Patents

Literature

45results about How to "Improve welding firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

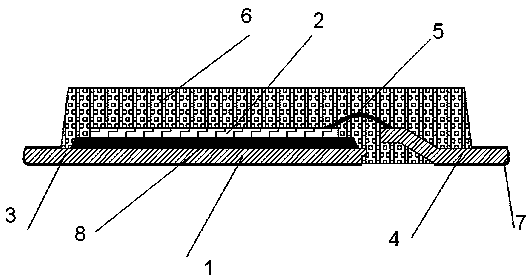

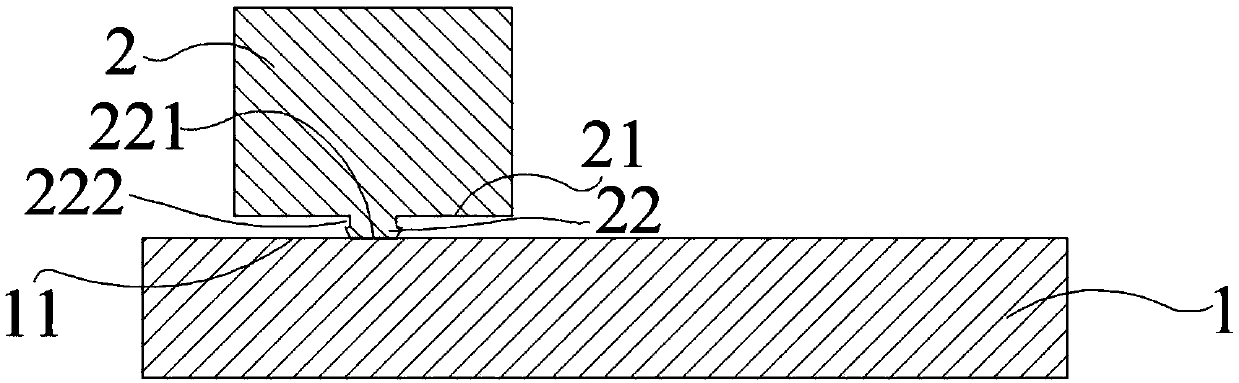

Semiconductor package piece and manufacturing method thereof

InactiveCN103441116AIncrease the areaImprove welding firmnessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention discloses a semiconductor package piece and a manufacturing method thereof. The semiconductor package piece comprises a lead frame and a chip, wherein an electroplated layer is plated at the exposed part of the lead frame, and an electroplated layer is plated on the side surface of the pin of the lead frame. According to the manufacturing method of the semiconductor package piece, before an electroplating process, a notch is made so as to increase the area of the electroplated layer on the side surface of the pin of the lead frame. As the electroplated layer is plated at the exposed part of the lead frame, and particularly, the electroplated layer is plated on the side surface of the pin of the lead frame, the semiconductor package piece and a PCB (printed circuit board) are guaranteed to be welded firmly in the following process of welding the semiconductor package piece onto the PCB. The semiconductor package piece manufactured by the manufacturing method and the PCB are guaranteed to be welded firmly in the following process of welding the semiconductor package piece onto the PCB.

Owner:GREAT TEAM BACKEND FOUNDRY (DONGGUAN) LTD

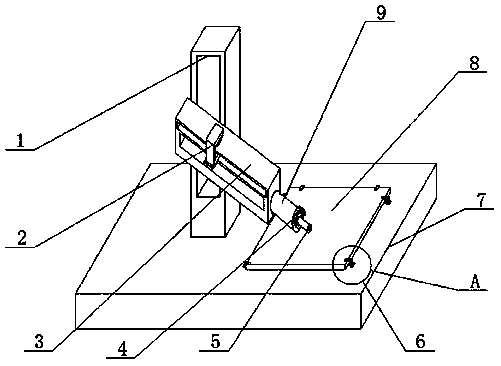

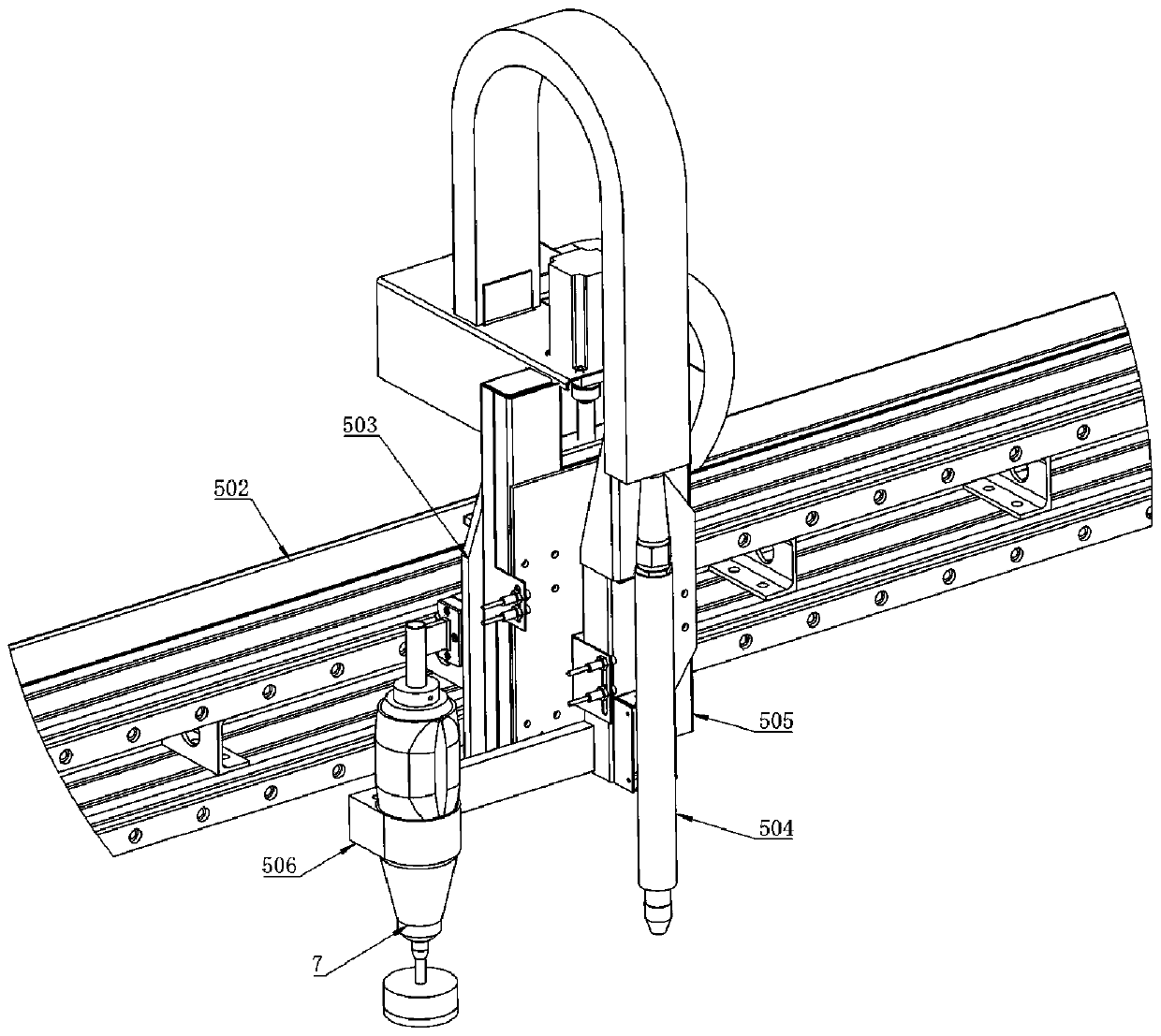

Automatic laser welding arm

ActiveCN110421256AImprove uniformityAvoid crackingLaser beam welding apparatusShielding gasEngineering

The invention discloses an automatic laser welding arm and relates to the technical field of laser welding arms. According to the automatic laser welding arm, a laser welding head is connected to a supporting arm by adopting a welding oscillation mechanism, protection gas injecting heads are connected to the supporting arm through oscillation mechanisms correspondingly, and thus, when the laser welding head performs welding, a controller controls the welding oscillation mechanism to drive the laser welding head to oscillate in the weld joint width direction in a reciprocating mode; and meanwhile, the controller further controls the laser welding head to be driven by the oscillation mechanisms to make oscillation movement in the welding feeding direction of the laser welding head, in this way, the welding uniformity can be improved, although a weld joint is large, the position where the weld joint is located can be heated effectively and uniformly, the hot melting uniformity is improved, the welding reliability and stability are guaranteed, the welding uniformity is improved, the problem that only the welding power is improved, the center of the welding head is overheated and excessively melted, and cracks are prone to occurring in the weld joint connecting position on the contrary is solved, and the welding fastness is improved.

Owner:苏州肯美特设备集成股份有限公司

Bi-leg front fork of tricycle

InactiveCN102167119AHigh strengthImprove rigiditySteering deviceAxle suspensionsEngineeringThree-wheeled car

The invention relates to a bi-leg front fork of a tricycle, which comprises a plurality of fork stand pipes, a plurality of fork shoulders, a plurality of fork legs and a plurality of fork hooks, wherein the upper planes of the fork shoulders are fixedly provided with the fork stand pipes; the lower planes of the fork shoulders are fixedly provided with two symmetrical fork legs; the lower end of each fork leg is fixedly provided with the fork hook; the back of each fork leg which is fixedly arranged at the lower plane of each fork arm is further fixedly provided with a pair of fork legs, so that the fork legs form into two pairs at the front and the back; the four fork legs are evenly distributed and fixedly arranged at the lower planes of the fork shoulders; and the fork stand pipes are fixedly arranged at the center of the upper planes of the fork arms. The bi-leg front fork is further fixedly provided with another front fork based on the original mono-leg front fork to form the bi-leg front fork, so that the intensity and the rigidity of the front fork can be greatly enhanced, and the resistance strength of the horizontal impact generated in the running can be improved; and simultaneously, as a pair of damping springs is additionally arranged on the bi-leg front fork, the damping performance of the tricycle can be improved, and the comfortable sensation of the driver can be correspondingly increased.

Owner:天津市润佳金属制品有限公司

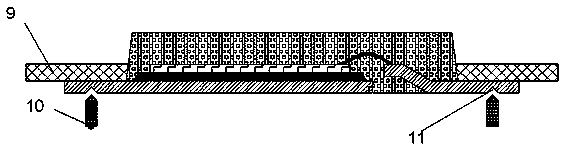

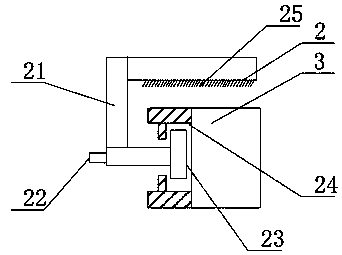

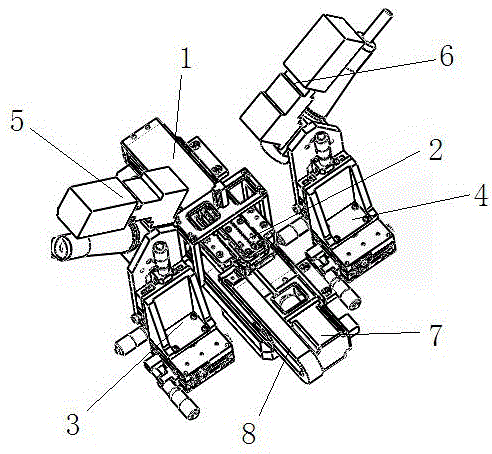

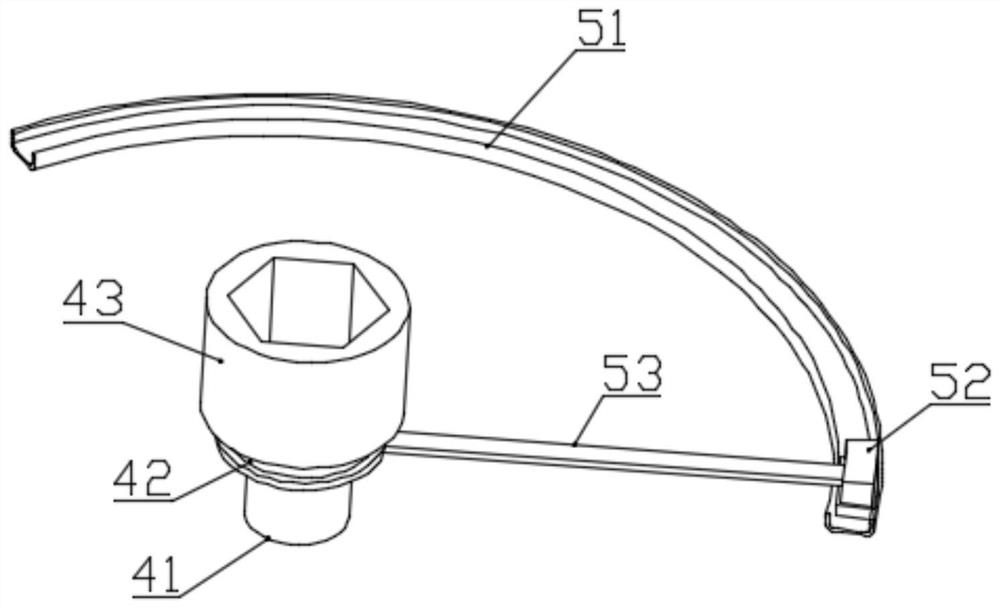

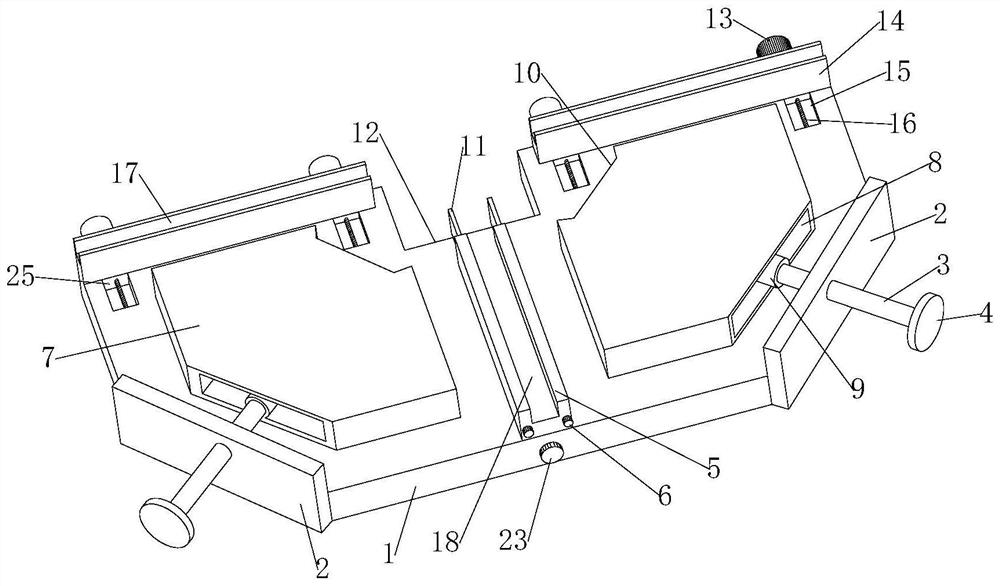

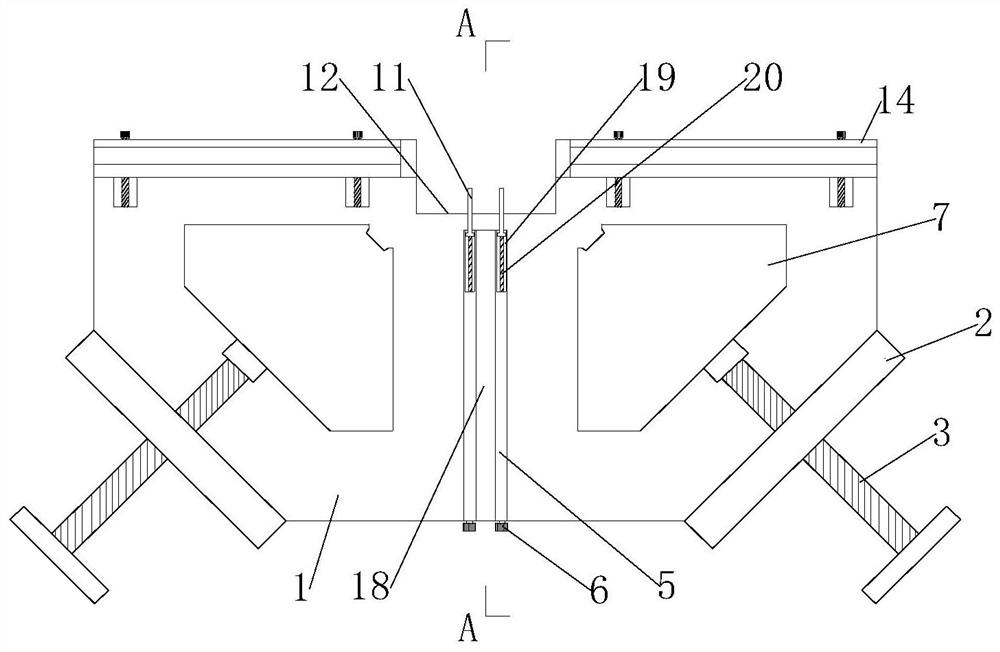

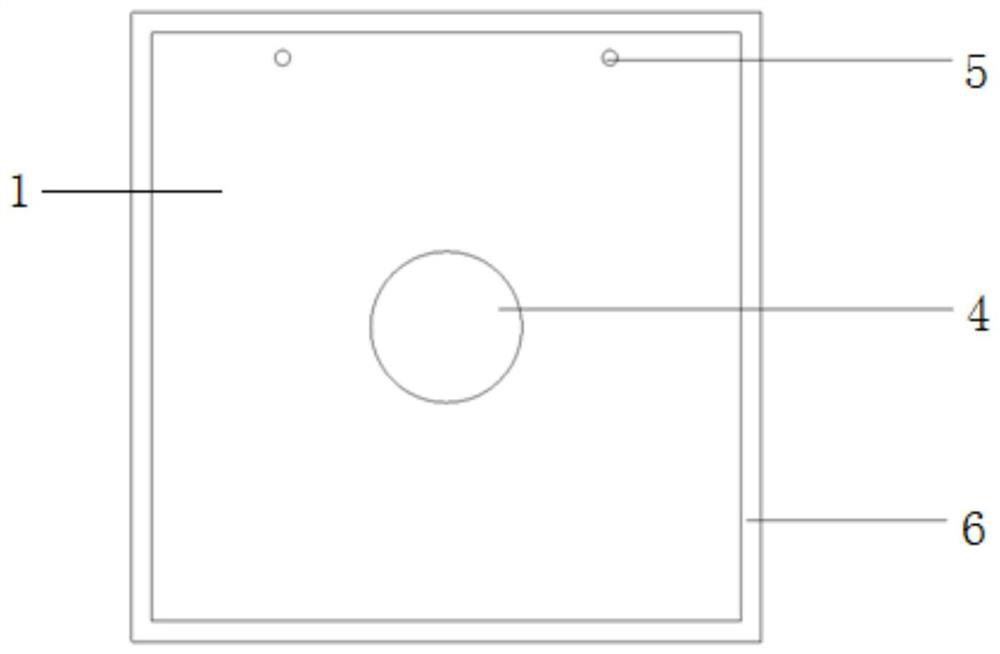

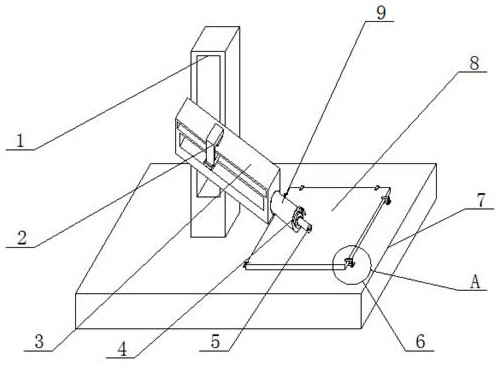

Laser spot welding device used for lenses

ActiveCN105665930AImprove welding firmnessImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a laser spot welding device used for lenses. The laser spot welding device comprises a push platform, a lens carrying jig, a left spot welding support, a right spot welding support, a left laser spot welding machine, a right laser spot welding machine and a push air cylinder. The push platform is installed on a sliding table of a welding base. Before welding, the multiple lenses are put on the lens carrying jig, the lens carrying jig on which the lenses are well placed is connected to a feeding platform in a clamped manner, batched laser welding is conducted at a time through the left laser spot welding machine and the right laser spot welding machine under the push of the push air cylinder, the welding firmness is good, the welding efficiency can be greatly improved, and good application prospects are achieved.

