Patents

Literature

30results about How to "Simple splicing structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

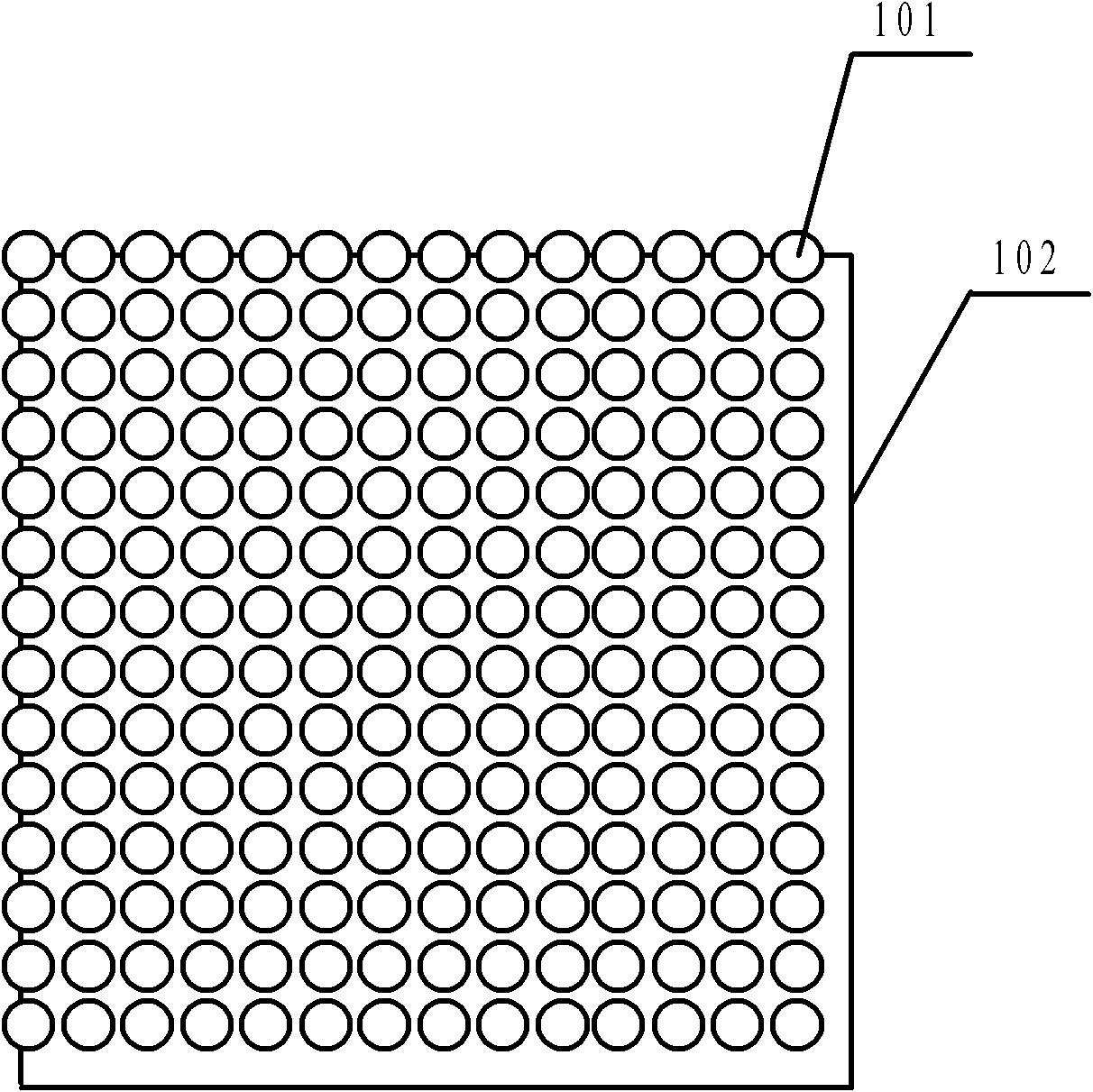

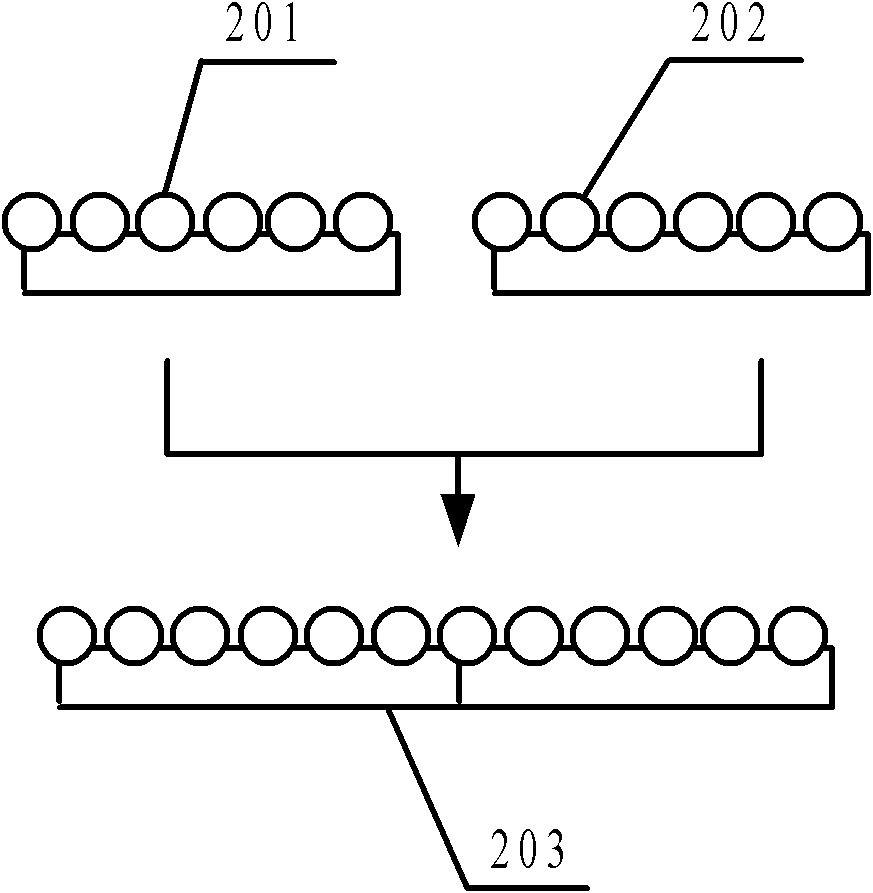

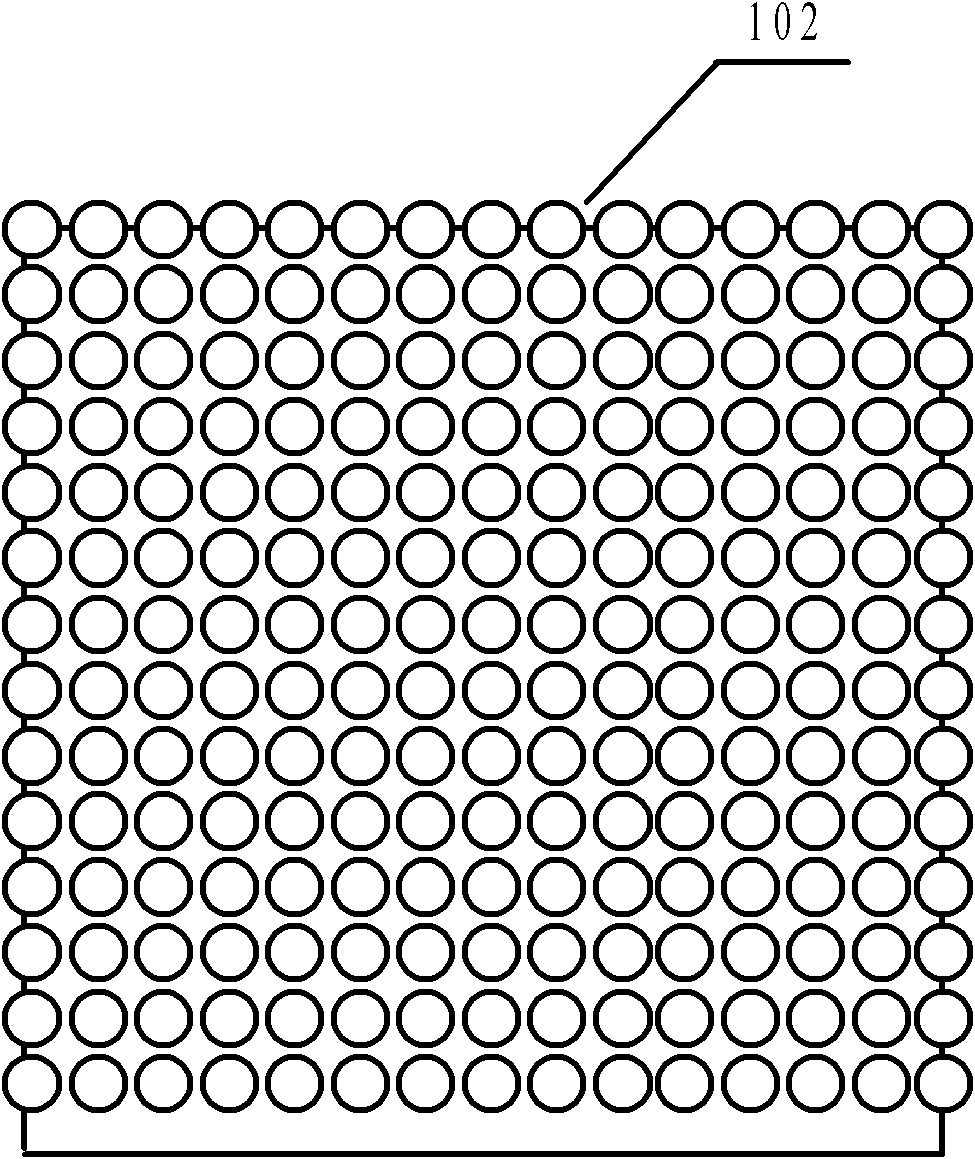

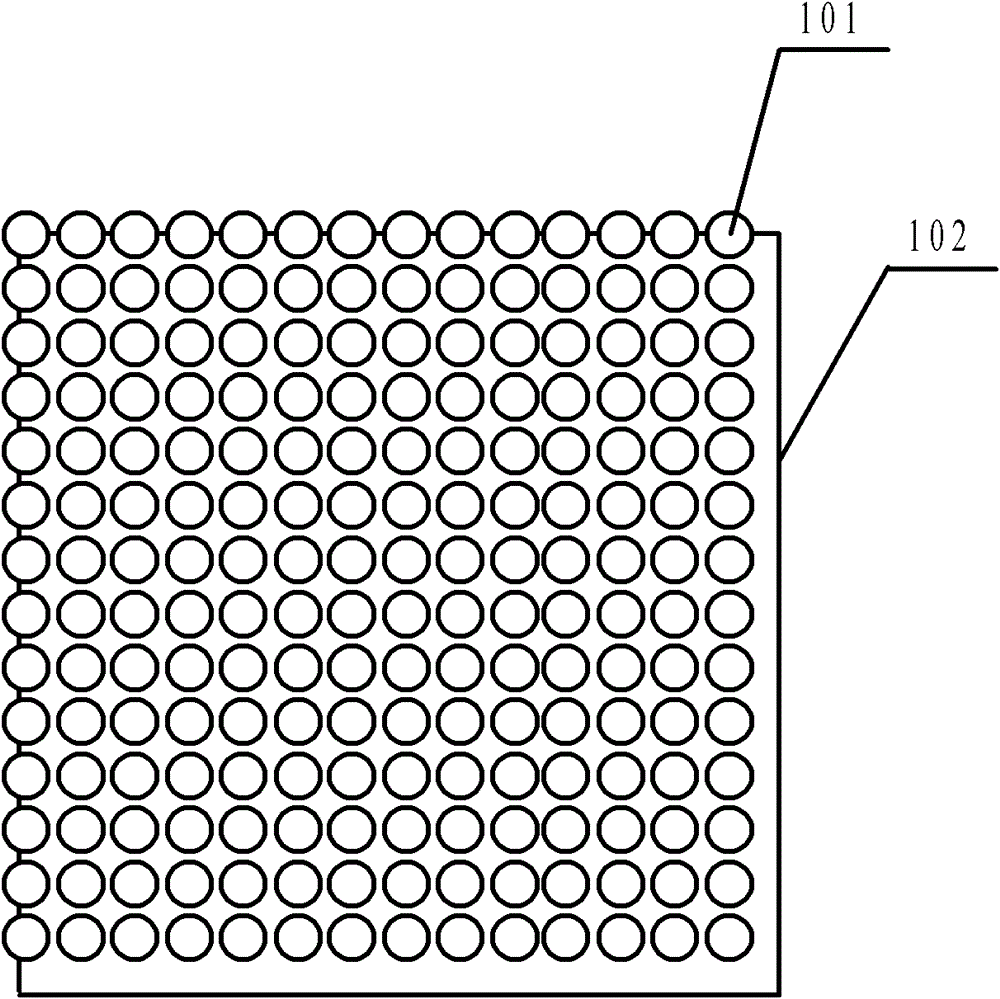

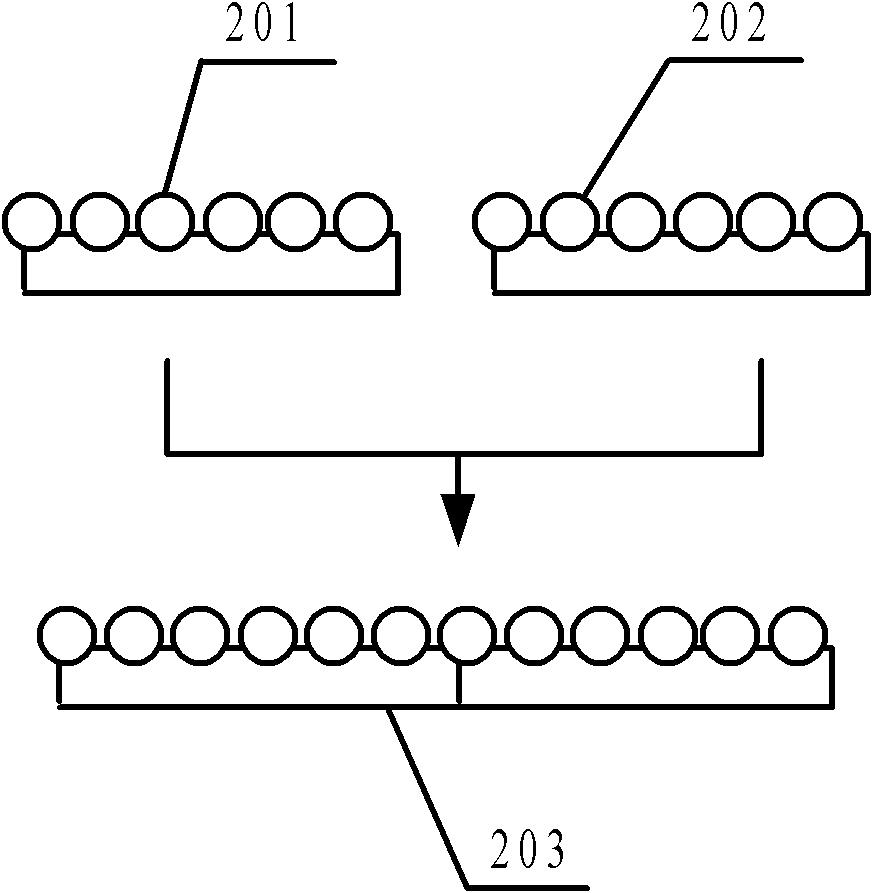

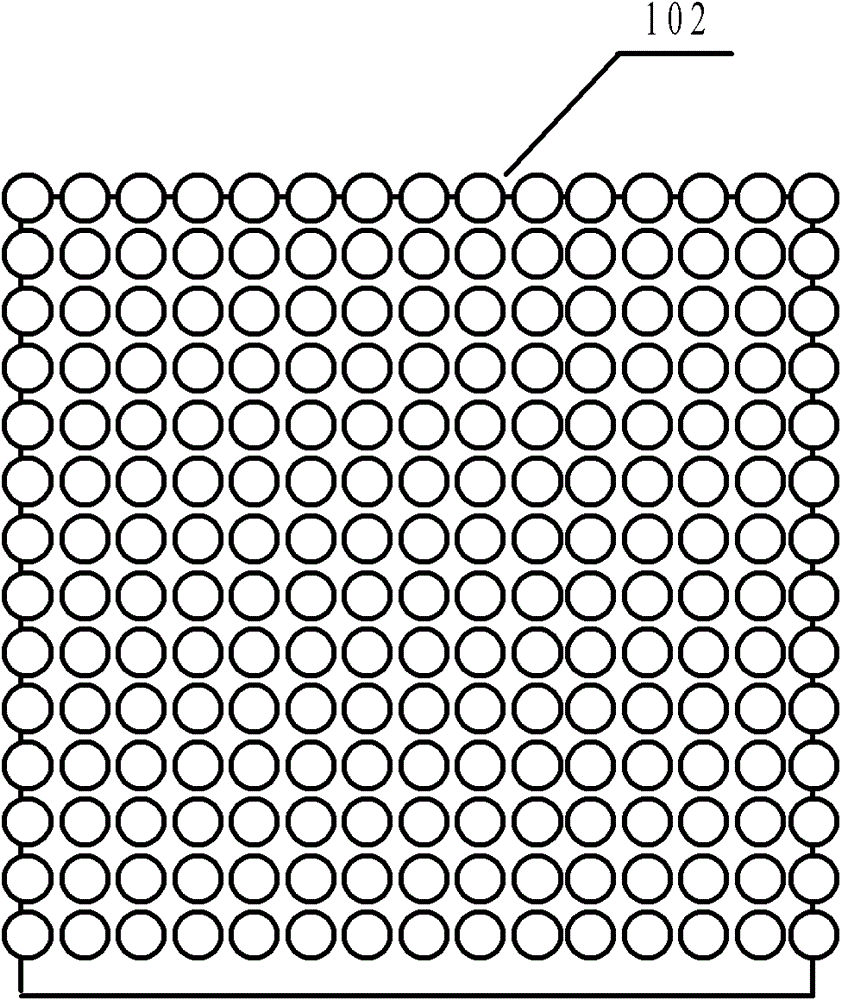

Seamlessly-spliced standard LED (light emitting diode) unit board and LED display device

ActiveCN102136228ASimple splicing structureGood splicing effectIdentification meansDot matrixLED display

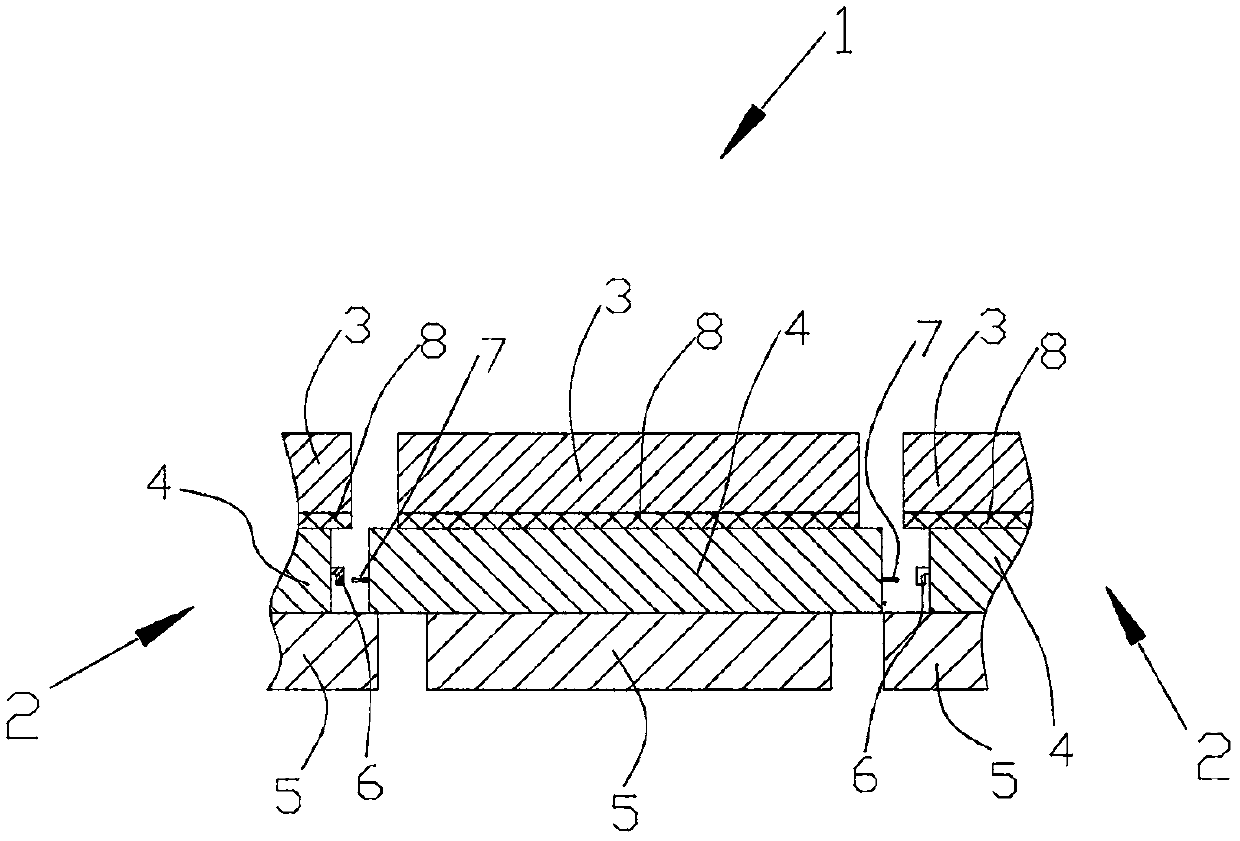

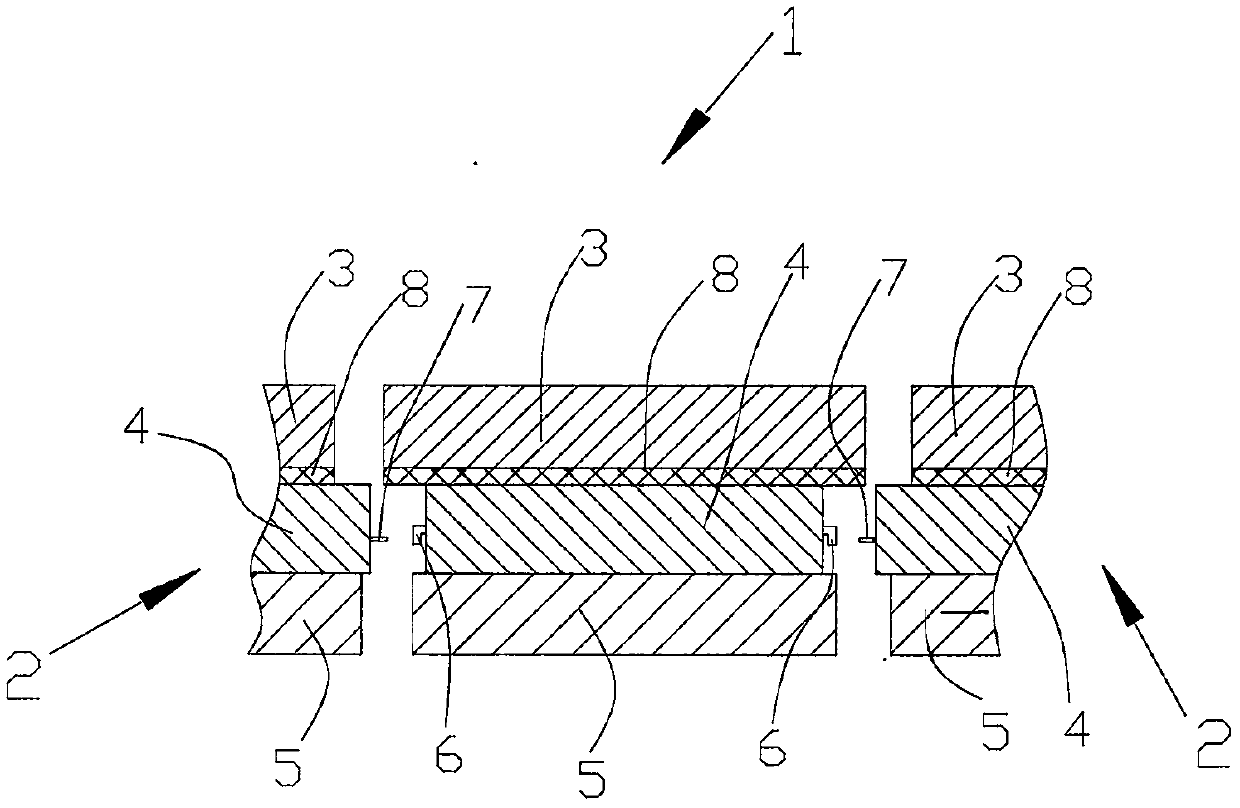

The invention discloses a seamlessly-spliced standard LED (light emitting diode) unit board and an LED display device. The standard LED unit board comprises LED pixel points arranged in the mode of dot matrix; the shape of the regular dot matrix formed by arranging each LED pixel point is similar to the shape of the standard LED unit board; the regular dot matrix and the standard LED unit board are partially coincident and are fixedly installed on the standard LED unit board; the regular dot matrix is provided with a first coincident part and at least one edge part; the standard LED unit board is also provided with a second coincident part coincident with the first coincident part; the edge part is set into a row of LED pixel points; any LED pixel point of the edge part is fixedly installed on the standard LED unit board; and parts of LED pixel points are arranged out of the standard LED unit board. The standard LED unit board has the advantages of simple splicing structure, good splicing effect and good display effect and can be spliced seamlessly and display.

