Air cylinder and compressor

A technology of compressors and cylinders, which is applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve problems such as reduced lifespan, high power consumption, and excessive operating current of compressors, so as to reduce welding time and weld Good firmness and smooth operation of the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

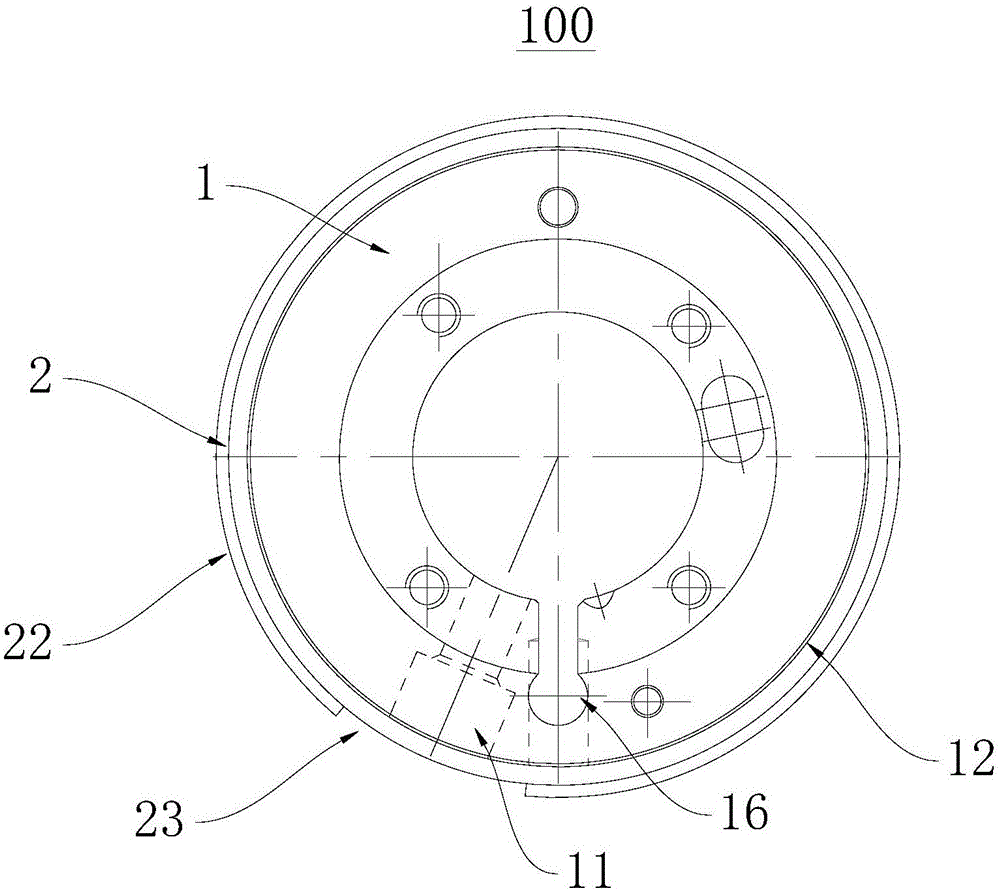

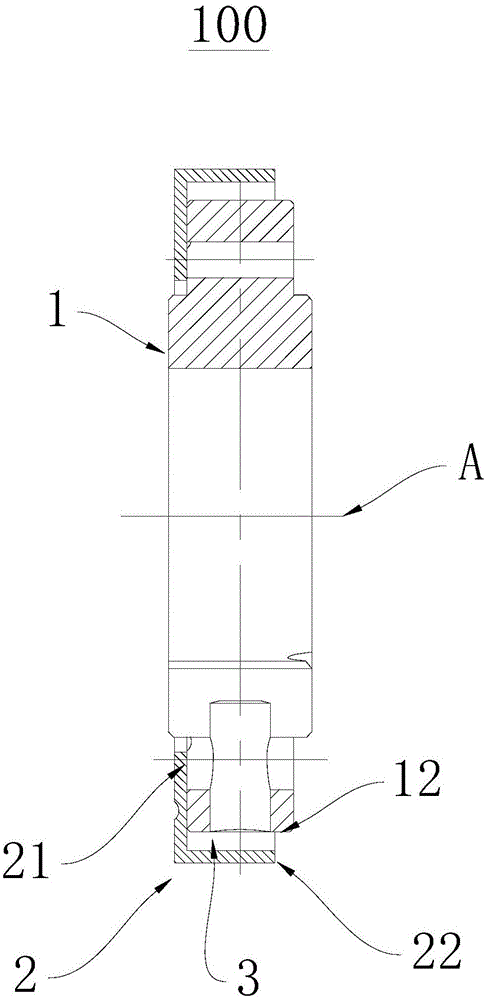

[0034] Such as figure 1 and figure 2 As shown, the cylinder 100 according to the present invention comprises a main body 1 having an inlet passage 11; a connecting mechanism 2 within which the main body 1 is at least partially located, and