Owner:SUZHOU JIALAN ZHIYUAN ELECTRONICS TECH CO LTD

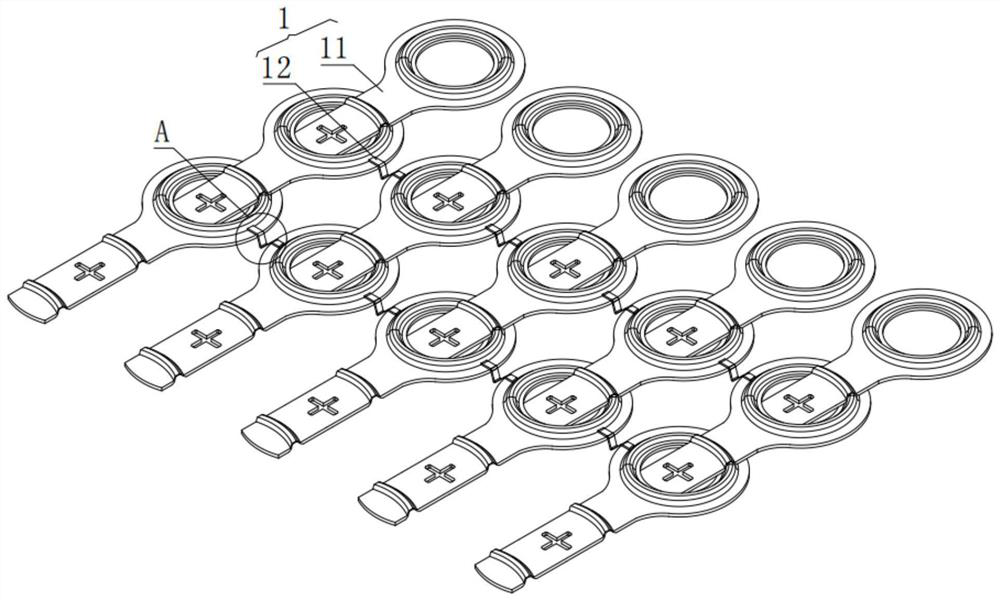

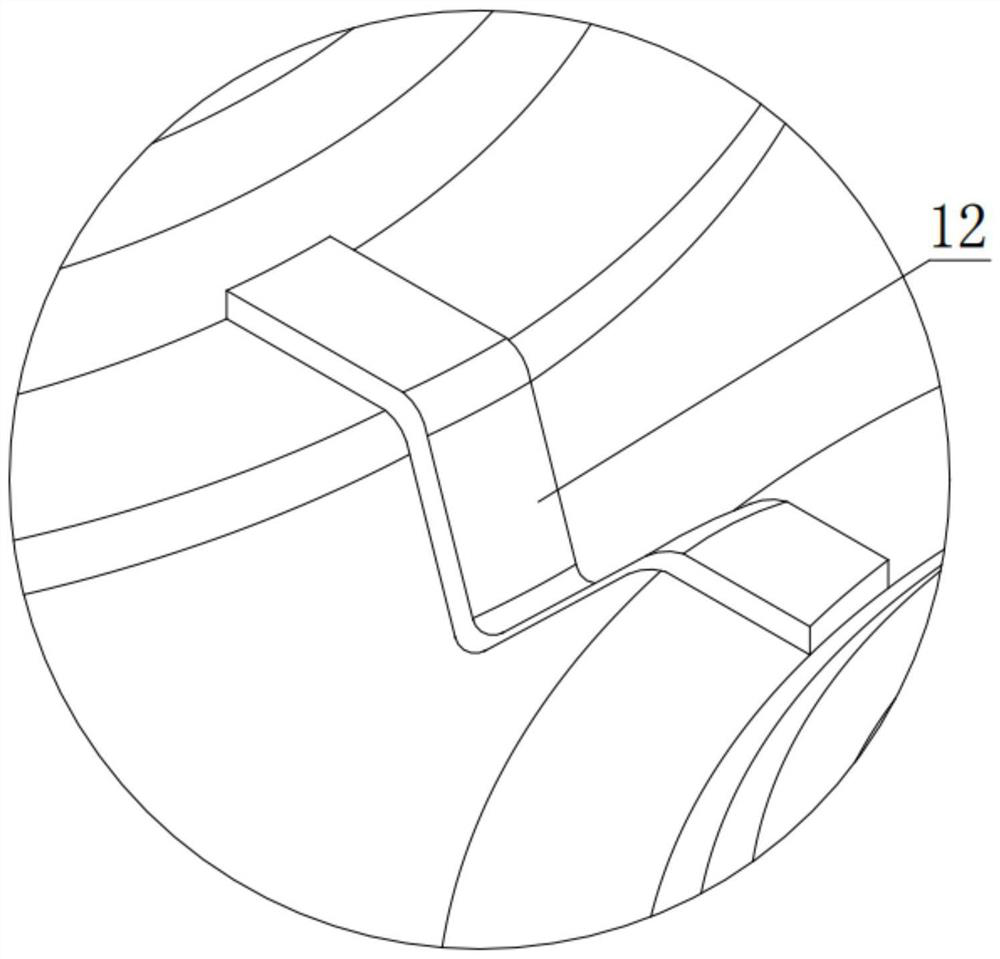

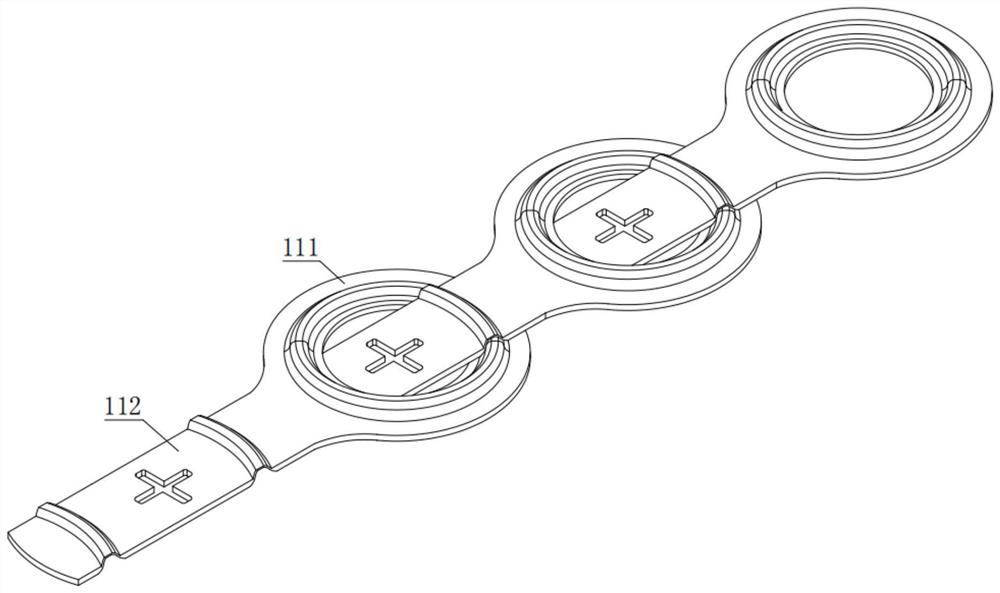

Splicing spot welding type battery nickel sheet and spot welding process thereof

ActiveCN114069162AEliminate bumpsIncrease the welding areaMagnetic/electric field screeningCell component detailsSpot weldingBattery cell

The invention discloses a spliced spot welding type battery nickel sheet and a spot welding process thereof, belongs to the technical field of battery nickel sheets, and solves problems that the requirement for limiting the placement position of a single battery in a battery pack is high, welding position errors easily exist, and the application range is narrow during nickel sheet welding. The nickel sheet comprises a nickel sheet part, wherein the nickel sheet part comprises a plurality of nickel sheet assemblies and V-shaped connecting pieces, a plurality of nickel sheet assemblies are arranged in a rectangular shape, the two longitudinally arranged nickel sheet assemblies are connected with each other in a staggered manner, and the two transversely arranged nickel sheet assemblies are connected with each other through the V-shaped connecting pieces. By utilizing the characteristic of high toughness of the battery nickel sheets, the two nickel sheet assemblies are spliced and fixed in a mutually staggered and superposed manner, and the two spliced nickel sheet assemblies can relatively rotate and adjust the angle so as to adapt to batteries in different placement forms, and a corresponding number of nickel sheet assemblies can be spliced according to different numbers of batteries, so the battery nickel sheet assembly is wide in application range.

Owner:安徽金欣源工业材料有限公司

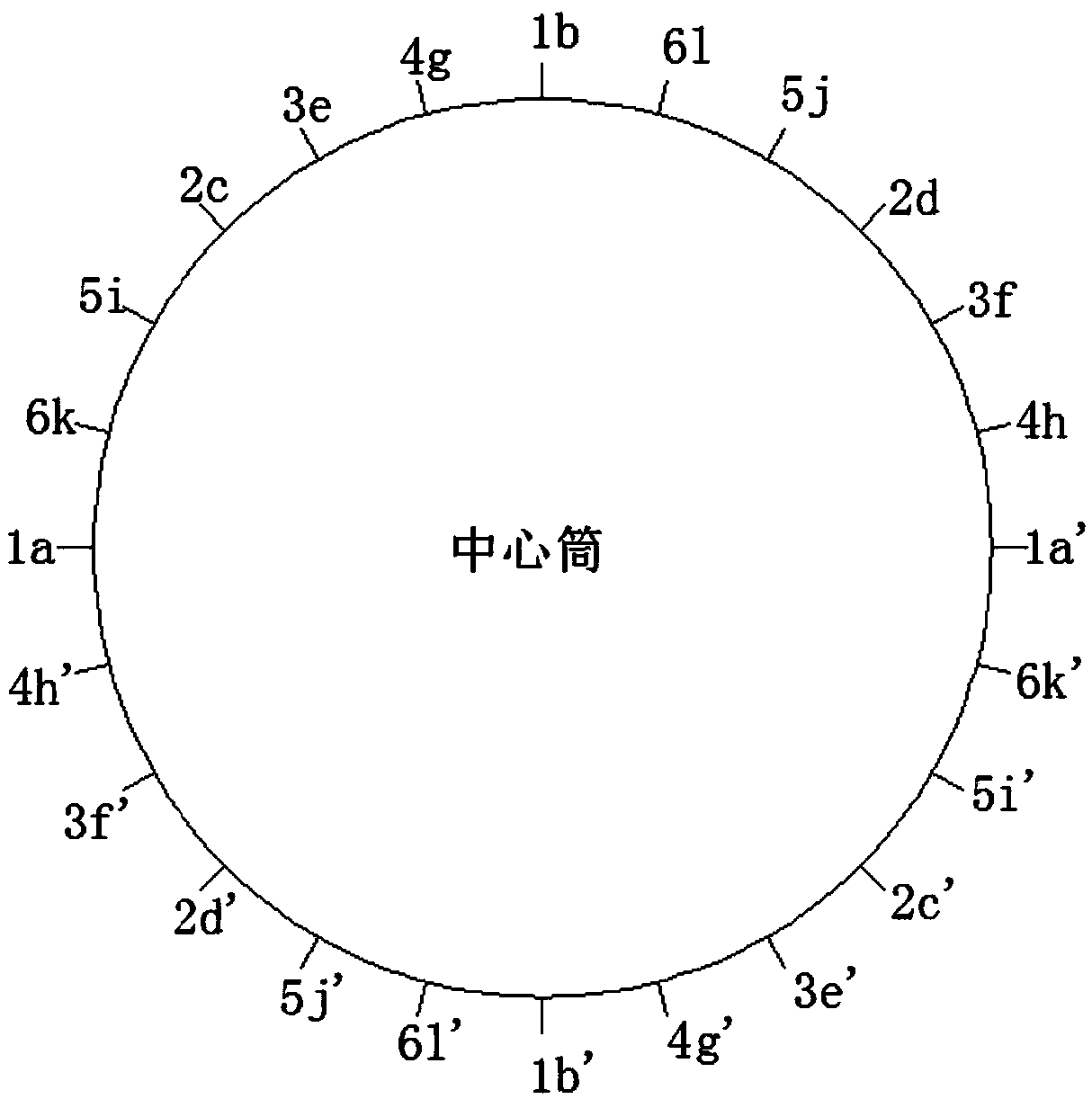

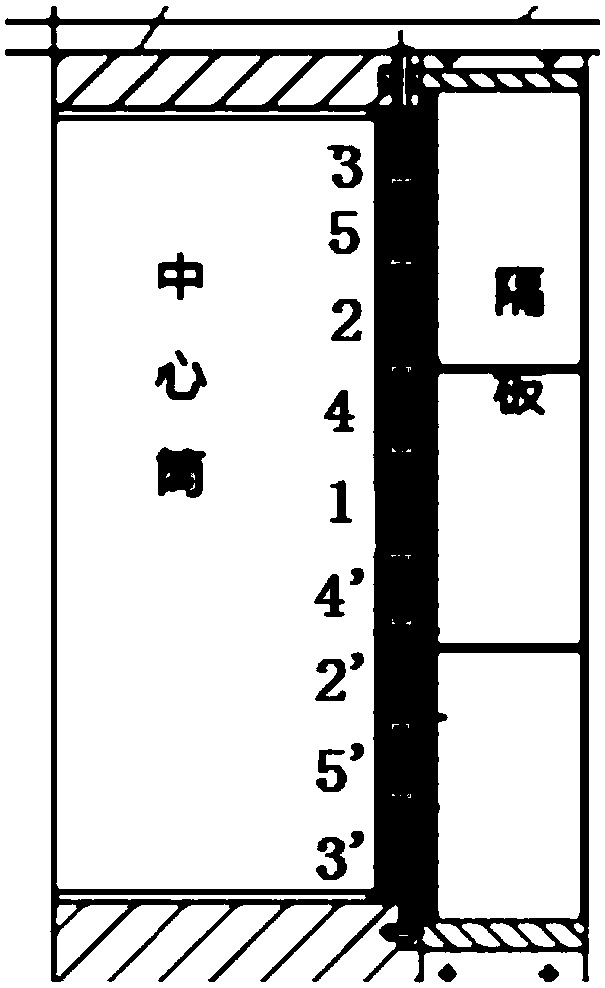

Welding installation process of rotor partition plates of rotary air preheater

InactiveCN109079283ACounteracts welding distortionMeet the installation quality requirementsArc welding apparatusAir preheaterEngineering

The invention discloses a welding installation process of rotor partition plates of a rotary air preheater, and belongs to the technical field of installation of rotary air preheater rotors. The process includes the steps that (1) two partition plates symmetrically located on the two sides of a center cylinder in a first group of partition plates are welded to the wall of the center cylinder, andthe other two partition plates symmetrically located on the two sides of the center cylinder in the first group of partition plates are welded to the wall of the center cylinder; (2) each partition plate in a second group of partition plates is located between two adjacent partition plates in the first group of partition plates, and the second group of partition plates are welded according to thewelding sequence of the first group of partition plates; (3) N groups of partition plates located between the second group of partition plates and the first group of partition plates which are adjacent clockwise are uniformly distributed clockwise in the circumferential direction of the center cylinder; (4) N groups of partition plates located between the first group of partition plates and the second group of partition plates which are adjacent clockwise are uniformly distributed anticlockwise in the circumferential direction of the center cylinder. By means of the process, overall symmetry welding of the partition plates can be realized, and welding deformation in the prior art is reduced to the maximum.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