Owner:徐州博创建设发展集团有限公司

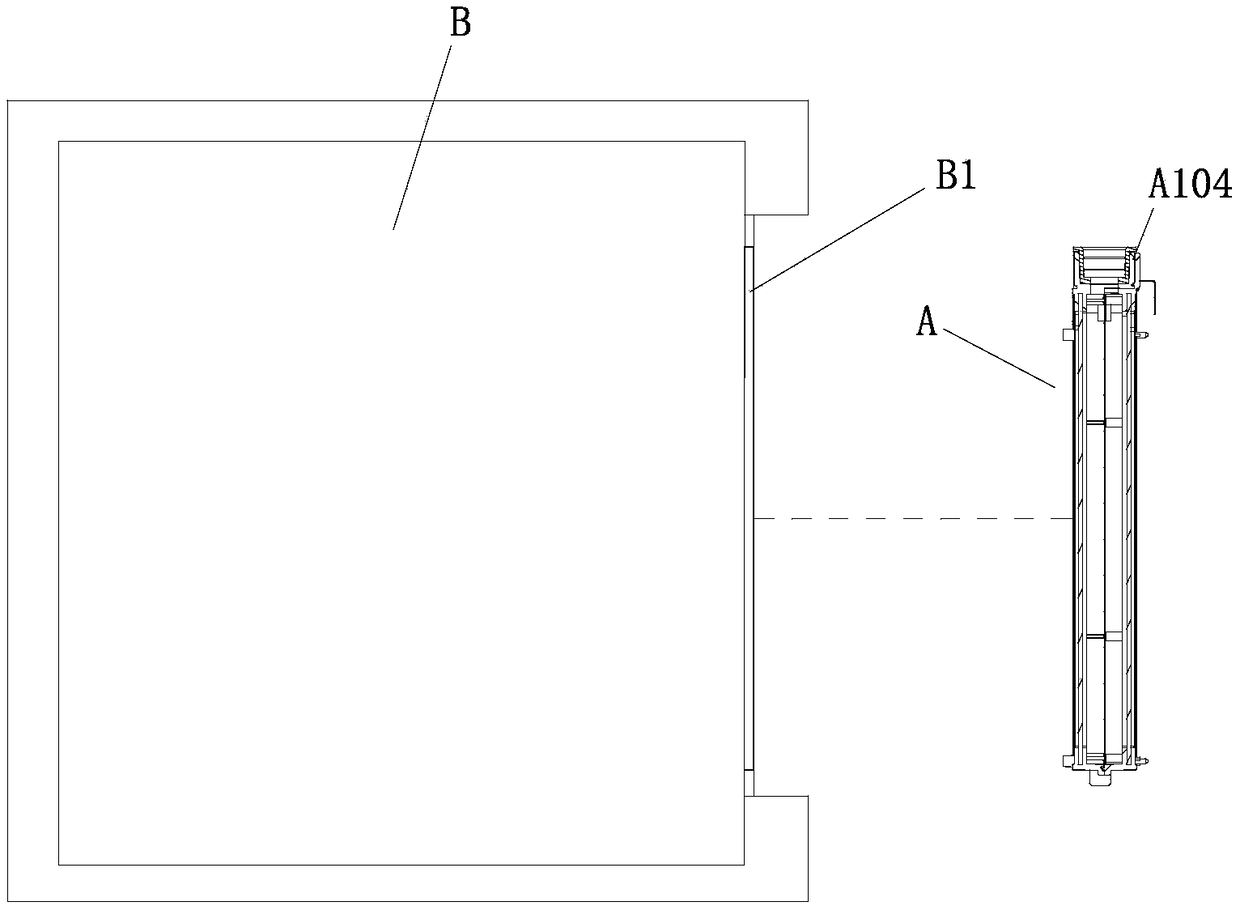

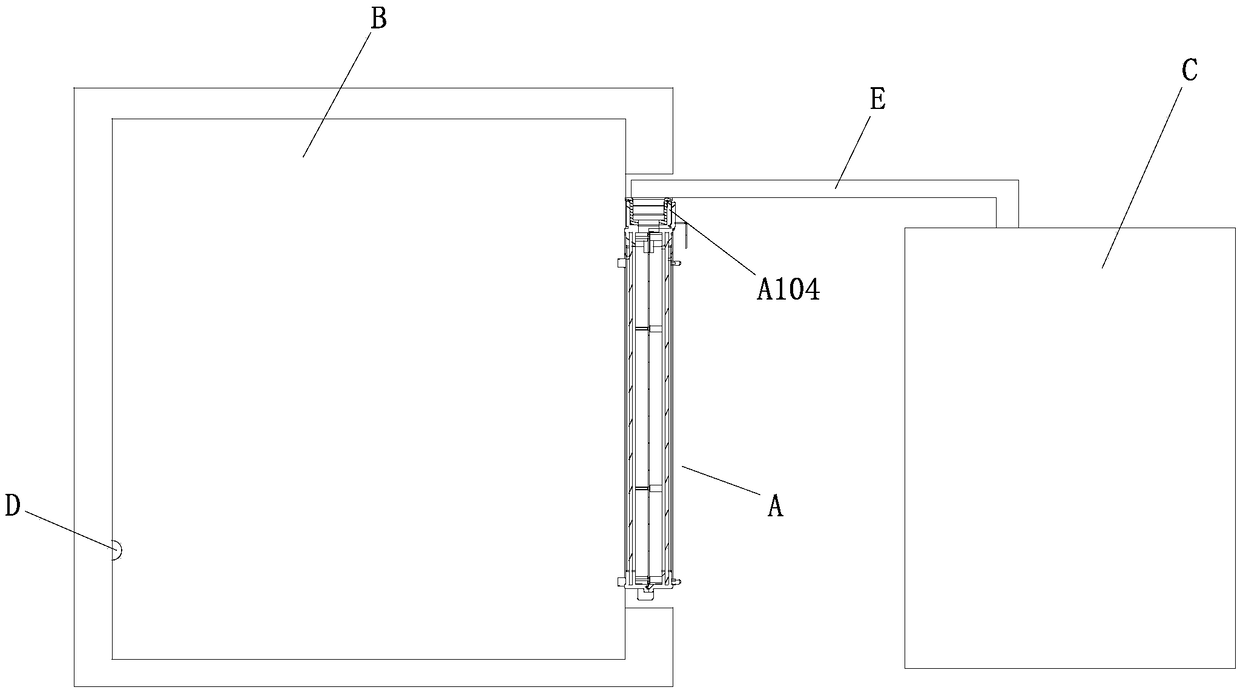

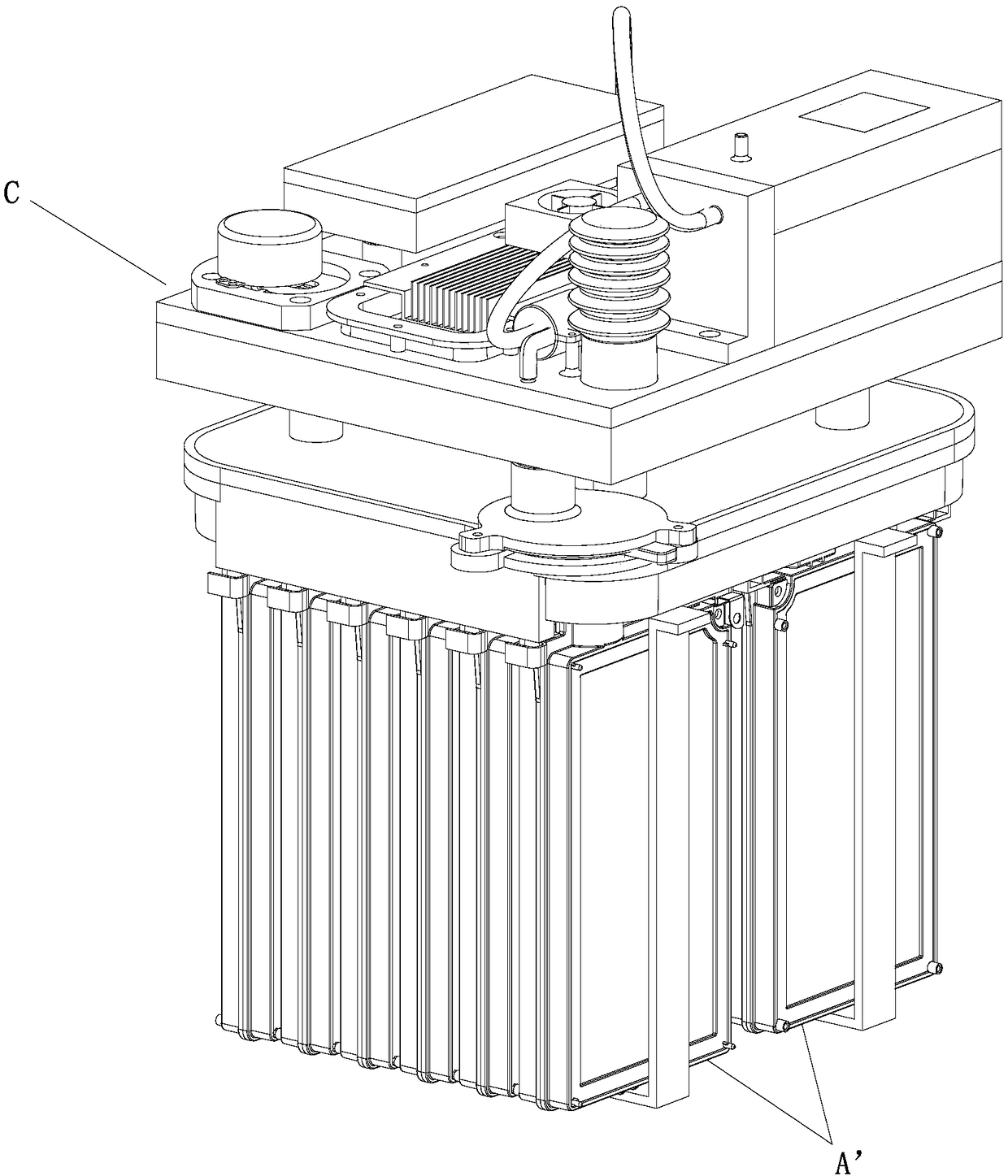

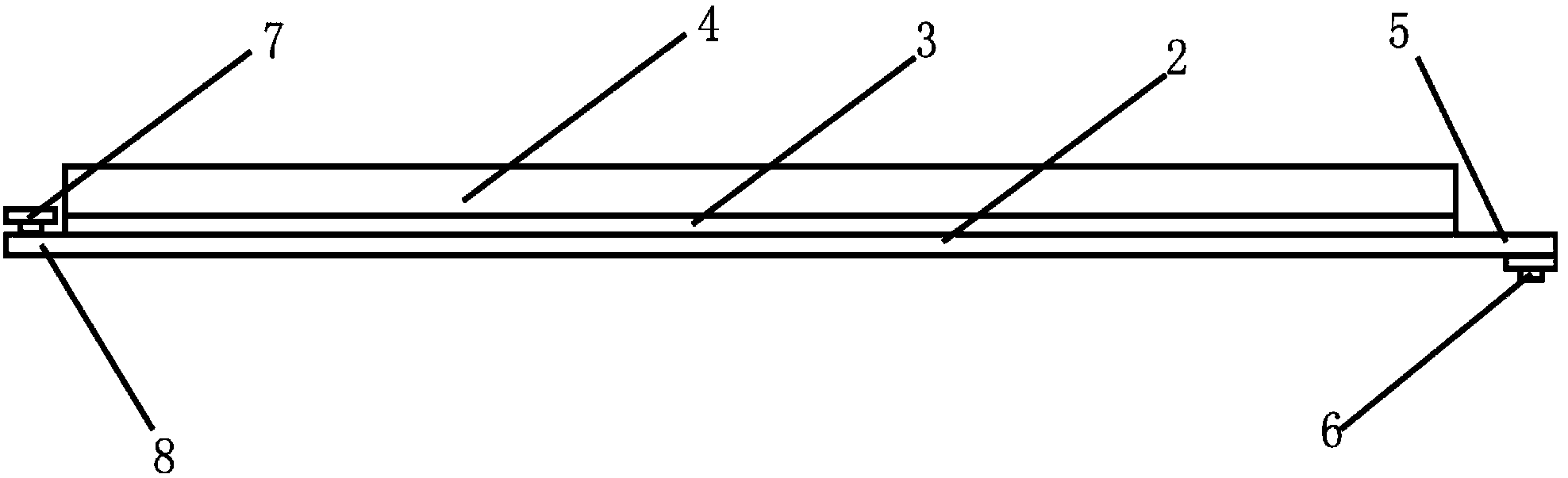

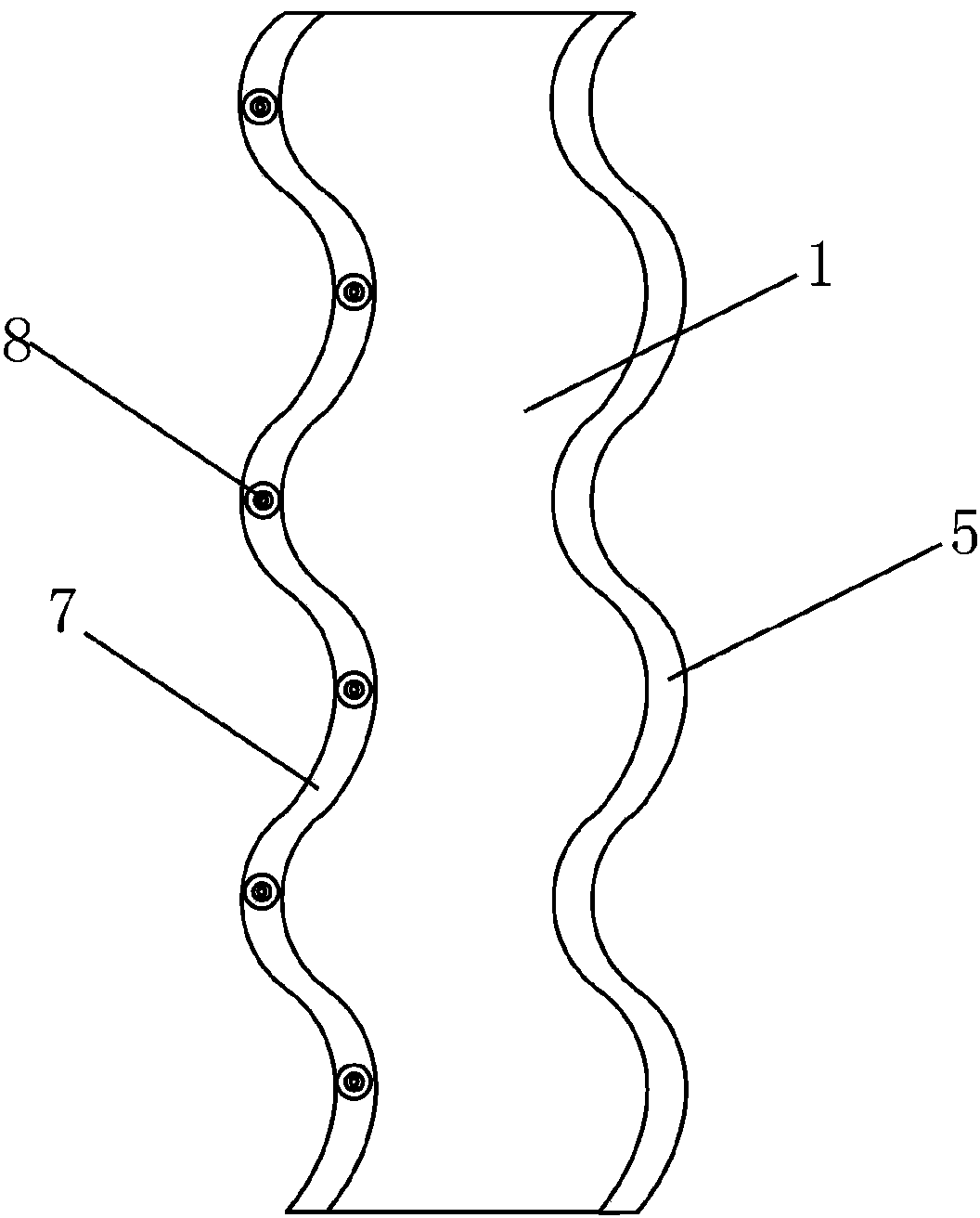

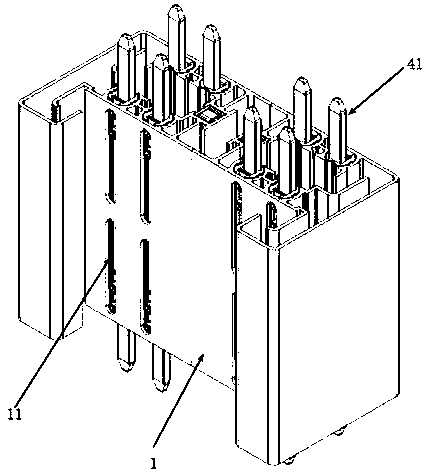

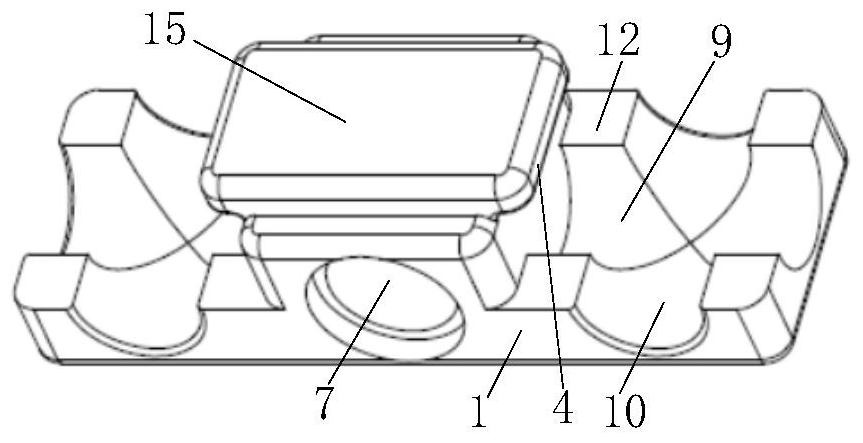

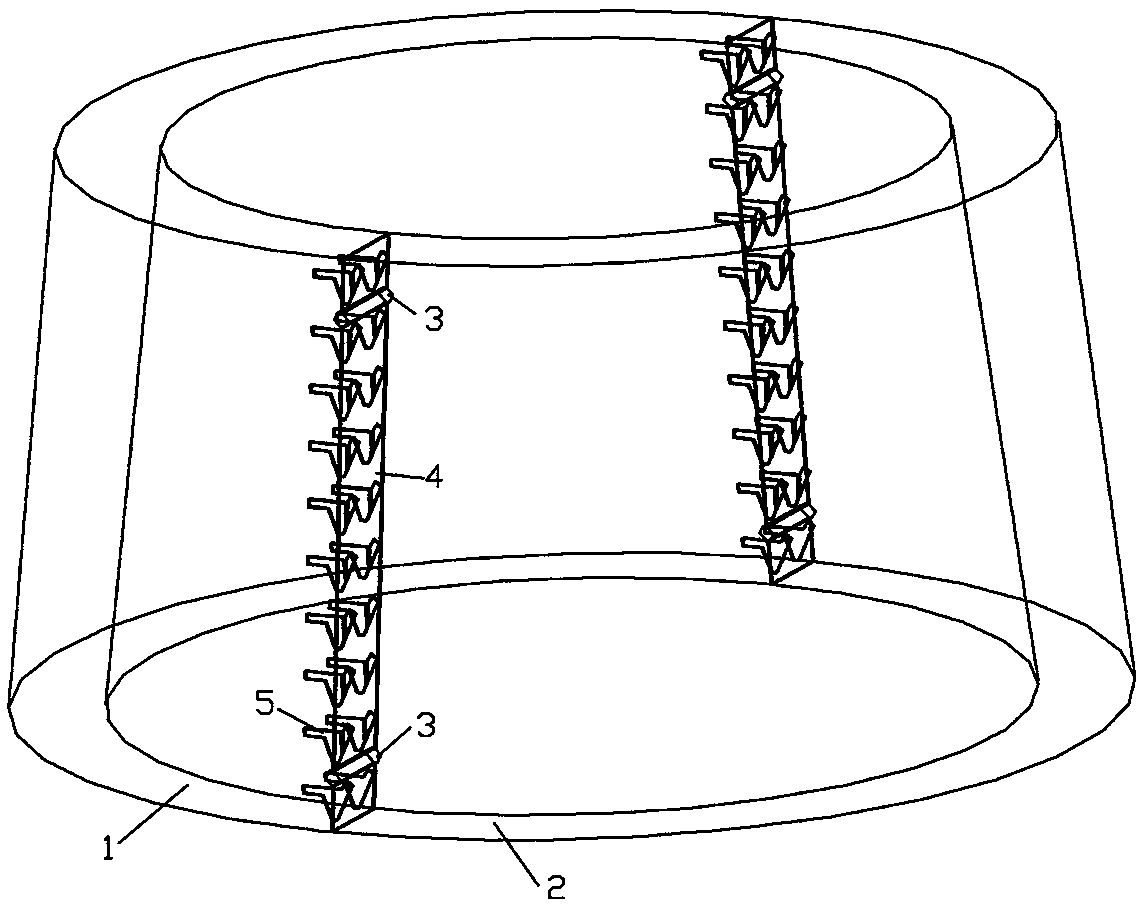

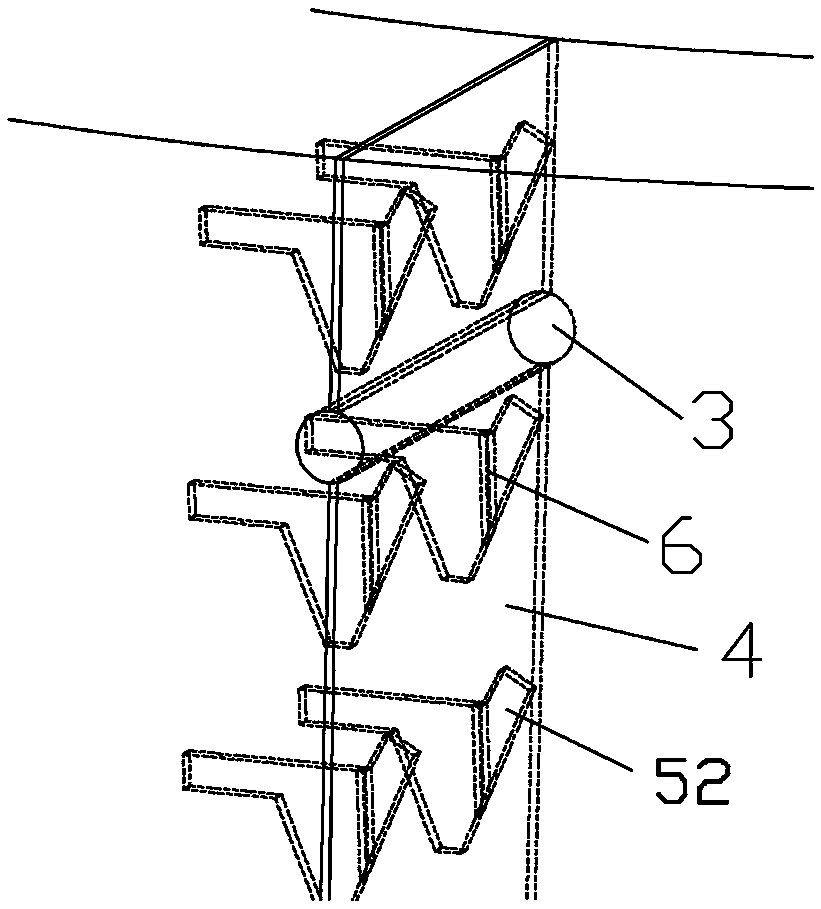

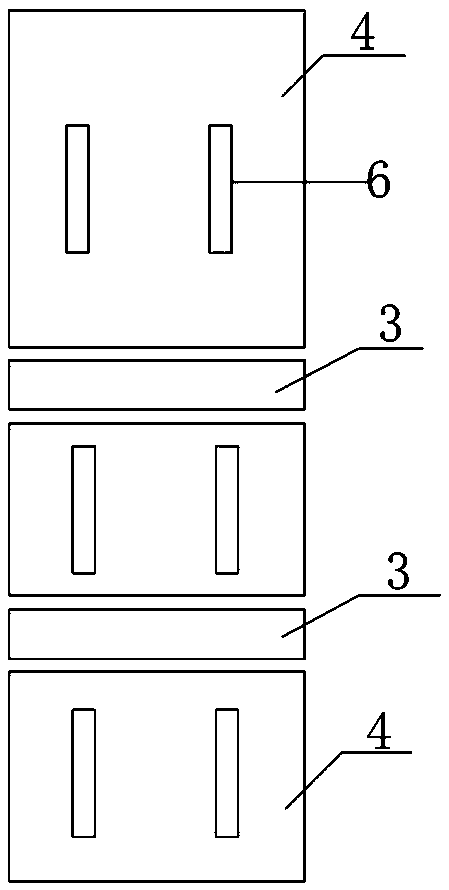

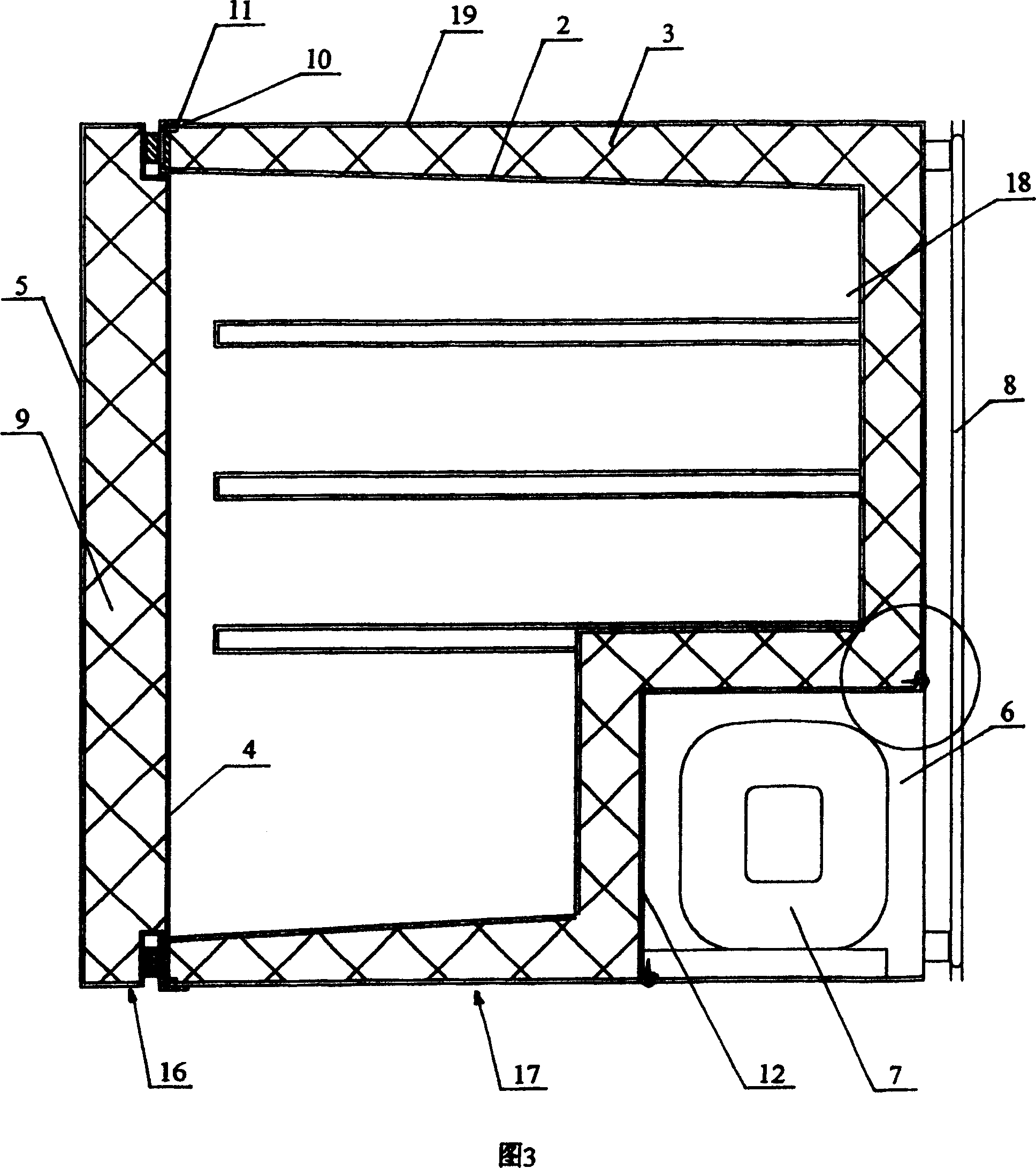

Nitrogen-self-generating storage system

PendingCN109018704AImplement a modular setupIncrease or decrease quantityPackaging under vacuum/special atmosphereShock-sensitive articlesNitrogenNitrogen gas

The invention relates to a nitrogen-self-generating storage system. The nitrogen-self-generating storage system comprises a storage space and is characterized in that the nitrogen-self-generating storage system further comprises an electronic sieve oxygen generation module; the electronic sieve oxygen generation module comprises an oxygen generation membrane and a gas outlet channel; the interiorof the storage space communicates with the oxygen generation membrane so as to adsorb oxygen in air in the storage space, and thus nitrogen in the air is left in the storage space; the electronic sieve oxygen generation module has the characteristics of adsorbing and collecting the oxygen in the air, and when being combined with any object with a storage space, the electronic sieve oxygen generation module can rapidly absorb and collect oxygen in the storage space and reserves nitrogen in the storage space for refreshment and preservation of food, valuables and the like; and the system can bewidely used for transportation and logistics, cultural relic storage, refrigerator preservation, food refreshment and quality preservation and the like.

Owner:FOSHAN SHUNDE GELINMEI ELECTRONIC PROD CO LTD

Cotton loop-pile carpet

InactiveCN104095485ASimple splicing structure and splicing processGood fixed effectFloor carpetsWoven fabricFastener

The invention belongs to the field of textiles, and particularly relates to a cotton loop-pile carpet. The cotton loop-pile carpet comprises a carpet splicing unit, wherein the carpet splicing unit comprises a base cloth layer, a bonding agent layer and a cotton loop-pile surface layer; the bonding agent layer is formed on the base cloth layer; the cotton loop-pile surface layer is fixed on the base cloth layer through the bonding agent layer. The cotton loop-pile carpet is characterized by further comprising a snap fastener, wherein the snap fastener comprises a secondary fastener and a primary fastener; the carpet splicing unit is spliced with the primary fastener through the secondary fastener. The cotton loop-pile carpet provided by the invention is simple in splicing structure and splicing process, and has a good fixing effect.

