Outer box shell assembly and refrigerator

An outer box and component technology, which is applied to lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve the problems of high manufacturing requirements for molding molds, increase manufacturing costs, leakage of foam materials, etc., and achieves a simplified bottom plate structure, The effect of improving processing efficiency and simplifying step structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

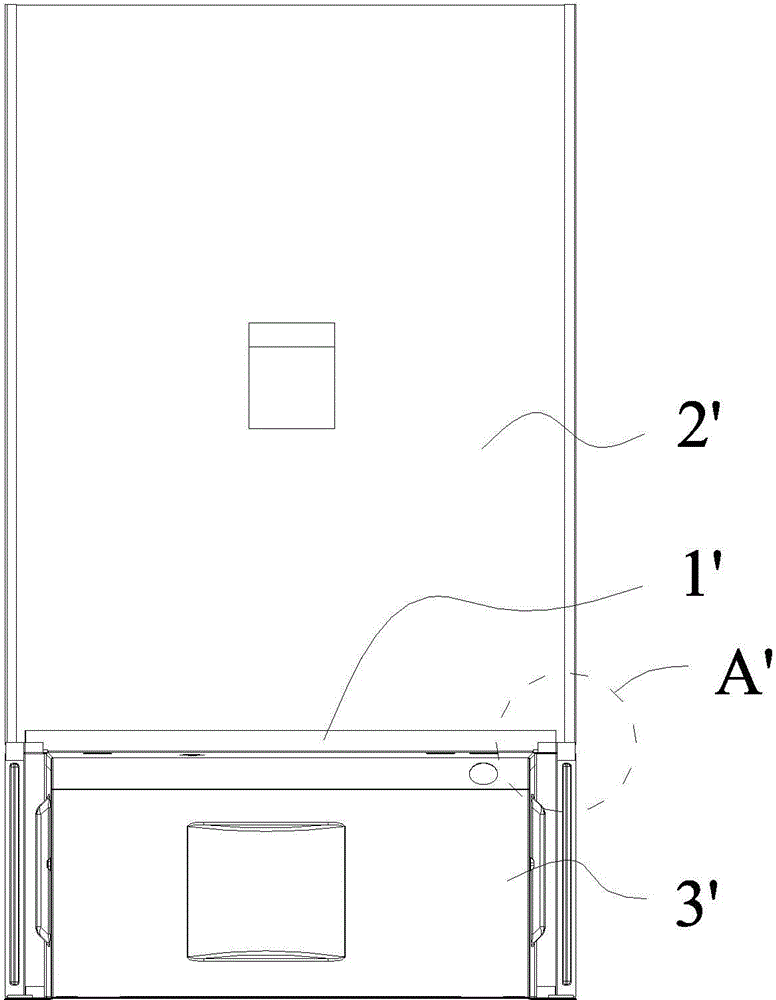

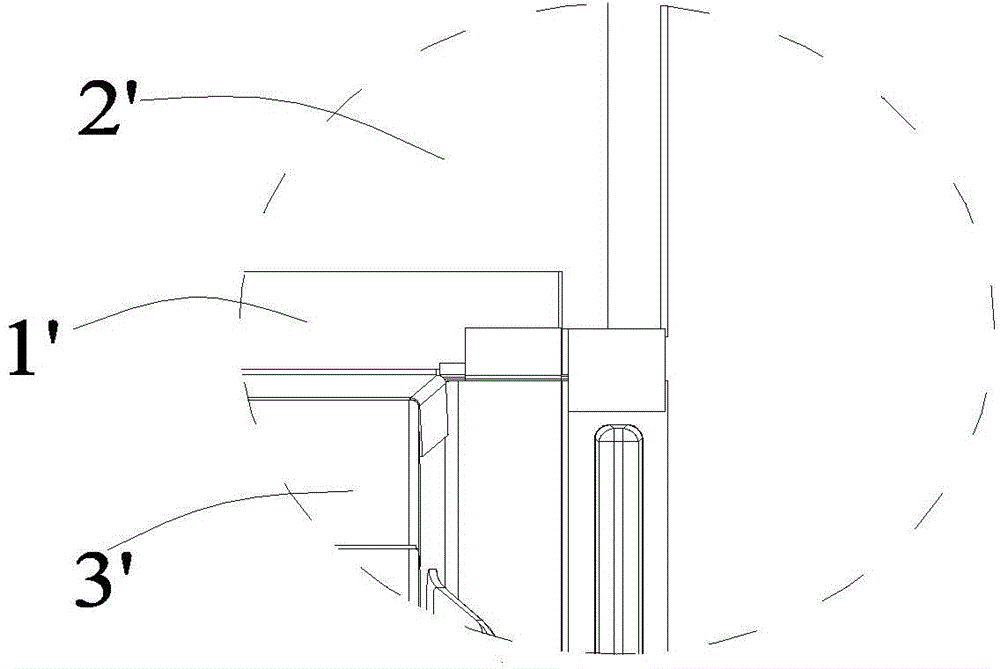

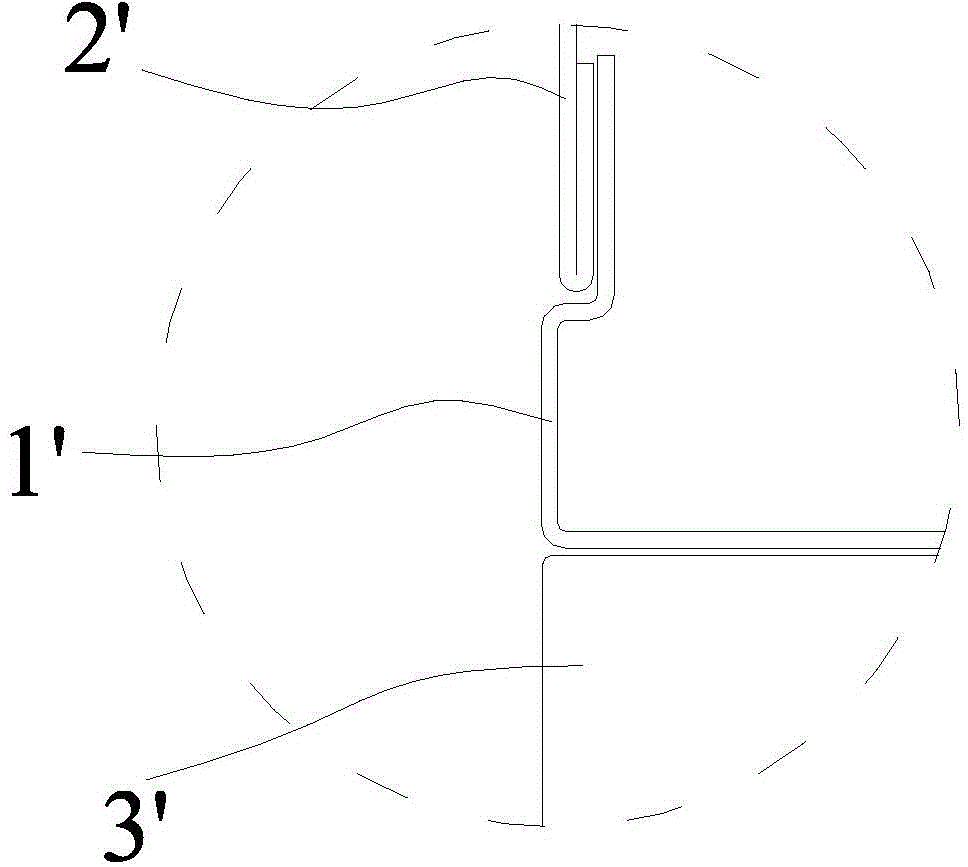

[0027] The invention provides an outer box shell assembly, such as Figure 4 to Figure 7 As shown, it includes a base plate 1 and a back plate 2. The back plate 2 includes a back plate main body 21 and a back plate flanging plate 22 connected to the bottom end of the back plate main body 21. The back plate flange plate 22 is folded toward the base plate 1 and makes The backboard 2 is an L-shaped board, and the backboard flange 22 is attached to the bottom board 1 . exist Figure 4 to Figure 7 A compressor accommodating box 3 is arranged at the rear and lower part of the middle refrigerator, and the splicing structure of the bottom plate 1 and the back plate 2 is placed on the upper surface of the compressor accommodating box 3 .

[0028] Compared with the prior art, the present invention extends downward through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com