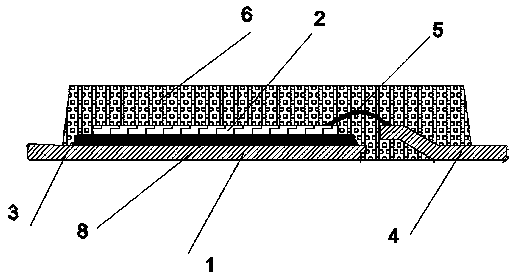

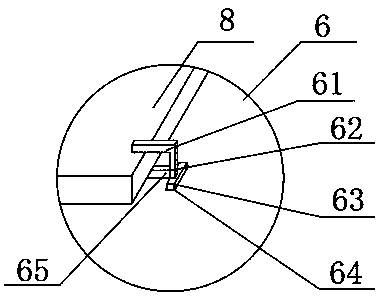

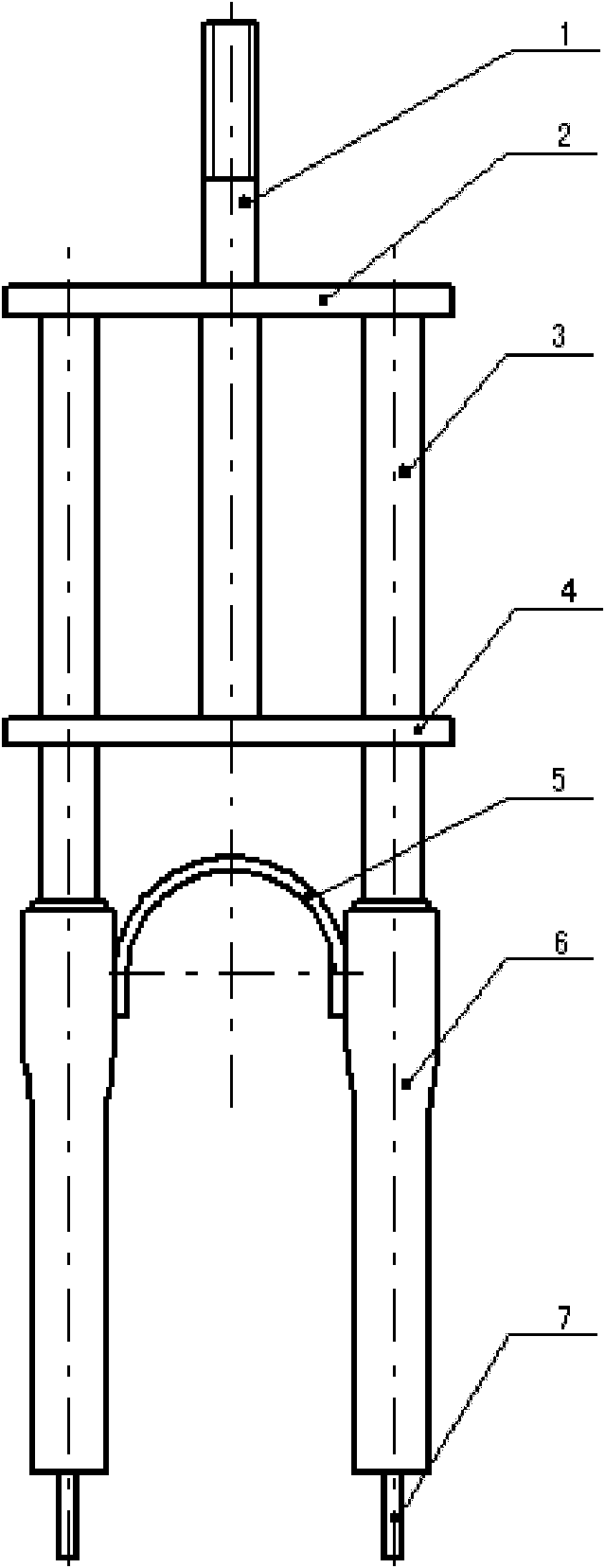

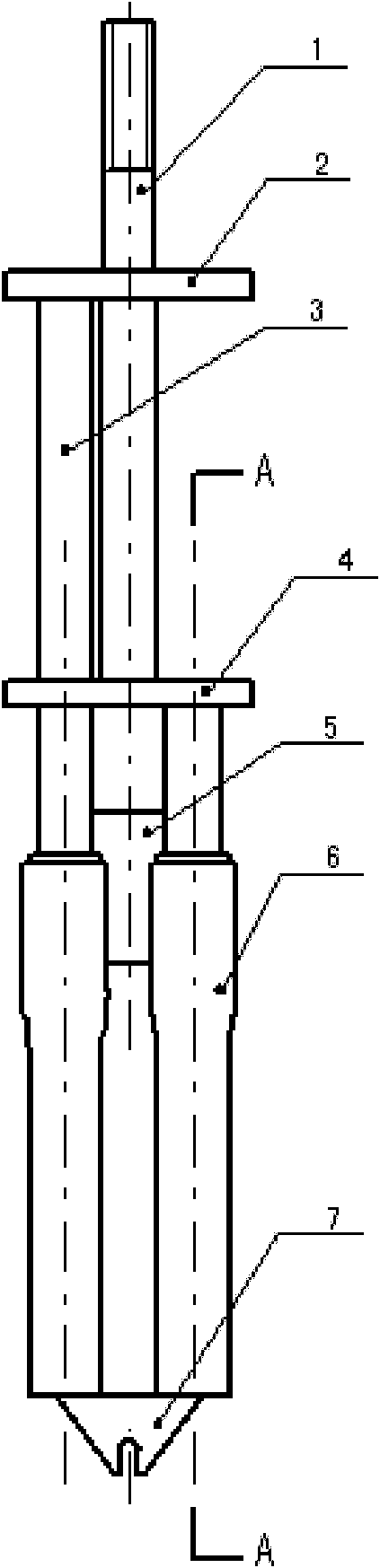

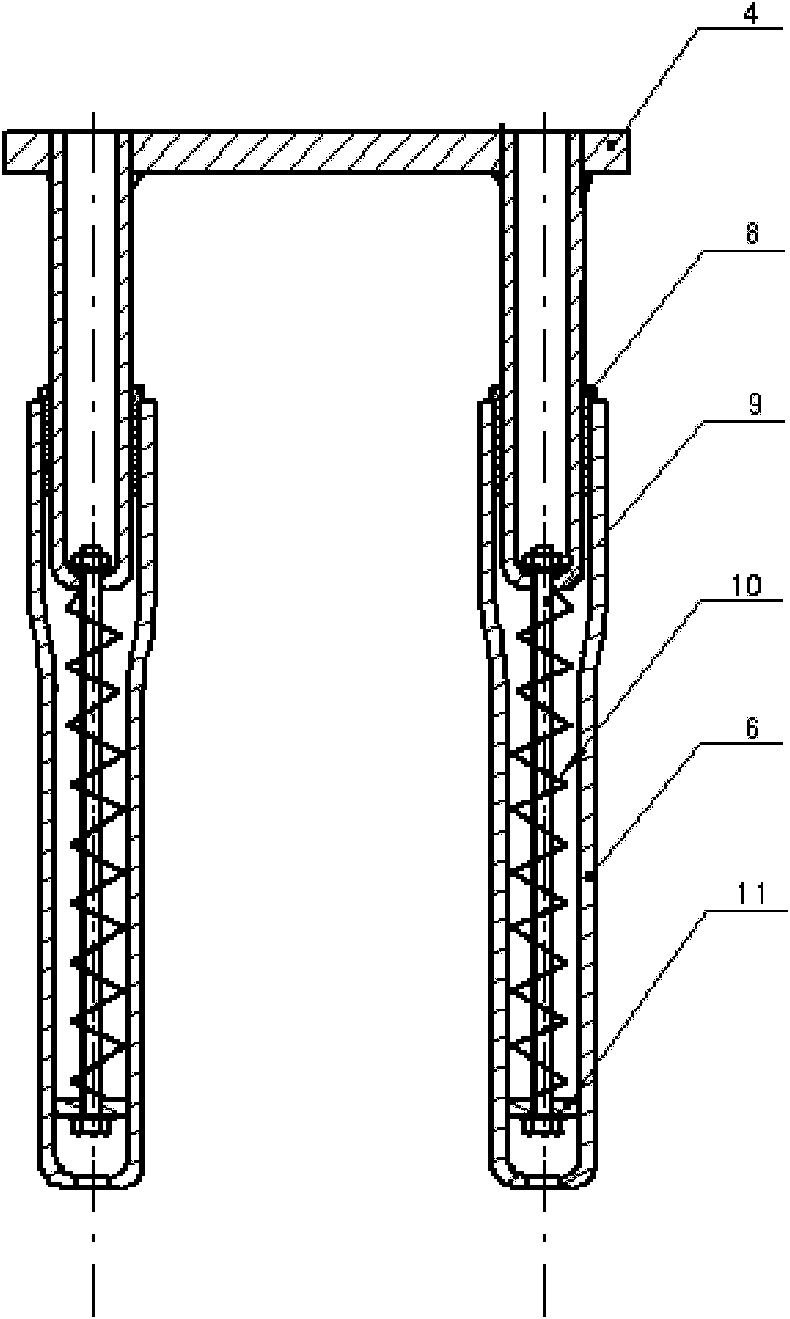

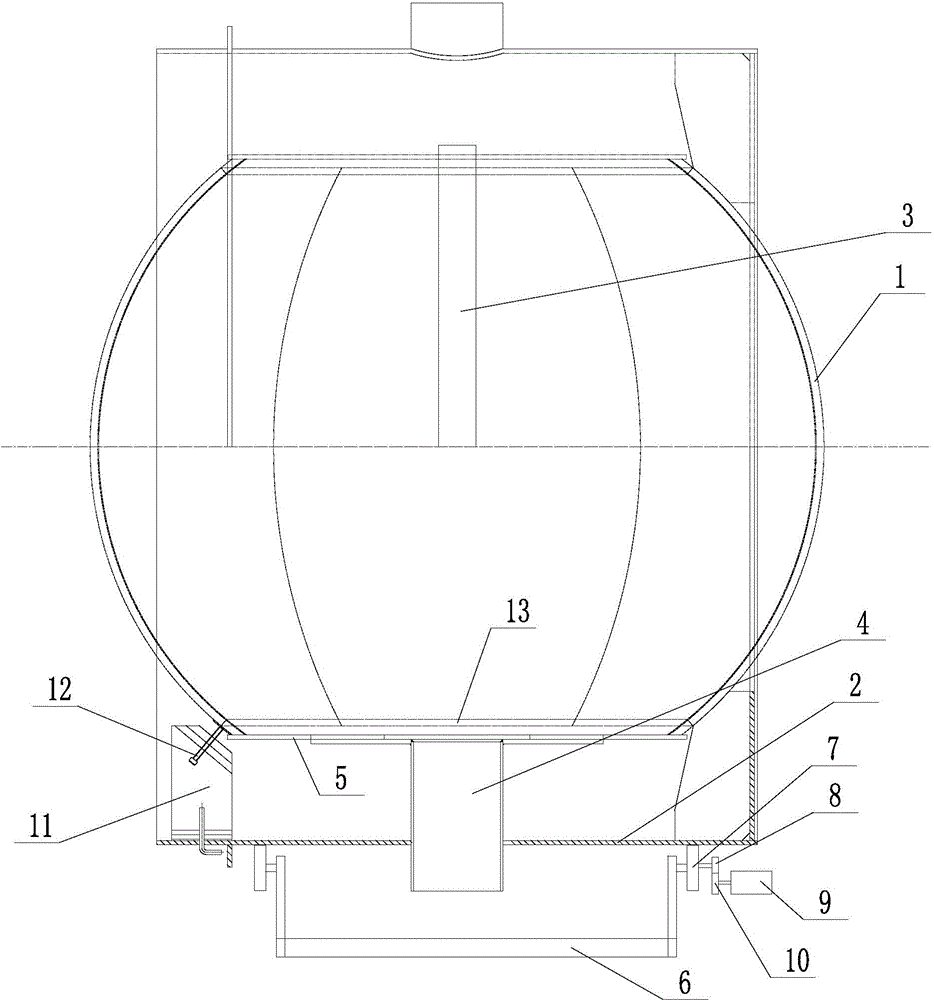

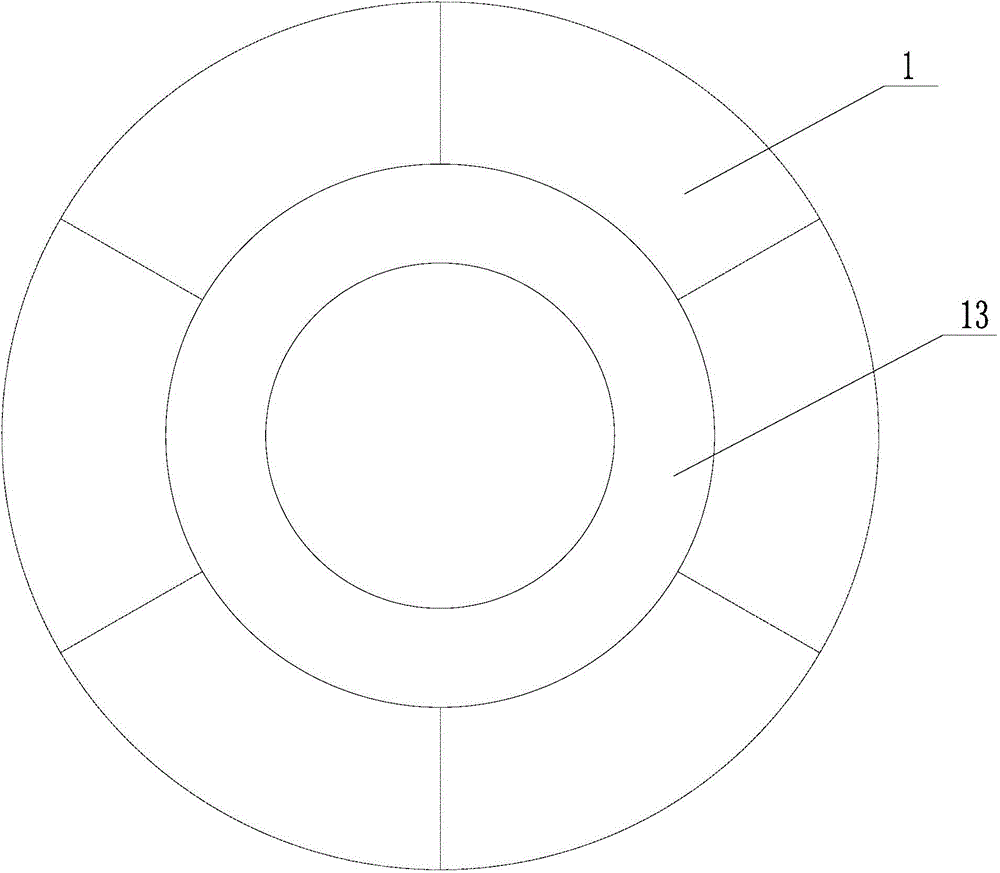

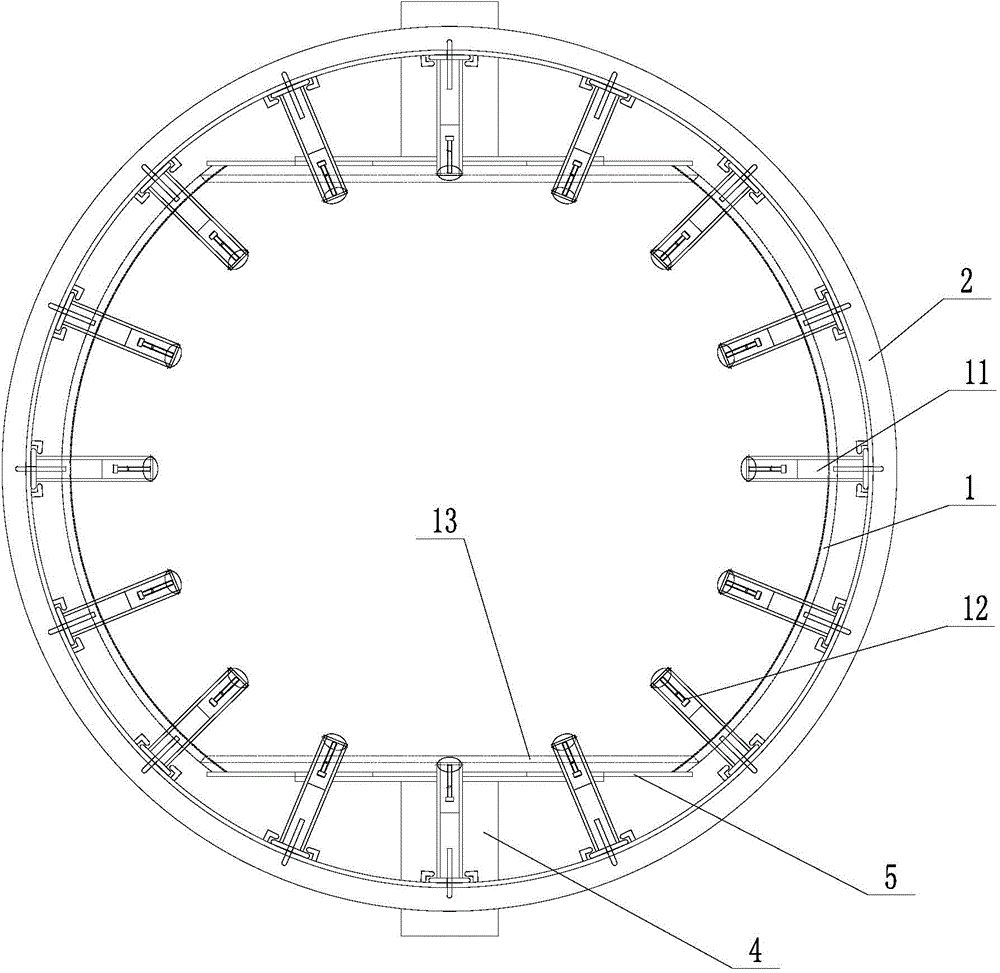

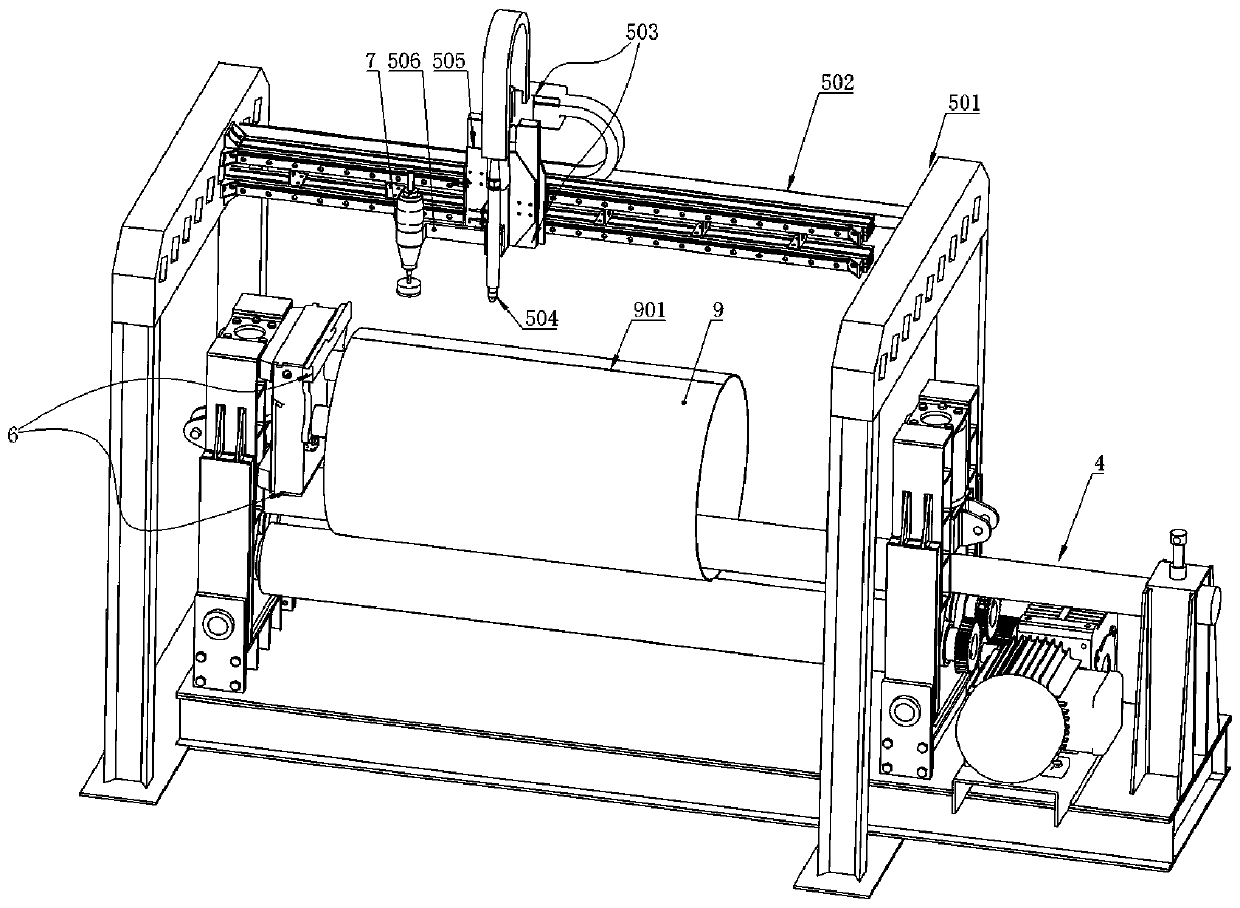

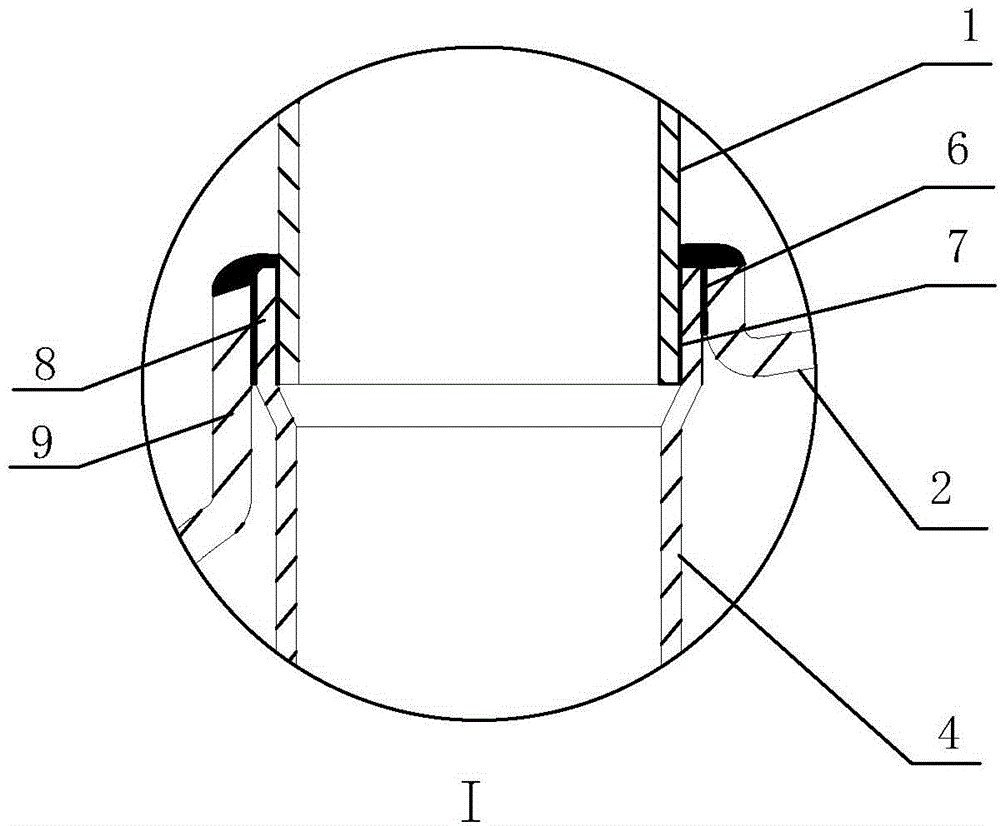

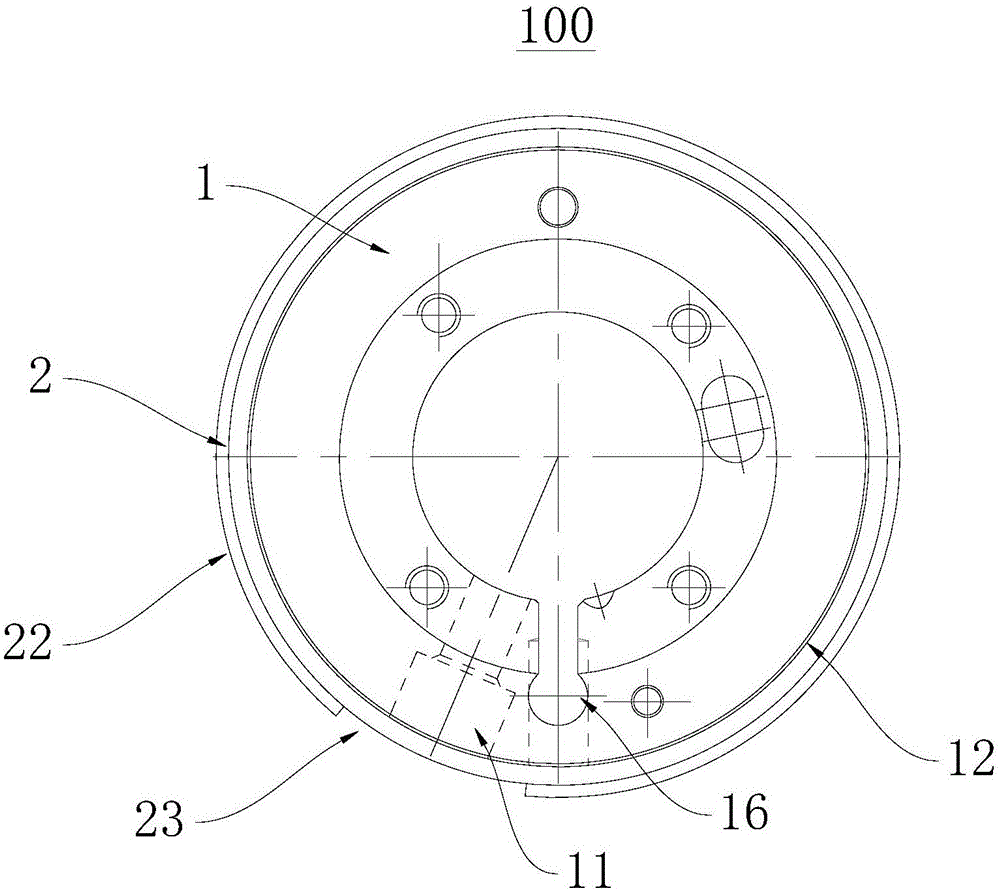

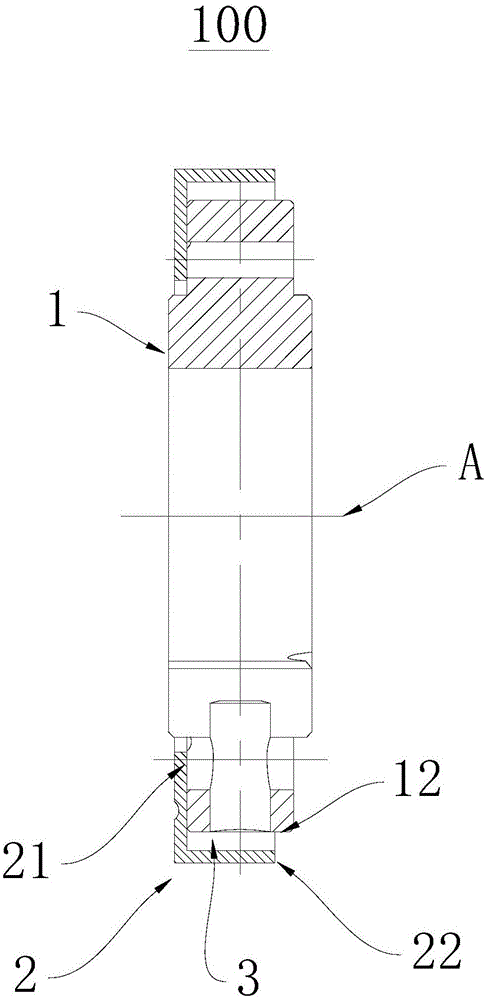

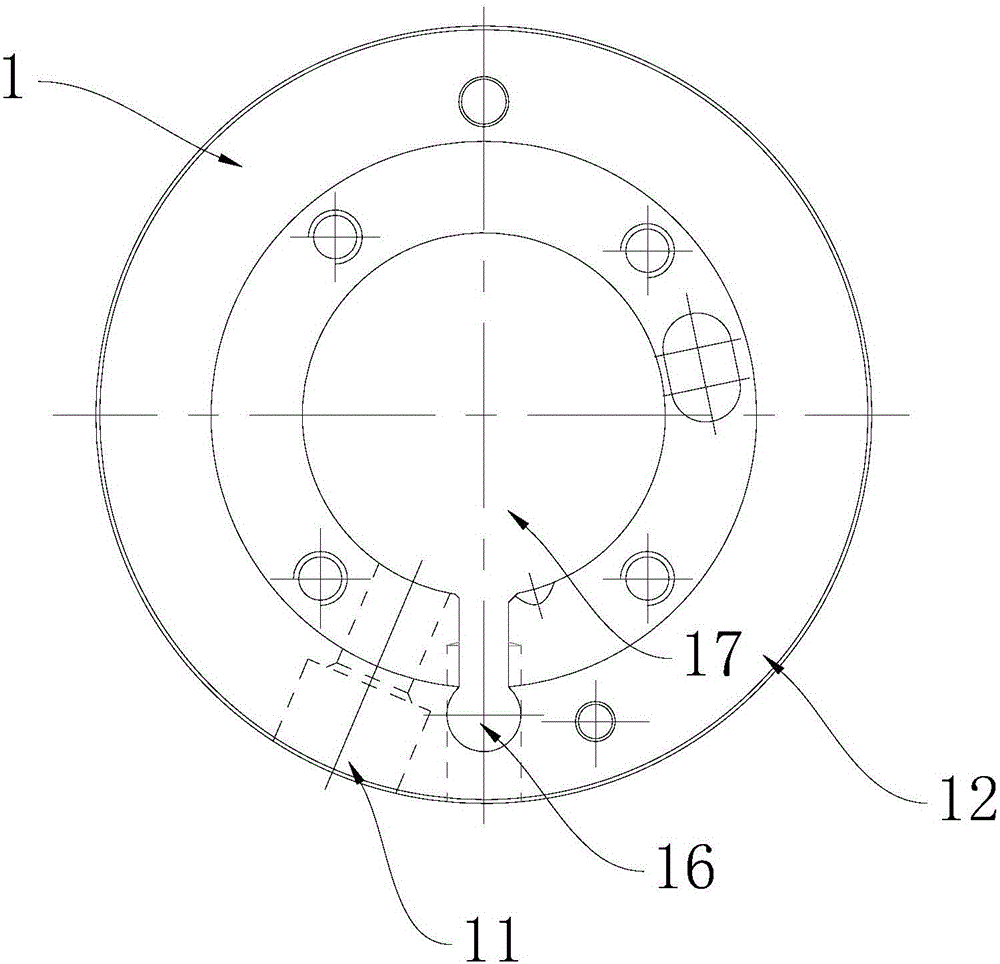

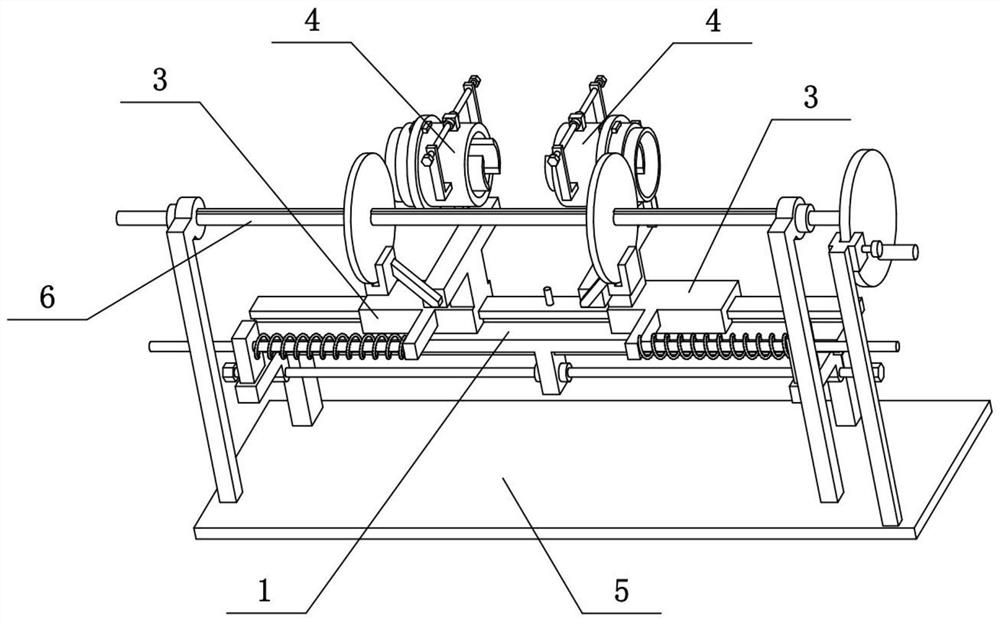

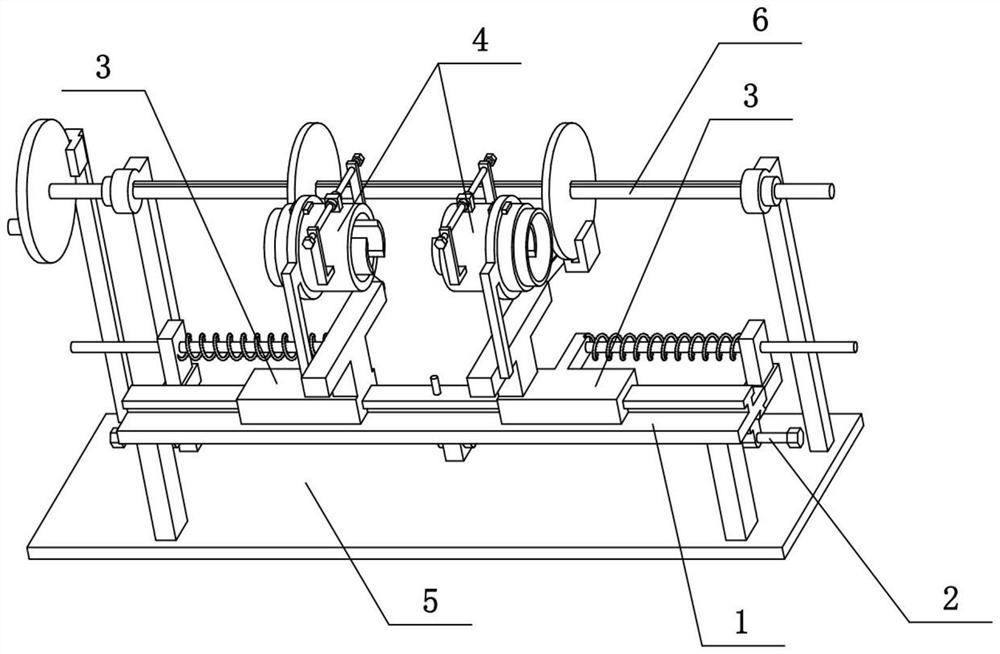

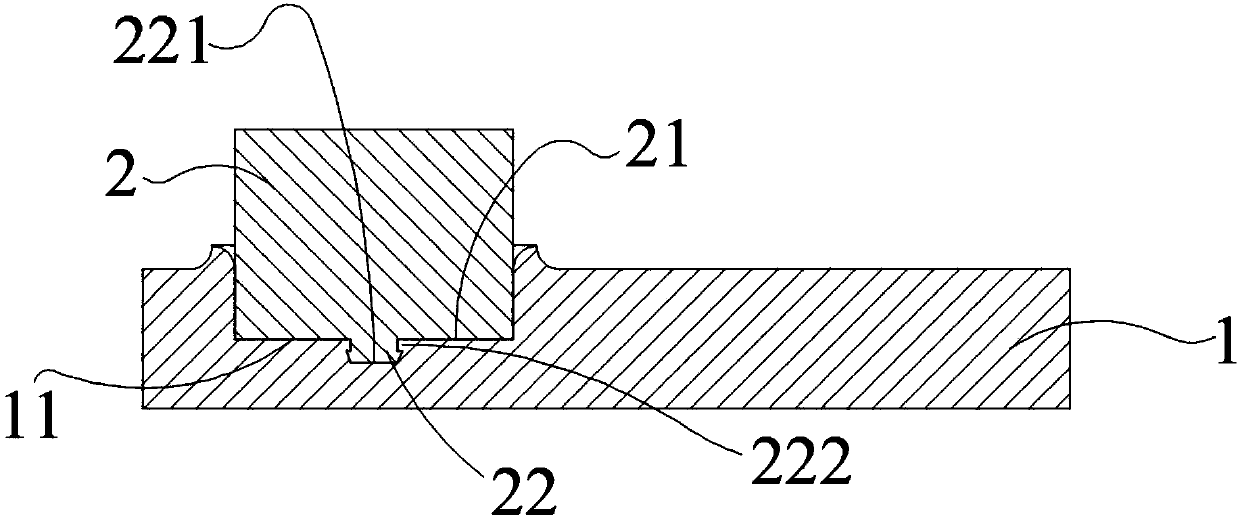

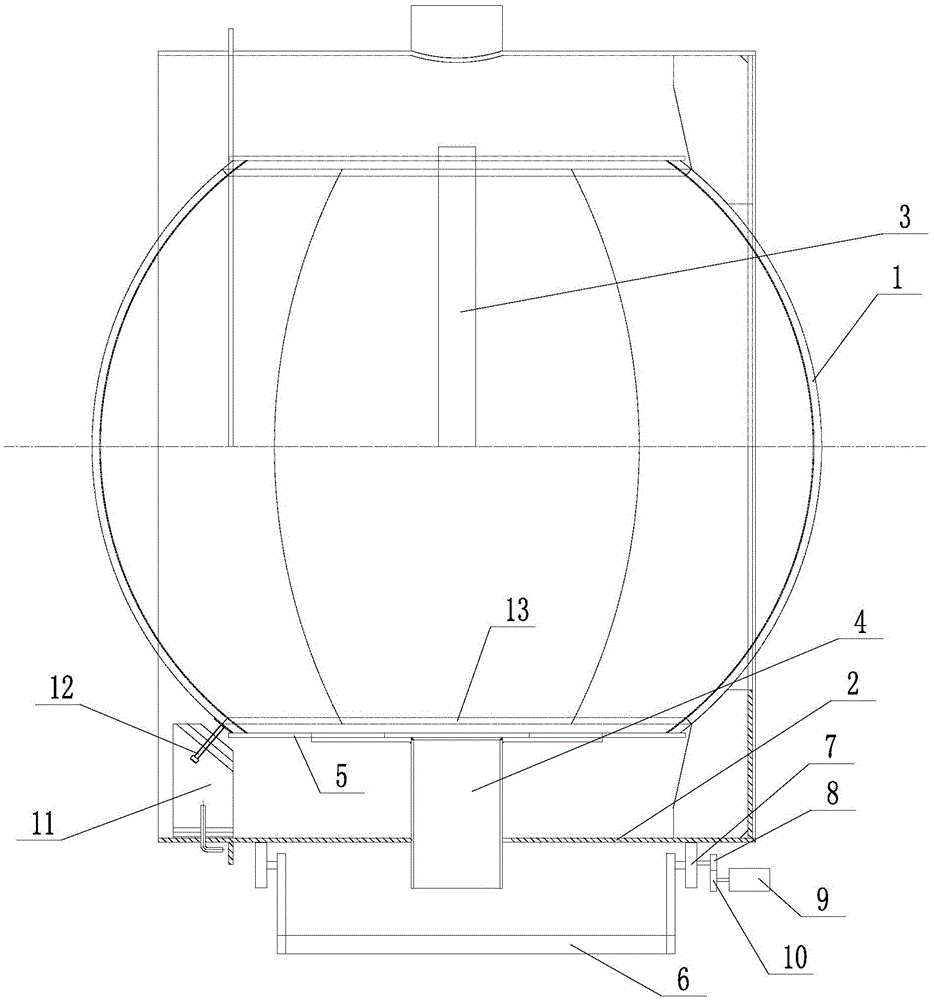

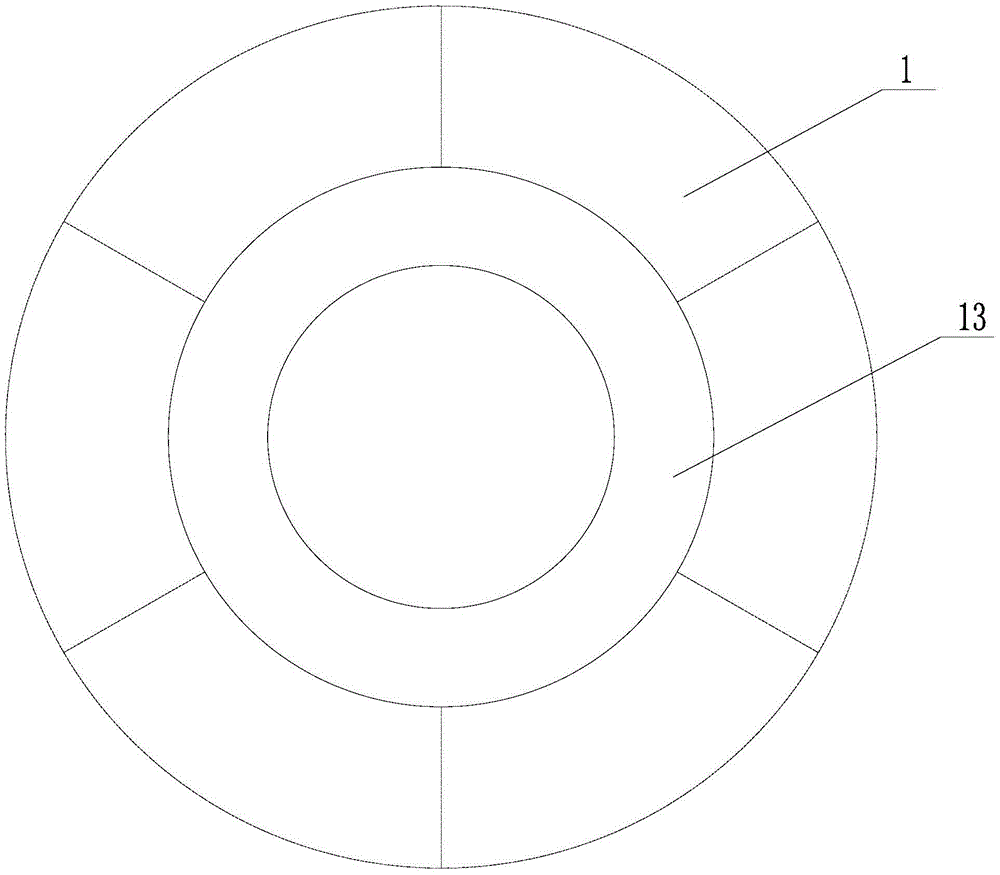

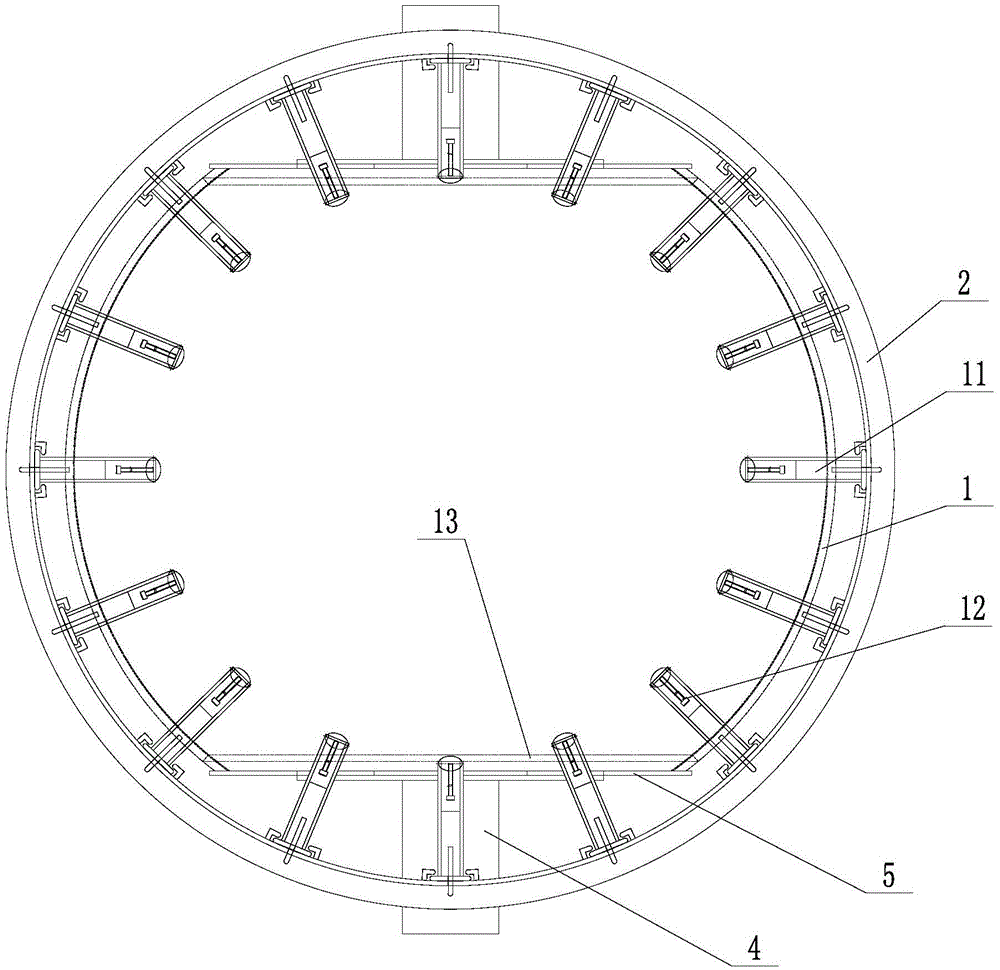

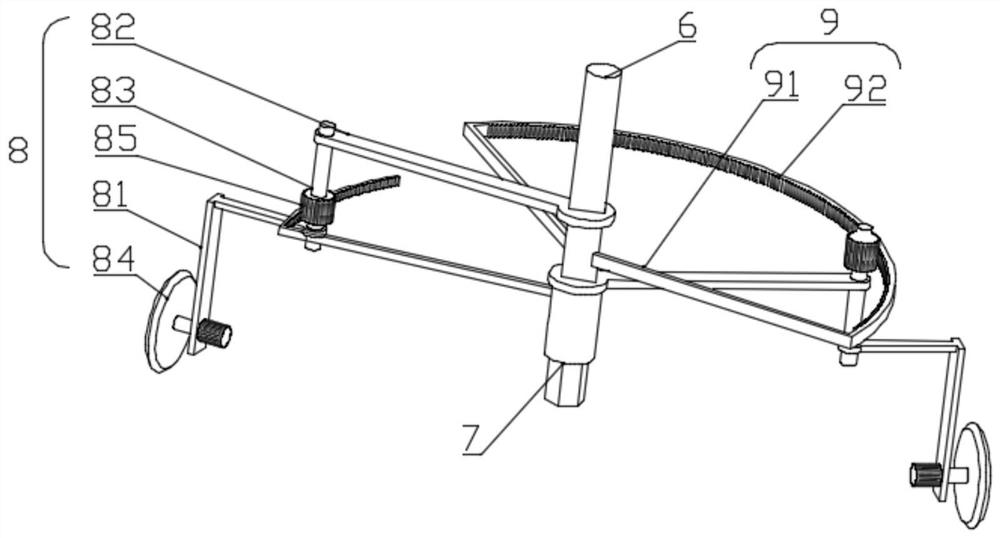

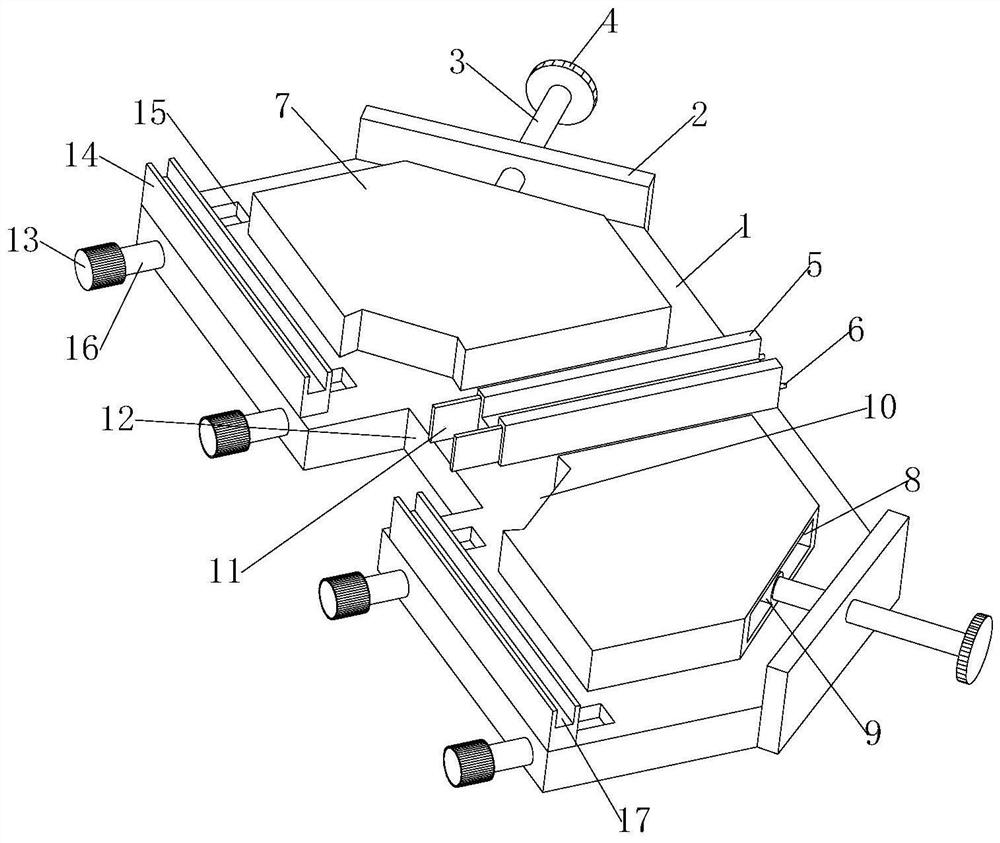

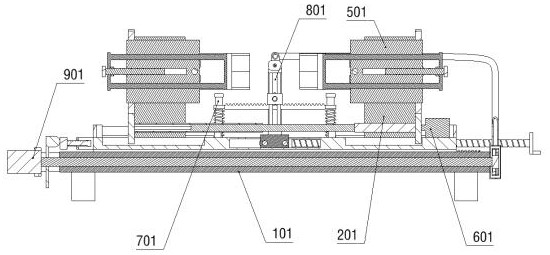

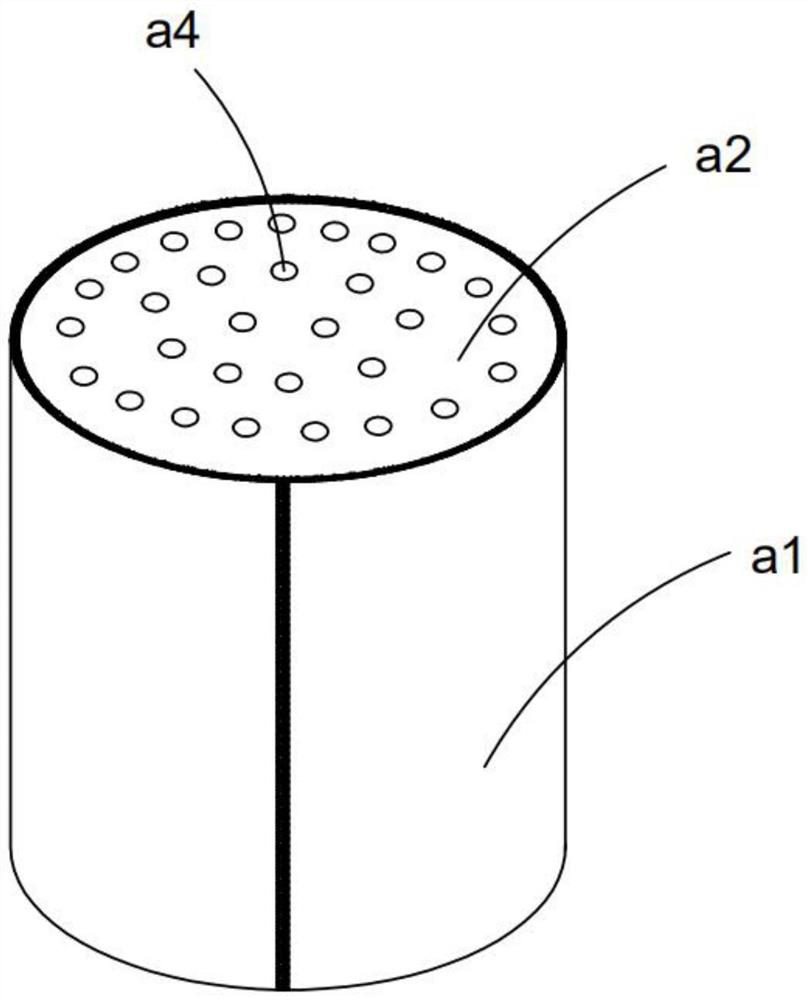

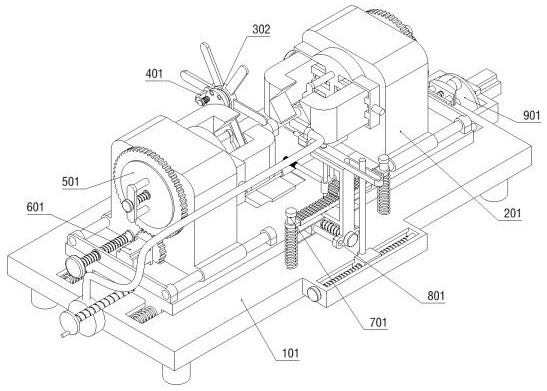

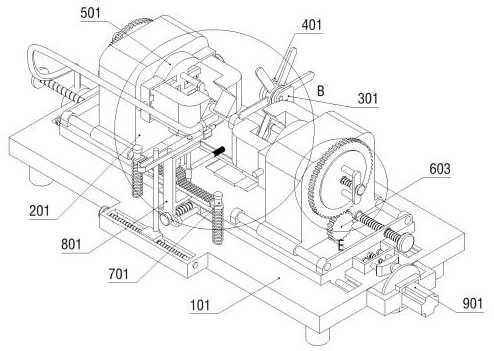

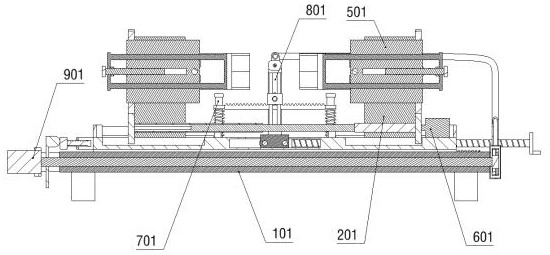

Automatic welding fixture for longitudinal joint of spherical shell in safety injection tank

ActiveCN104785995AMeet the requirements of automatic weldingImprove welding firmnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an automatic welding fixture for a longitudinal joint of a spherical shell in a safety injection tank. The automatic welding fixture comprises a cylinder for containing the spherical shell in the safety injection tank. Two through holes are formed in the cylinder wall of the cylinder. The connecting line of circle centers of the two through holes intersects with and is perpendicular to the central axis of the cylinder, a welding hole allowing a welding head of a welding machine to stretch into the cylinder is formed in the cylinder wall of the cylinder, the plane formed by the center of the welding hole and the circle centers of the two through holes is perpendicular to the central axis of the cylinder, rotary shafts are arranged in the two through holes respectively, and discs connected with the spherical shell in the safety injection tank are arranged on the rotary shafts respectively. The automatic welding fixture has the advantages that the spherical shell can rotate, the automatic welding requirements can be met, and welding firmness and working efficiency can be improved.

Owner:SUZHOU HAILU HEAVY IND

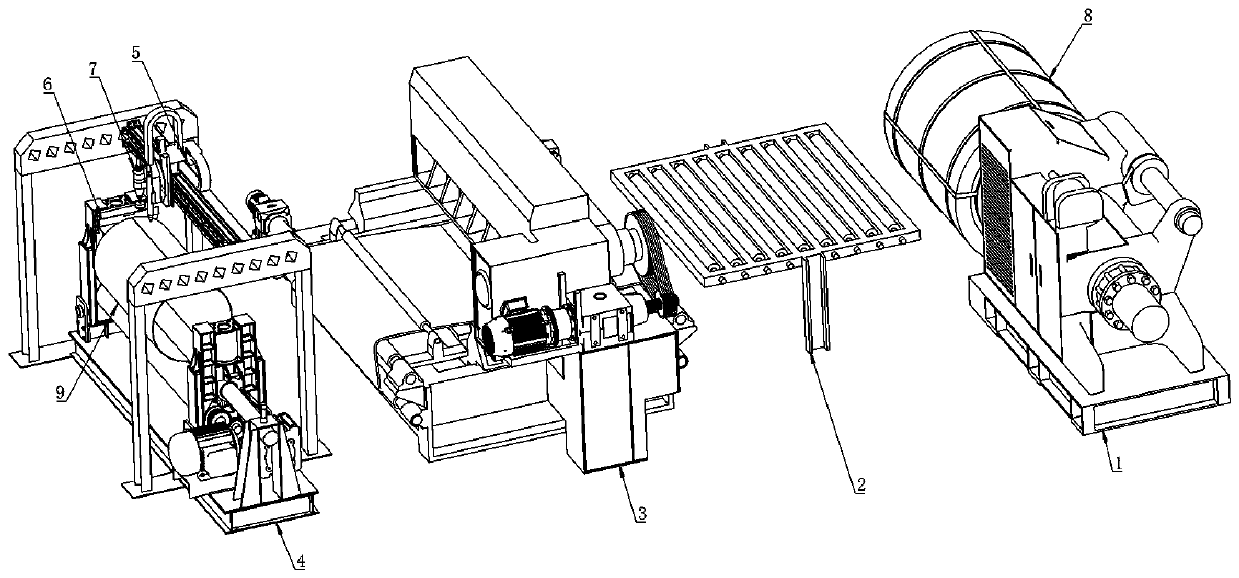

Production process for preparing cold-rolled thin-wall sleeve

The invention relates to the technical field of cold-rolled sleeves, in particular to a production process for preparing a cold-rolled thin-wall sleeve. According to the production process, a cold-rolled sheet comprising Q345-B material is used as a raw material to replace a traditional seamless steel pipe, so that the raw material cost is greatly reduced, and the production cost of the cold-rolled sleeve is reduced; the cold-rolled sleeve is manufactured through a flow production line of sheet cutting, sheet rolling, welding, calibrating and polishing instead of a traditional seamless pipe cold heading and reaming process, and the production efficiency is greatly improved; a special straight seam automatic welding machine and an automatic polishing machine are arranged