Owner:天津市宇通工艺品有限公司

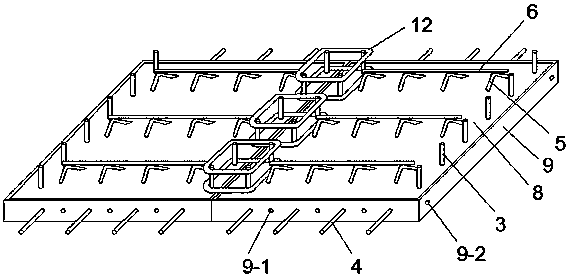

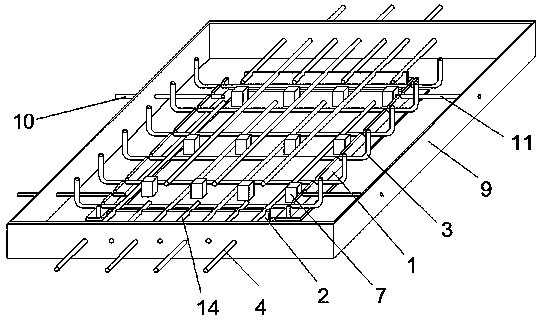

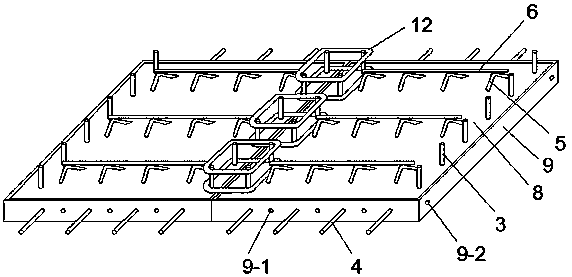

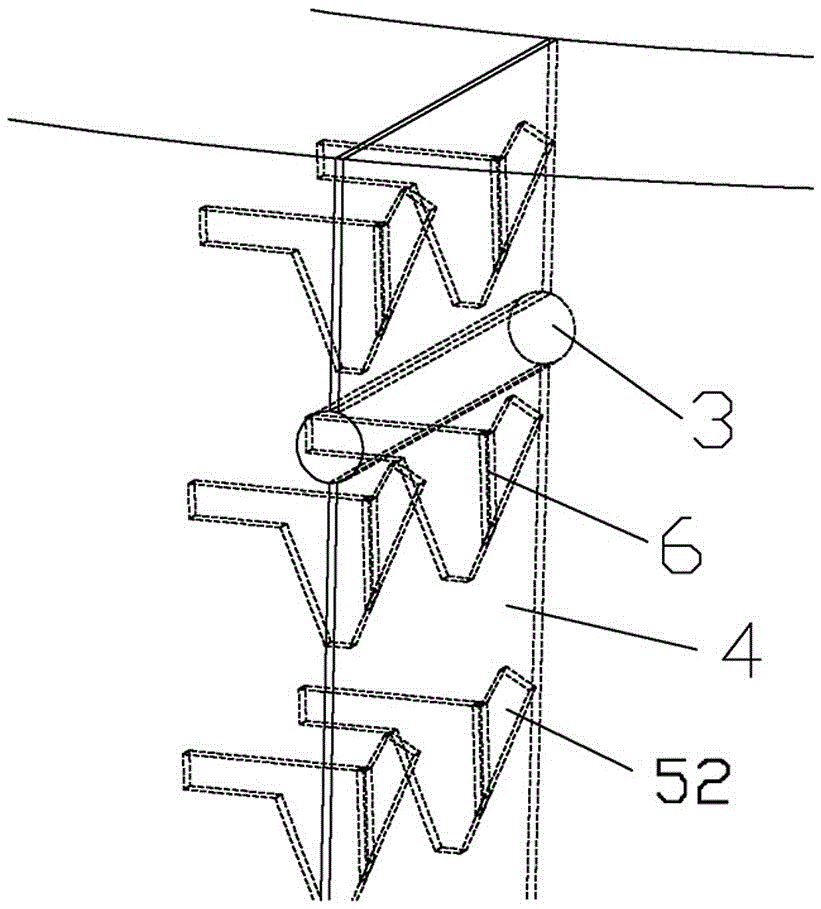

Environment-friendly concrete composite floor slab

The invention provides an environment-friendly concrete composite floor slab. The environment-friendly concrete composite floor slab is characterized in that the environment-friendly concrete composite floor slab comprises a connecting steel bar support, a bottom plate steel bar support, four connecting steel bars, a bottom plate steel bar, a tie steel bar, a top steel bar, anti-shearing keys, anouter frame, positioning steel bars, positioning pipes, stirrups and a bottom plate steel bar casing pipe; outer frame connecting holes are formed in the two ends of the outer frame, outer frame positioning holes are formed in the two sides of the outer frame, and the anti-shearing keys are arranged on the inner sides of the connecting steel bars and the bottom plate steel bar; the bottom plate steel bar and the upper sides and the lower sides of the connecting steel bars are subjected to concrete pouring to form composite floor slab concrete layers; the positioning pipes penetrate into the space between the composite floor slab concrete layers through the positioning steel bars for fixed connection; the stirrups are arranged on the outer sides of the top ends of the four connecting steelbars in an embracing mode and fixedly connected with the connecting steel bars. Distributed bars in the composite floor slab are distributed evenly, the steel bars are aligned accurately, the structure is simple, the manufacturing process is easy and convenient, manufacturing is easy, the structure strength is high, and construction and mounting are easy.

Owner:中耕耘成建筑科技(镇江)有限公司

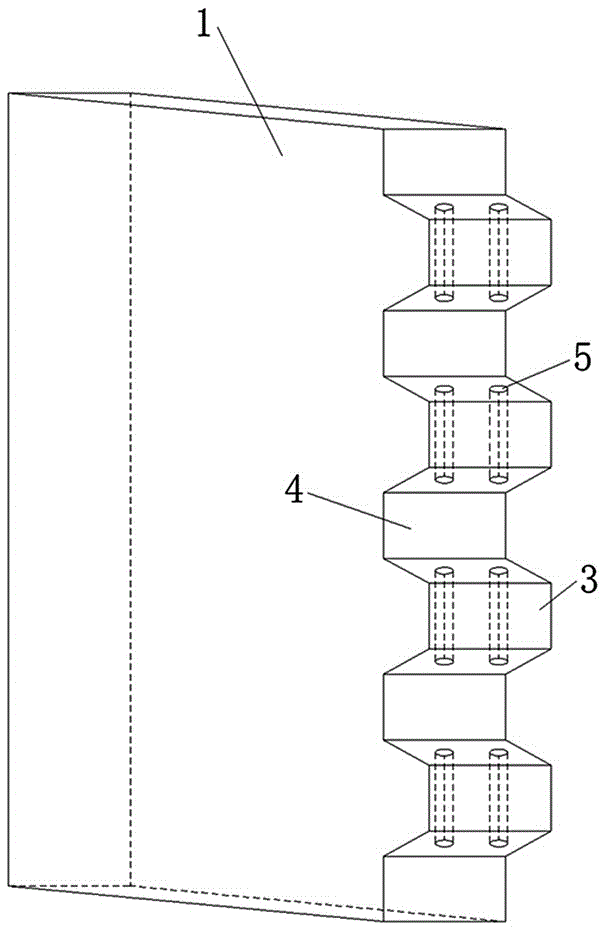

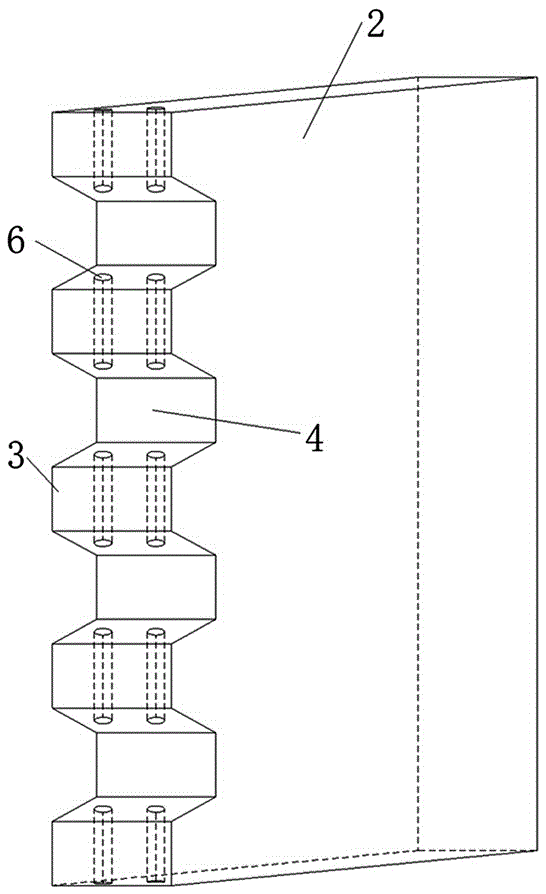

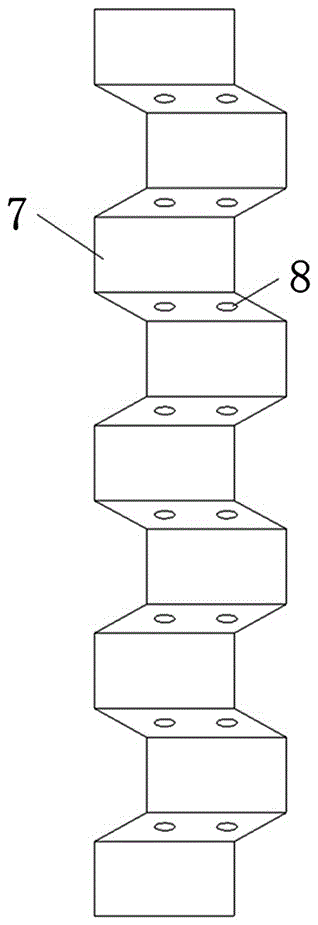

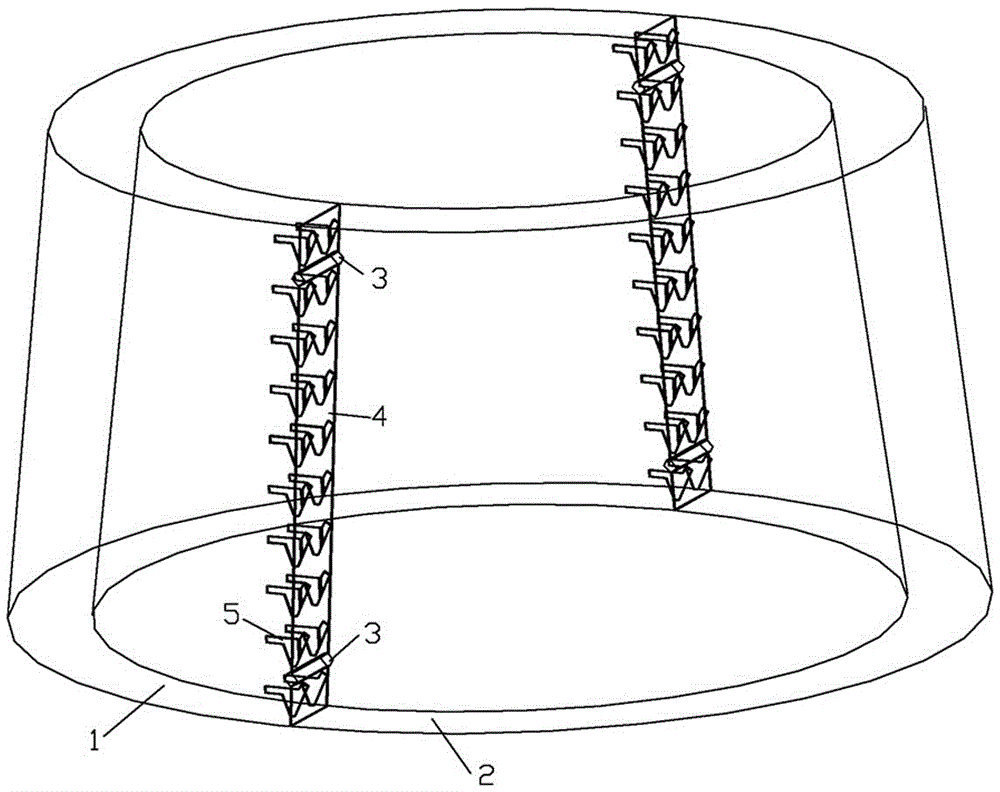

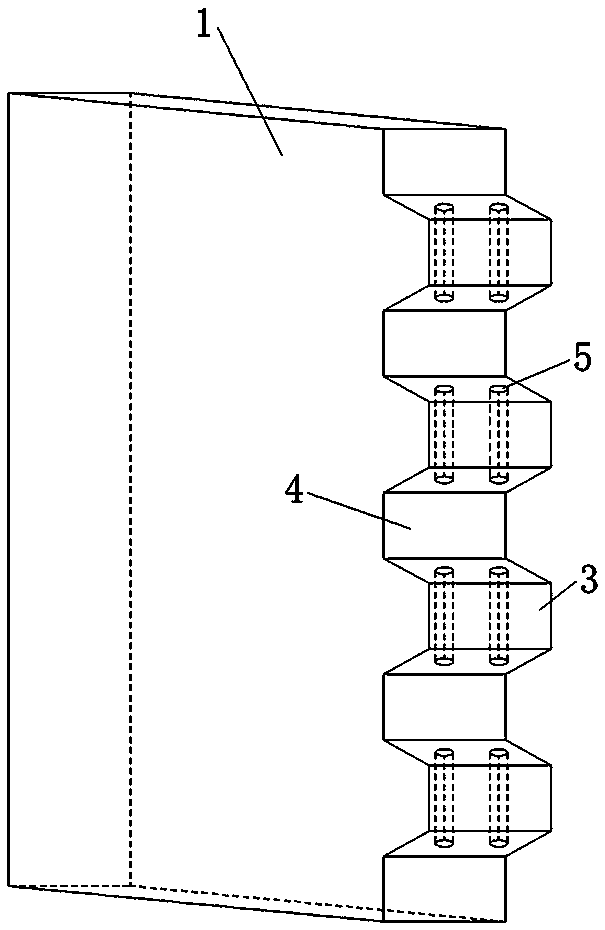

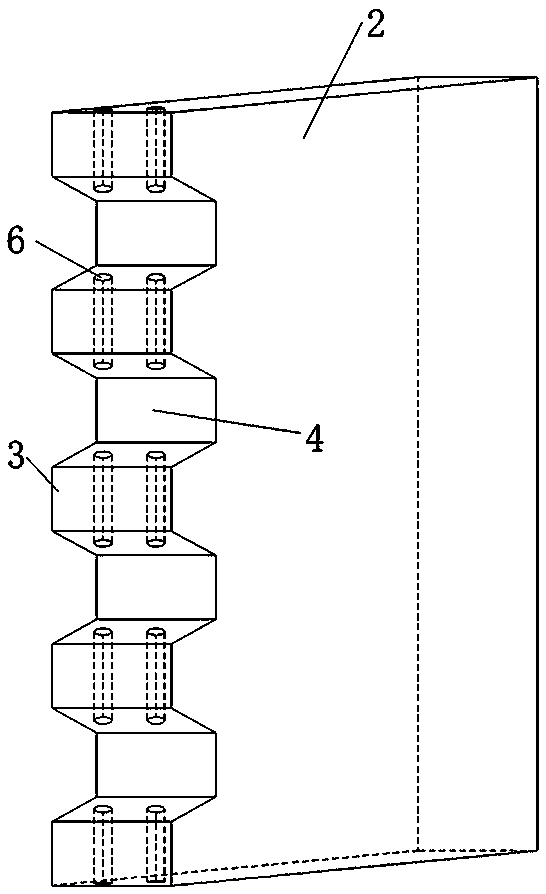

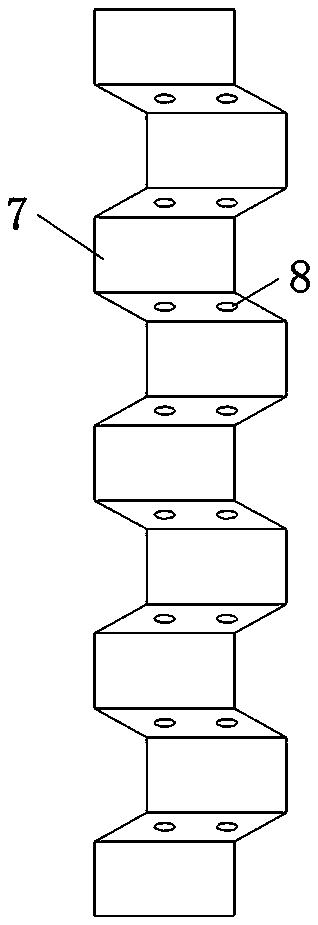

Bolt pin-type crossed tenon tooth precast concrete unit and preparation method thereof

ActiveCN106182361ASimple structureReduced precision requirementsCeramic shaping apparatusBuilding constructionsPrismTongue and groove

