Light guide plate and side light type backlight module with light guide plate

A technology of backlight module and light guide plate, which is applied in the directions of optics, light guide, electric light source, etc., can solve the problem of uneven brightness of the light-emitting surface of the light guide plate, and achieve the effect of uniform brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

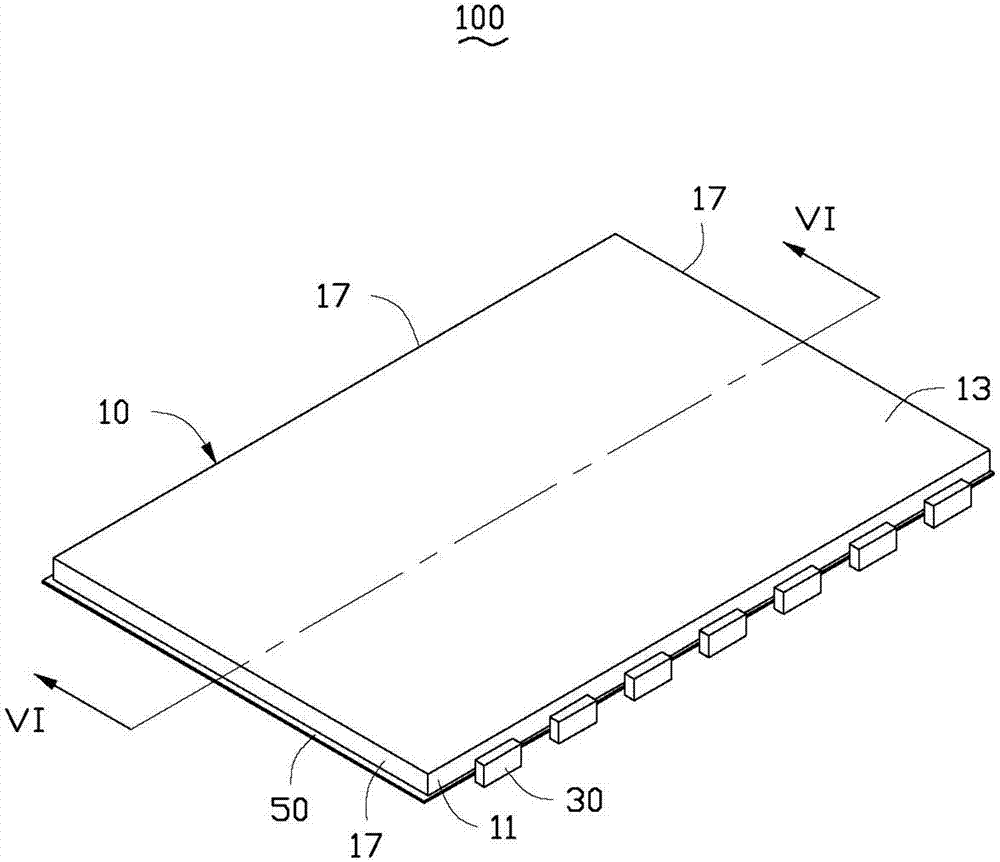

[0017] see figure 1 , the edge-lit backlight module 100 according to the embodiment of the present invention includes a light guide plate 10 , a light source 30 and a reflector 50 . The light source 30 is disposed on one side of the light guide plate 10 to emit light to the light guide plate 10 , and the reflection plate 50 is mounted on the bottom of the light guide plate 10 to reflect the light to the light guide plate 10 . The edge-lit backlight module 100 also includes other optical elements such as a prism sheet, which are used to realize various corresponding functions, however, to save space, the description is omitted.