into a whole, the polishing machine in the rear polishes a welding seam of a welding head for the first time when the welding head is welded, and when the welding head is reset, the polishing machine resets at the sametime to polish the welding seam of the welding head for the second time; and a self-made hydraulic calibrating machine and a special seedless two-roller sheet rolling machine are arranged into a whole, the sheet rolling and the calibrating are carried out in sequence, and the sleeve does not need to be transferred and machined for the second time.

Owner:唐山曹妃甸工业区长白机电设备检修有限公司

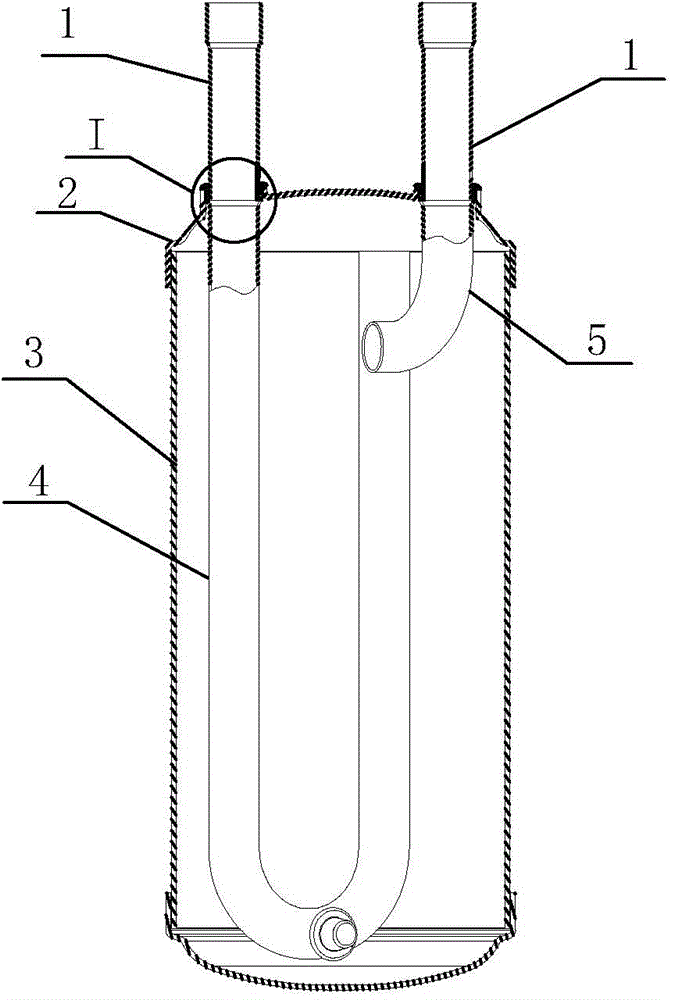

Vapor-liquid separator input and output structure and manufacturing process thereof

ActiveCN103983055AAvoid damageReduce welding processRefrigeration componentsVapor–liquid separatorCopper

The invention provides a vapor-liquid separator input and output structure and a manufacturing process thereof, which belong to the technical field of refrigerating system part manufacturing. The vapor-liquid separator input and output structure comprises a tank, an upper end cover, a stainless steel input pipe and a stainless steel output pipe, wherein the upper end cover covers the end part of the tank and is provided with an inlet, an outlet and flanging parts at the inlet and the outlet, the stainless steel input pipe penetrates through the inlet, the stainless steel output pipe penetrates through the outlet, the outer end of the stainless steel input pipe and the outer end of the stainless steel output pipe are respectively provided with a flaring part, a copper insertion pipe is inserted into each flaring part, and the bottom end of each copper insertion pipe, each flaring part and each flanging part are fixed in a welding manner for forming a five-layer structure consisting of a copper insertion pipe, a first flux layer, a flaring part, a second flux layer and an upper end cover flanging part from inside to outside. The manufacturing process of the vapor-liquid separator input and output structure comprises the following steps: step one, manufacturing the flanging parts; step two, manufacturing the flaring parts of the input and output pipes; step three, preparing the copper insertion pipes; step four, respectively welding the input pipe and the output pipe. The welding working procedures are reduced, the manufacturing cost is lowered, the welding firmness is improved, and the potential quality hazards are reduced.

Owner:新昌县杰创控股有限公司

Ceramic cigarette lighter used for battery lighter and manufacturing method of ceramic cigarette lighter

InactiveCN103776055ACompact structureBeautiful appearanceIncandescent ignitionCeramicWork in process

The invention relates to a ceramic cigarette lighter used for a battery lighter and a manufacturing method of the ceramic cigarette lighter. Ceramic materials are made into a cigarette lighter ceramic body with a cavity in a die pressing mode, an inner plate of the cavity of the cigarette lighter is provided with a spiral resistance heating wire, two metallization sizing agent coatings printed on the back face of the cigarette lighter ceramic body serve as conductive metal layers, the resistance heating wire penetrates through small holes in two sides of the cigarette lighter ceramic body to make contact with the