The invention discloses a bolt pin-type crossed tenon tooth precast concrete unit and a preparation method thereof. The bolt pin-type crossed tenon tooth precast concrete unit comprises a first splicing part, a second splicing part, segregation boards and shearing force locking bolt pins. Tenon teeth and mortises are arranged at the splicing ends of the first splicing part and the second splicing part at intervals. Each tenon tooth is a prism with the trapezoidal cross section. The segregation boards are provided with folding structures consistent with the tenon teeth and the mortises of the second splicing part. Bolt pin holes are formed in the positions, corresponding to bolt pin mounting cavities of the second splicing part, of the segregation boards. The shearing force locking bolt pins are mounted in the first bolt pin mounting cavities and the second bolt pin mounting cavities in a penetrating mode. The bolt pin-type crossed tenon tooth precast concrete unit is simple in structure. The precision requirement for formworks is low at the prefabrication stage. After prefabrication is completed, precision of joint cracks between precast parts is high, and no subsequent repairing treatment is required after splicing is completed. In addition, the highest splicing speed can be realized under the condition of not decreasing the cross section of the precast concrete unit.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

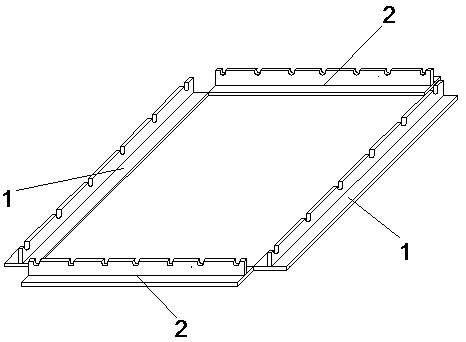

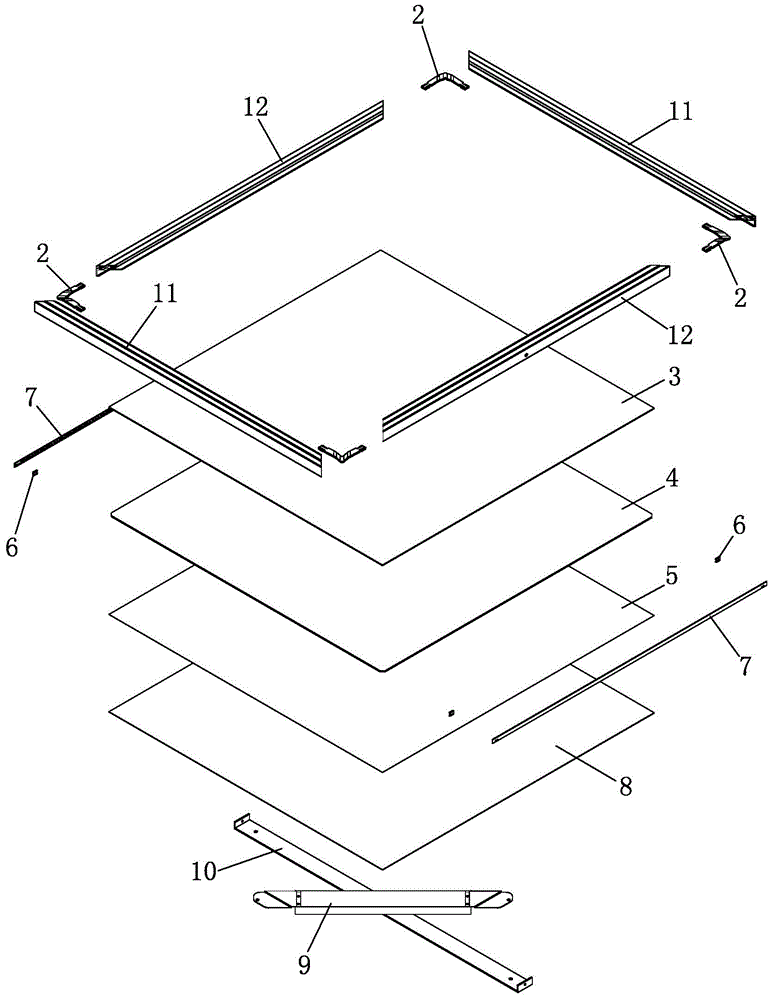

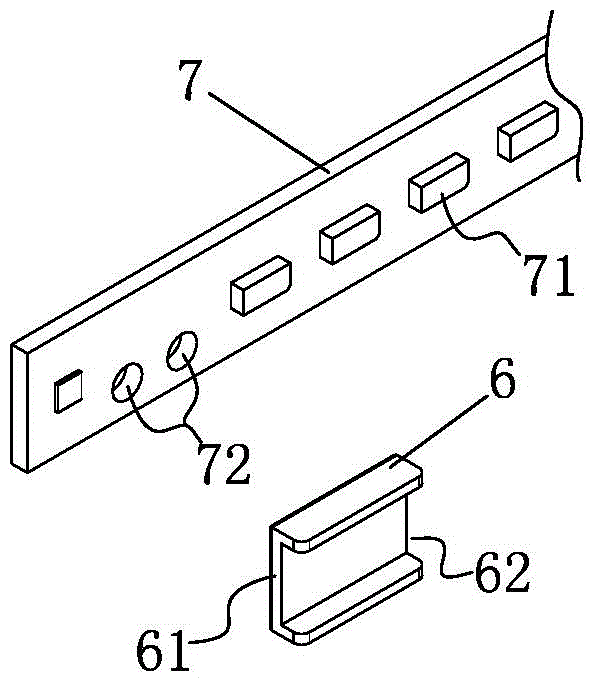

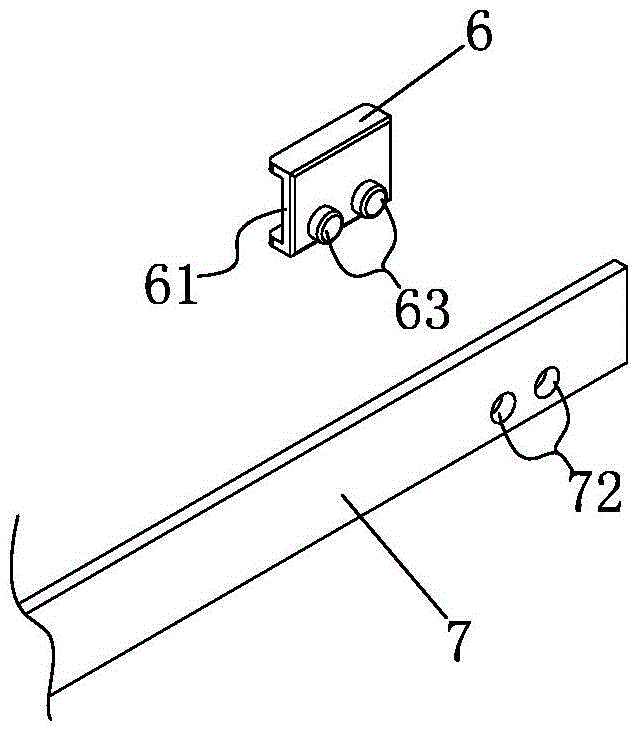

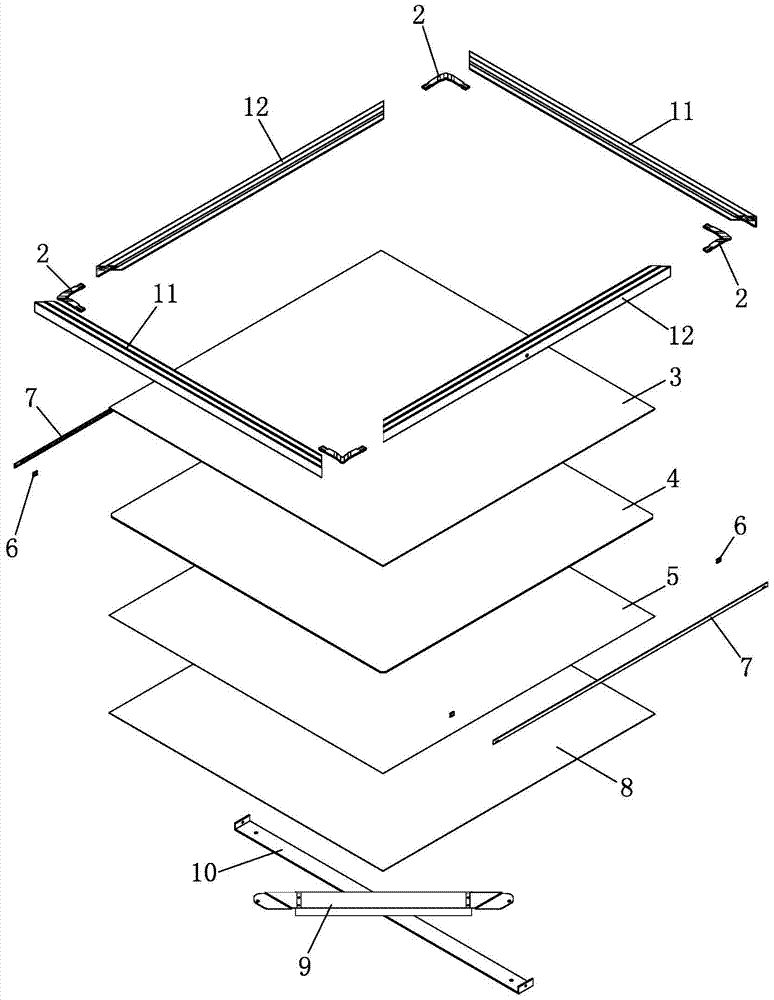

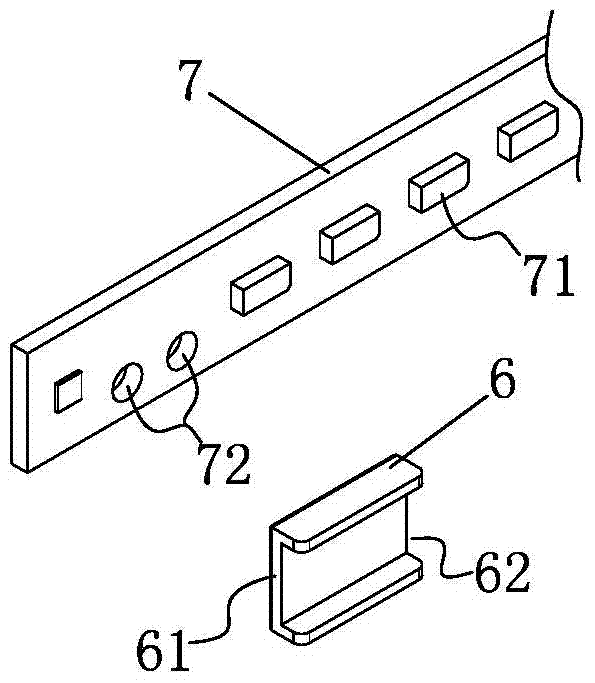

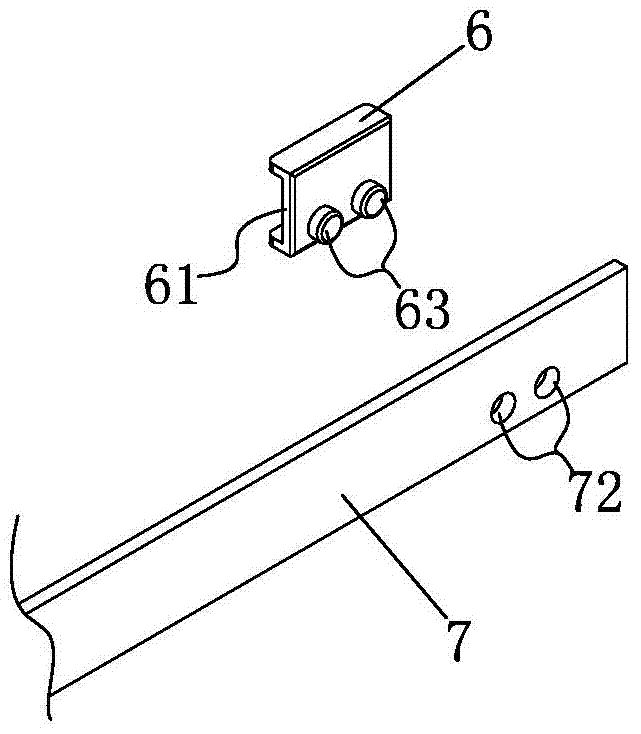

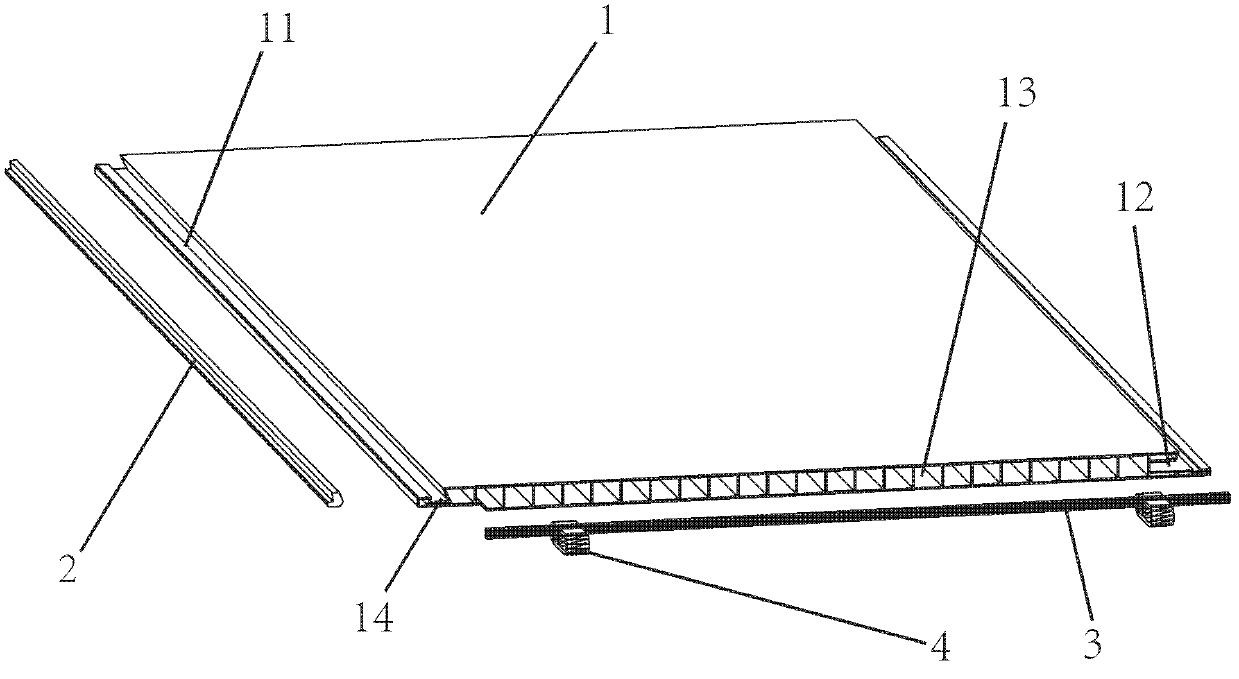

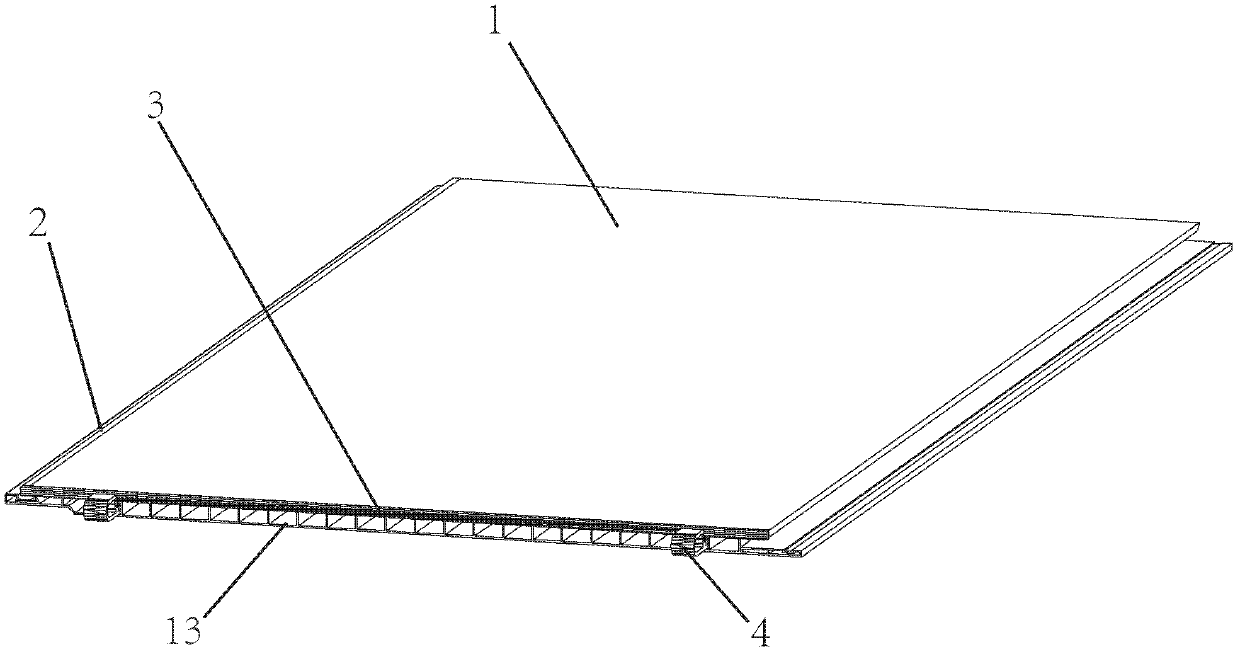

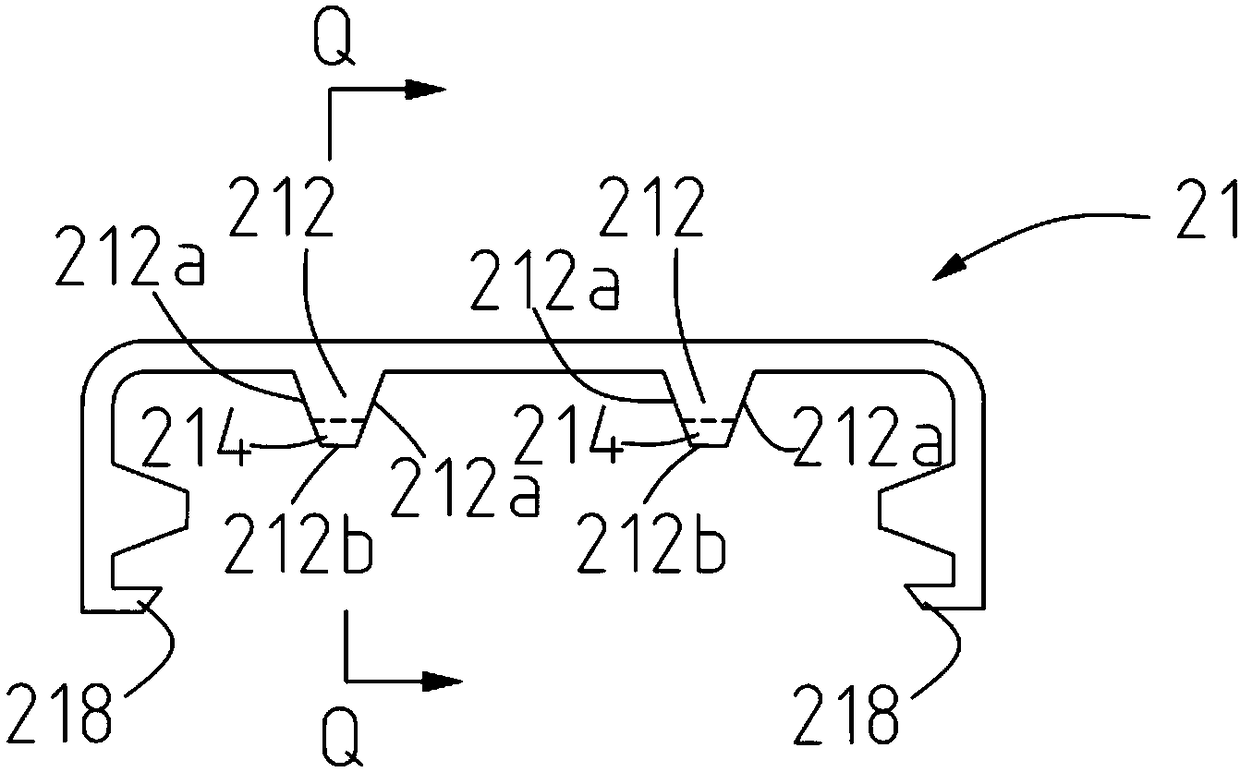

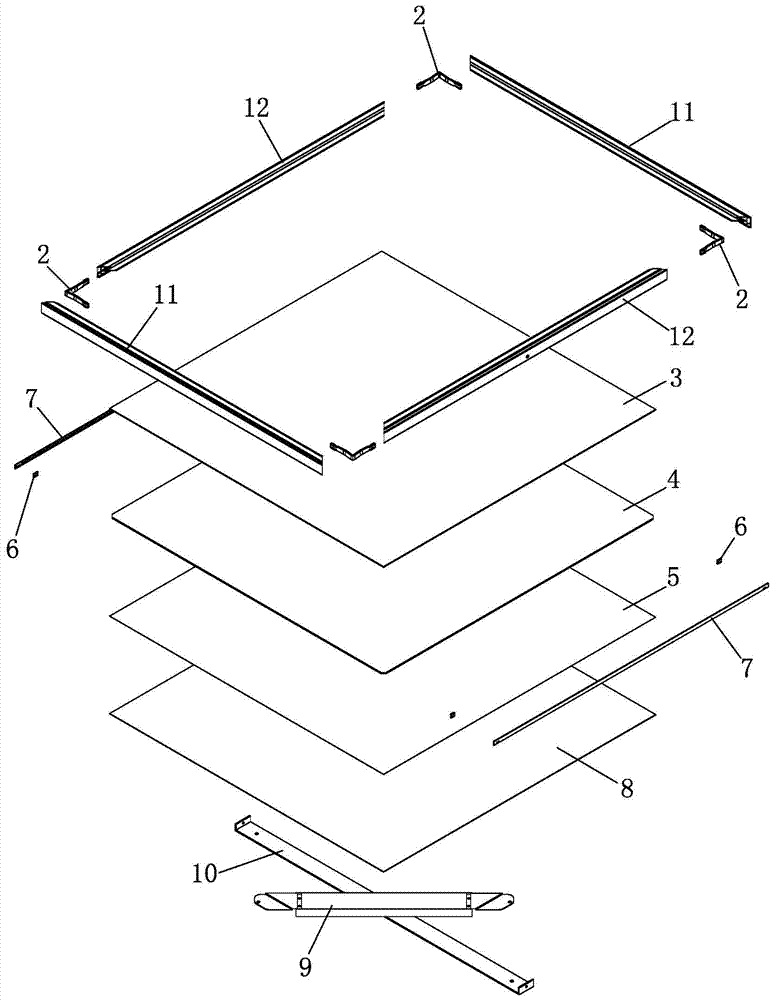

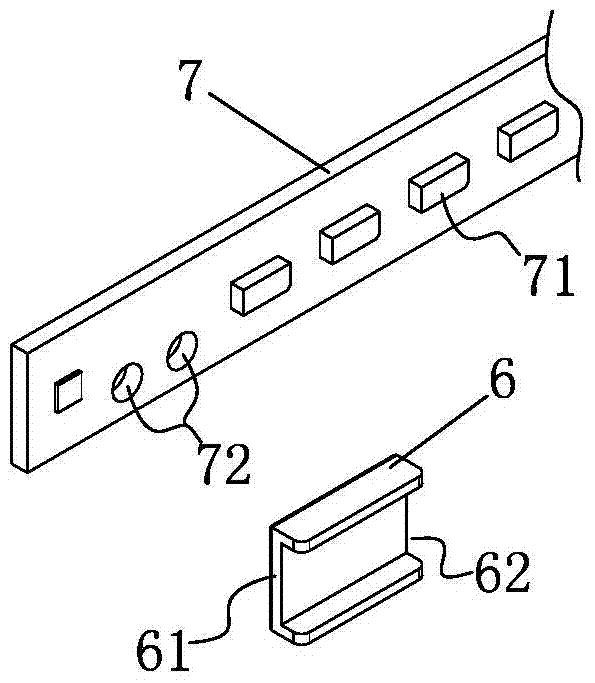

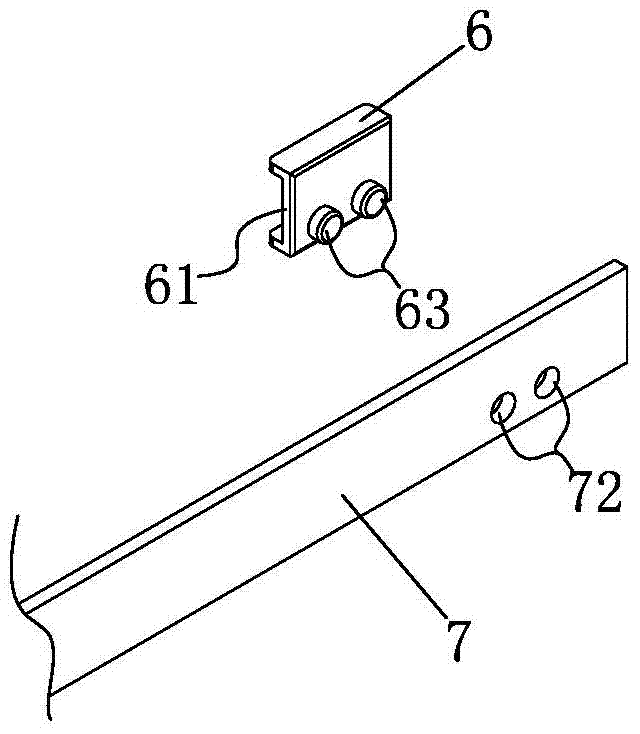

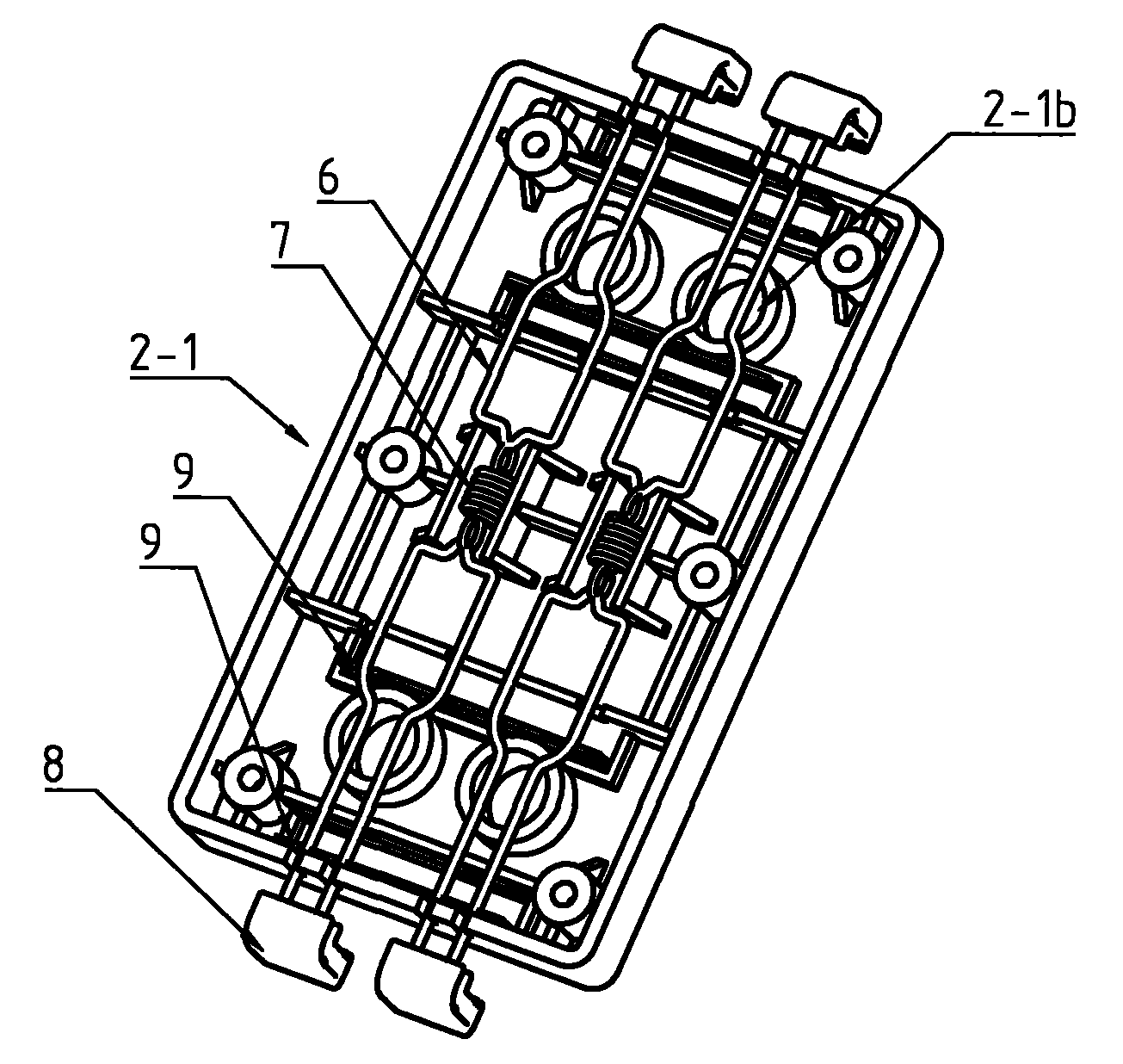

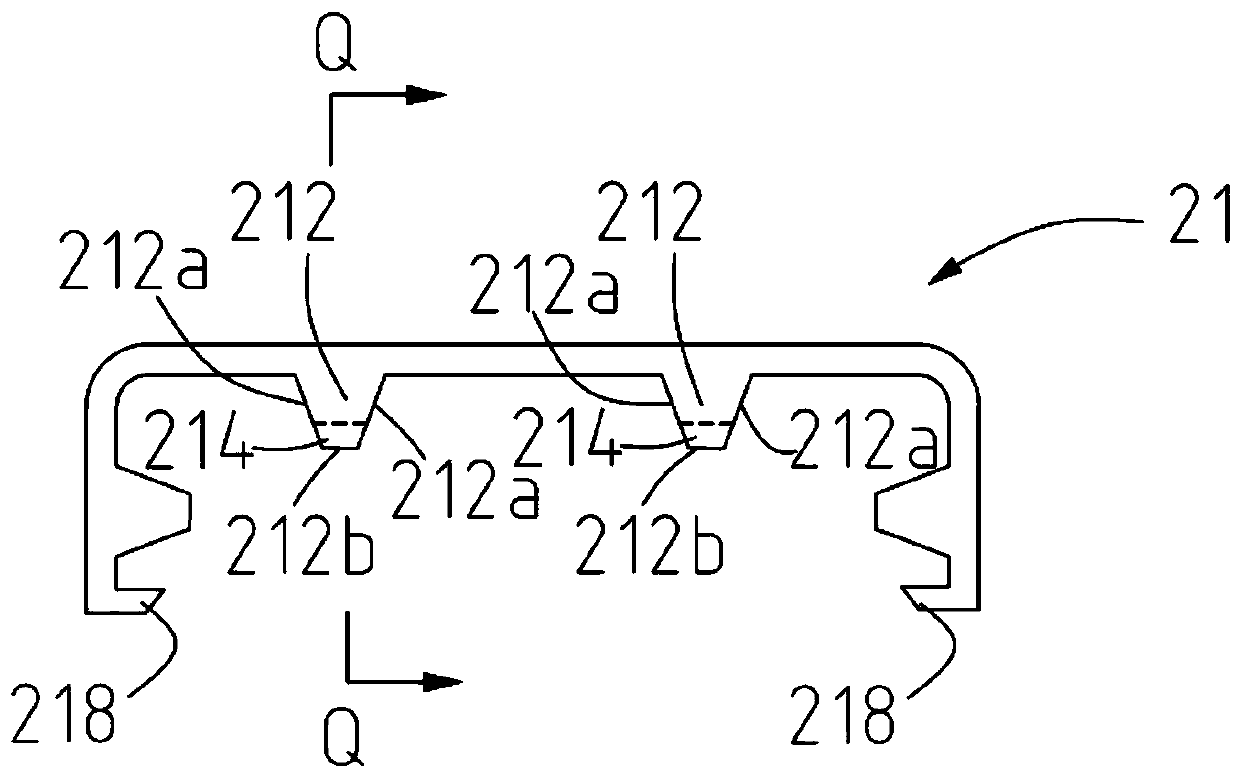

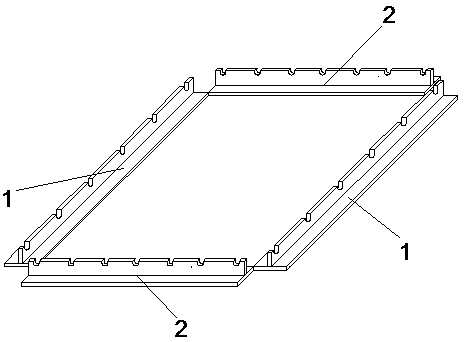

LED (light emitting diode) panel lamp and frame thereof

ActiveCN104482465AThe splicing structure is simple and reasonableEasy to assemble and debugPoint-like light sourceElongate light sourcesEngineeringSurface plate

The invention discloses an LED (light emitting diode) panel lamp and a frame thereof. The frame is spliced by two first frame section bars and two second frame section bars through four corner joints; the two second frame section bars are arranged oppositely, each corner joint is provided with a first plugging arm and a second plugging arm; the root part of each first plugging arm is connected with the corresponding second plugging arm, the head part of each first plugging arm is inserted into a first jack of the corresponding first frame sections bar, the top of each first plugging arm and the top inner wall of the corresponding first jack are provided with at least three contacts which are not in the same line, and the bottom of each first plugging arm and the bottom inner wall of the corresponding first jack are provided with at least three contacts which are not in the same line; the head part of each second plugging arm is inserted into a second jack of the corresponding second section bar, and is connected with the same method; the root part of each first plugging arm is larger than the head part of the first plugging arm, and the root part of each second plugging arm is larger than the head part of the second plugging arm. The LED panel lamp and the frame thereof adopting the technical scheme have the advantages that the structure is simple and reasonable, the assembly and debugging are convenient, the yield is high, and the productivity is high.