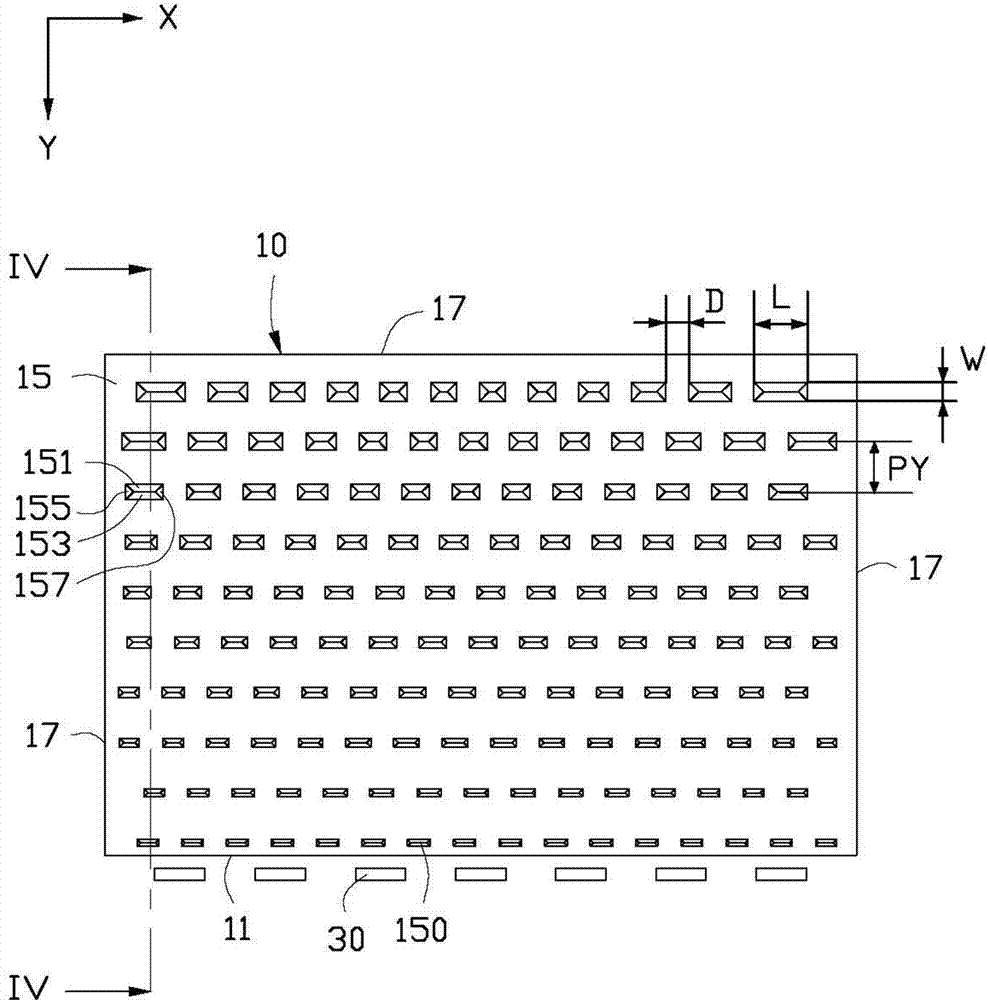

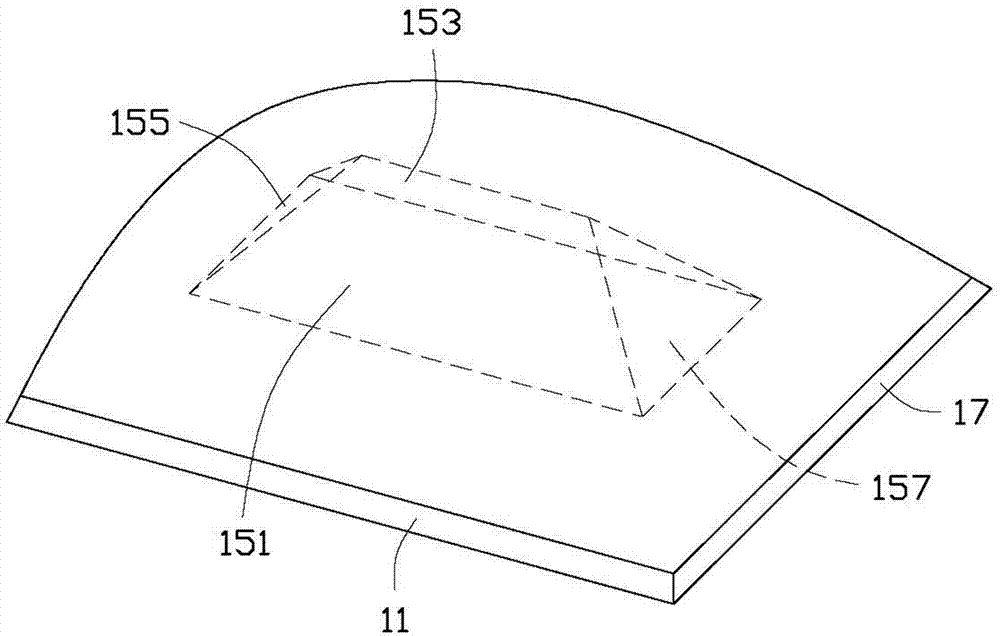

[0018] Please also see Figure 2 to Figure 5 , the light guide plate 10 is substantially rectangular, and includes a light incident surface 11 , a light exit surface 13 , a reflective surface 15 and three side surfaces 17 . The light-emitting surface 13 and the reflective surface 15 are arranged parallel to each other on the upper and lower sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com