conductive metal layers, the two tail ends of the resistance heating wire are coated with silver sizing agents, an assembled semi-finished product is placed in a metallization furnace for metallization and welded at the same time, and the silver sizing agents serve as metallization sizing agents of the conductive metal layers. The main technical parameter is as follows: the set resistance value of the product is 1.2-2.2 omega, the power is 6-8 W, the contact resistance value of the conductive metal layers and the resistance heating wire is 0 omega, and the value of the resistance between the conductive metal layers and the ceramic is larger than 100 M omega. Once arranged on the battery lighter, the cigarette lighter can be safely and reliably used for a long time.

Owner:湖南省新化县湘中电子陶瓷有限公司

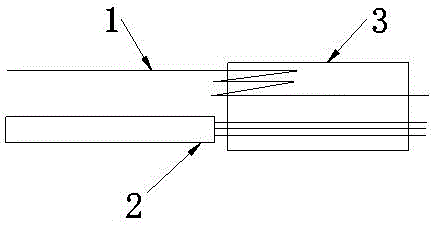

M-shaped welding process for electric resistance wires and high temperature wires

InactiveCN106825970AEasy to operateFunctionalMetal working apparatusWelding apparatusElectrical resistance and conductanceEngineering

The invention discloses an M-type welding process between a resistance wire and a high-temperature wire, which comprises the following steps: A. Do a good job of cleaning the surface of the resistance wire and the high-temperature wire, and clean the metal sleeve; B. Break the resistance wire into an M-type ; C. Peel the high-temperature wire, and the wire exposed after peeling is in the same plane as the M-shaped resistance wire; D. Cover the M-shaped resistance wire and the high-temperature wire with the metal sleeve, and the M-shaped resistance wire and the high-temperature wire end The part is exposed to the outside of the metal casing; E, the metal casing is crimped, and the M-shaped resistance wire, the high-temperature wire, and the metal conduit are fixed to form a welding surface; F, the welding surface of the end of the metal conduit is welded. The invention has the advantages of simple operation, time saving and labor saving, practical function, safety and reliability, and can effectively prolong the service life.

Owner:艾克森(江苏)节能电热科技有限公司

Air cylinder and compressor

InactiveCN106401918ASmooth runningReduce distortionPositive displacement pump componentsPositive-displacement liquid enginesEngineeringCarbon steel

The invention provides an air cylinder and a compressor. The air cylinder comprises a main body and a connecting mechanism, wherein the main body is provided with an inlet passage and at least partially located in the connecting mechanism; the connecting mechanism is provided with a communication groove used for enabling the inlet passage and a pumping air pipe to communicate. The air cylinder and the compressor have the following advantages that the welding position of the main body and the connecting mechanism is located on the lateral wall, facing a first end, of the main body; according to the welding mode, the acting force on the main body mainly extends in the axial direction of the main body, so that the radial deformation of the main body is reduced as much as possible, and smooth operation of a shell is guaranteed; and the connecting mechanism can be made of low carbon steel with better welding performance, the welding time can be greatly shortened, welding stress is small, and welding firmness is good.