Owner:ANHUI ZERUN OPTOELECTRONICS

led panel light and its frame

ActiveCN104482465BSimple splicing structureEasy assembly and debuggingPoint-like light sourceElongate light sourcesLight-emitting diodeSurface plate

Owner:ANHUI ZERUN OPTOELECTRONICS

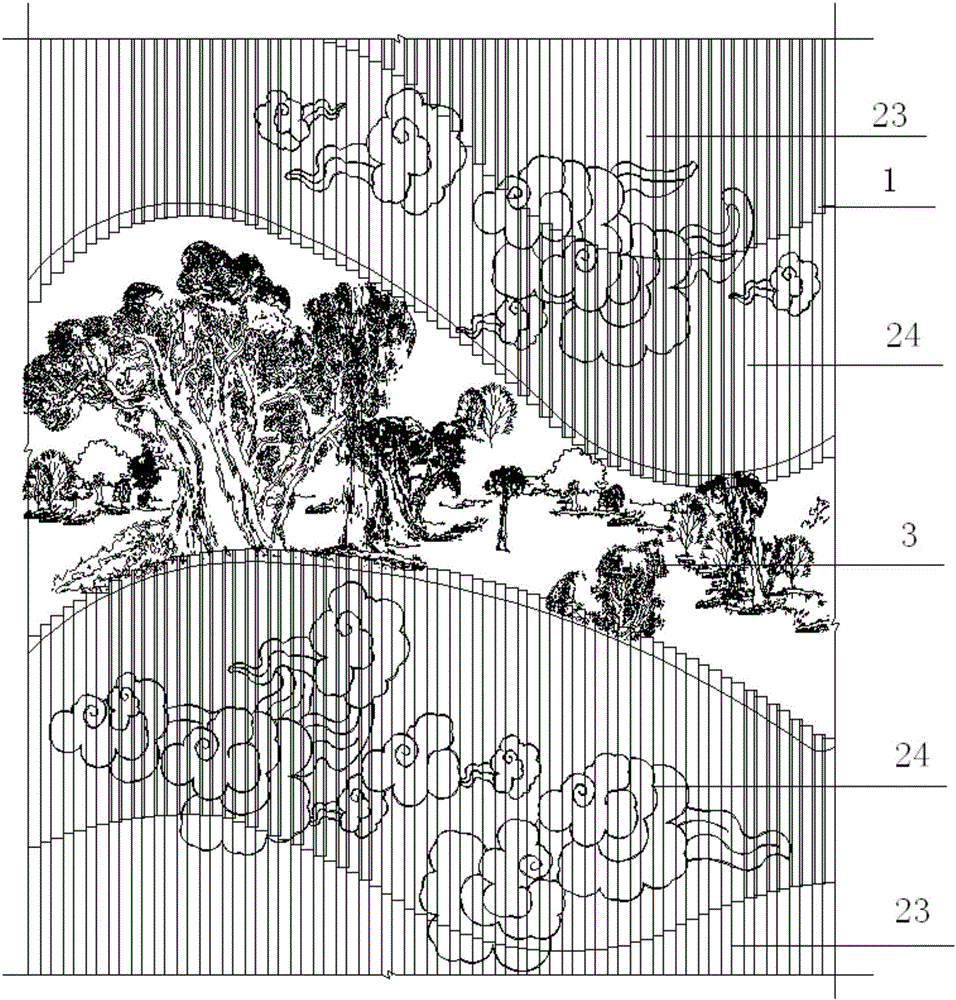

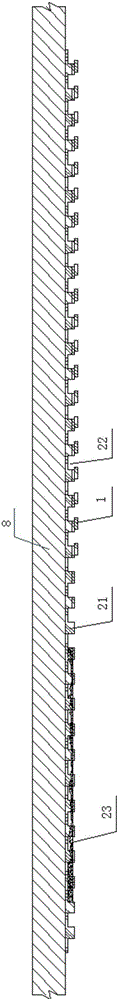

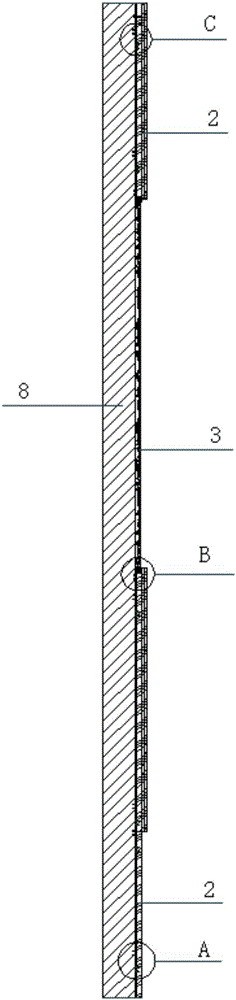

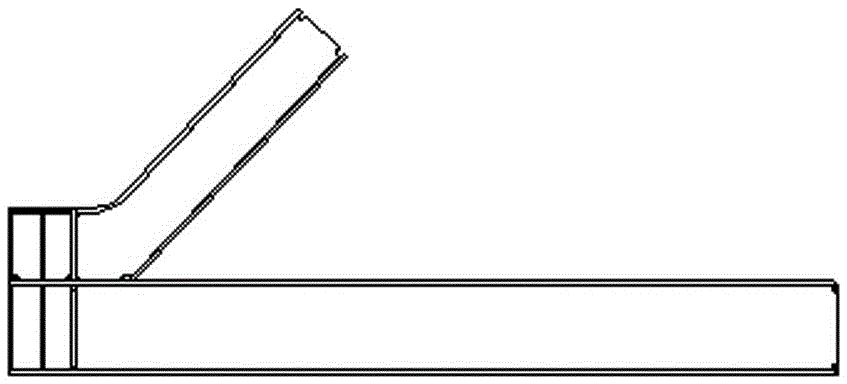

Splicing structure and method for metal and three-dimensional carving glass

InactiveCN105774364ASimple splicing structureSimple methodDecorative surface effectsOrnamental structuresOblique angleMetal

The invention discloses a splicing structure and method for metal and three-dimensional carving glass. The splicing structure comprises the three-dimensional carving glass arranged on a wall, a plurality of metal plates arranged on the wall and arranged above and / or below the three-dimensional carving glass, an oblique angle metal assembly, a right-angle metal assembly and a bevel metal assembly, wherein the metal plates are installed on the wall through the oblique angle metal assembly, the right-angle metal assembly is used for splicing the multiple metal plates, and the bevel metal assembly is used for splicing the metal plates and the three-dimensional carving glass. According to the splicing structure and method for the metal and the three-dimensional carving glass, the splicing structure is simple, the splicing method is simple and convenient, multiple different types of metal installing assemblies are used for conducting splicing and strengthening the wall, and splicing is firm; and the effect is good, high ornamental value is achieved, and attractiveness and functionality are unified.

Owner:GOLD MANTIS CONSTR DECORATION

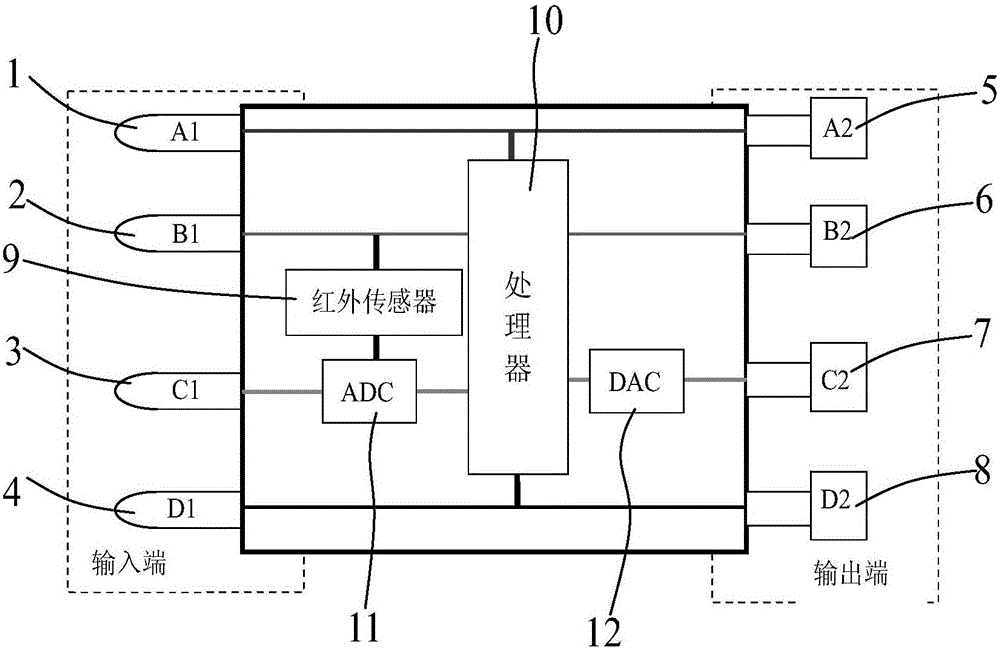

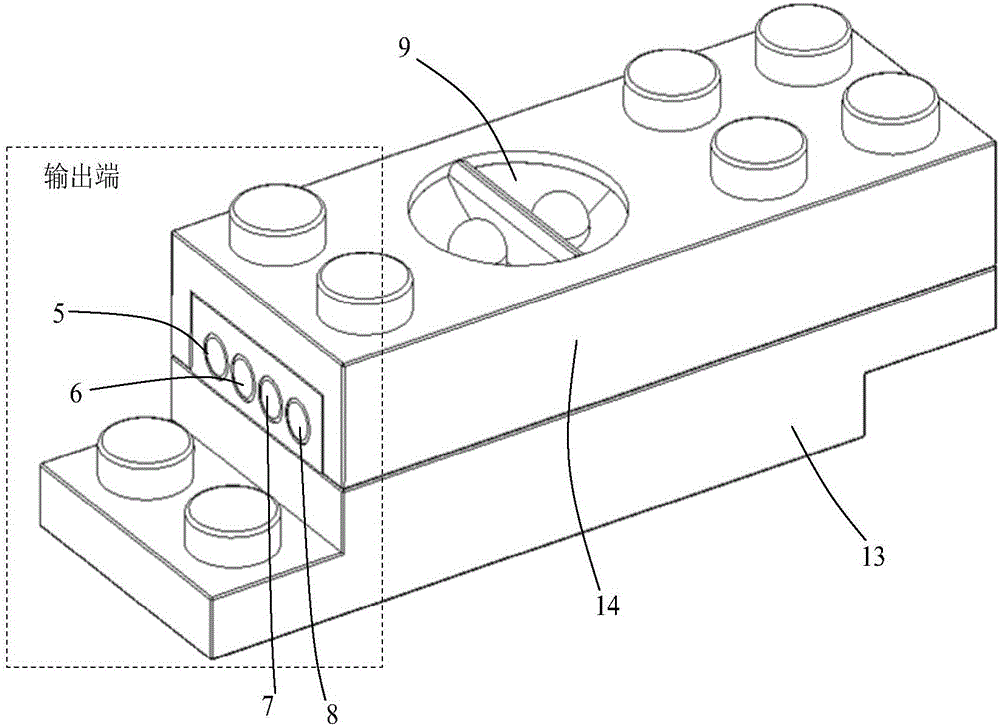

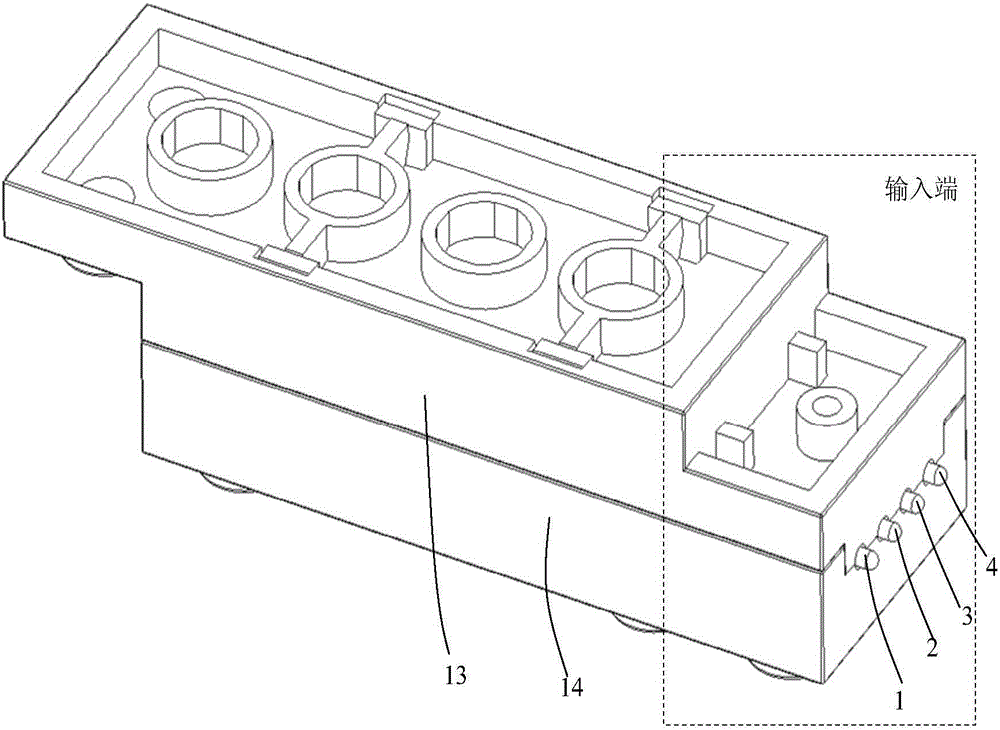

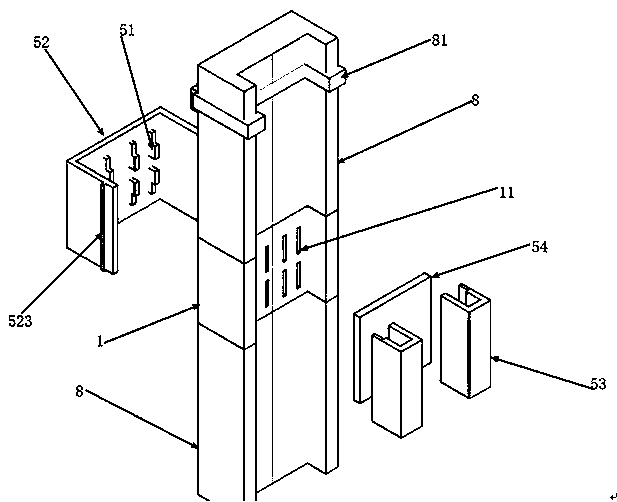

Infrared sensing module for intelligent electronic building blocks

InactiveCN106139615ASimple splicing structureEasy to useNon-electrical signal transmission systemsToysDigital analog converterComputer module

The invention discloses an infrared sensing module for intelligent electronic building blocks. The infrared sensing module for the intelligent electronic building blocks comprises a high level input end, a data bus input end, a signal input end, a low level input end, a high level output end, a data bus output end, a signal output end, a low level output end, an infrared sensor module, a module processor, an analog-digital converter, a digital-analog converter, a splicing structure body, an upper cover shell, an input end mounting body and an output end mounting body. By adopting an infrared receiving and transmitting structure with a special design, the distance of a to-be-detected object can be identified sensitively; an acquired electric signal is processed through an analog-digital conversion module to generate a digital signal; the sensitivity and a trigger value of the infrared sensor can be set by the module processor according to a regulator. According to the infrared sensing module disclosed by the invention, different types of modules can be spliced freely according to requirements by adopting a unified splicing structure with a special design, so that any building block constructing forms can be realized. The intelligent building blocks disclosed by the invention are simple in overlapping structure and convenient to use.