the connecting mechanism 2 has a The communication groove 23 in which the inlet passage 11 communicates with the pump suction pipe 41 .

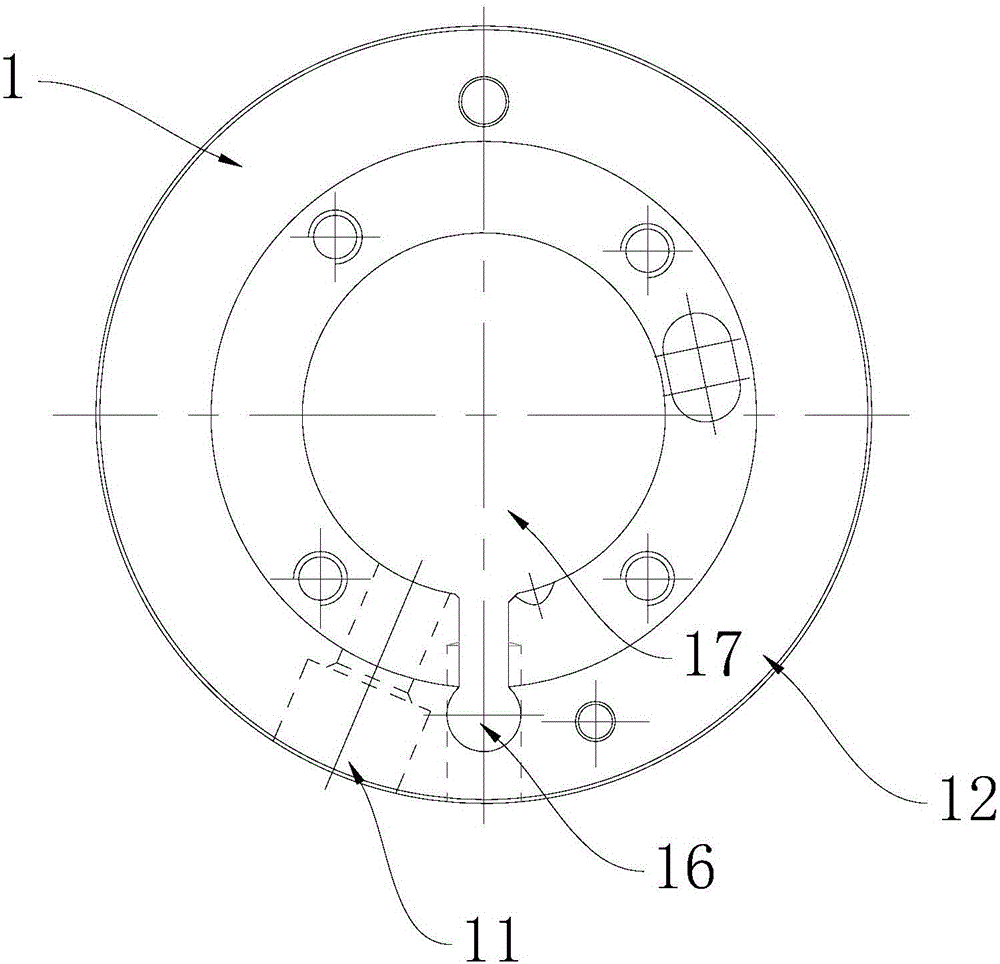

[0035] Such as image 3 and Figure 4 As shown, the main body 1 is generally in the shape of a ring. The main body 1 is formed with an inlet passage 11 communicating with the pump suction pipe 41 of the housing 4 , an outlet passage and a slide groove 16 for installing the slide. The main body 1 extends along its axial direction A, and along the axial direction A has opposite first and second ends 13 and 14 . The main body 1 also has a cavity 17 penetrating in its axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com