Owner:ZHUHAI LANDA COMPRESSOR +1

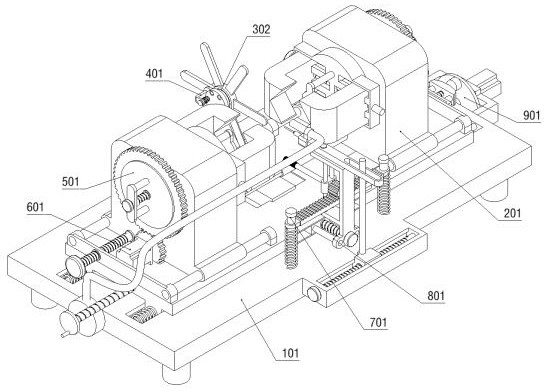

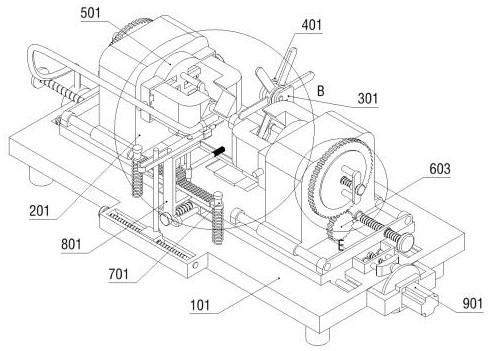

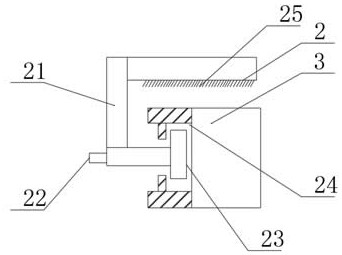

A New Metal Material Welding Fixture

ActiveCN110883489BEasy to weldImprove welding firmnessWelding/cutting auxillary devicesAuxillary welding devicesMetallic materialsEngineering

Owner:嘉兴易达新材料科技股份有限公司

Rotary friction welding method

ActiveCN107627021ASolve the problem of uneven welding effectImprove welding firmnessNon-electric welding apparatusFriction weldingEngineering

The invention discloses a rotary friction welding method which comprises the following steps: providing a first workpiece and a second columnar workpiece; treating a weld face of the first workpiece into a plane; arranging a step column in the center of a bottom surface of the second workpiece, wherein a groove is formed in a peripheral side face, which is close to the bottom surface of the secondworkpiece, of the step column, and the step column comprises a step column bottom surface; fixing the first workpiece and the second workpiece; rotating the second workpiece, enabling the weld face of the first workpiece to be contacted with the bottom surface of the step column, enabling the bottom surface of the step column to be rubbed with the weld face of the first workpiece so as to raise the temperature, pressing and upsetting the first workpiece and the second workpiece until the bottom surface of the second workpiece is contacted with the weld face of the first workpiece, maintaininga state of rotating the second workpiece and a state of pressing the first workpiece and the second workpiece, and upsetting the bottom surface of the second workpiece and the weld face of the firstworkpiece; stopping rotating the second workpiece, stopping pressing the first workpiece and the second workpiece, and completing welding after the weld contact surface is cooled.

Owner:惠州荣德隆科技有限公司

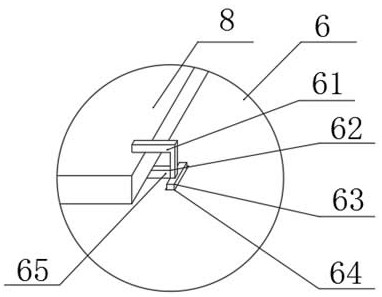

Automatic welding tool for longitudinal seam of spherical shell in safety injection box

ActiveCN104785995BMeet the requirements of automatic weldingImprove welding firmnessWelding/cutting auxillary devicesAuxillary welding devicesCircular discWelding

The invention discloses an automatic welding fixture for a longitudinal joint of a spherical shell in a safety injection tank. The automatic welding fixture comprises a cylinder for containing the spherical shell in the safety injection tank. Two through holes are formed in the cylinder wall of the cylinder. The connecting line of circle centers of the two through holes intersects with and is perpendicular to the central axis of the cylinder, a welding hole allowing a welding head of a welding machine to stretch into the cylinder is formed in the cylinder wall of the cylinder, the plane formed by the center of the welding hole and the circle centers of the two through holes is perpendicular to the central axis of the cylinder, rotary shafts are arranged in the two through holes respectively, and discs connected with the spherical shell in the safety injection tank are arranged on the rotary shafts respectively. The automatic welding fixture has the advantages that the spherical shell can rotate, the automatic welding requirements can be met, and welding firmness and working efficiency can be improved.

Owner:SUZHOU HAILU HEAVY IND

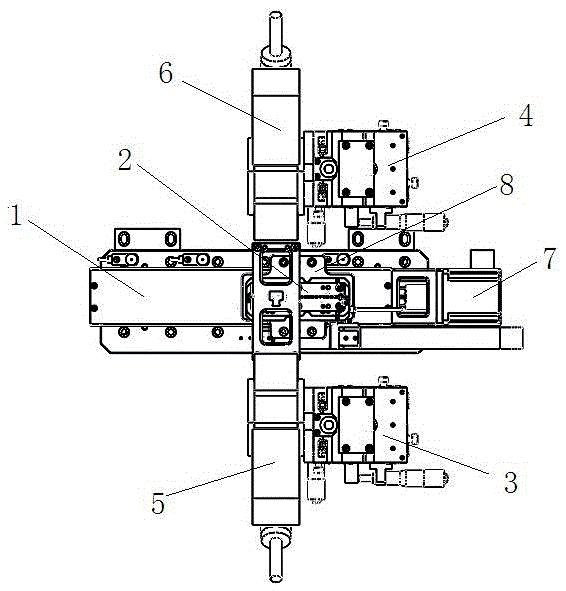

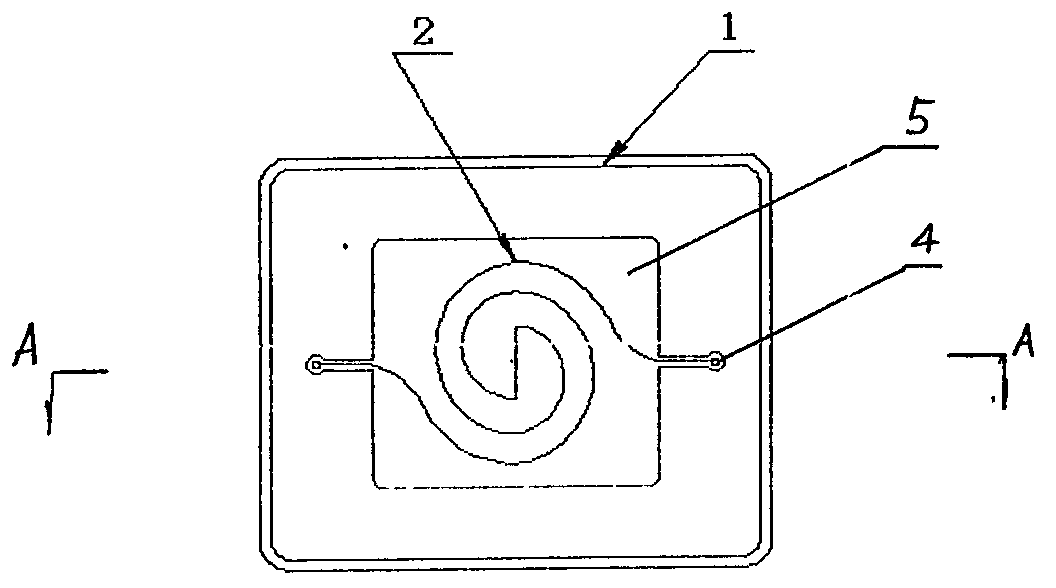

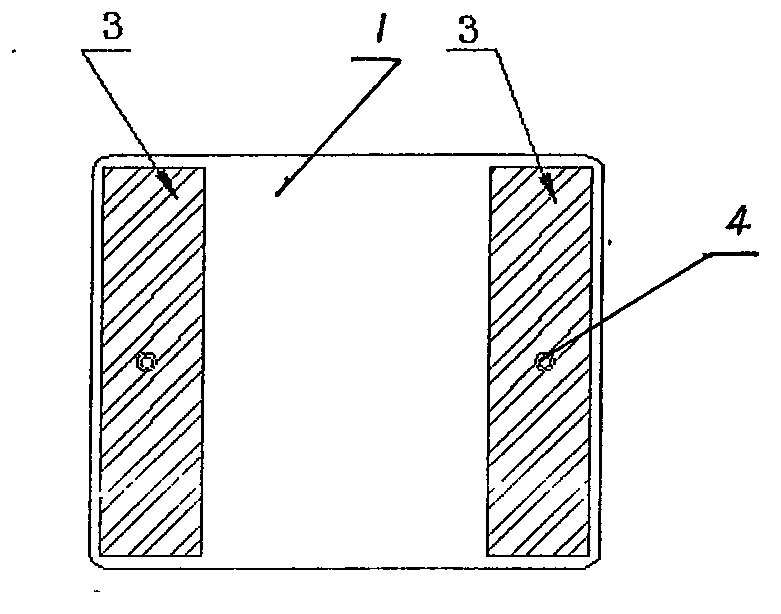

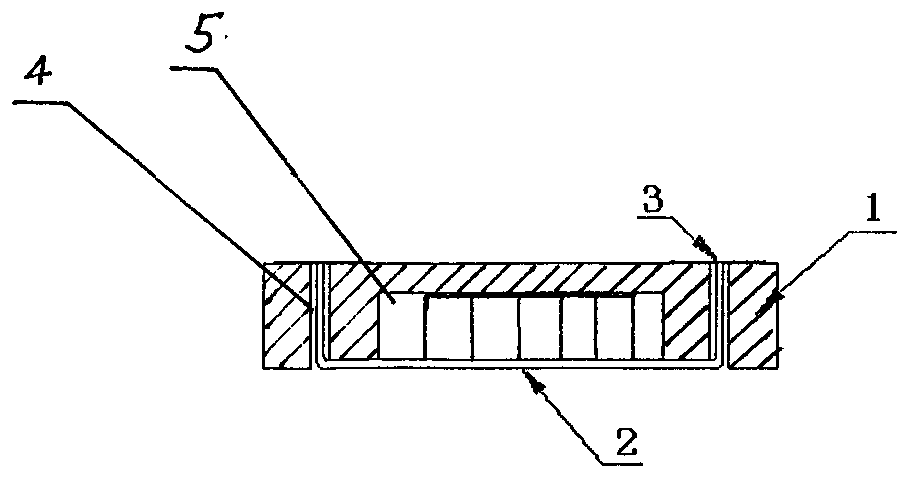

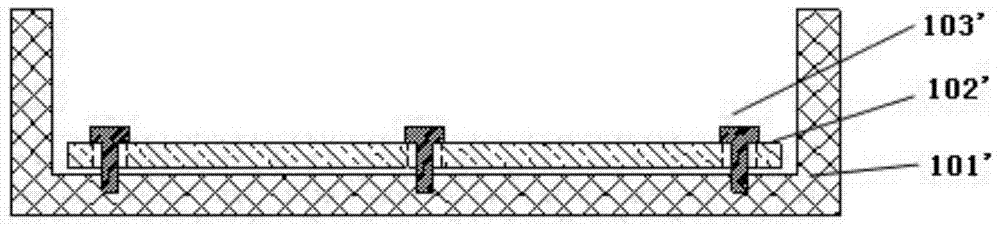

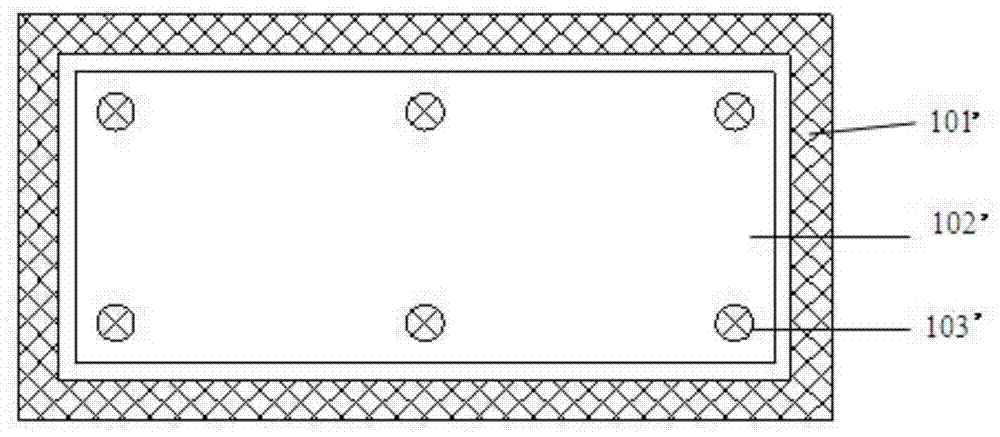

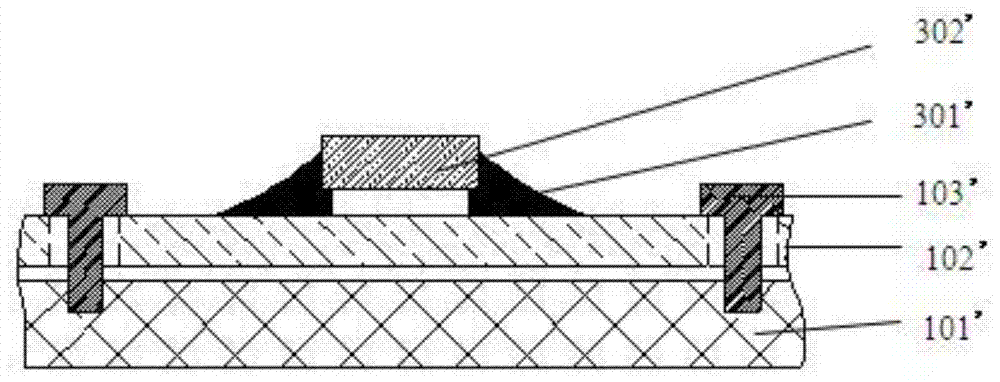

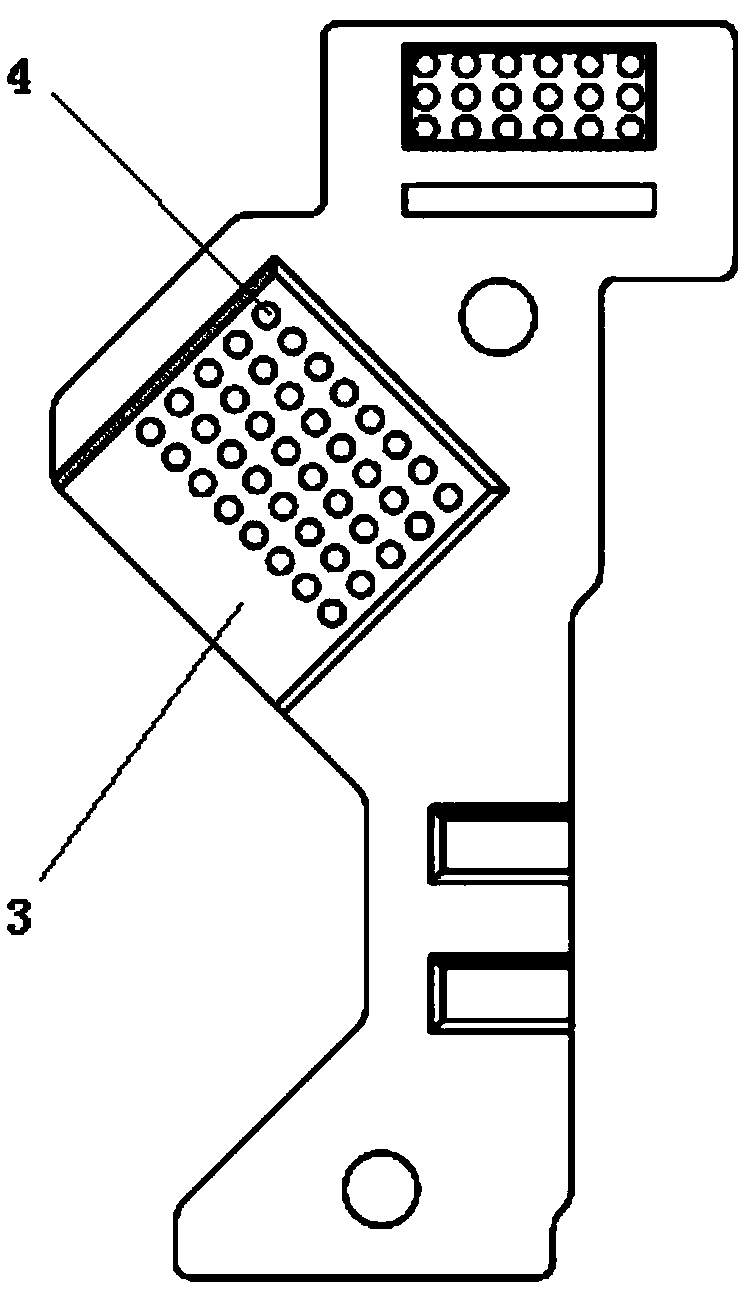

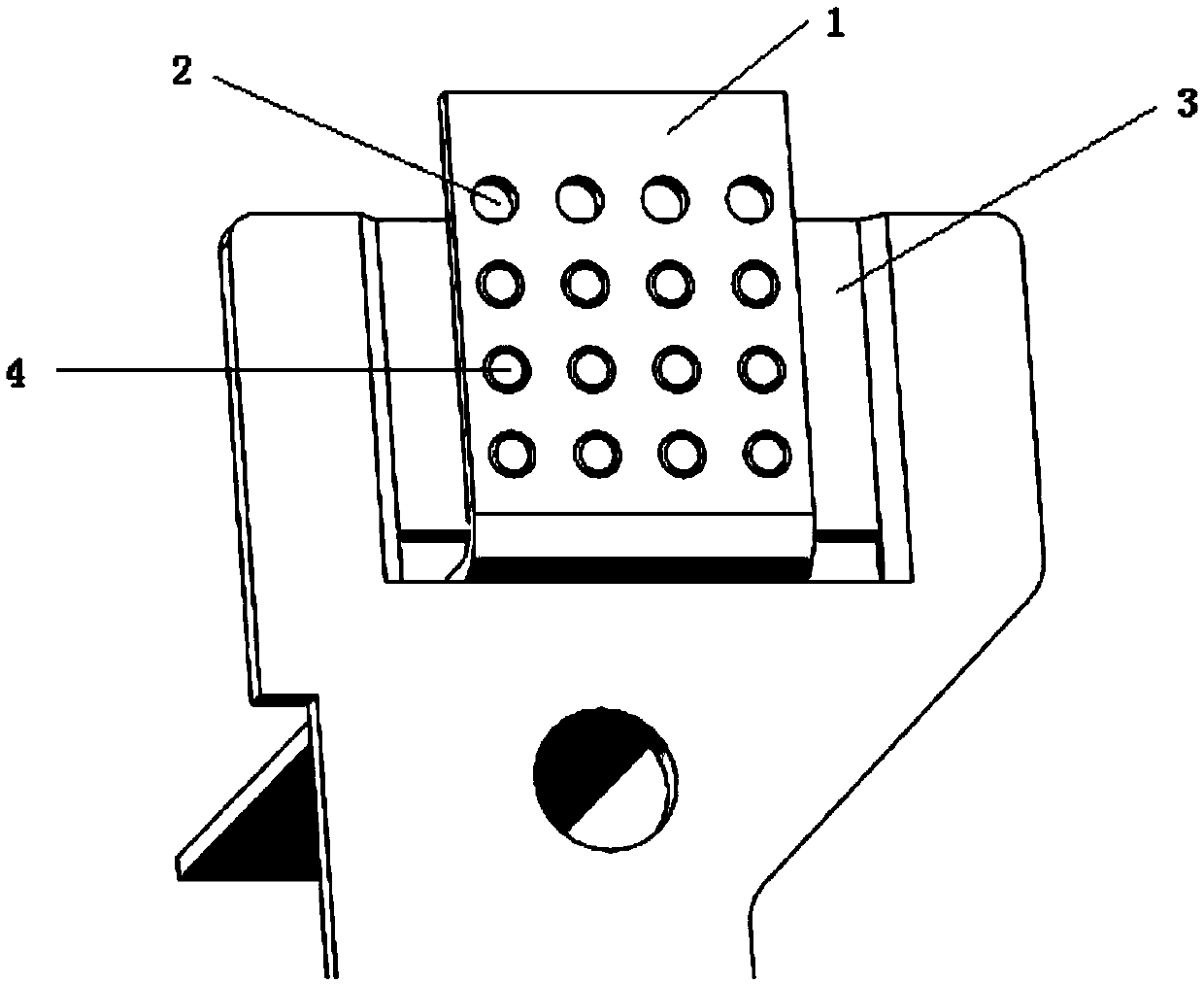

Welding Process and Welding Mechanism of Microwave Substrate and Housing

ActiveCN104125722BImprove welding firmnessImprove cooling effectPrinted circuit assemblingSoldering auxillary devicesMicrowave substrateElectrical performance

The invention relates to a welding process and a welding mechanism for a microwave substrate and a housing. The process comprises machining a through hole in the microwave substrate, and machining a column on the inner bottom surface of the housing, which corresponds to the through hole, wherein the through hole can be penetrated by the column, the diameter of the through hole is larger than that of the column, and the height of the column is smaller than the thickness of the microwave substrate; forming integrated metalized layers on the surfaces of both the microwave substrate and the housing; placing the microwave substrate, solder blocks and the housing correspondingly and sequentially from top to bottom, performing reflow soldering on the microwave substrate and the housing, and during the reflow soldering process, exerting pressure on the upper surface of the microwave substrate to guarantee fitting of the microwave substrate and the housing. The welding process of the microwave substrate and the housing can improve the welding firmness of the substrate and the housing, guarantee the cleanliness of the upper surface of the substrate, improve the grounding and radiating performance of the substrate and further improve the electrical performance and the reliability of components.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

Welding method of photovoltaic assembly junction box

PendingCN109623060AReduce the chance of false weldingImprove welding firmnessWelding/cutting auxillary devicesAuxillary welding devicesSolderingPhotovoltaic power station

The invention discloses a welding method of a photovoltaic assembly junction box. The welding method comprises the steps that a bus bar with a penetrating through hole and a junction box welding discwith a cylindrical protrusion are provided; and the cylindrical protrusion is inserted into the through hole in the bus bar, heating is conducted to enable soldering tin on the surface of the bus barto be molten, the molten soldering tin enters the through hole of the bus bar, and then the molten soldering tin is condensed. In the welding process of the photovoltaic assembly junction box, the cylindrical protrusion on the surface of the welding disc is completely inserted into the through hole of the bus bar, assembly pseudo soldering caused by relative moving of the bus bar and the welding disc in the welding process of the junction box is avoided, the probability of pseudo soldering can be effectively decreased, welding firmness is improved, and thus the safety and stability of a photovoltaic power station are improved.