Owner:SHANTOU WANGE TOYS IND

Combination type installed shingle splicing structure

InactiveCN103216070AAvoid destructionSimple splicing structureCovering/liningsMechanical engineeringBuilding construction

The invention discloses a combination type installed shingle splicing structure and belongs to a board splicing structure. The splicing structure comprises a first shingle body and a second shingle body. Bell and spigots are respectively arranged on the end portions, wherein the first shingle body and the second shingle body are mutually spliced on the end portions. Cushion blocks are arranged on bottoms of the bell and spigots. Rabbet connecting pieces are arranged on top portions of the bell and spigots. The cushion blocks adapt to the bottoms of the bell and spigots of the first shingle body and the second shingle body. The cushion blocks and the rabbet connecting pieces are added between the spliced shingle bodies, smooth transition can be carried out between shingles with different specifications, and gaps do not exist. The combination type installed shingle splicing structure is especially suitable for serving as splicing structures of end portions when conventional flat plates and circular wave plates are combined and installed, independent side-dealing is not needed to be conducted on two boards, and construction steps are simplified.

Owner:南京士兴钢结构安装有限公司

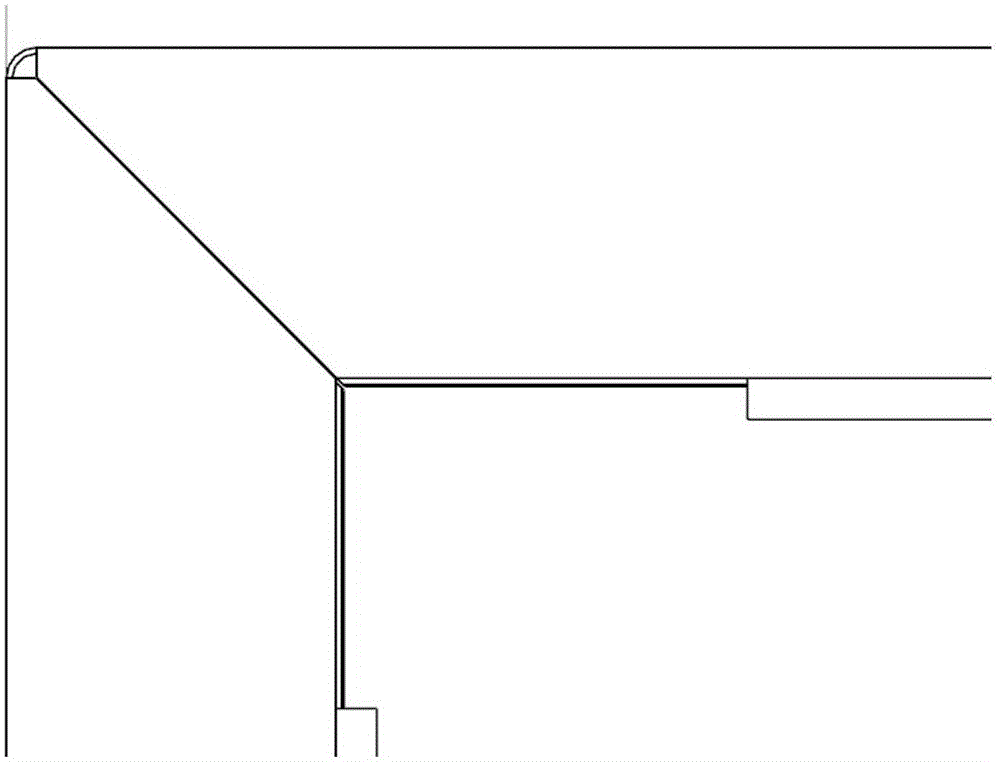

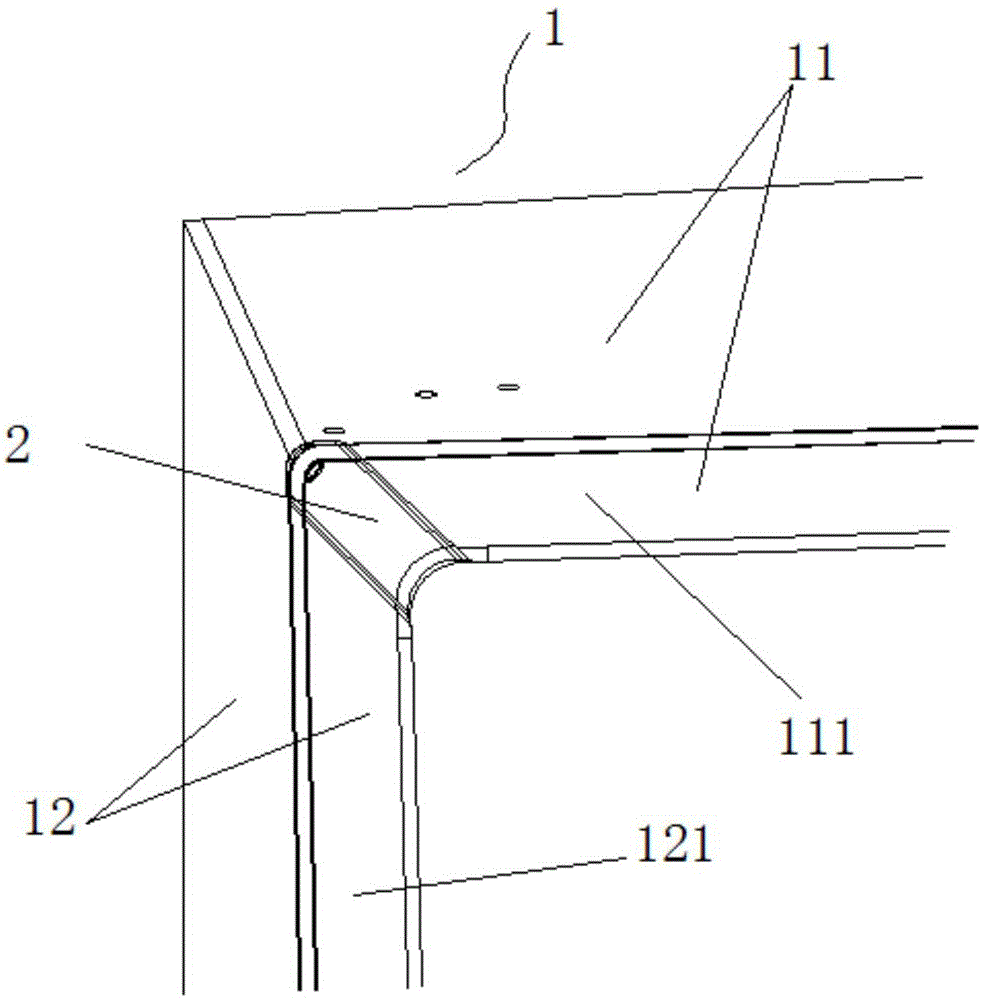

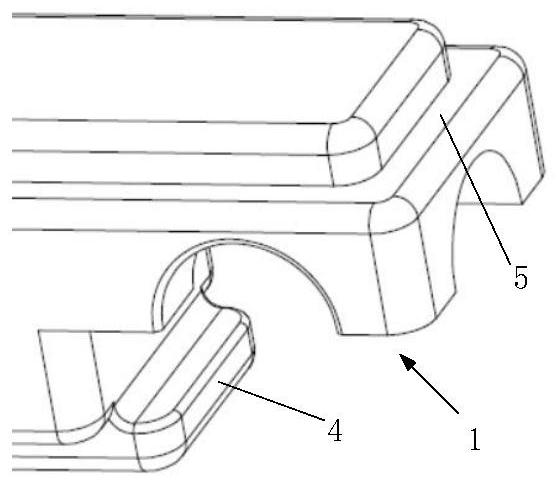

Bent U-shaped box shell bending and splicing structure

InactiveCN105004134AFix appearance problemsBeautiful appearanceDomestic cooling apparatusLighting and heating apparatusPunchingEngineering

The invention relates to a bent U-shaped box shell bending and splicing structure. The structure comprises a first splicing plate with a first folded edge and a second splicing plate with a second folded edge. The first splicing plate and the second splicing plate are spliced to form a spliced corner structure. One end of the first folded edge and one end of the second folded edge are each provided with a 45-degree splicing edge. The first folded edge and the second folded edge are spliced through the 45-degree splicing edges. The spliced part is provided with a covering element capable of being detachably connected with the first folded edge and the second folded edge. Sharp corners, burrs, malposition and other problems caused by insufficient strength or insufficient punching precision of a punching die can be reduced. Besides, the structure is attractive after splicing, and the surface of a box shell is clean. Cut corners, smaller than 2 mm, of the punching die can be eliminated and optimized, and reliability of the punching die is improved. The splicing structure is simple, consistency is good in the production process, the yield is high, and the market and inspection complaint rate is reduced.

Owner:HEFEI HUALING CO LTD +1

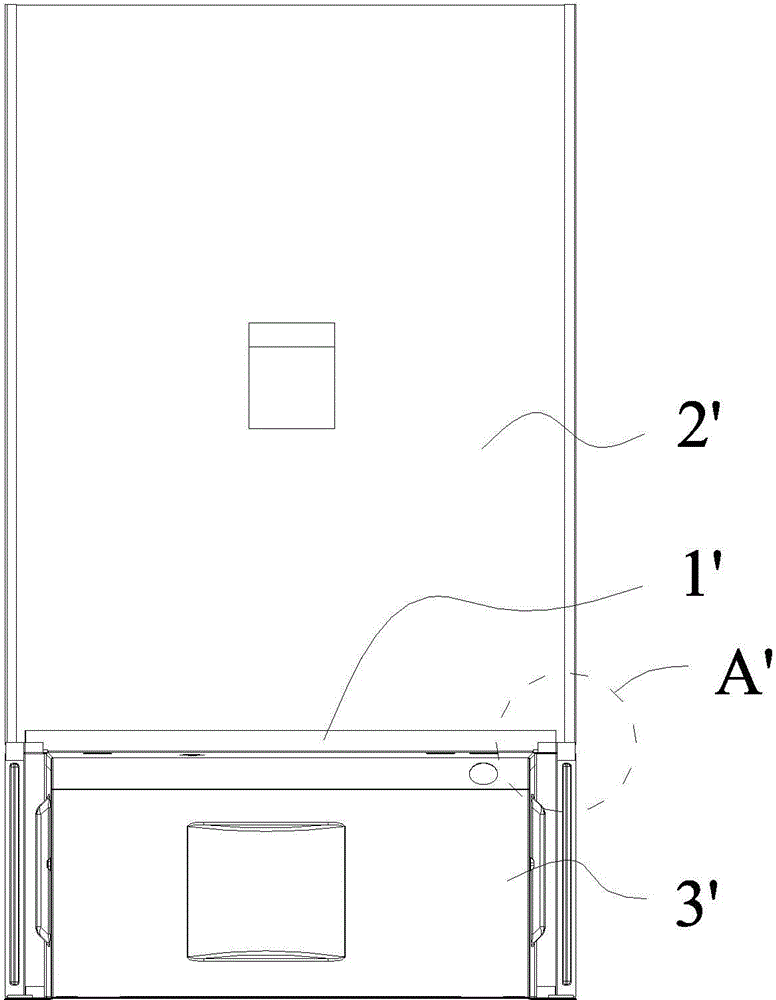

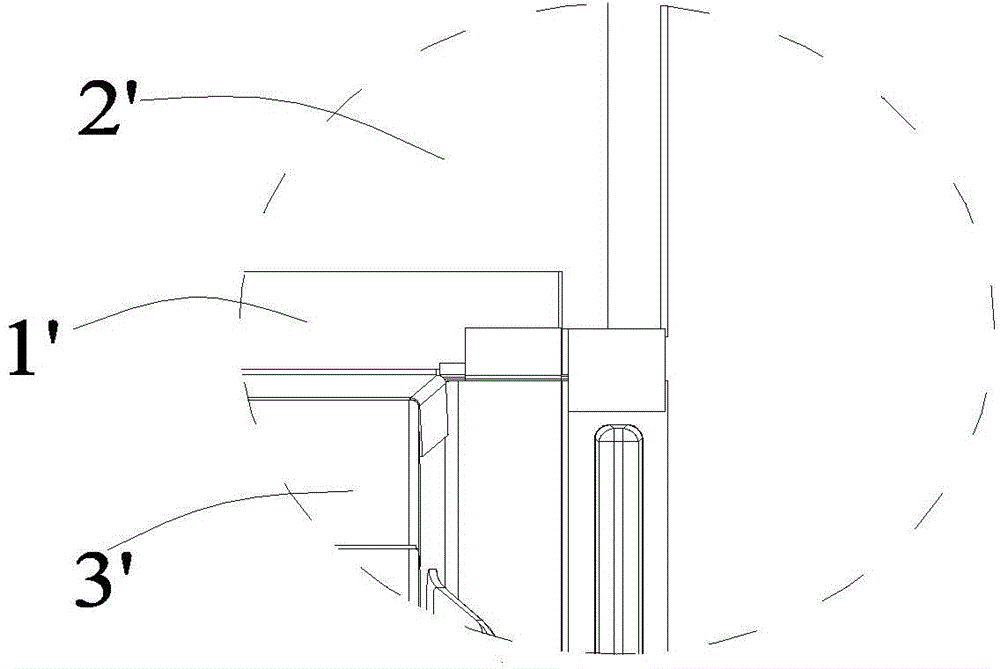

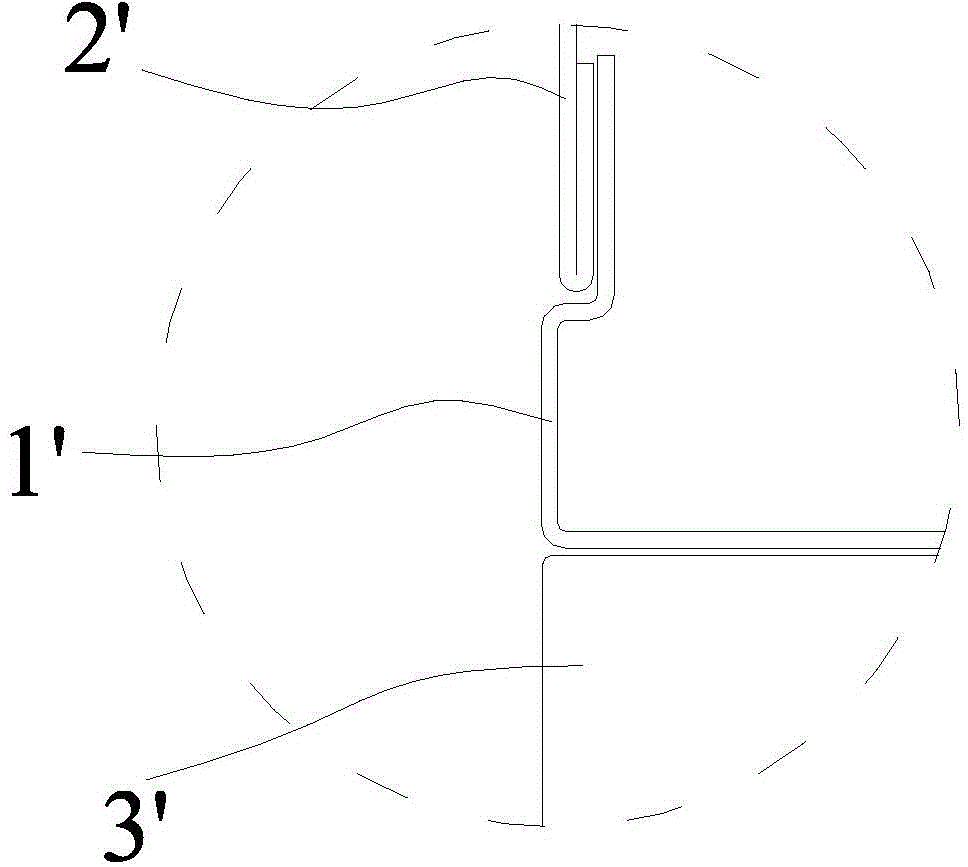

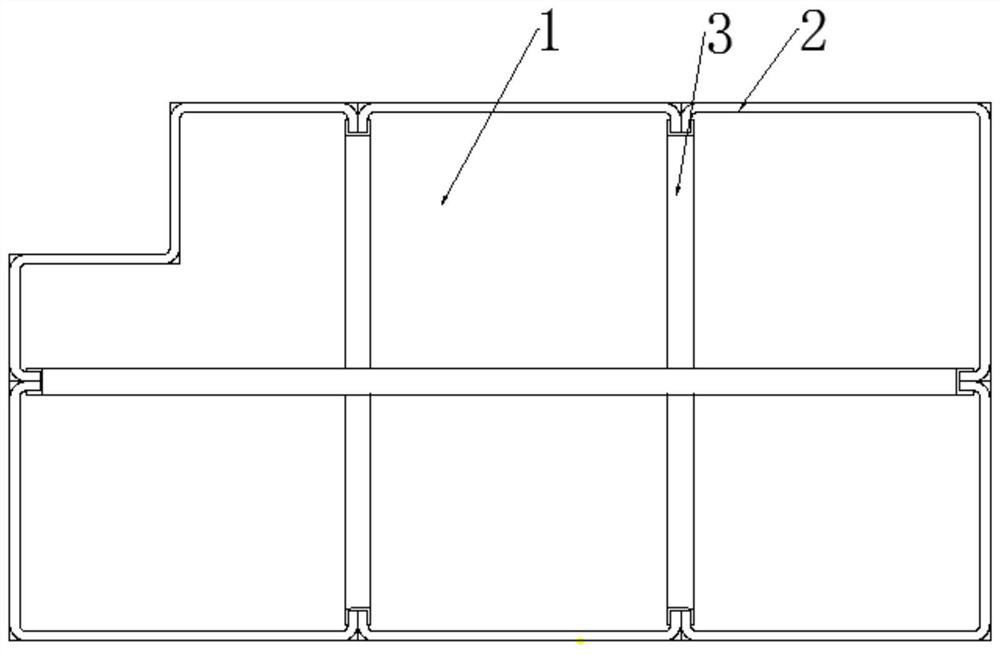

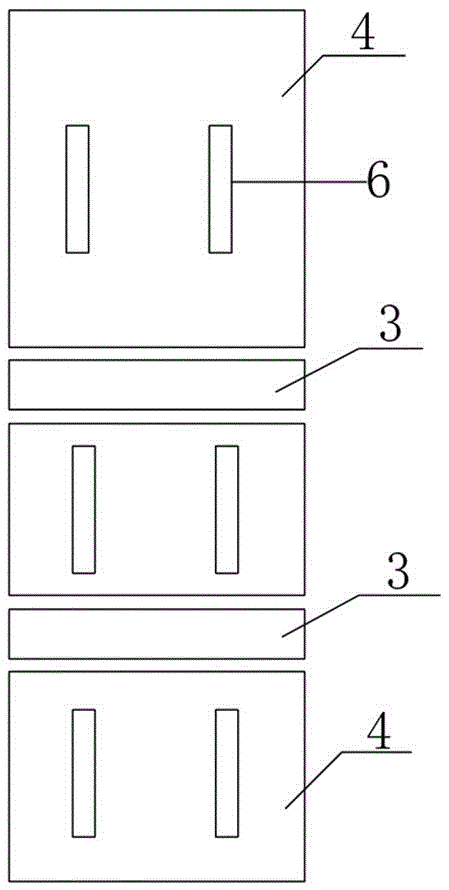

Outer box shell assembly and refrigerator

InactiveCN104792100ASimple splicing structureIncreased step structureDomestic cooling apparatusLighting and heating apparatusRefrigerated temperatureComputer engineering

The invention discloses an outer box shell assembly which comprises a bottom plate and a back plate. The back plate comprises a back plate body and a back plate edge turning plate connected to the bottom end of the back plate body. The back plate edge turning plate turns an edge to one side of the bottom plate and makes the back plate an L-shaped plate. The back plate edge turning plate is attached to the bottom plate. The invention further discloses a refrigerator. The outer box shell assembly which is formed by splicing the back plate and the bottom plate and has no exposed seams, and the refrigerator are provided.

