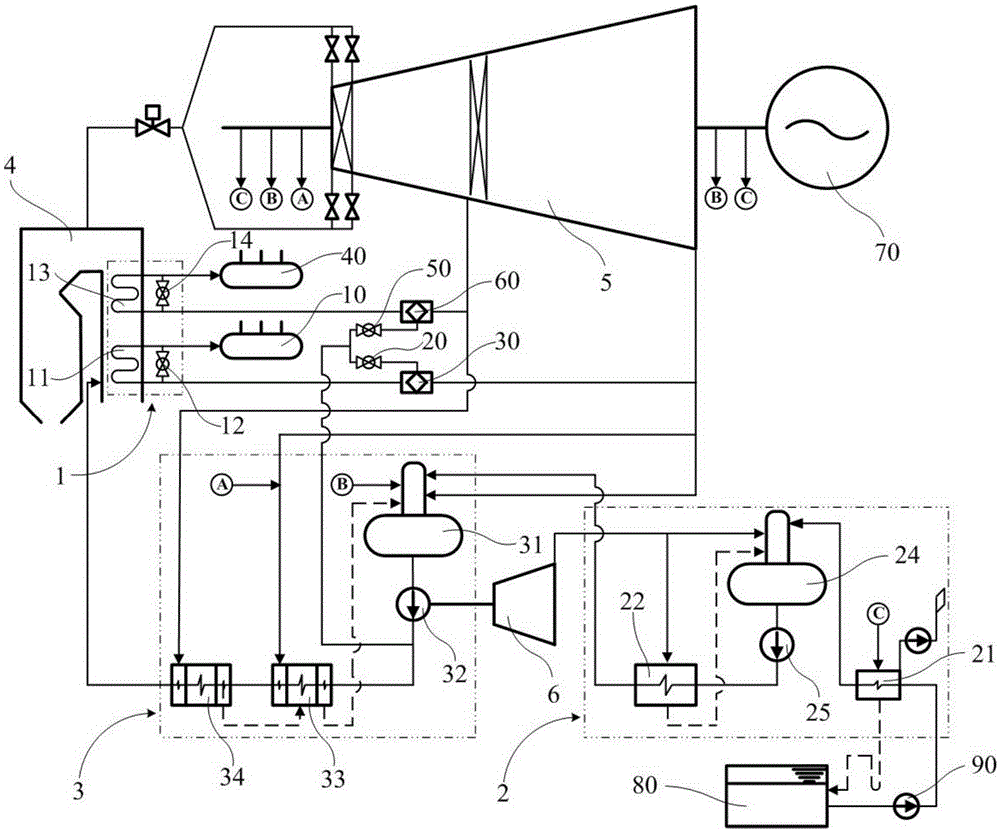

[0041] The thermal system of Example 3 is similar to that of Example 1, except that the specific design of the supplementary heat system and the main steam parameters are further increased to 16.67MPa / 535°C. Figure 4 It shows that the supplementary heat system in Example 1 mainly includes a supplementary heater and a supplementary heat bypass valve, and the supplementary heater is arranged in the tail flue of the boiler, roughly juxtaposed with the economizer; Figure 5 It shows another technical solution of the supplementary heating system. The supplementary heater is arranged in the flue bypass at the tail of the boiler, and there are flue bypass baffles at the bypass outlet and inlet. Adjusting the opening of the baffle can adjust the steam temperature. by Figure 5 Supplemental heating system shown in place of figure 2 The supplementary heat system in is the thermodynamic system diagram of embodiment 3. It is worth noting that it is difficult to make the low-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com