Owner:HEFEI & SOLAR TECH

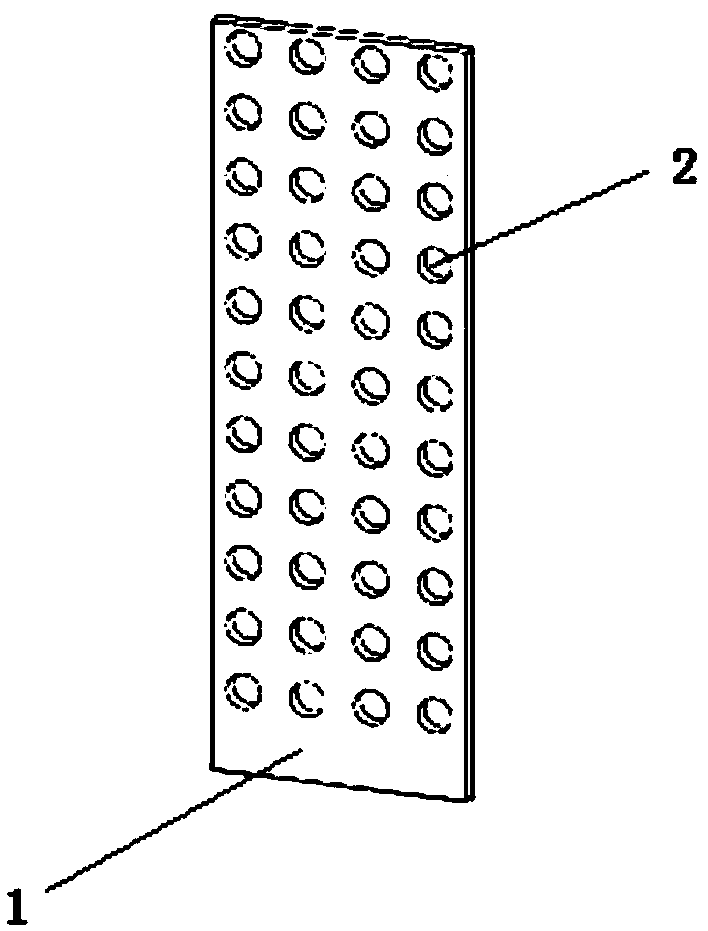

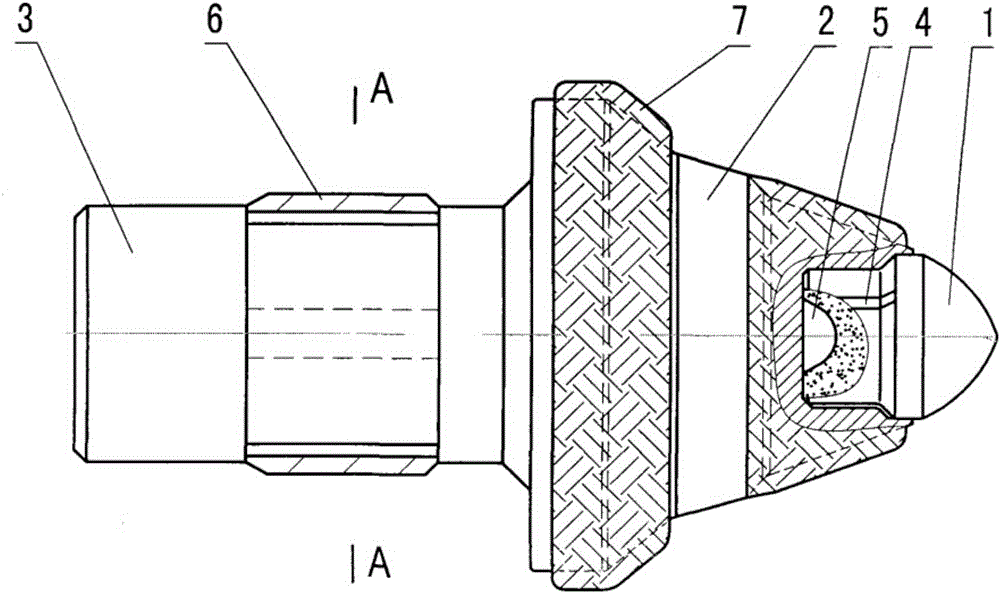

Novel wear-resisting point-attack pick

The invention discloses a novel wear-resisting point-attack pick. The novel wear-resisting point-attack pick mainly comprises a pick body and a hard alloy. The pick body is composed of a pick head and a pick handle, the hard alloy is welded to an alloy hole of the pick body and composed of a cone-shaped big head and a cylinder-shaped small handle, the small handle of the hard alloy is evenly provided with protruded ribs which are arranged longitudinally, the bottom of the small handle is provided with a concave counterbored hole, and the pick handle of the pick body is provided with a clamp spring through an annular concave clamp groove in a clamped mode; the periphery of the pick head is provided with a wear-resisting layer, and the wear-resisting layer is metal carbide compounded by chromium, vanadium and niobium metal powder and a nonmetallic boron and carbon compound material. The novel wear-resisting point-attack pick has the advantages that the welding quality is high, wear is resistant, the alloy structure is reasonable, the use amount is few, and the working is stable; the service life of the point-attack pick is effectively prolonged.

Owner:ANQING HUAQI MACHINERY ACCESSORIES CO LTD

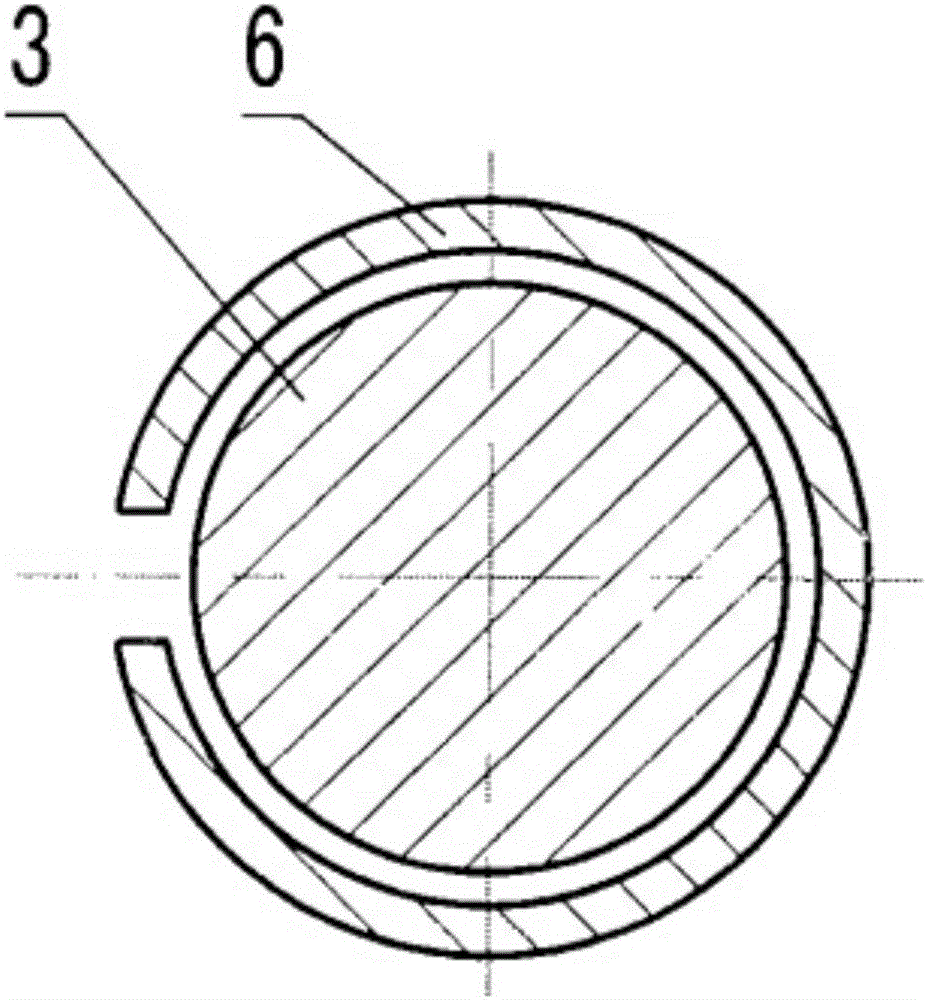

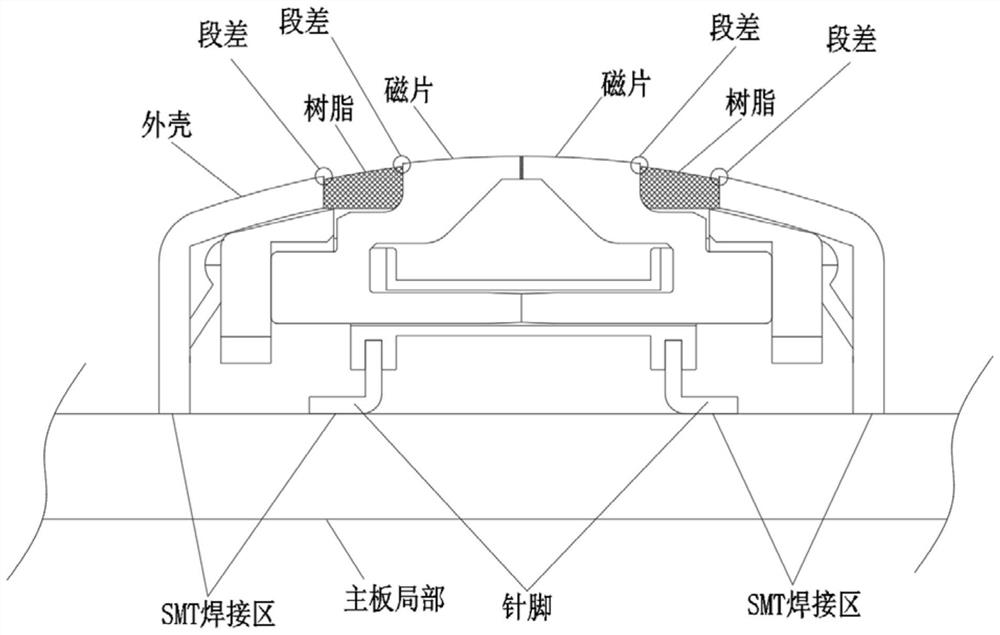

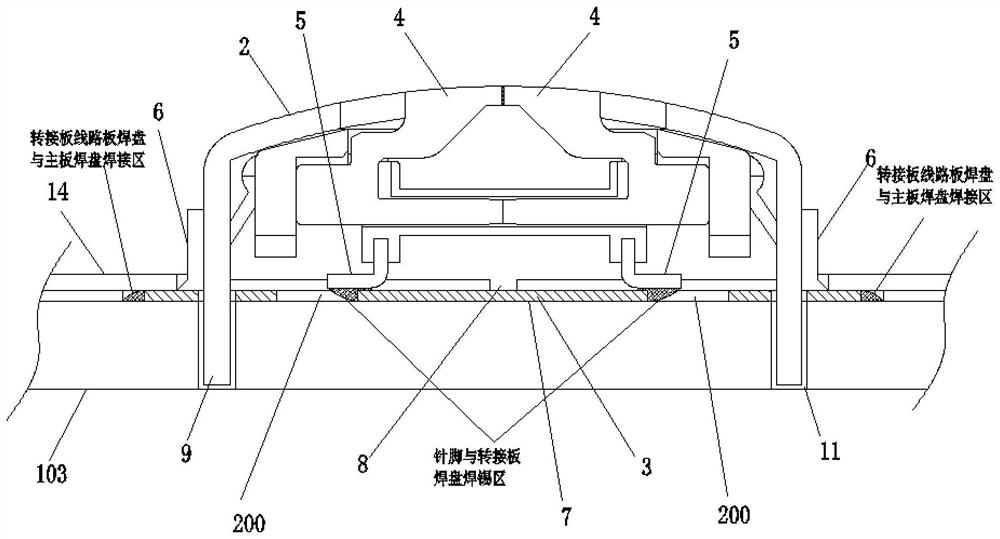

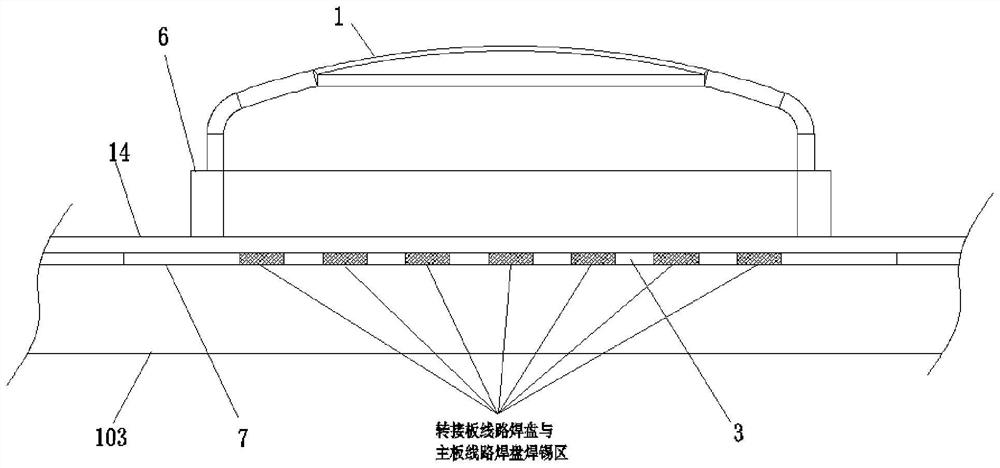

Magnetic head manufacturing and mainboard assembling method for equivalently replacing surface mounting and magnetic head

PendingCN114364155AHigh speedShorten the timePrinted circuit assemblingSensing record carriersSurface mountingStructural engineering

The invention provides a magnetic head manufacturing and mainboard assembling method for equivalently replacing surface mounting and a magnetic head, and the method comprises the steps: carrying out the automatic welding of a magnetic head pin and a bonding pad of a switching circuit board, sleeving a silica gel sealing ring on an outer frame of a magnetic head housing, injecting glue into the magnetic head from a glue injection hole of the switching circuit board, and carrying out the packaging. A double-sided gum insulation sheet is pasted on the surface of the switching circuit board to form a magnetic head which equivalently replaces surface mounting; the magnetic head is assembled on a main board of the card reading equipment, the bonding pads of the switching circuit board are welded with the bonding pads of the main board in a one-to-one correspondence manner in an automatic manner, and a metal safety board with insulating films on two sides is assembled on the silica gel sealing ring outer frame of the magnetic head, so that the magnetic head and the main board can be assembled. The method can avoid the influence of the high temperature of a reflow oven on the resin in the magnetic head to cause segment difference, does not need to require higher welding pin flatness according to SMT parts, and has the purposes of long service life, good welding firmness, high working efficiency, low magnetic head manufacturing cost and the like.

Owner:APOLLO ZHUHAI ELECTRONICS

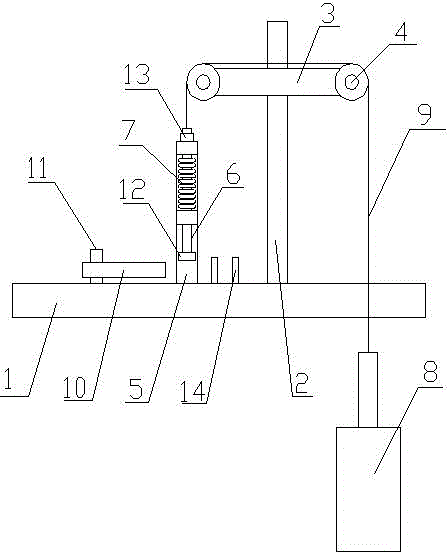

Argon welding device for magnesium base

ActiveCN104588843AEasy to weldPlace stableWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention provides an argon welding device for a magnesium base. The argon welding device comprises a working table, a support is arranged on the working table, a guide rod is arranged on the support, guide wheels are arranged at the two ends of the guide rod, a flange fixing device is arranged on the portion, under the guide wheel on the left side, of the working table and comprises a supporting frame and a positioning rod, and the positioning rod is arranged on the supporting frame through a pressure spring; an air cylinder is arranged at the bottom end of the working table, a telescopic rod of the air cylinder is connected with the positioning rod through a steel wire, and the steel wire is guided through the guiding wheels. The positioning rod is driven by the spring to fix a flange, and the magnesium base is attached to the positioning rod to be positioned and can be welded conveniently; as an auxiliary positioning block is arranged and used for positioning the magnesium base from the side face, it is ensured that the magnesium base is placed stably, and the welding firmness of the magnesium base is improved.

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

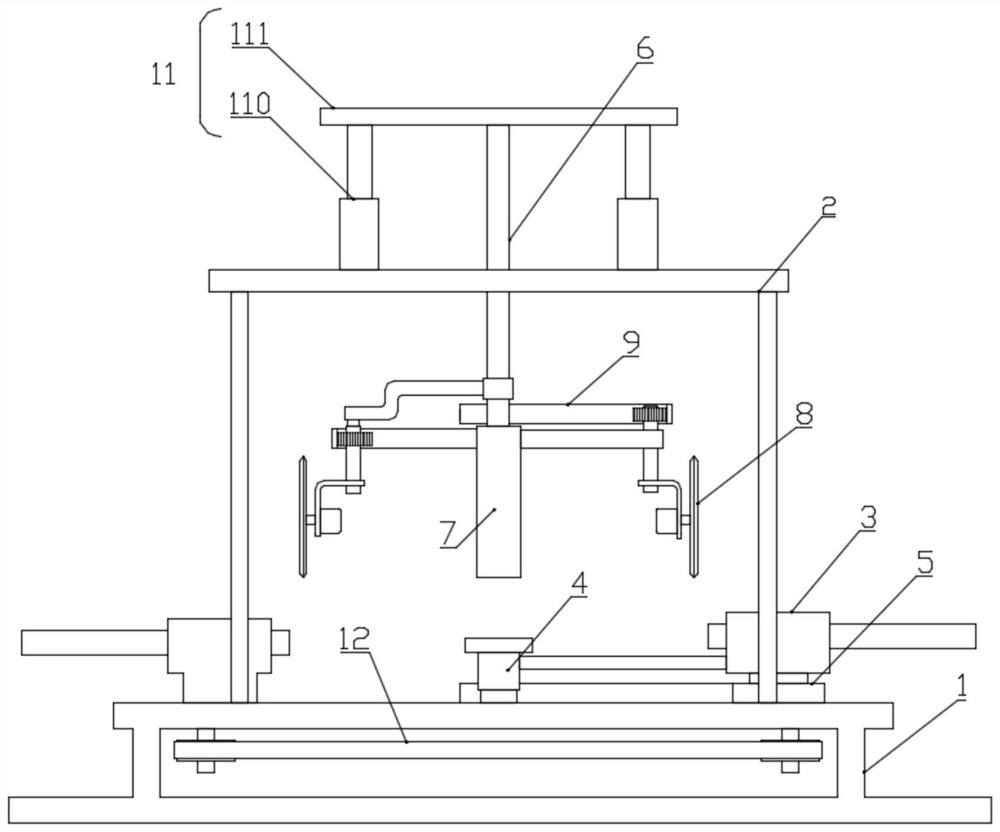

A welding construction device for building roof steel structure

ActiveCN114012439BPrecise positioningImprove welding firmnessOther manufacturing equipments/toolsConstruction engineeringMechanical engineering

The invention discloses a welding construction device for a steel structure of a building roof. The welding construction device comprises a welding construction platform, a frame body arranged on the welding construction platform, two conveying brackets and two welding ports for cutting the steel structure A cutting head assembly; also includes a central rotating connecting piece, an arc-shaped supporting assembly, a hanging rod piece, a rotating sleeve body and a rotating connecting driving piece; the central rotating connecting piece is arranged on a rotating welding construction platform; the hanging rod The vertical sliding part is arranged on the frame body, and the frame body is provided with a lifting member that drives the suspension rod to rise and fall; two cutting head assemblies are respectively arranged on the rotating sleeve body and the side wall of the suspension rod member, and the two cutting head assemblies Opposite to the two conveying brackets; both the rotating sleeve body and the side wall of the hanger are provided with rotating connection driving parts. The invention has a simple structure, can adjust the connection angle of the steel structure before welding, and can cut the welding end of the steel structure to match the connection angle obliquely, so as to improve the firmness after welding; the operation is convenient and the practicability is strong.

