Steam distribution method for steam turbine nozzles based on the difference of vane angles of regulating stages

A level-adjusting and differentiated technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problem that the main steam pressure does not reach the optimal value, the area does not reach the optimal match, and the partial load economy of the nozzle steam turbine is affected To improve the main steam pressure and improve the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

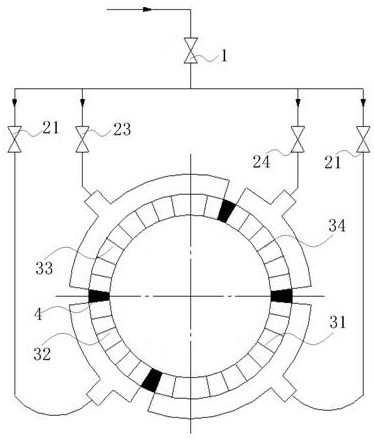

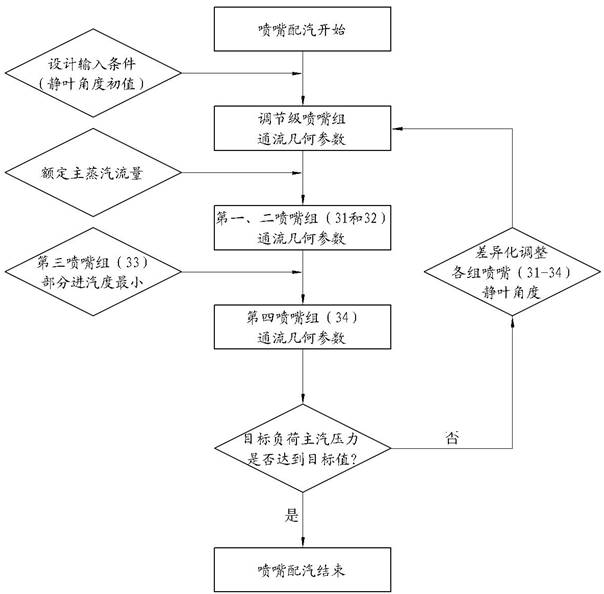

[0029] The steam turbine nozzle steam distribution method based on the difference of the vane angle of the regulating stage, such as figure 2 shown, including the following steps:

[0030] a. According to the design input conditions such as the maximum steam inlet volume of the steam turbine, determine the total flow geometric parameters of the adjustment stage nozzle group;

[0031] b. Determine the through-flow geometric parameters of the first nozzle group 31 according to the difference between the rated steam inlet volume and the maximum steam inlet volume of the steam turbine; obtain the through-flow geometric parameters of the second nozzle group 32 according to the mid-face structure of the adjustment stage;

[0032] c. According to the premise that the two valves can meet the steam intake under the target load of the unit when the two valves are fully opened, and the main steam pressure under the load is as close as possible to the rated pressure as the goal, the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com