Automatic welding fixture for longitudinal joint of spherical shell in safety injection tank

An automatic welding and safety injection box technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of enterprise loss, large volume, and high requirements for workers' welding level, so as to improve work efficiency and improve Solid welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

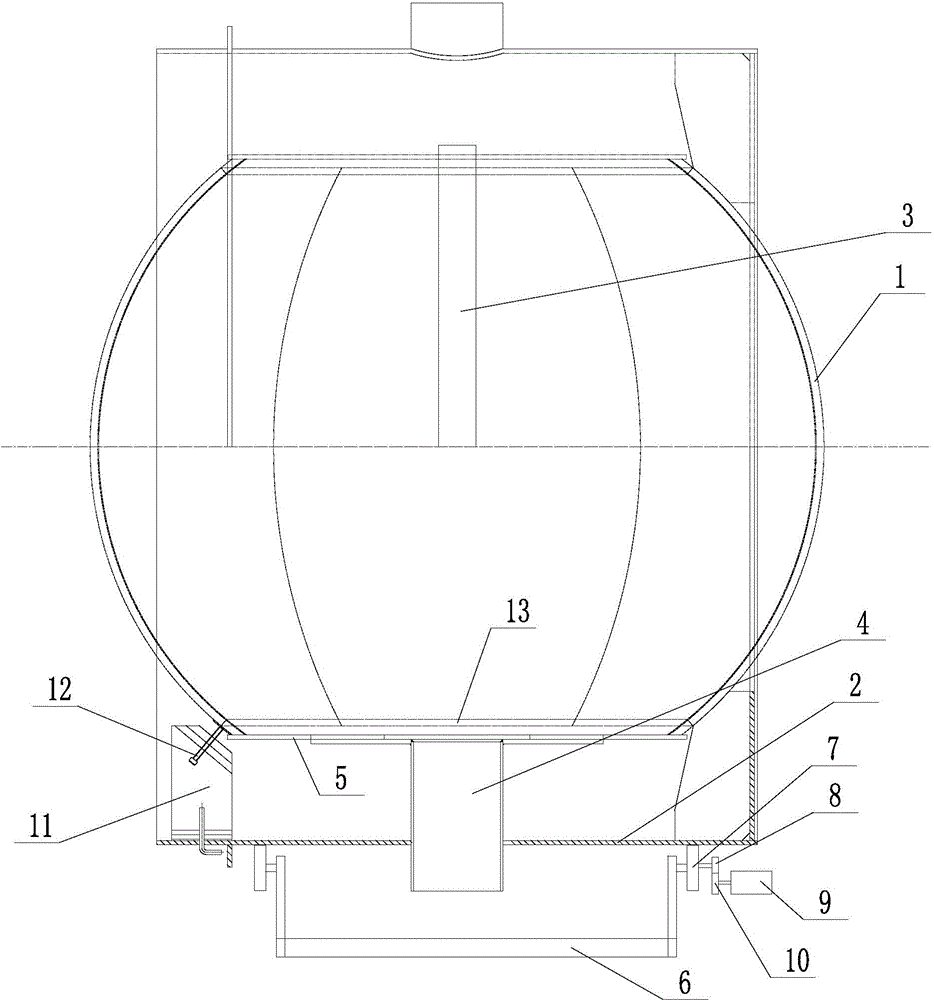

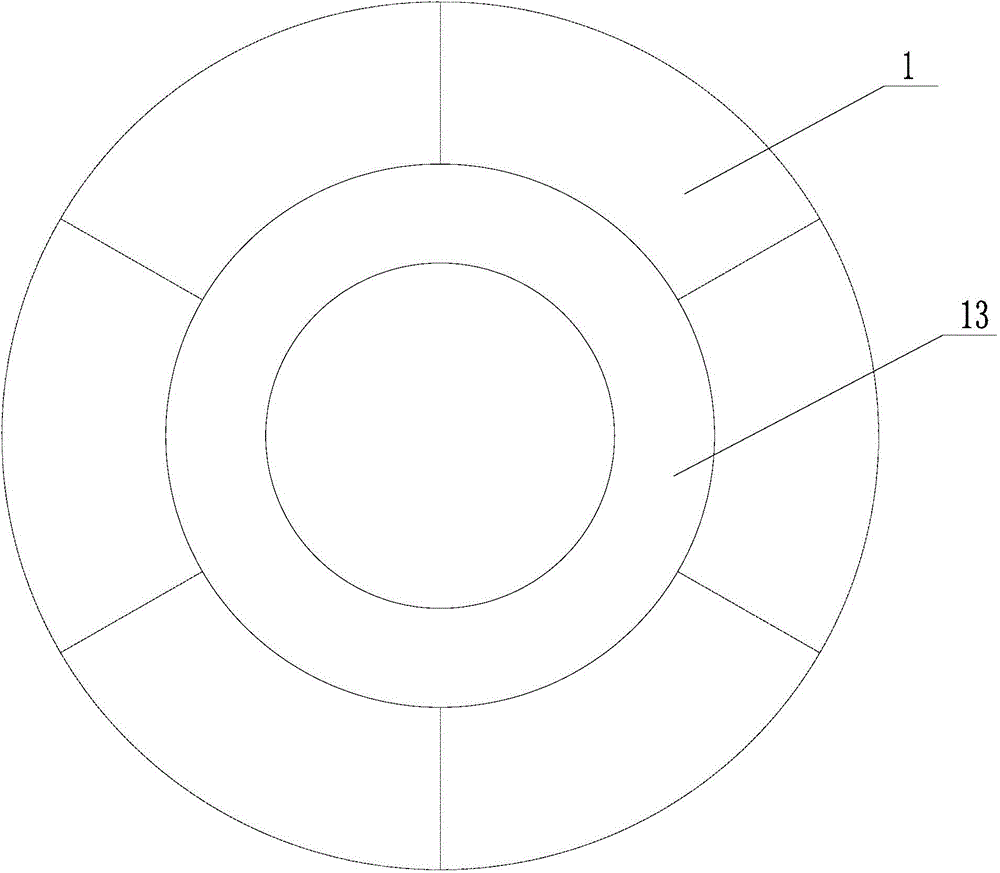

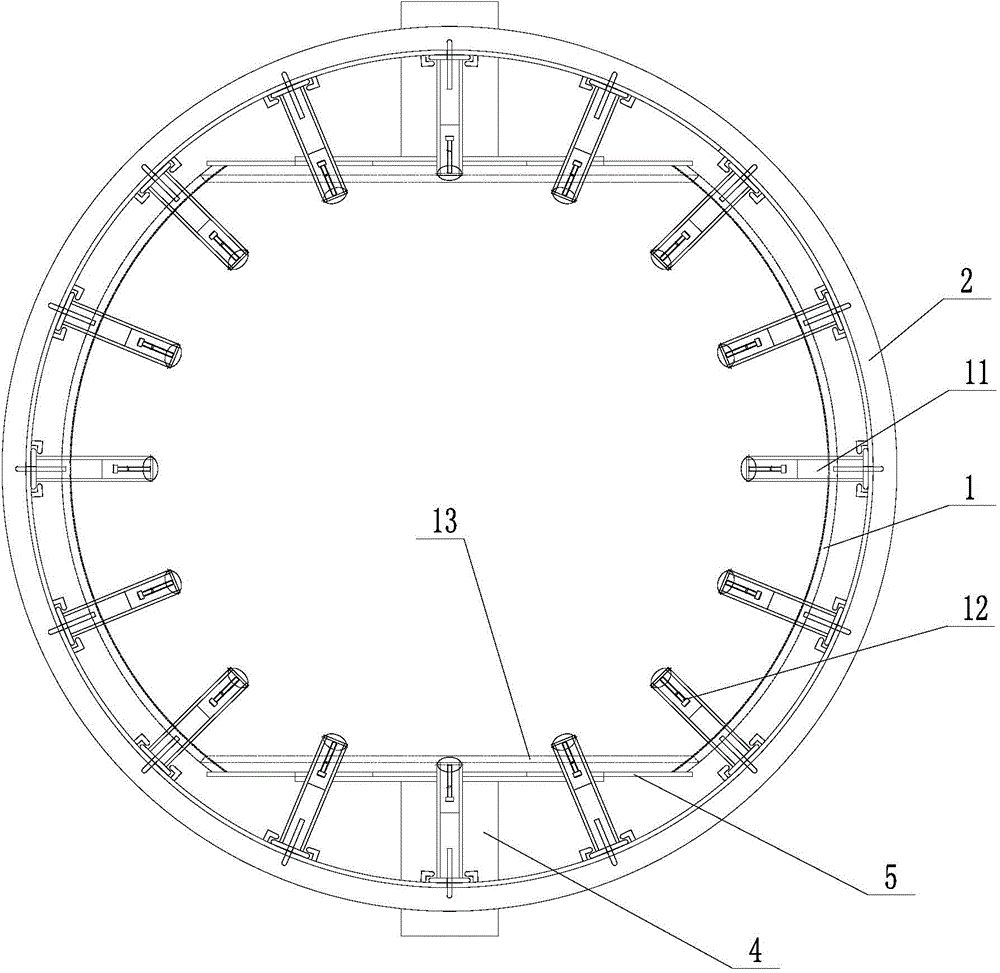

[0014] Such as figure 1 , image 3 As shown, the automatic welding tool for the longitudinal seam of the spherical shell in the safety injection box according to the present invention includes a cylinder 2 for accommodating the spherical shell 1 in the safety injection box. The cylinder wall of the cylinder 2 is provided with two through holes. The line of the center of the hole intersects and is perpendicular to the central axis of the cylinder 2. The cylinder wall of the cylinder 2 is also provided with a welding hole 3 for the welding head of the welding machine to extend into the cylinder 2. The welding hole 3 covers the safety injection box The longitudinal seam of the spherical shell, the plane formed by the center of the welding hole 3 and the center of the two through holes are perpendicular to the central axis of the cylinder 2. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com