Owner:HEFEI HUALING CO LTD +1

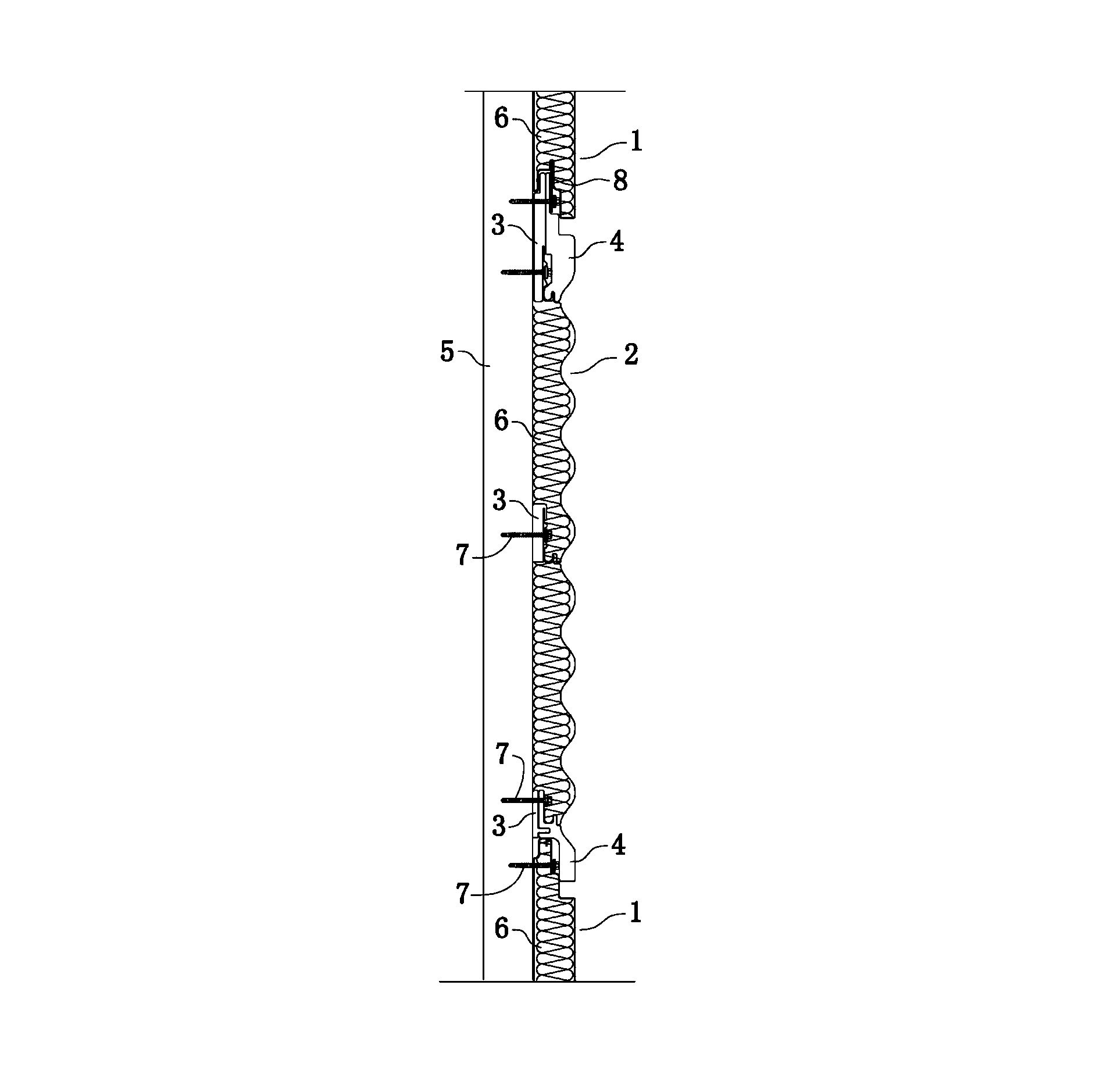

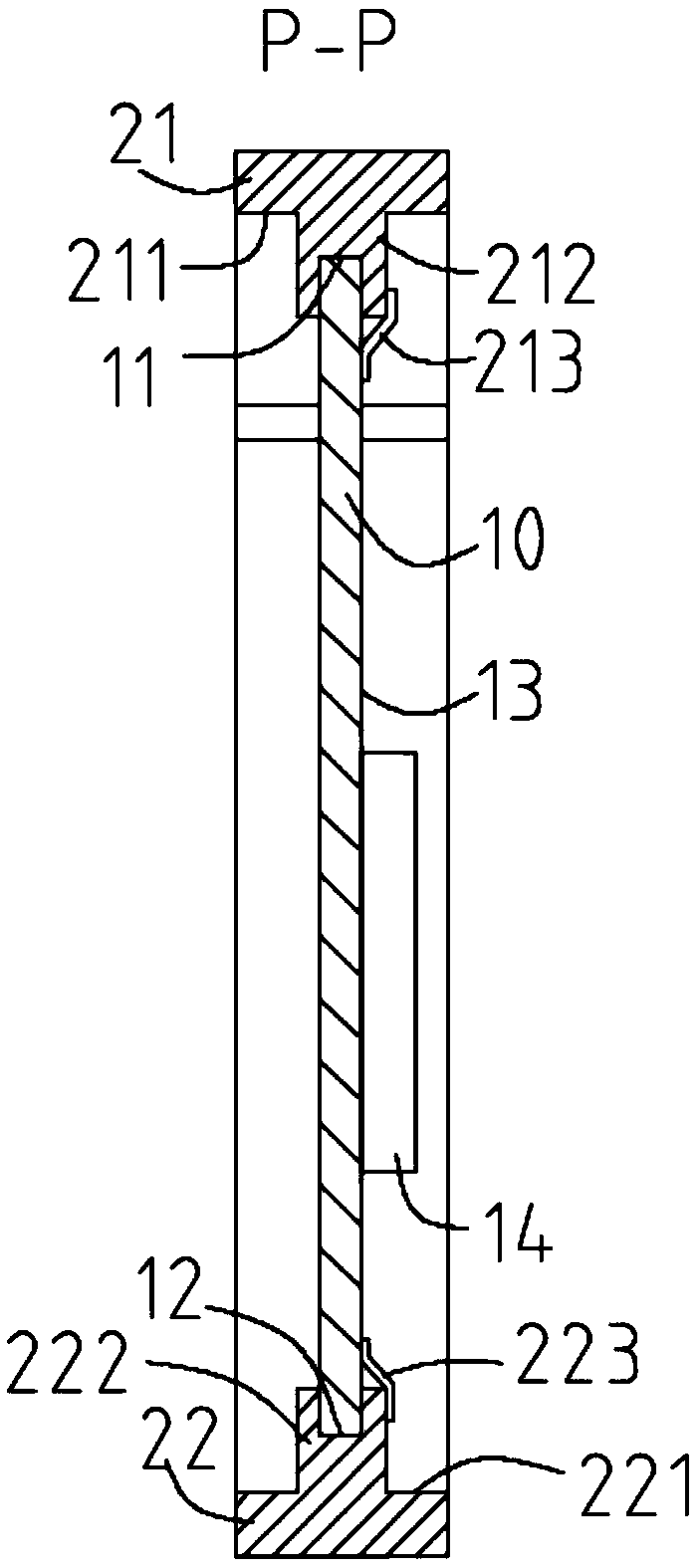

Splicing structure of sliding contact line and sliding contact line thereof

PendingCN110808516ASimple splicing structureSimple structureNon-rotary current collectorClassical mechanicsEngineering

The invention relates to the field of engineering equipment and in particular to a splicing structure of a sliding contact line. A splicing block is provided with a hollowed-out slot in communicationwith an installation slot. The installation slot is provided therein with a conductive slot. The conductive slot includes a sliding contact slot and an engagement slot. A stopping convex rib extends from the notch of the engagement slot. The splicing structure further includes a plug-in portion. The plug-in portion includes a plug-in board and a stopping board, which is connected to the plug-in board by a fastening bolt. The fastening bolt is provided with a convex edge. The plug-in board is disposed inside the engagement slot. The stopping board is also located inside the engagement slot andis abutted against the stopping convex rib. One end of the fastening bolt passes through the stopping board to be connected with the plug-in board, and the other end of the fastening bolt is located in the hollowed-out slot. The convex edge is abutted against the stopping convex rib. The splicing structure of the sliding contact line provided by the invention is stable in connection. The multiplesliding contact lines including the splicing structure are easy to disassemble and repair.

Owner:GUANGZHOU BOYANG MACHINERY MFG CO LTD

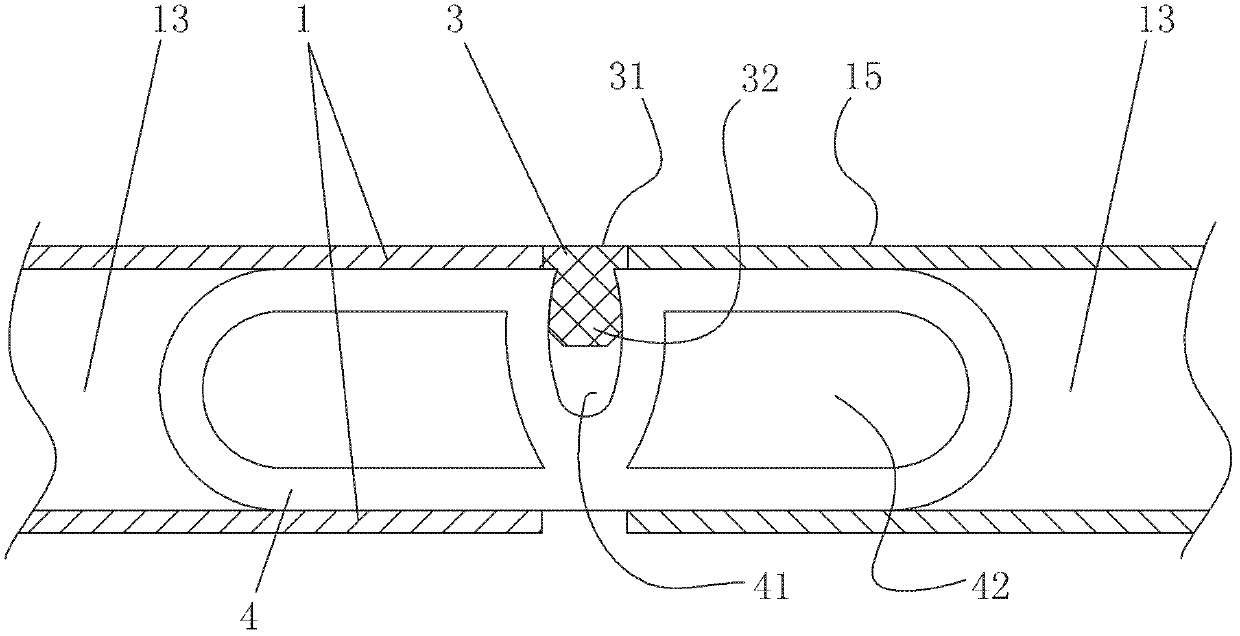

Connecting structure of buckle plate

InactiveCN102383557ASimple structureThe overall structure is simple and reliableCovering/liningsVisible surfaceMechanical engineering

The invention discloses a connecting structure of a buckle plate, which comprises buckle plate substrates, wherein a plurality of connecting ribs are arranged between an upper panel and a lower panel of each buckle plate substrate; the upper panel, the lower panel and the connecting ribs form a plurality of connecting rib grooves; the connecting structure also comprises a first splicing bar positioned between the two buckle plate substrates which are spliced forwards and backwards; the first splicing bar is provided with a visible surface which is visible between the two buckle plate substrates which are spliced forwards and backwards; a plurality of splicing members are connected with one surface of the first splicing bar, which is opposite to the visible surface of the first splicing bar, through concave-convex buckles; and the front sides and the back sides of the splicing members are respectively inserted into the connecting rib grooves of the two buckle plate substrates which are spliced forwards and backwards and are fixed. The concave-convex buckles mean convex buckle bosses which are arranged on the first splicing bar and extend along the length direction of the first splicing bar; the splicing members are provided with concave buckle grooves which are in matched, buckled and sleeved connection with the convex buckle bosses; cavities are arranged between side walls of the concave buckle grooves and outer walls of the splicing members; and the convex buckle bosses are clamped by the side walls of the concave buckle grooves. According to the technical scheme, each part has a simple structure; the manufacturing cost is greatly reduced; and in addition, the splicing operation is carried out simply and conveniently.

Owner:ZHEJIANG HUAXIAJIE MACROMOLECULE BUILDING MATERIAL

Mortise and tenon building block and mortise and tenon building block system

The invention provides a mortise and tenon building block and a mortise and tenon building block system.The mortise and tenon building block comprises a building block body; the building block body is provided with one or more mortise structures, first limiting edges located on the front faces of the mortise structures and limiting tables located on the back faces of the mortise structures and matched with the first limiting edges; the mortise structure on one building block body can be spliced on the mortise structure on the other building block body along the length direction and / or the width direction of the building block body; and the limiting tables on the two spliced mortise structures are axially limited by the corresponding first limiting edges, and one or two first splicing holes are formed between the two mortise structures. A new building block splicing system is formed through the designed mortise and tenon building block component, the splicing structure is simple, and the number of parts is small; and the mortise and tenon building block system is stable after splicing, attractive in appearance, and good in interestingness, has the flexibility of multi-direction splicing expansion, and expands the development range of building block toys, and a foundation is laid for the development of the mortise and tenon building block system.

Owner:SHANGHAI PUTAO TECH CO LTD

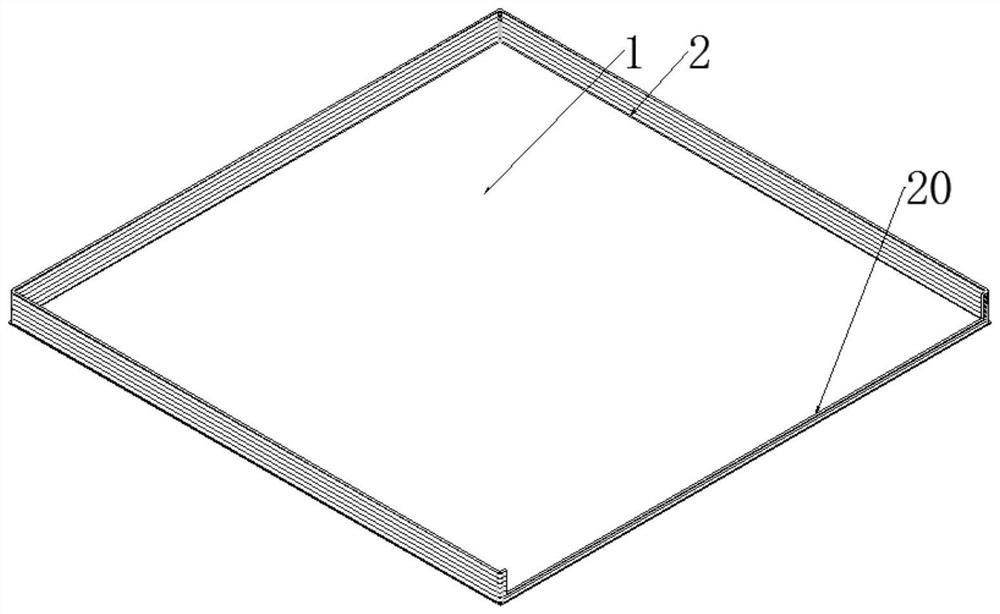

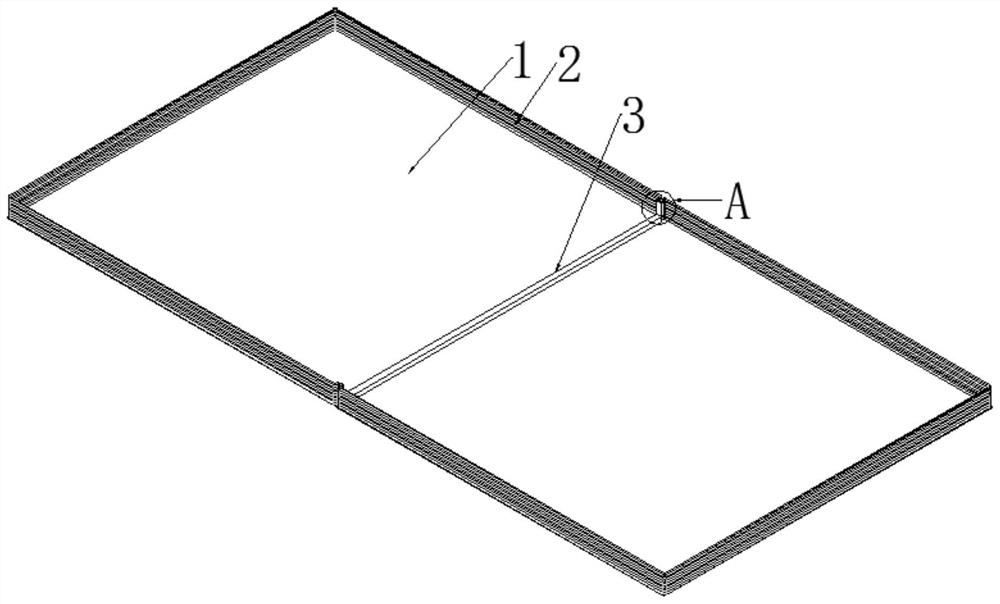

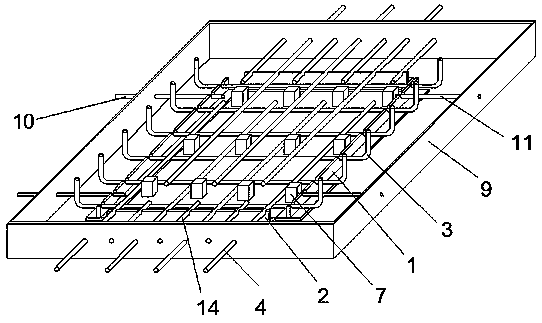

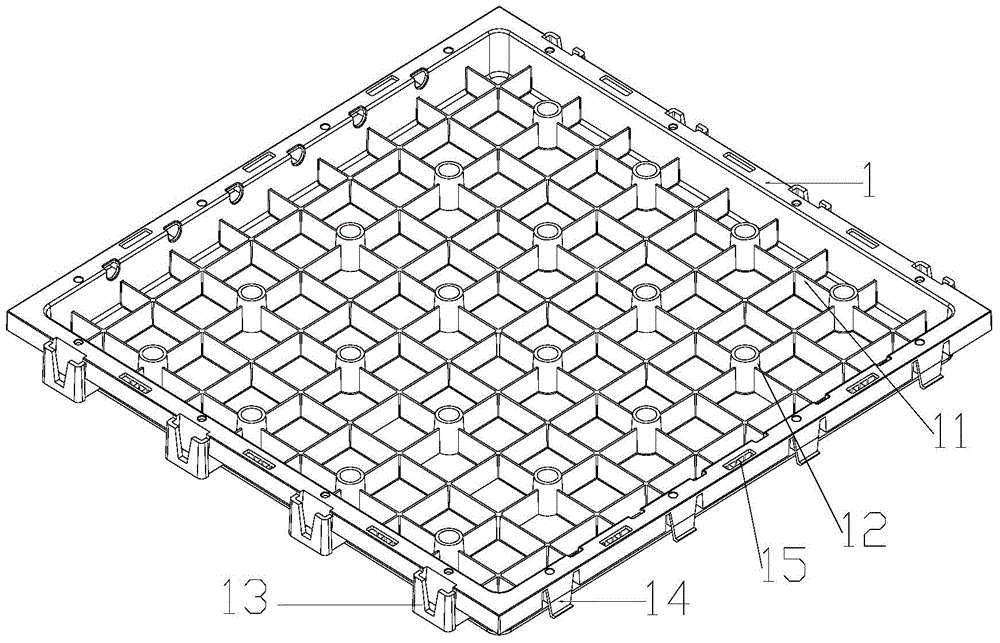

Spliced 3D printing waterproof chassis

ActiveCN113502999ASimple splicing structureImprove the fixed effectAdditive manufacturing apparatusFlooring insulationsBackplaneManufacturing engineering

The invention discloses a spliced 3D printing waterproof chassis. The spliced 3D printing waterproof chassis comprises at least two first bottom plate parts, wherein the at least two first bottom plate parts are spliced to form a chassis body; each first bottom plate part is subjected to 3D printing in the circumferential direction to be provided with a first waterproof fence with a spiral bulge; the splicing edge of each first waterproof fence is cut to form a first splicing notch; the part, located in the chassis body, of each first splicing notch is a horizontal edge with the same height, and the end, close to the periphery of the chassis body, of each first splicing notch protrudes upwards to form a vertical edge; the space between every two adjacent splicing edges is filled with a sealant; and the horizontal edges and the vertical edges of every two adjacent first splicing notches are clamped and fixed through splicing profiles. The spliced 3D printing waterproof chassis has the beneficial effects of being simple in structure, safe, reliable, free of water leakage and free of sealing weak points.

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

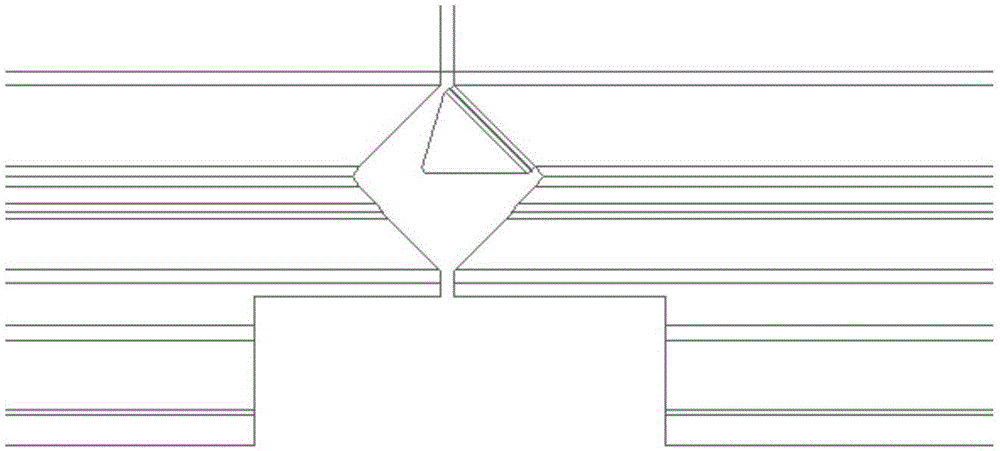

A seamlessly spliced standard led unit board and led display device

ActiveCN102136228BSimple splicing structureGood splicing effectIdentification meansLED displayDot matrix

The invention discloses a seamlessly-spliced standard LED (light emitting diode) unit board and an LED display device. The standard LED unit board comprises LED pixel points arranged in the mode of dot matrix; the shape of the regular dot matrix formed by arranging each LED pixel point is similar to the shape of the standard LED unit board; the regular dot matrix and the standard LED unit board are partially coincident and are fixedly installed on the standard LED unit board; the regular dot matrix is provided with a first coincident part and at least one edge part; the standard LED unit board is also provided with a second coincident part coincident with the first coincident part; the edge part is set into a row of LED pixel points; any LED pixel point of the edge part is fixedly installed on the standard LED unit board; and parts of LED pixel points are arranged out of the standard LED unit board. The standard LED unit board has the advantages of simple splicing structure, good splicing effect and good display effect and can be spliced seamlessly and display.

Owner:徐州博创建设发展集团有限公司

Novel spliced carpet

InactiveCN109965646AEasy to fixEasy to operateSynthetic resin layered productsFloor coveringsSurface layerEngineering

The invention discloses a novel spliced carpet. The novel spliced carpet comprises an inner carpet block and at least one outer ring carpet, the inner carpet block and the at least one outer ring carpet are in sleeving connection in sequence from inside to outside, the inner carpet block and the at least one outer ring carpet are rectangular, and each of the inner carpet block and the at least oneouter ring carpet comprises a surface layer, a middle layer and a bottom layer from top to bottom, a plurality of hooks and lint sleeve rings are uniformly distributed along the circumferential direction on respective middle layers on sleeving opposite faces of the inner carpet block and the at least one outer ring carpet, and a plurality of hooks and lint sleeve rings are uniformly distributed along the circumferential direction on respective middle layers on sleeving opposite faces of the plurality of outer ring carpets. For the novel spliced carpet, at least one layer of outer ring carpetsequentially sleeves the outer periphery of the inner carpet block, the hooks and the lint sleeve rings used for connecting are uniformly distributed on the periphery of the outer side of the middle layer, so that the spliced carpet can be easily fixed, and in addition, the splicing structure is simple and is easy to operate.

