Splicing spot welding type battery nickel sheet and spot welding process thereof

A technology of splicing points and nickel sheets, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of inability to adjust the angle between welded nickel sheets, high requirements for placement restrictions, and narrow application range. Achieve the effect of improving welding firmness, wide application range and improving use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

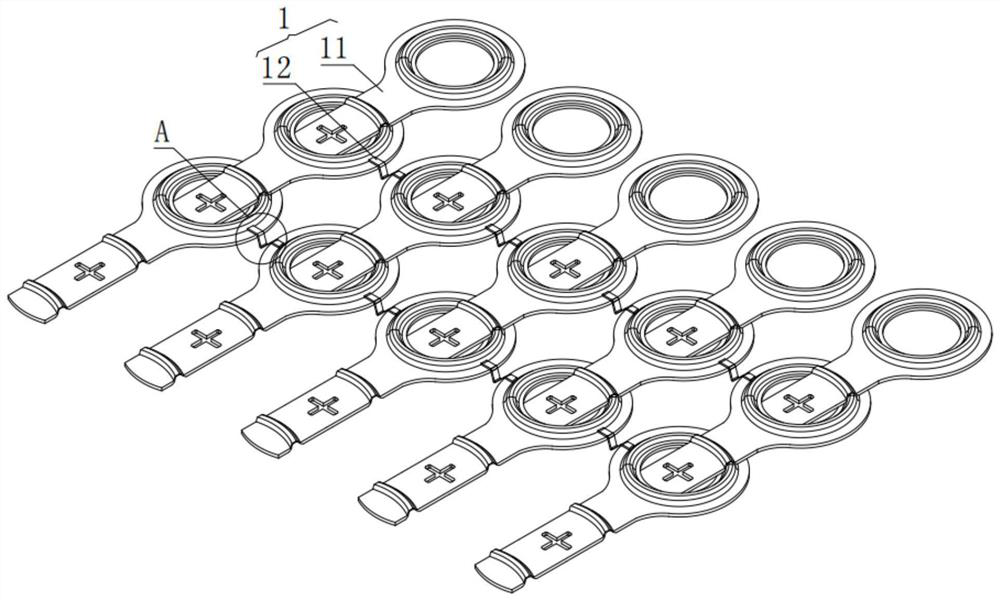

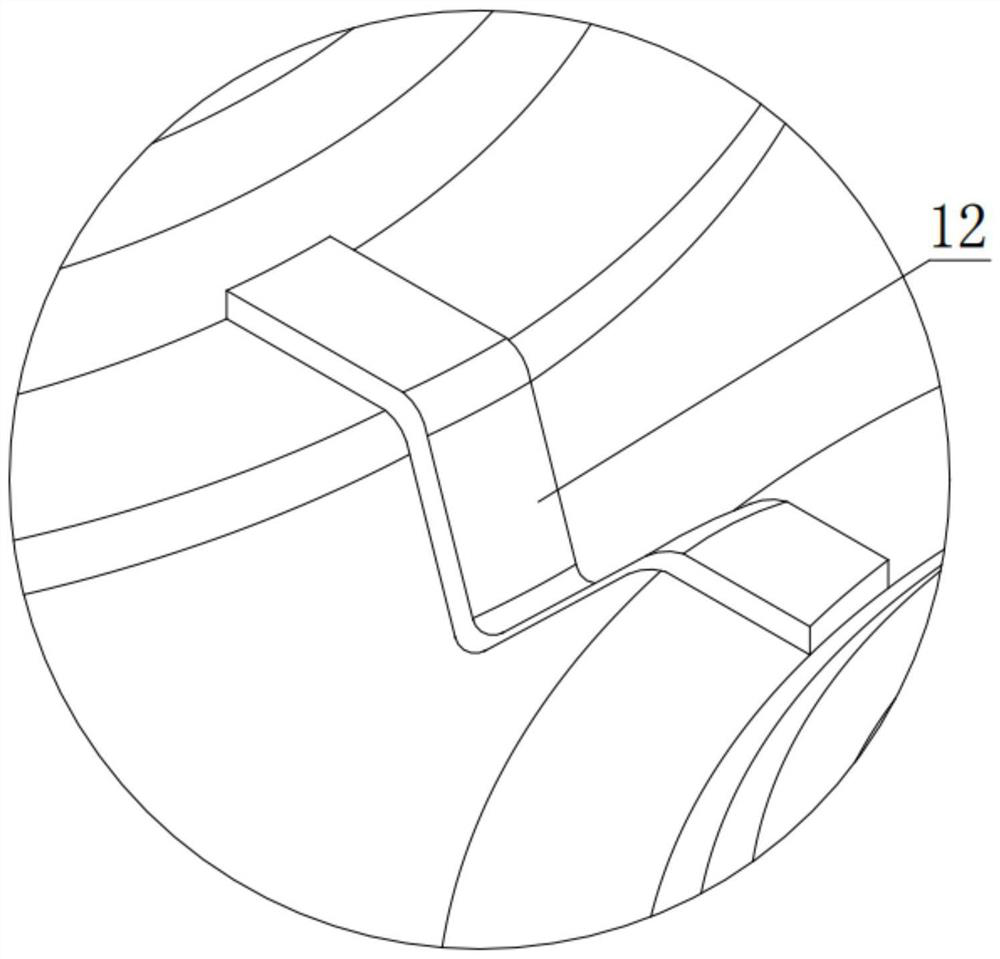

[0038] refer to Figure 1 to Figure 2 , a splicing spot welding battery nickel sheet, comprising a nickel sheet part 1, the nickel sheet part 1 includes a nickel sheet assembly 11 and a V connector 12, several nickel sheet assemblies 11 are arranged in a rectangle, wherein two nickel sheets arranged vertically The components 11 are staggeredly connected to each other, and the two nickel sheet components 11 arranged horizontally are connected to each other through the V connector 12; the two ends of the V connector 12 are respectively welded with a nickel chip component 11, and the middle part of the V connector 12 It is bent downwards, and the bent part extends downwards into the gap between the two nickel sheet components 11 .

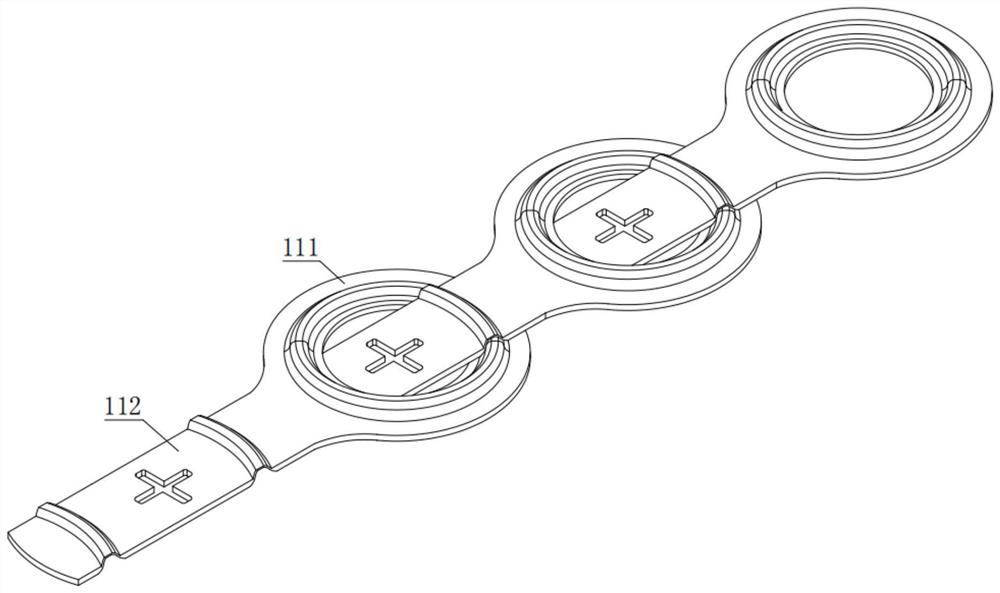

[0039] refer to Figure 3 to Figure 4, the nickel sheet assembly 11 is composed of an annular portion 111 and a handle portion 112, wherein the annular portion 111 and the handle portion 112 are integrally formed, the handle portion 112 passes throug...

Embodiment 2

[0042] The difference between this embodiment and the first embodiment is that the locking structure one 113 in this embodiment is different from the locking structure one 113 in the first embodiment;

[0043] refer to Figure 5 to Figure 6 , the first locking structure 113 is a dot-shaped structure that protrudes upwards, the second locking structure 114 is located above the dot-like structure, and the two coincide with each other, the third locking structure 115 is located below the dot-like structure, and both Snap-in connection, the top of the dot structure is provided with a welding hole 116, this design can also make the two nickel plate assemblies 11 rotate with each other.

Embodiment 3

[0045] The difference between the present embodiment and the first embodiment is only that the parallel nickel sheets 2 are added in the present embodiment;

[0046] refer to Figure 7 , the left side of the nickel sheet part 1 is provided with a parallel nickel sheet 2, and the parallel nickel sheet 2 includes a nickel sheet straight bar 21 and a cross block 22, and the nickel sheet straight bar 21 is provided with some equidistantly distributed cross blocks 22, and the cross block 22 Connected with a cross interface 118, the design of the parallel nickel sheet 2 is to reduce the number of battery connection ports, connect the batteries in series and then in parallel, and effectively use the battery as an energy storage unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com