Constant current drive led overcurrent and overvoltage protection circuit

A technology of overcurrent and overvoltage protection and constant current drive, which is applied in the direction of lamp circuit layout, electric light source, light source, etc., and can solve problems such as electronic device burnout, load LED overcurrent, and LED damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

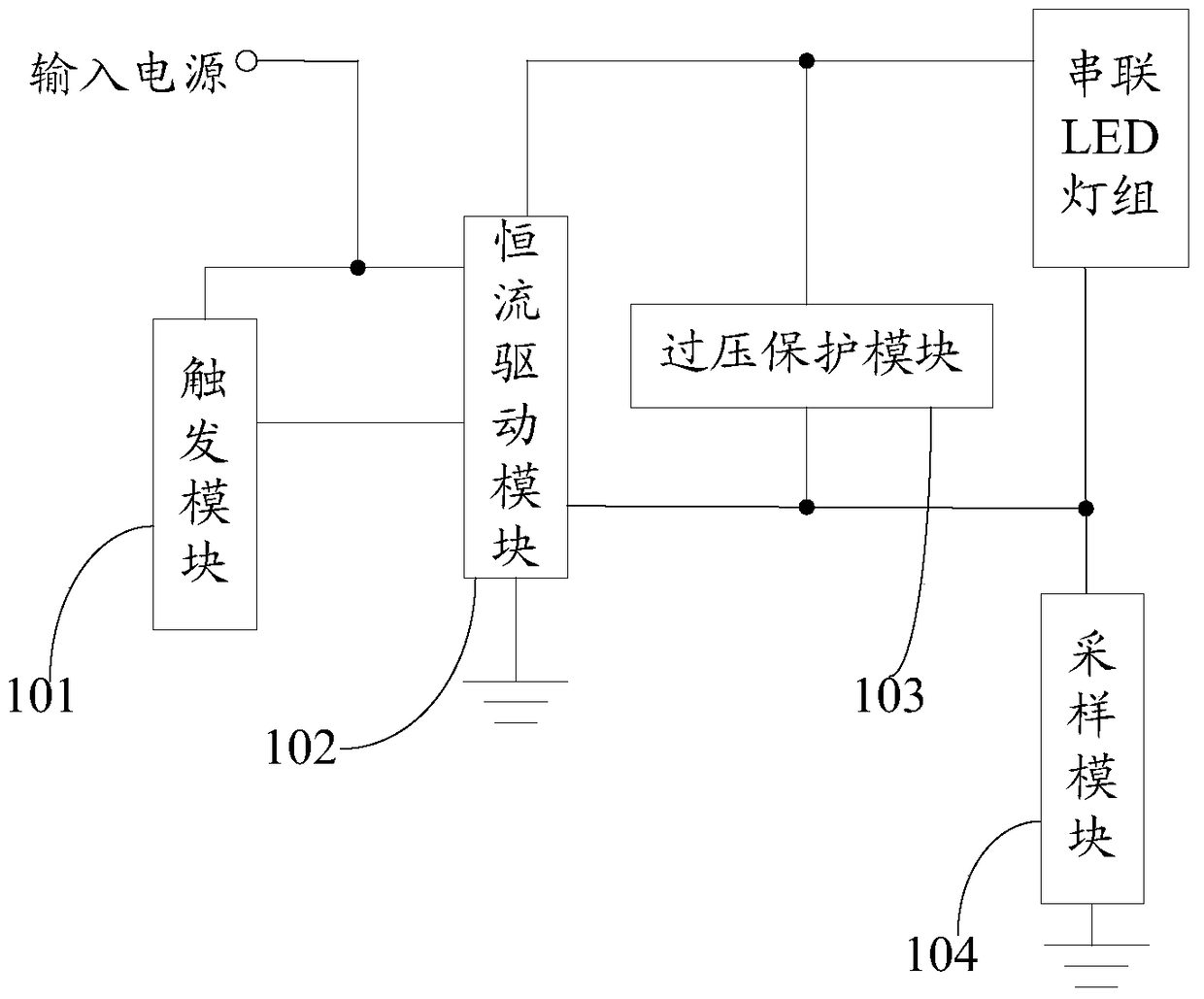

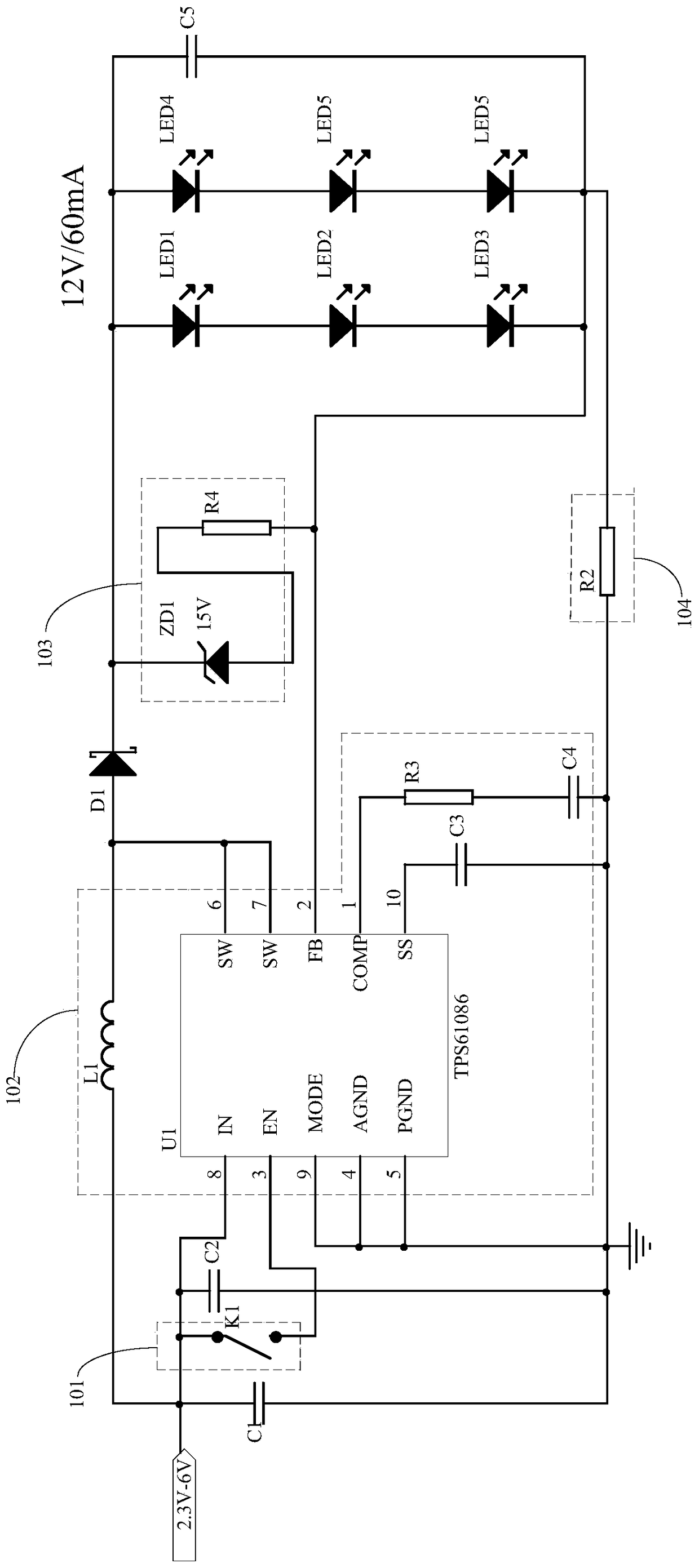

[0020] Such as figure 1 Shown is the block diagram of the constant current drive LED over-current and over-voltage protection circuit.

[0021] A constant current drive LED overcurrent and overvoltage protection circuit is used to protect series LED lights when overvoltage and overcurrent occur, including a trigger module 101 , a constant current drive module 102 , an overvoltage protection module 103 and a sampling module 104 .

[0022] The input terminal of the trigger module 101 is connected to the input power supply, and the output terminal is connected to the enable terminal of the constant current drive module 102; the input terminal of the constant current drive module 102 is connected to the input power supply, and the output terminal is connected to the positive pole of the series LED lamp group , the feedback terminal is connected to the negative pole of the series LED lamp group, and the ground terminal is grounded; the input terminal of the overvoltage protection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com