Electric railway section post automatic passing over of neutral section system and control method thereof

A technology for automatic phase separation and electrification of railways, applied in power lines, transportation and packaging, vehicle components, etc., can solve problems such as unacceptable traction drive systems, operating overvoltage and overcurrent, and damage to component failures, so as to avoid the expansion of accidents simplification, less distraction, and ease of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

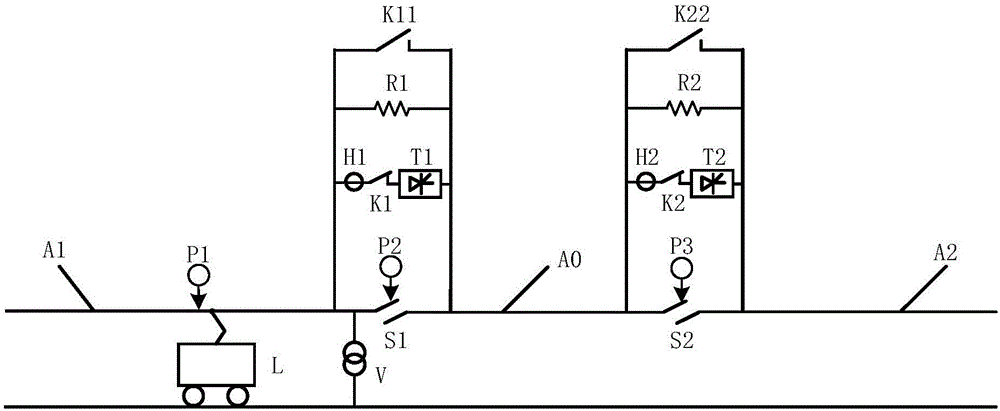

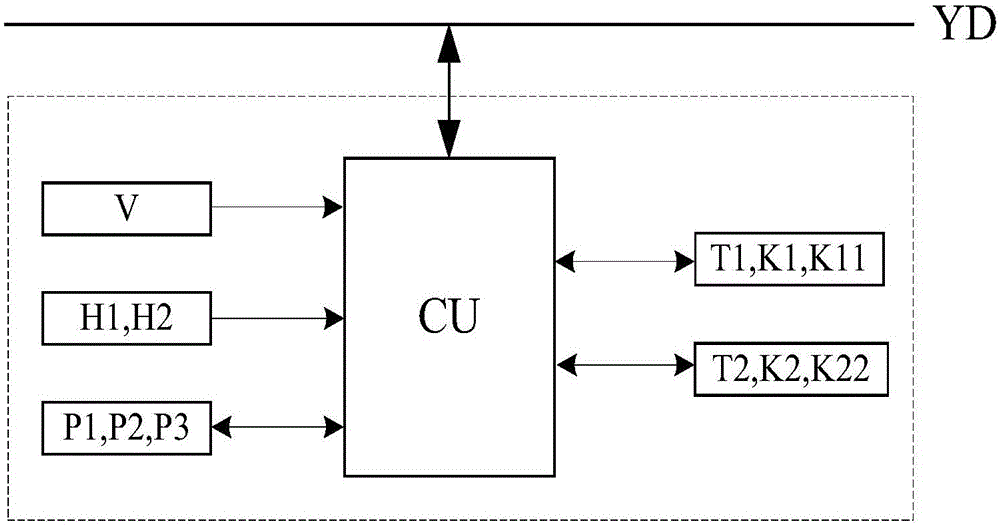

[0032] figure 1 Shown, a specific embodiment of the present invention, a kind of electrified railway sub-division automatic phase splitting system, includes power supply arm one (A1), neutral section (A0), power supply arm two (A2), power supply arm one (A1 ) is connected to one end of the neutral section (A0) through the sectionalizer one (S1), and the second end of the power supply arm (A2) is connected to the other end of the neutral section (A0) through the second sectionalizer (S2). (A1) Equipped with a pantograph identification device 1 (P1) on the pillar near the segmenter 1 (S1) at the end, and equipped with a pantograph identification device 2 (P2) on the pillar with the segmenter 1 (S1) ), equipped with pantograph identification device 3 (P3) on the pillar with sectionalizer 2 (S2); load switch 1 (K1), thyristor switch 1 (T1) and current transformer 1 (H1) in series after Connected in parallel at both ends of sectionalizer 1 (S1), resistor 1 (R1) and spare switch 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com