Owner:宜昌东阳建设工程有限公司

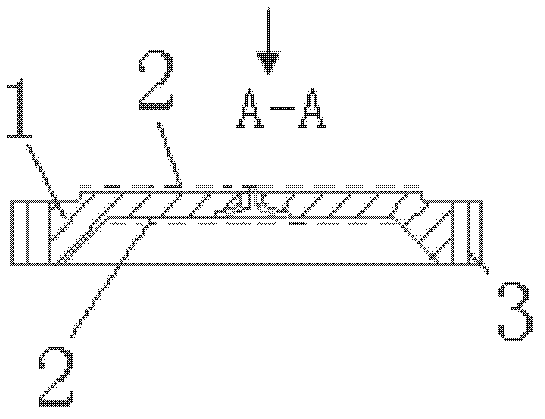

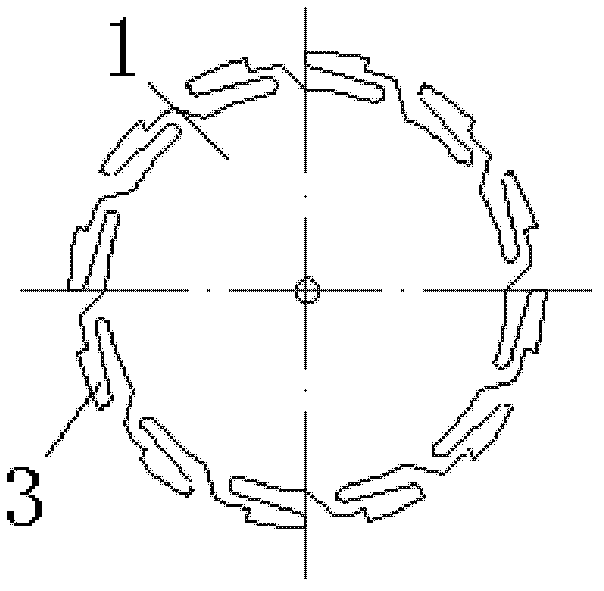

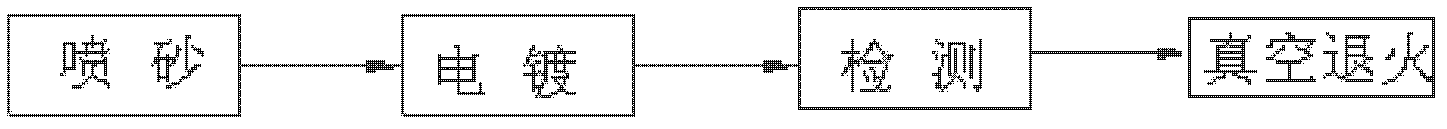

Collector inner core of space traveling wave tube and production technology of collector inner core

ActiveCN102446675BPerformance impactImproved ability to resist electron bombardmentTransit-tube collectorsNon-emitting electrodes manufactureNuclear engineeringSand blasting

The invention discloses a collector inner core of a space traveling wave tube and a production technology of the collector inner core. The collector inner core of the space traveling wave tube comprises an oxygen-free copper inner core body. A black chrome layer is arranged on the oxygen-free copper inner core body. The production technology of the collector core of the space traveling wave tube comprises the following processes of: sand blasting, electroplating, detection and vacuum annealing. By electroplating the black chrome layer on the oxygen-free copper inner core body and by using the product performance of the black chrome layer, the collector inner core of the space traveling wave tube and the production technology of the collector inner core have the advantages that the electron bombardment resisting capacity of the oxygen-free copper inner core body is improved; the backflow of secondary electrons is effectively suppressed and the collection efficiency of the electrons of the collector inner core of the traveling wave tube is improved; and the influence of low-energy electrons on the product performance of the space traveling wave tube is further eliminated.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

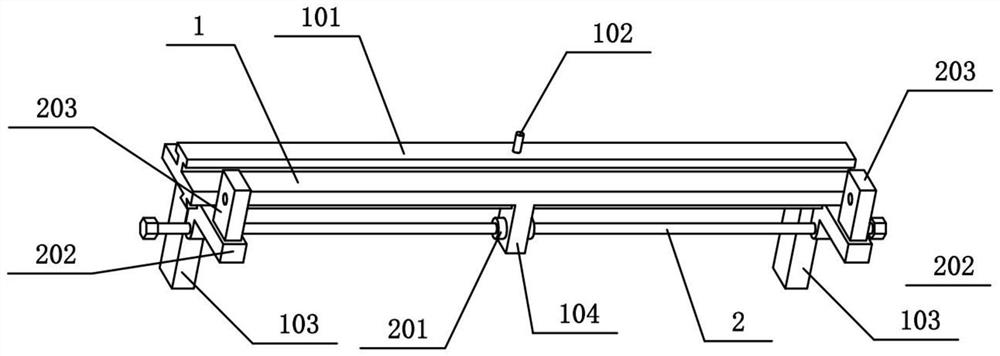

Welding locking and fixing device for connection point of steel structure

ActiveCN111203678BAffect firmnessEasy to clamp and fixWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringPhysics

The invention discloses a welding locking and fixing device for connection points of steel structures, which relates to the technical field of steel structure processing, and comprises a horizontally fixed bottom plate, a square block-shaped first block is installed in the middle of the top end of the bottom plate, and the first block is installed on the top of the bottom plate. A second stopper is installed on the left and right sides of the front end of a stopper, the first stopper and the second stopper are fixed at right angles, and the front end of the first stopper is located in the middle of the second stopper on both sides There is a relief opening, and the relief opening is in a U-shaped structure. Top blocks are symmetrically installed on the left and right sides of the first block, and two of the side walls of the top block are connected to the first block and the second block. parallel. In the present invention, second stoppers are installed on the left and right sides of the front end of the first stopper. The first stopper and the second stopper are fixed at right angles. There is a relief opening in the middle, which is convenient for connecting two steel structures at right angles.

Owner:HEBEI HUATONG HEAVY IND MACHINERY MFG CO LTD

Outer edge welding device for hydraulic cylinder manufacturing

ActiveCN114589439AWeld firmlyLow costWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention provides an outer edge welding device for hydraulic cylinder manufacturing, and relates to the technical field of hydraulic cylinder welding. Two sliding adjusting parts are mounted on the mounting supporting part; the structures on the two sliding adjusting parts are the same; a movable seam clamping device is connected to the mounting supporting part in a sliding manner; the movable seam clamping device is fixedly connected with an elastic positioning device; the two sliding adjusting parts are rotationally connected with rotating mounting parts correspondingly. Arc-shaped swing welding can be achieved, welding is firmer, the overall linkage performance is higher, and auxiliary smoke removal and cleaning work can be achieved; the problems that an existing outer edge welding device for hydraulic cylinder manufacturing is low in overall installation precision, meanwhile, welding is not stable enough, simultaneous rotating welding cannot be achieved, meanwhile, flexible welding line adjustment cannot be achieved, the welding quality is affected, meanwhile, arc swing welding cannot be achieved, and swing adjustment is not convenient and fast enough are solved.

Owner:江苏力速达液压有限公司

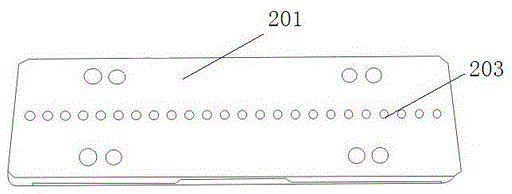

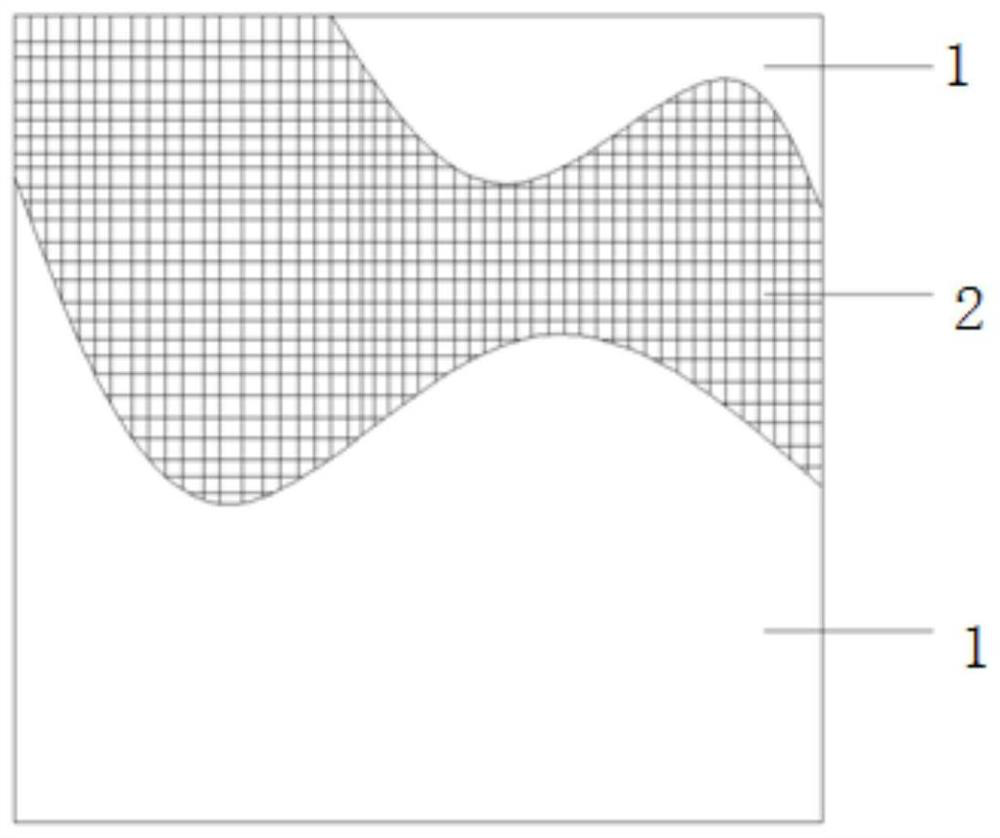

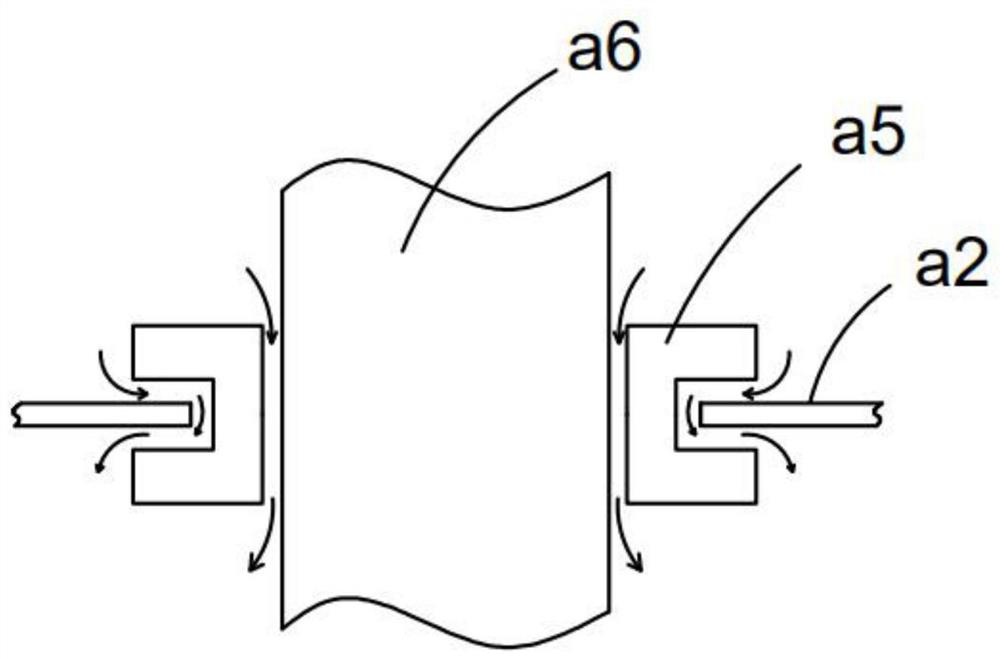

Membrane element for flat membrane bioreactor and flat membrane bioreactor

ActiveCN112456637BReduce thicknessSmall filter resistanceSustainable biological treatmentBiological water/sewage treatmentThermodynamicsFiltration

The invention discloses a membrane element for a flat membrane bioreactor and a flat membrane bioreactor. The membrane element comprises: a first filter membrane layer, a mesh layer and a second filter membrane layer; a first filter membrane layer, a mesh layer The grid layer and the second filter membrane layer are stacked in sequence and sealed at the edges to form an inner membrane cavity between the first filter membrane layer and the grid layer, and between the grid layer and the second filter membrane layer; There is a water outlet at the center and a fixed structure at the top edge. The invention can reduce the filtration resistance, enhance the filtration capacity, reduce the pollution of the mud cake layer on the membrane surface, reduce the manufacturing cost and increase the packing density.

Owner:BEIJING DRAINAGE GRP CO LTD

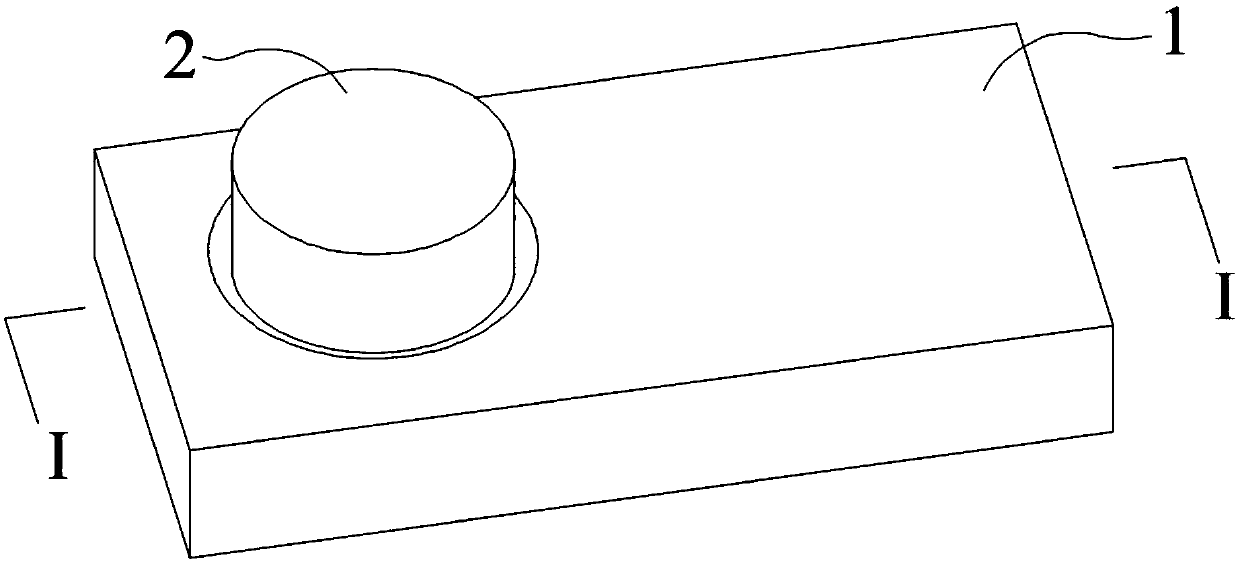

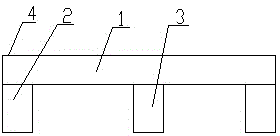

High-load-bearing cheese supporting plate

InactiveCN104129549AImprove welding firmnessIncreased load-bearing capacityRigid containersEngineeringHigh load

The invention provides a high-load-bearing cheese supporting plate which comprises a plurality of transverse plates, two side base plates and a middle base plate located between the two side base plates. The transverse plates are evenly arranged above the side base plates and the middle base plate, the transverse plates, the side base plates and the middle base plate are made of metal materials, covering plates are arranged on the outer sides of the upper ends of the side base plates, an inner cavity for the transverse plates to the placed is formed between the covering plates and the side base plates, and the transverse plate are respectively welded and fixed to the inner cavity and the middle base plate. By adoption of the transverse plates and the base plates which are made of the metal materials and fixed through welding, a fixing mode is reliable and firm, and the bearing capacity of the supporting plate can be effectively improved. The covering plates are arranged on the side base plates, the transverse plates are welded on the side base plate in an excess mode, accordingly the welding firmness of the transverse plates and the base plates is improved, the overall bearing capacity of the supporting plate is improved, and the supporting plate is prevented from being damaged when bearing large weight, is good in bearing capacity and can bear a ton of cheeses and will not be damaged.

Owner:WUHU FUCHUN DYEING & WEAVING

a welding process

The invention discloses a welding technology. The welding technology comprises the welding steps that 1, cutting is carried out, particularly, a joint of connection pipes is obliquely cut, oblique cutting at different angles is carried out according to different pipe specifications, a grinding machine is adopted at a cut position for grinding treatment, and the outer surface is made in a smooth state; 2, corner pressing is carried out; 3, welding is carried out; 4, polishing treatment is carried out; and 6, welding joint appearance examination is carried out on welded pipe bodies, and follow-up paint spraying appearance treatment is carried out. The spliced position is in smooth transition, no sharp corner structure is formed, therefore, personnel safety is ensured, the appearance is moreattractive, two combining ways are adopted for welding, welding firmness is better, the production efficiency is improved, the production cost is reduced, the mechanical strength of a steel pipe welding joint is improved, follow-up polishing treatment work is reduced, and the yield is improved.

Owner:WUXI TIANLI BOILER EQUIP MFG

Boiler body welding method of thin metal gravity type heat pipe boiler

ActiveCN113134711AImprove securityImprove welding efficiencyArc welding apparatusThin metalWater leakage

The invention provides a boiler body welding method of a thin metal gravity type heat pipe boiler. The boiler body welding method comprises the following steps that S1, carrying and cutting are conducted; S2, a boiler body barrel is machined; S3, a splicing bottom plate is machined; S4, the boiler body barrel is welded; S5, the splicing bottom plate is welded; S6, the splicing bottom plate and an inner partition plate are welded; and S8, final assembly welding is conducted. According to the boiler body barrel and the splicing bottom plate, a 90-degree welding folded edge I and a 90-degree welding folded edge II are bent for end welding, overheating deformation in the welding process is prevented, assembly of all components is prevented from being affected, welding can be conducted through an automatic welding machine, the welding efficiency and quality are improved, the labor cost is reduced, welding firmness is good, and safety is high. During welding, water is injected into a water disc, so that overheating deformation caused by too high welding temperature is further prevented. A gravity type heat pipe hole wraps a gasket piece through a gasket piece sleeve, the thickness of the gravity type heat pipe hole is increased, a thick sealing ring can be adopted, the contact area is increased, and water leakage is not prone to occurring.

Owner:永安市方热锅炉设备有限公司

An Outer Edge Welding Device for Hydraulic Cylinder Manufacturing

ActiveCN114589439BWeld firmlyLow costWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention provides an outer edge welding device for hydraulic cylinder manufacturing, which relates to the technical field of hydraulic cylinder welding and includes an installation support part; two sliding adjustment parts are installed on the installation support part; The structure is the same; a movable jamming device is slidably connected to the installation support part; an elastic positioning device is fixedly connected to the movable jamming device; Shape swing welding, the welding is firmer and the overall linkage is stronger, which can realize auxiliary smoke removal and cleaning work; it solves the problem that the overall installation accuracy of the outer edge welding device manufactured by the current hydraulic cylinder is low, and the welding is not stable enough to achieve simultaneous rotation welding. At the same time, it is impossible to realize flexible welding seam adjustment, which affects the welding quality. At the same time, arc swing welding cannot be realized, and swing adjustment is not convenient enough.

Owner:江苏力速达液压有限公司

An automatic laser welding arm

ActiveCN110421256BImprove uniformityAvoid crackingLaser beam welding apparatusShielding gasEngineering

The invention discloses an automatic laser welding arm, which relates to the technical field of laser welding arms. In the invention, a laser welding head is connected to a support arm by a welding oscillation mechanism, and a protective gas injection head is connected to the support arm by a swing mechanism. In this way, when the laser welding head is welding, the controller controls the welding oscillating mechanism to drive the laser welding head to reciprocate in the width direction of the weld; and the controller also controls the laser welding head to move along the The laser welding head swings in the direction of welding feed, so that the uniformity of welding can be improved. Even if the weld is large, it can effectively make all the positions of the weld be heated evenly, and the uniformity of thermal fusion can be improved. Ensure the reliability and stability of welding, improve the uniformity of welding, solve the problem of overheating and melting at the center of the welding head only to increase the welding power, and cracks are prone to appear at the joint of the weld, and improve the firmness of welding.

Owner:苏州肯美特设备集成股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com