A Magneto-rheological Valve Using Permanent Magnets and Double Coils for Composite Control

A technology of permanent magnets and magnetorheological valves, applied in the field of magnetorheological valves, can solve the problems of narrow pressure adjustment range, complex structure of magnetorheological valves, single adjustment method, etc., and achieve the increase or decrease of the pressure difference between the inlet and outlet , Flexible pressure regulation method and wide pressure regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the drawings and embodiments:

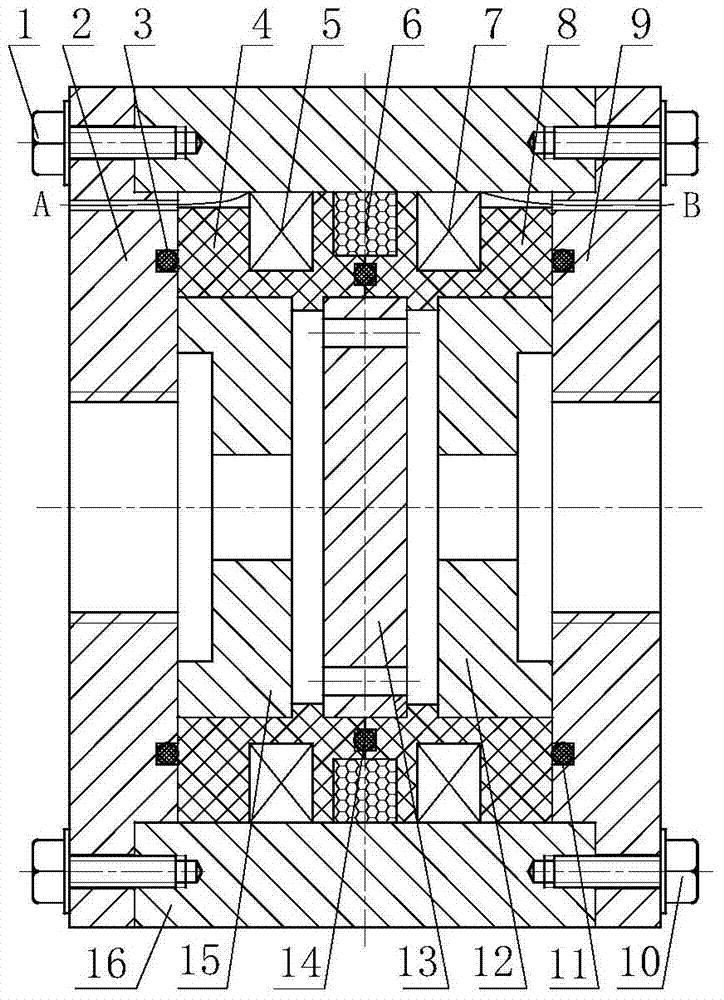

[0022] Such as figure 1 As shown, the present invention includes: screw I1, left end cover 2, sealing ring I3, left winding frame 4, excitation coil I5, permanent magnet 6, excitation coil II7, right winding frame 8, right end cover 9, screw II10, sealing Ring II11, right positioning disc 12, damping disc 13, sealing ring III14, left positioning disc 15 and valve body 16.

