Rotary friction welding method

A spin welding and welding surface technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of inconsistent welding effect on the contact surface, and achieve the effect of enhancing the welding firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

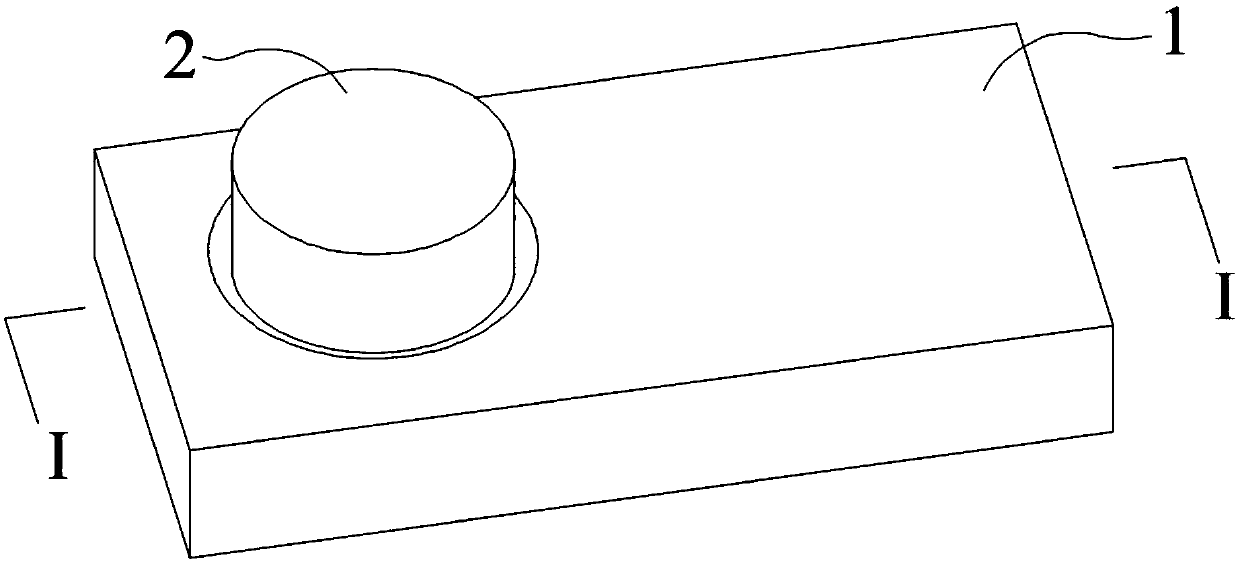

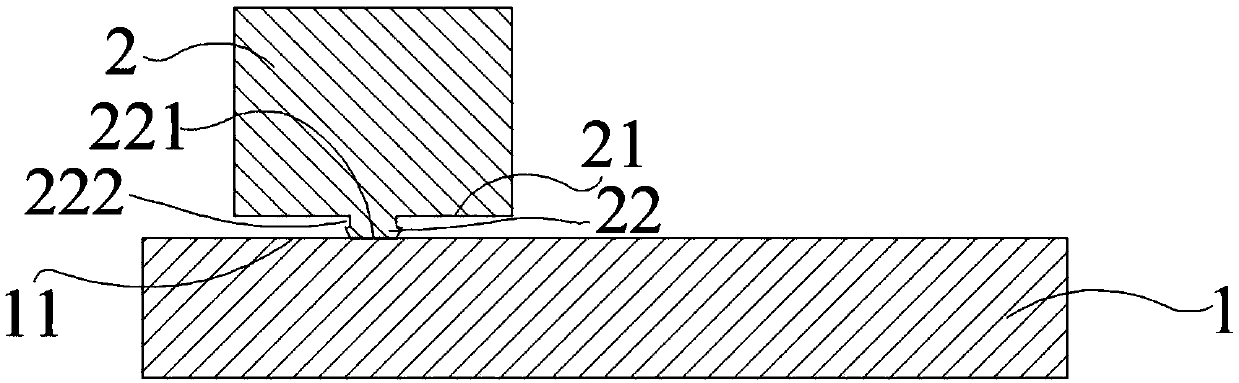

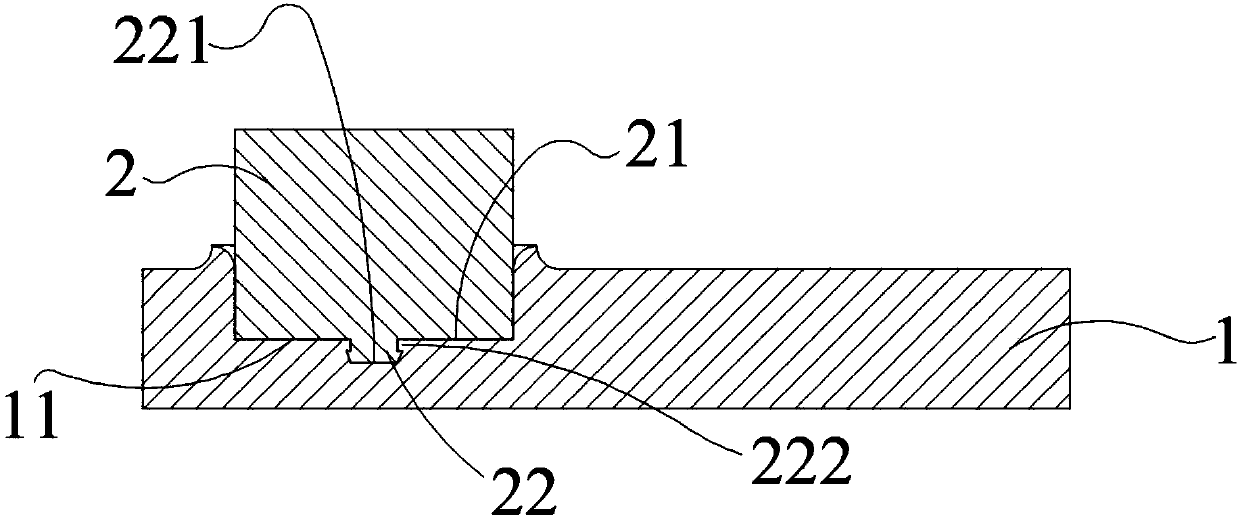

[0012] A rotary friction welding method, the main process of which is: providing a first workpiece 1 and a second workpiece 2, the first workpiece 1 is made of aluminum material, and the second workpiece 2 is a cylindrical copper material; the first workpiece is contacted The surface 11 is processed as a plane; the second workpiece bottom surface 21 is arranged with a step column 22, and the step column 22 has a groove 222 near the second workpiece bottom surface 21, and the step column 22 has a step column bottom surface parallel to the first workpiece welding surface 11 221; the first workpiece 1 and the second workpiece 2 are fixed; the second workpiece 2 is rotated so that the welding surface 11 of the first workpiece is in contact with the bottom surface 221 of the step column, so that the bottom surface 221 of the step column and the welding surface 11 of the first workpiece are frictionally heated, And apply pressure to squeeze the first workpiece 1 and the second workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com