Efficient and energy-saving automatic warehouse emergency electric goods taking device

An automated warehouse, high-efficiency and energy-saving technology, applied in the field of emergency electric pickup devices in automated warehouses, can solve the problems of complex structure and inconvenient movement, and achieve the effect of increasing safety and operation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

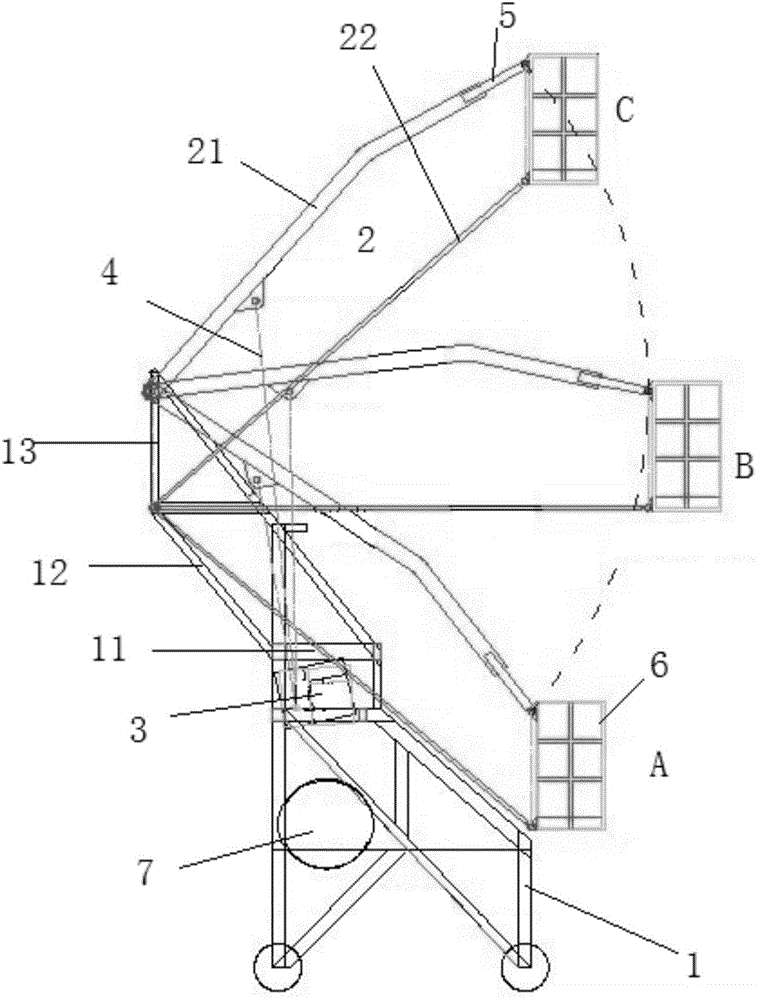

[0022] like figure 1 As shown, an efficient and energy-saving automatic warehouse emergency electric pickup device includes a trolley 1 and a boom 2 installed on the top of the trolley. The trolley 2 is provided with a motor 3, and the boom 2 includes a main The arm 21 and the auxiliary arm 22, one end of the main arm 21 and the auxiliary arm 22 are fixed on the trolley bracket, and the other end is connected with the pick-up platform of the protective fence (the main arm 21 is also provided with an electric pusher connected to the motor 3). rod 4.

[0023] The trolley 1 is provided with at least two layers of clapboards, wherein the cable winder 7 is installed on one layer of the clapboard, and the motor 3 is installed on the other layer of the clapboard. The top of the trolley 1 is provided with a bracket for installing the boom, the bracket includes a horizontal rod 11, a diagonal rod 12 and a vertical rod 13, the horizontal rod 11 is set on the trolley, and the diagonal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com