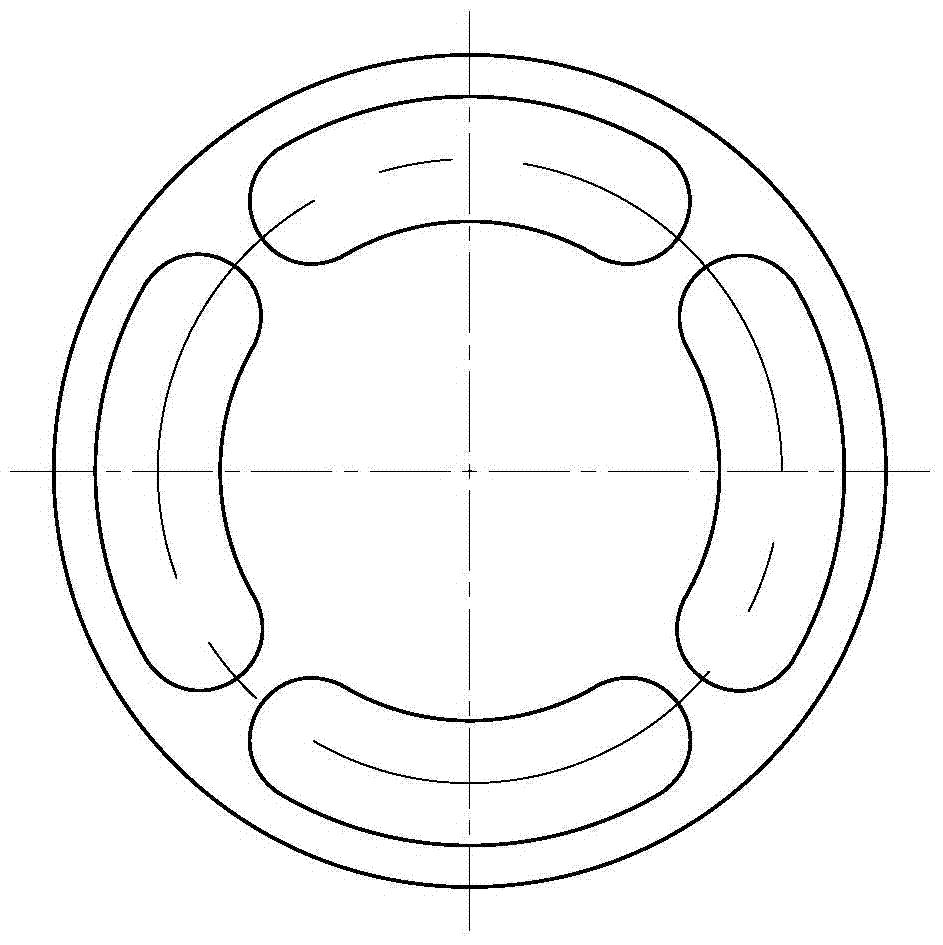

[0023] figure 2 Shown is a schematic diagram of the structure of the damping disc of the present invention. The damping disc 13 is processed with 4 waist-shaped through holes with the same structure and uniformly arranged to form a magnetorheological fluid flow channel.

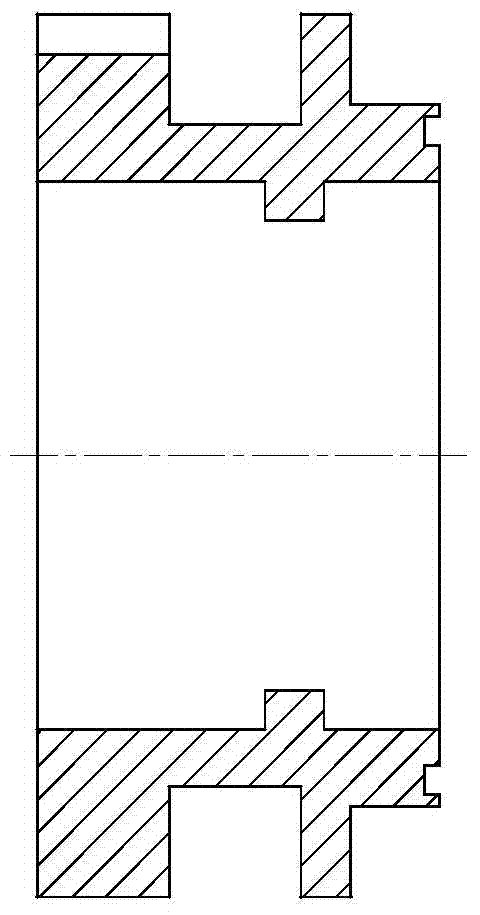

[0024] image 3 Shown is a schematic diagram of the structure of the left winding frame of the present invention, and the structure design of the left winding frame 4 and the right winding frame 8 are the same. The top of the left en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com