Ceramic cigarette lighter used for battery lighter and manufacturing method of ceramic cigarette lighter

A manufacturing method and technology for a cigarette lighter, which are applied in the directions of combustion method, combustion ignition, incandescent ignition, etc., can solve the problems of unreliable use, uncompact structure, pollute the environment, etc., and achieve good welding firmness, compact structure, and metal reduction. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

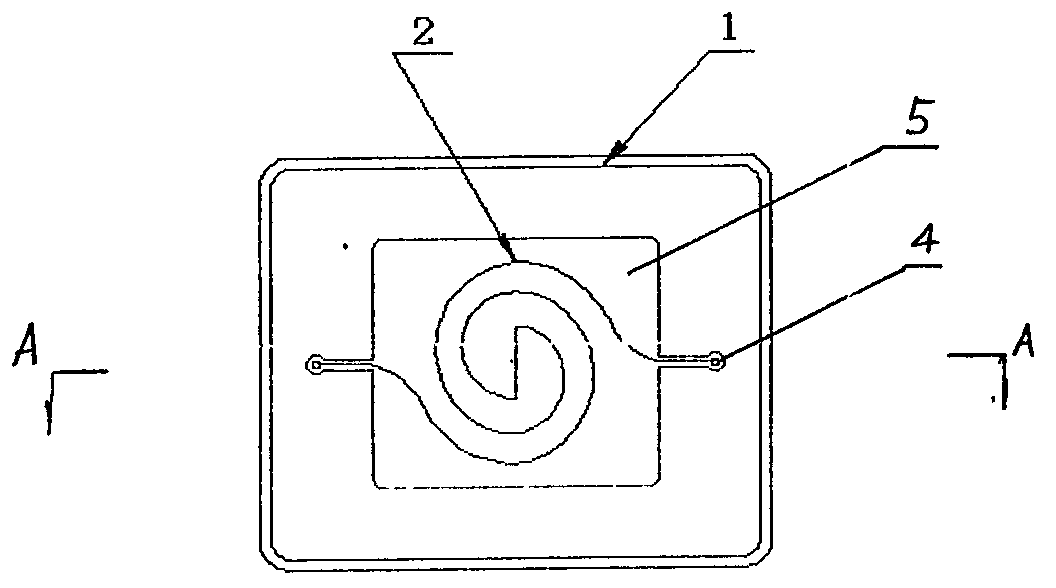

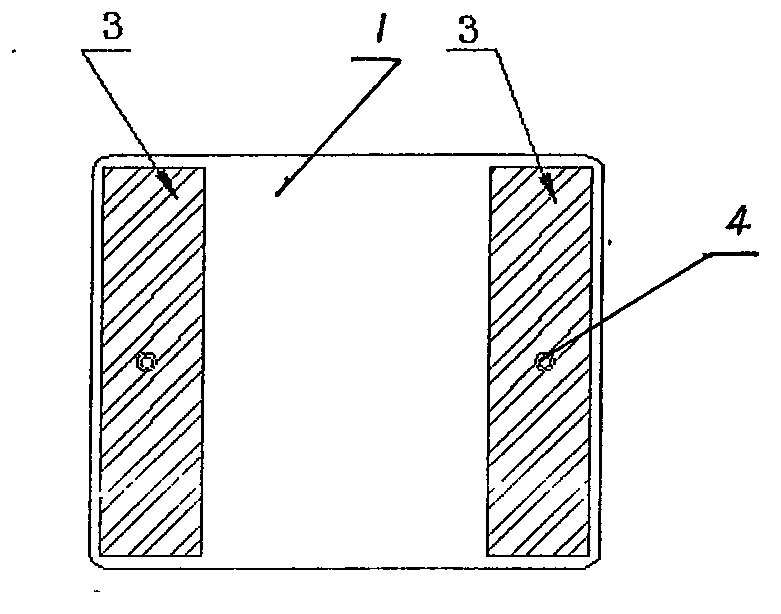

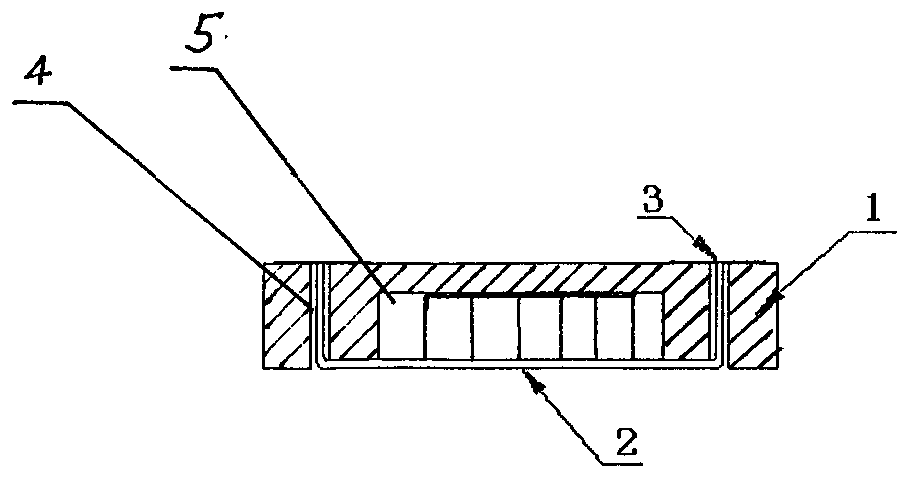

[0015] As shown in the figure, a cigarette lighter ceramic body (1) with a concave cavity (5) is made of ceramic material by molding, and it is on the inner plate of the concave cavity (5) of the cigarette lighter ceramic body (1) A spiral resistance heating wire (2), two metalized paste coatings are printed on the back of the cigarette lighter ceramic body (1) as a conductive metal layer (3), and the resistance heating wire passes through the cigarette lighter ceramic body ( 1) The small holes (4) on both sides are in contact with the conductive metal layer (3), the two ends of the resistance heating wire (3) are coated with silver paste, and the assembled semi-finished products are placed in the metalization furnace for metalization and simultaneous welding That's it. The metalized paste used for the conductive metal layer (3) is silver paste, and the concave cavity (5) on the ceramic body (1) of the cigarette lighter is one of square, round and oval.

[0016] The production s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com