Connection terminal

A terminal and wire technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of inconvenient replacement, inconvenient use, breakage, etc., to extend service life, increase convenience, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

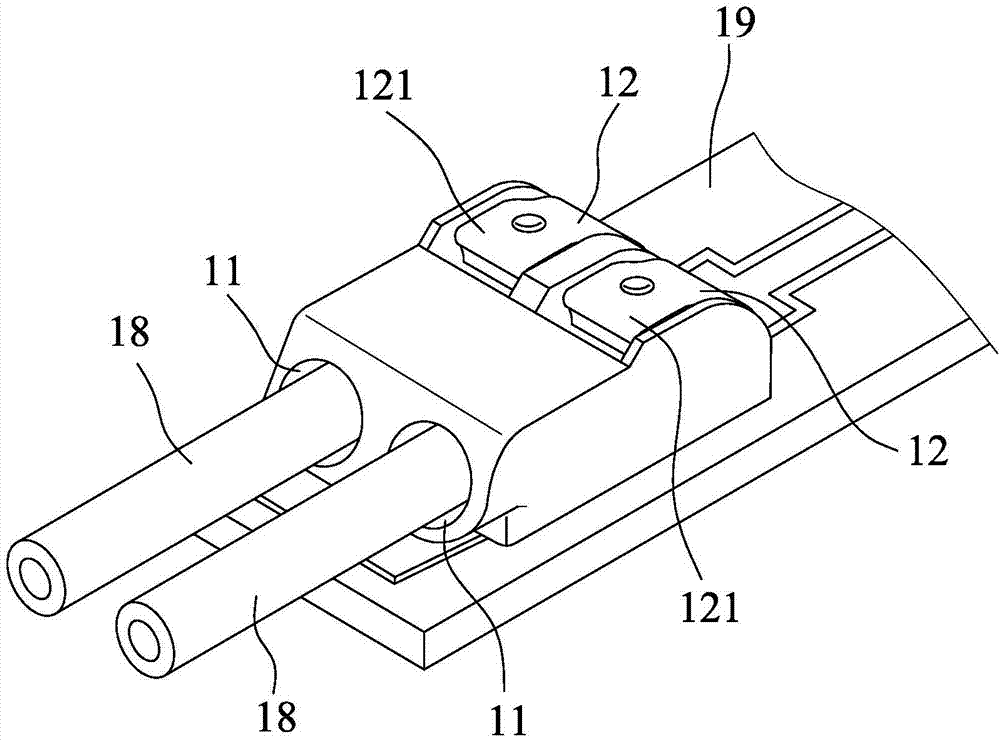

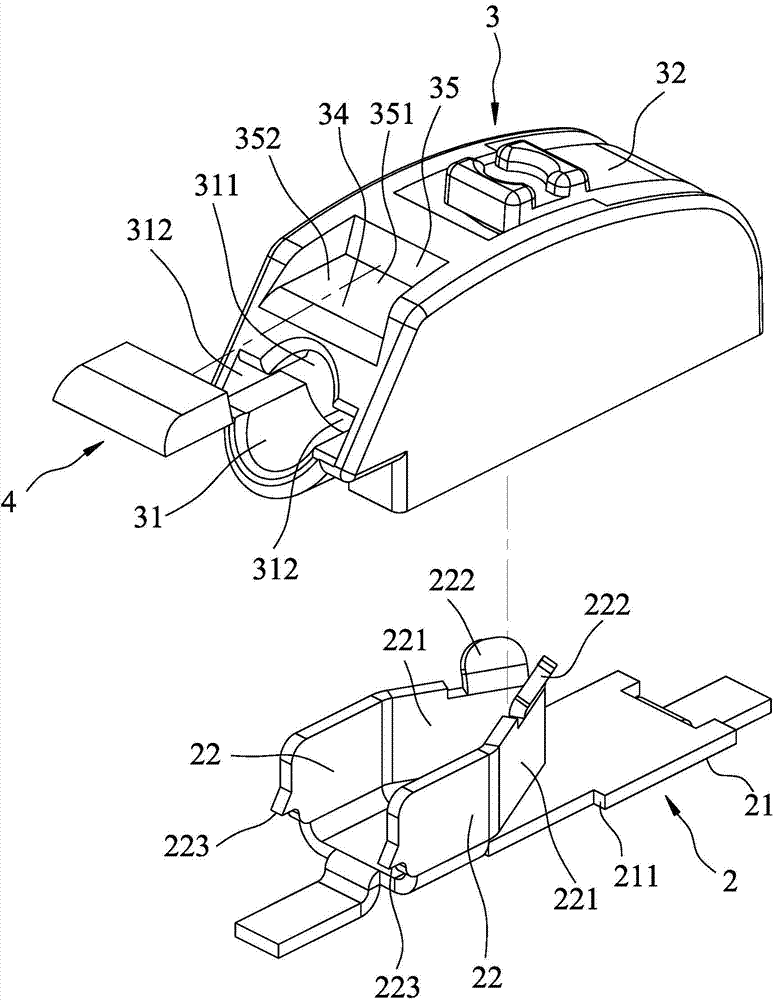

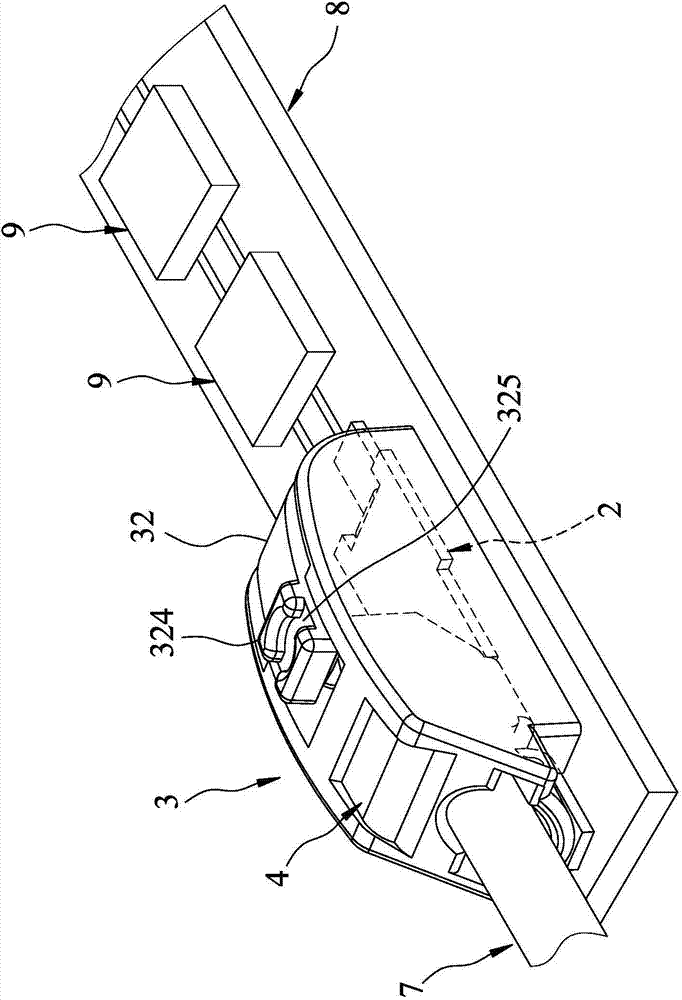

[0032] refer to figure 2 , image 3 and Figure 4 , the preferred embodiment of the terminal block of the present invention is suitable for connecting a wire 7 with a conductive end 71 that removes insulation, and the terminal block includes a lead frame 2, an insulating shell 3 and an identification block 4, wherein the The lead frame 2 is made of metal, and the insulating shell 3 is made of plastic.

[0033] The lead frame 2 includes a base plate 21, and two clamp elastic pieces 22 arranged on the base plate 21. The base plate 21 has two flanges 211 for fitting into the insulating shell 3. The clamp elastic pieces 22 are respectively There is a clamping part 221 suitable for clamping the conductive end 71 of the wire 7 and a pressing part 222 extending away from each other from the clamping part 221. The hook 223 of the shell 3 .

[0034] It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com