Multifunctional snow shovel and manufacturing method

A manufacturing method and multi-purpose technology, applied in snow surface cleaning, cleaning methods, construction, etc., can solve problems such as low snow removal efficiency, increased snow removal operation costs, damage to snow removal shovels, and poor removal of soft snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

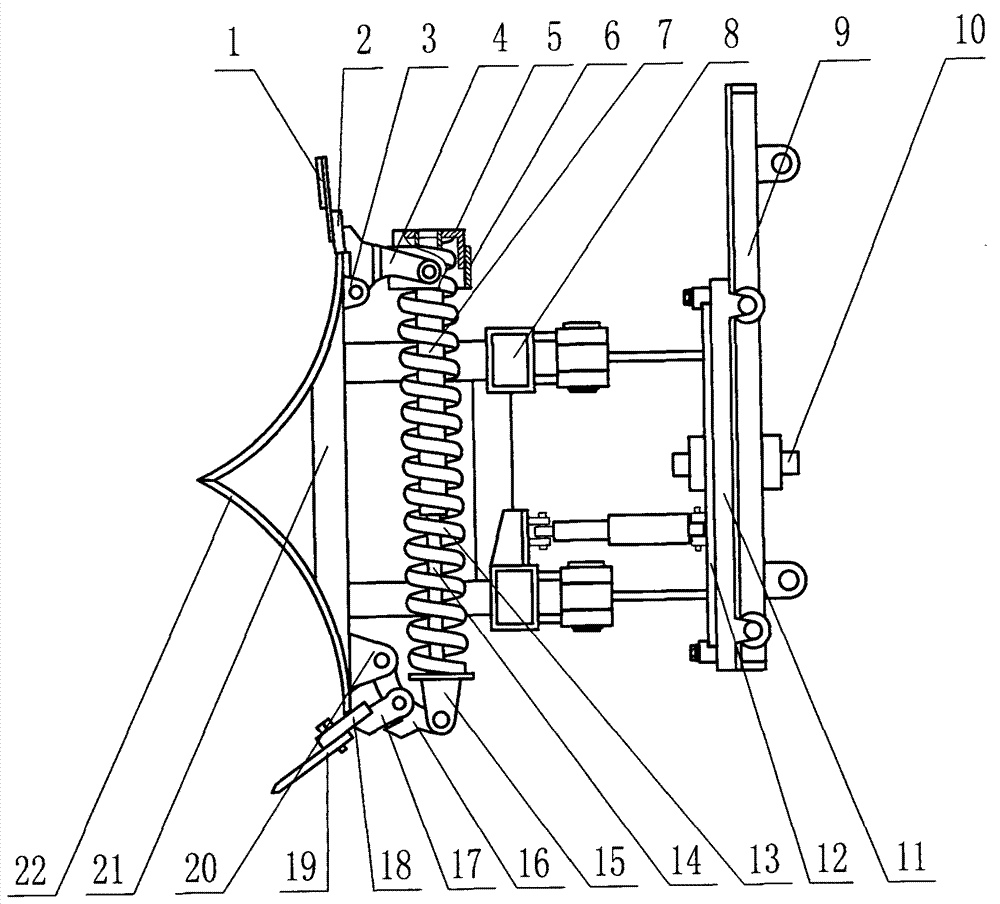

[0010] first figure 1 Mount plate (9) is mounted on the front end of special engineering vehicle with all structures. The shovel edge (1) is connected with the shovel edge support plate (2) for removing loose and soft snow, the spring nut bracket (4) is connected with the shovel edge support plate (2), and the spring nut support (6), and the spring nut support (4) passes through The support seat (3) is connected with the support frame (21), and the screw mandrel (7) and the spring screw (5) are welded together and connected with the spring nut (6). The shovel edge (19) is connected with the shovel edge fixed plate (18) in addition to the compacted snow, the shovel edge support (17) is connected with the shovel edge fixed plate (18), and the spring seat support (16), and the spring seat support (16) passes through the support The fixed seat (20) is connected with the support frame (21), and the spring seat mandrel (14) and the spring seat (15) are welded together and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com