Owner:天津香玉地毯有限公司

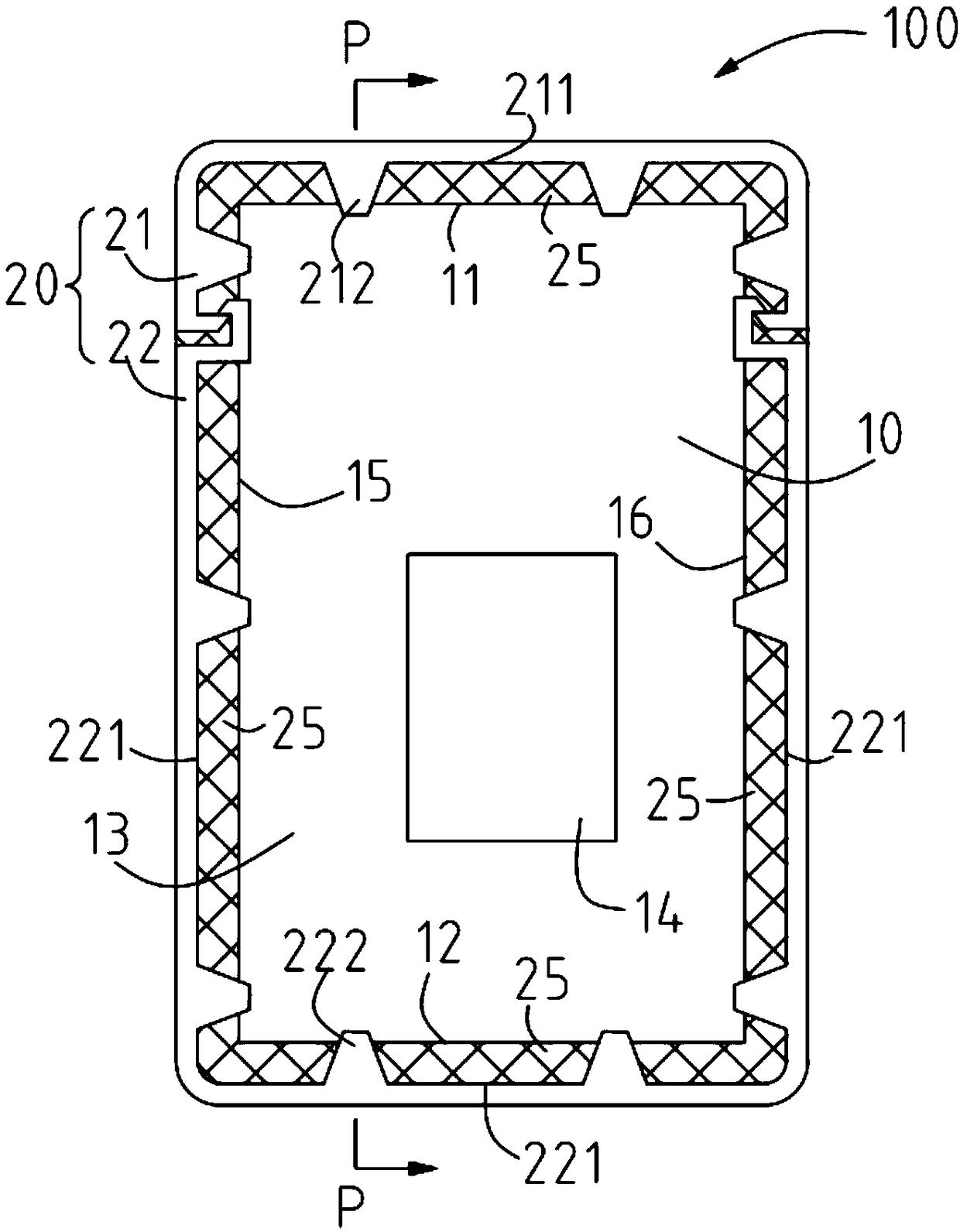

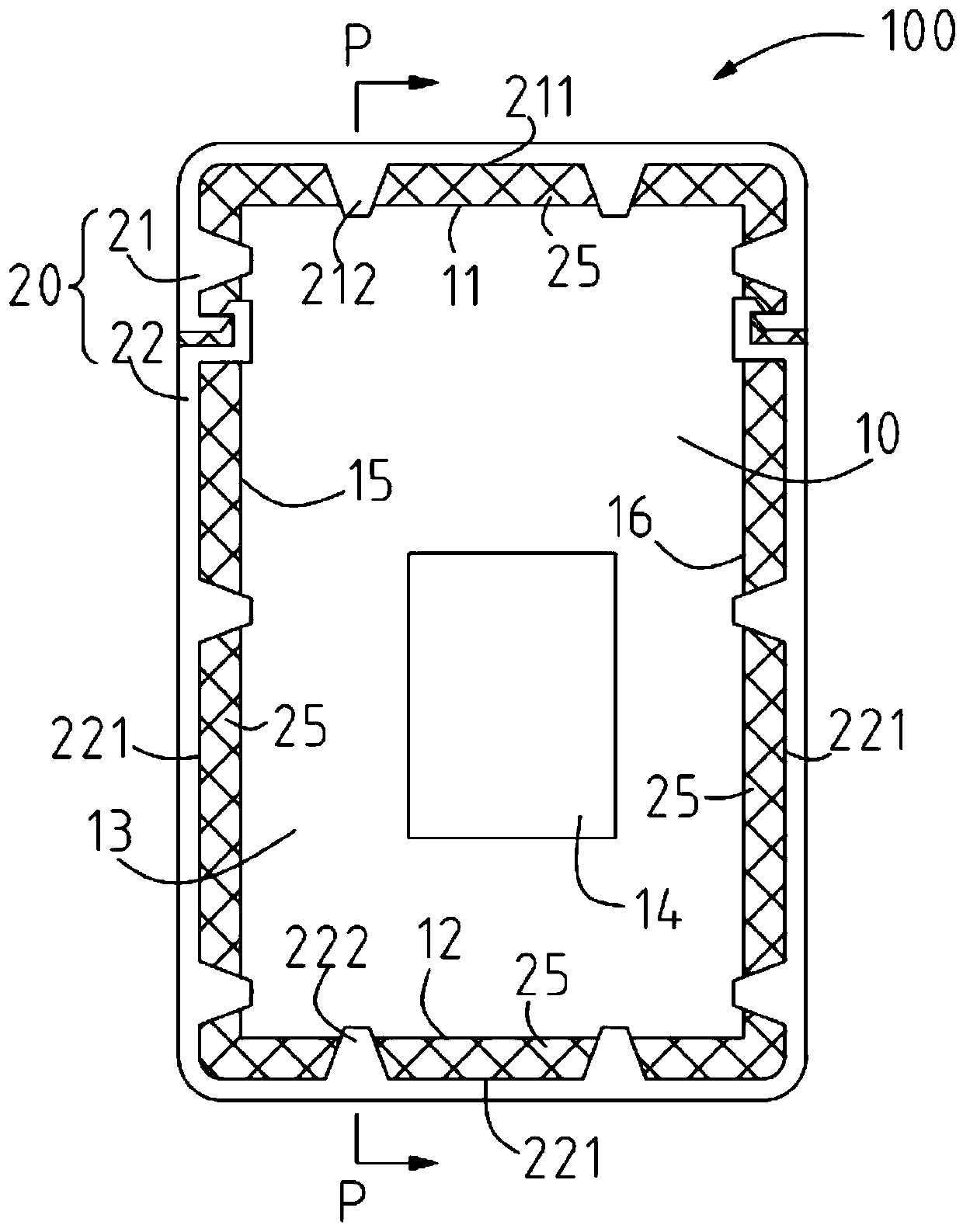

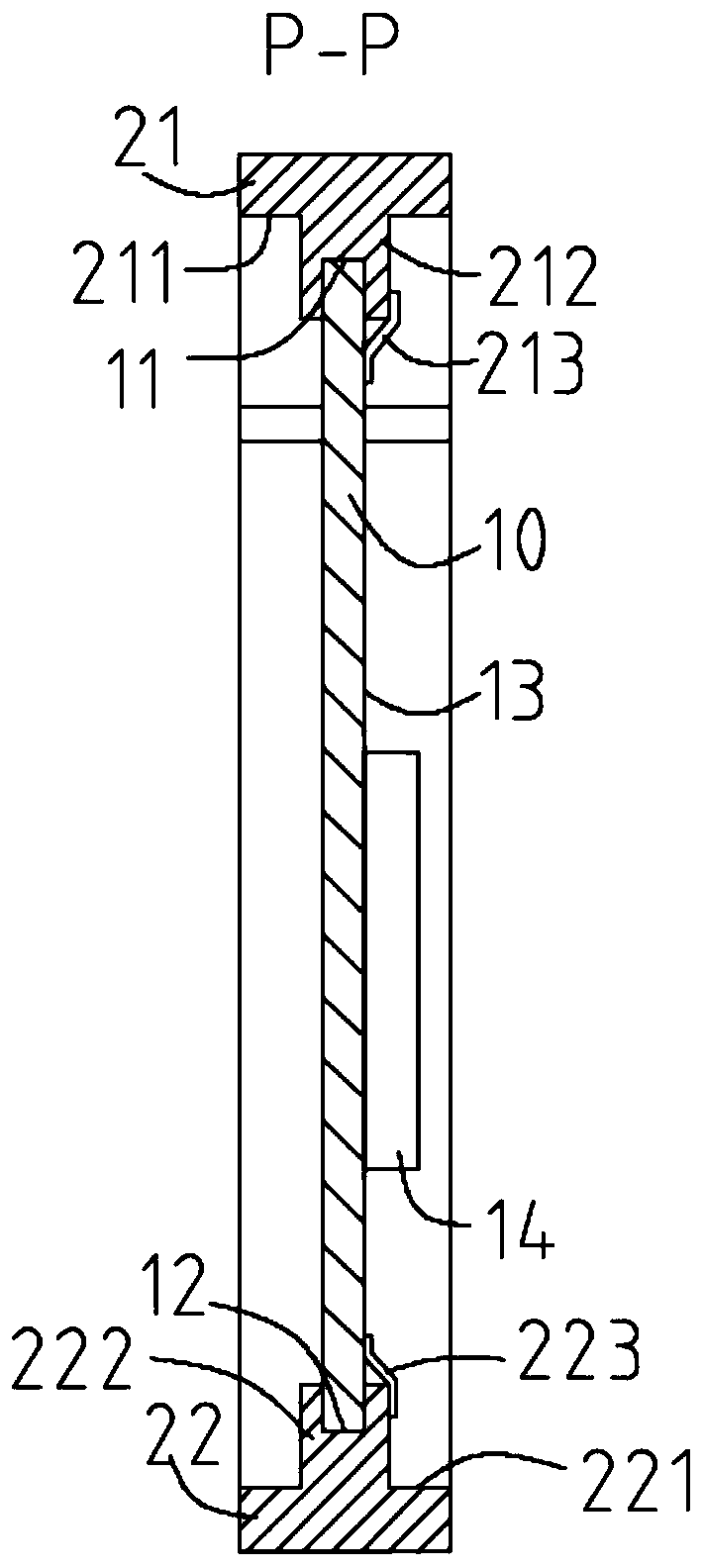

Shell, electronic equipment and shell manufacturing method

ActiveCN108882580AAchieve relative lockingSimple splicing structureCasings/cabinets/drawers detailsAgricultural engineeringElectronic equipment

The invention provides a shell, electronic equipment and a shell manufacturing method. The shell comprises a middle plate and a frame; the frame comprises a first segmented frame and a second segmented frame opposite to the first segmented frame; the two ends of the first segmented frame are buckled with the two ends of the second segmented frame respectively; the middle plate is clamped between the first segmented frame and the second segmented frame, and the middle plate has a first edge and a second edge opposite to the first edge; and the first edge abuts against the first segmented frame,and the second edge abuts against the second segmented frame. The splicing structure is simple, simplification of the splicing process is facilitated, and the processing cost is lowered.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

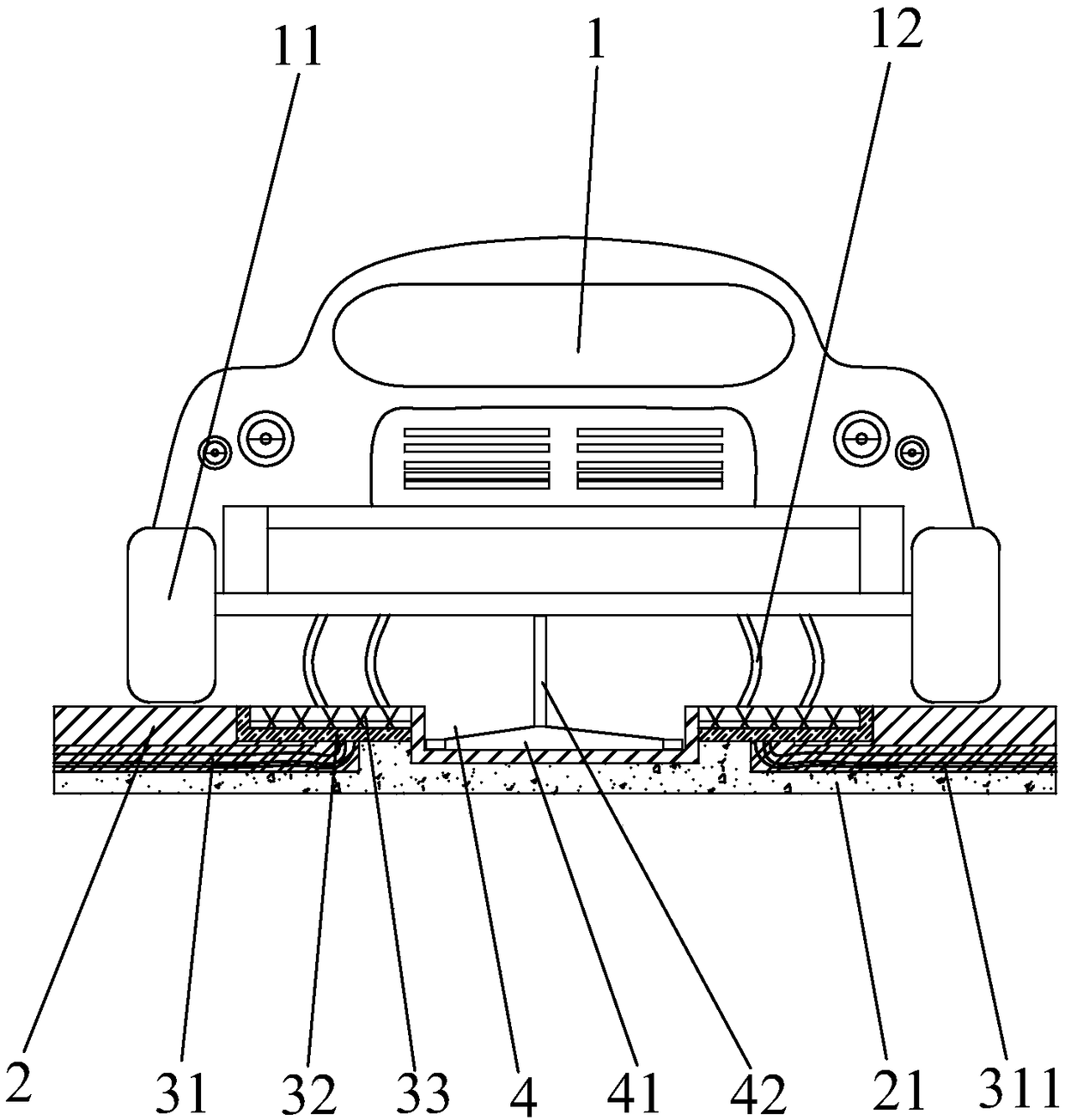

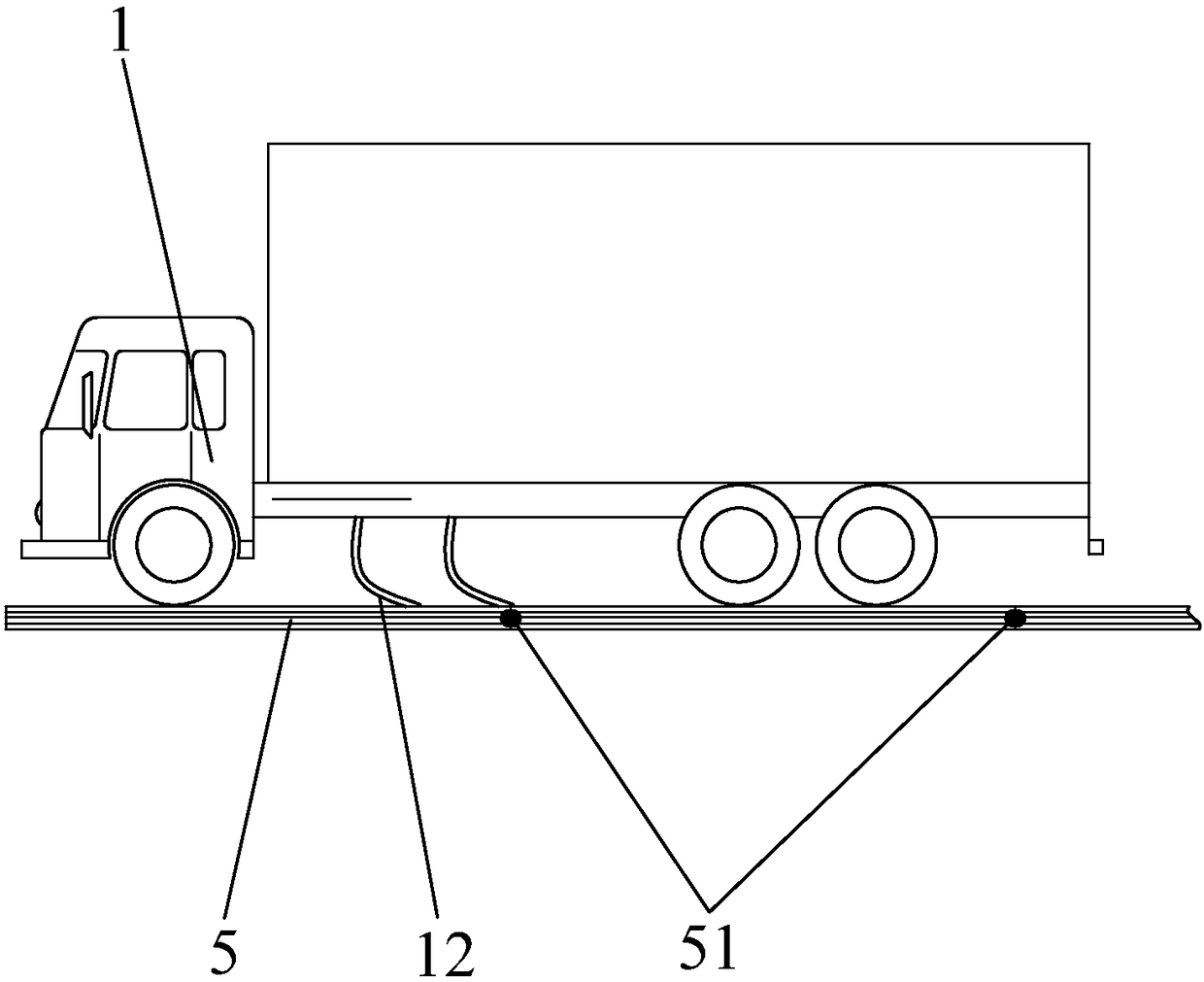

Semi-automatic wharf high-speed heavy-duty track and wharf loading and unloading system layout

InactiveCN106241409BDoes not affect trafficGuaranteed continuous operationStorage devicesMechanical conveyorsSemi automaticRoad surface

The invention discloses a semi-automatic high-speed heavy-load orbit and arrangement of a wharf loading and discharge system, and relates to the technical field of loading and discharge of port containers. The semi-automatic high-speed heavy-load orbit comprises a guide rail, wherein a guide clamping groove, contact lead cradle heads distributed on the two sides of the guide clamping groove, and conventional road surfaces distributed on the two sides of the contact lead cradle heads are arranged on the guide rail; an inertia guide part is arranged inside the guide clamping groove; the other end of the inertia guide part is connected on an AGV in a clamping manner; energization conducting wires are arranged on the AGV; and the energization conducting wires are connected on the contact lead cradle heads. According to the semi-automatic high-speed heavy-load orbit and arrangement of the wharf loading and discharge system provided by the invention, the operation of the AGV is stable, the energy consumption is low, the energy supplementation is convenient, and the safe operation level and capacity are high.

Owner:孟喆

A kind of preparation method of prefabricated concrete splicing member

ActiveCN106121058BEliminate section weakeningSectional weakening will notMould auxillary partsBuilding constructionsPrecast concreteShear force

The invention discloses a precast concrete splicing component and a preparation method thereof. The precast concrete splicing component comprises a first splicing part provided with at least one first splicing face, a second splicing part provided with at least one second splicing face, connecting tenons with base bodies fixed into the first splicing part and the ends protruding out of the first splicing faces, isolation boards with one sides connected with anchor bars, and shearing force locking keys installed in first shearing force key installation cavities and second shearing force key installation cavities. No bolt hole or operation hole needs to be formed in the precast concrete splicing component, and the situation that the section of the precast component is weakened by various hole channels required for splicing and connecting construction of the precast concrete splicing component is eliminated. By the adoption of the precast concrete splicing component, under the condition that the section of the precast concrete component is not weakened, the highest splicing speed can be reached. The splicing accuracy of the precast concrete splicing component is high.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

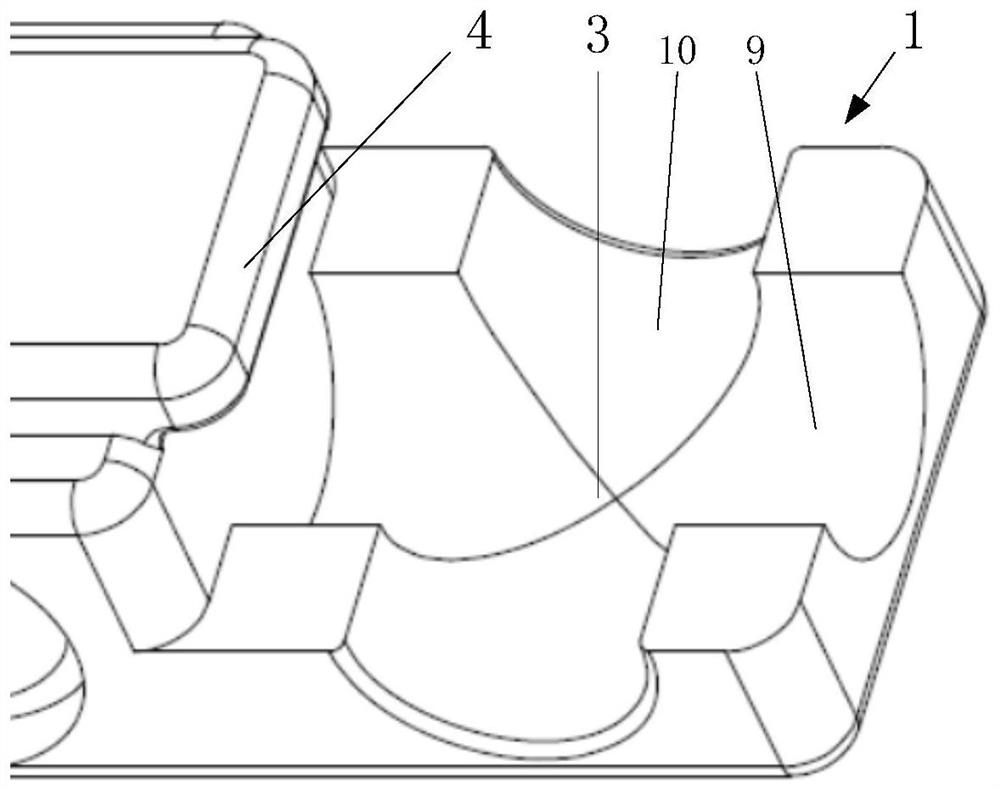

A kind of led panel lamp and its frame

ActiveCN104566067BSimple splicing structureEasy assembly and debuggingPlanar light sourcesLight fasteningsElectrical and Electronics engineeringSurface plate

The invention discloses an LED panel light and a border thereof. The border is formed by splicing two first border section bars and two second border section bards through four angle connectors. The two second border section bars are opposite to each other. First inserting holes are formed in the first border section bards, and second inserting holes are formed in the second border section bards. The angle connectors are plate punching parts and are provided with first inserting arms and second inserting arms. The included angle formed between plane surfaces of the first inserting arms and plane surface of the second inserting arms ranges from 80 degrees to 100 degrees. The roots of the first inserting arms are connected to the roots of the second inserting arms. The heads of the first inserting arms are inserted into the first inserting holes of the first border section bards, the heads of the second inserting arms are inserted into the second inserting holes of the second border section bards, and at least three prop-up positions are arranged on the inserting arms and the inner walls of the inserting holes. The roots of the first inserting arms are bigger than the heads of the first inserting arms, so are the second inserting arms. The LED panel light is simple and reasonable in structure, convenient to assemble and debug, and high in yield and production efficiency.

Owner:ANHUI ZERUN OPTOELECTRONICS

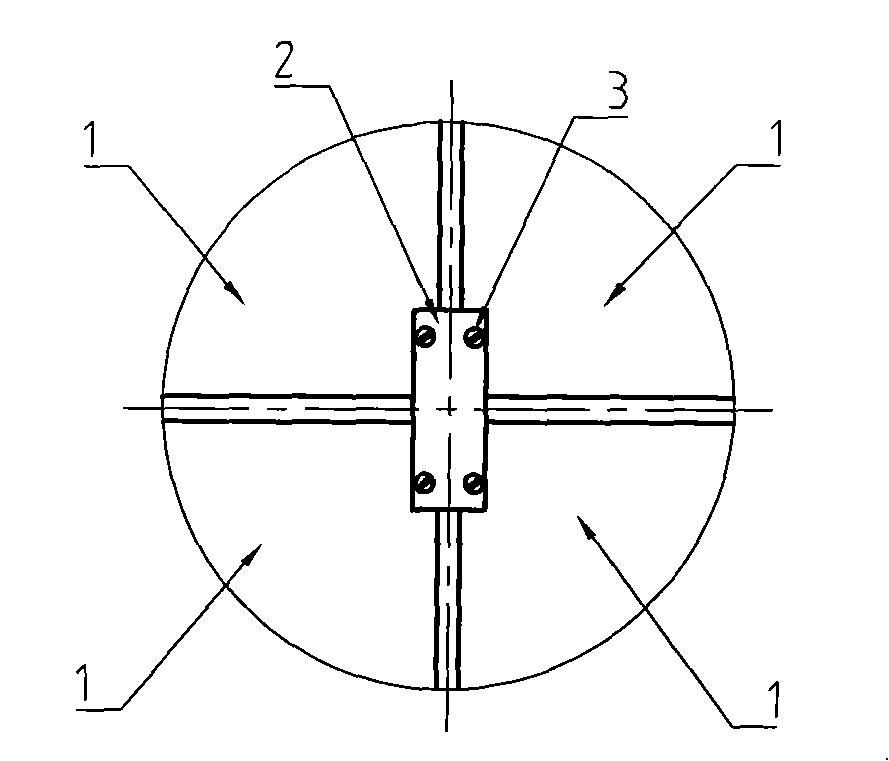

Splicing structure of combined screen

InactiveCN101465086BEasy maintenanceSimple splicing structureIdentification meansMaterial consumptionComputer engineering

The invention discloses a splicing structure of a combination screen, which comprises four rectangular screen units and connecting plates, wherein, the connecting plates are installed on the back of the screen units and positioned at the combining part of the four rectangular screen units, a connecting pin or a connecting screw combined with the connecting plates is arranged on the back of each screen unit and at the combining part, and the four rectangular screen units are connected into a whole. The invention replaces the lifting rope and the lifting tool in the prior art, simplifies the splicing structure, has less material consumption, is convenient for assembling and disassembling, and can not only greatly improve the operating efficiency of installation and disassembly, but also facilitate the maintenance operation of the screen units.

Owner:GTEK GRP LTD

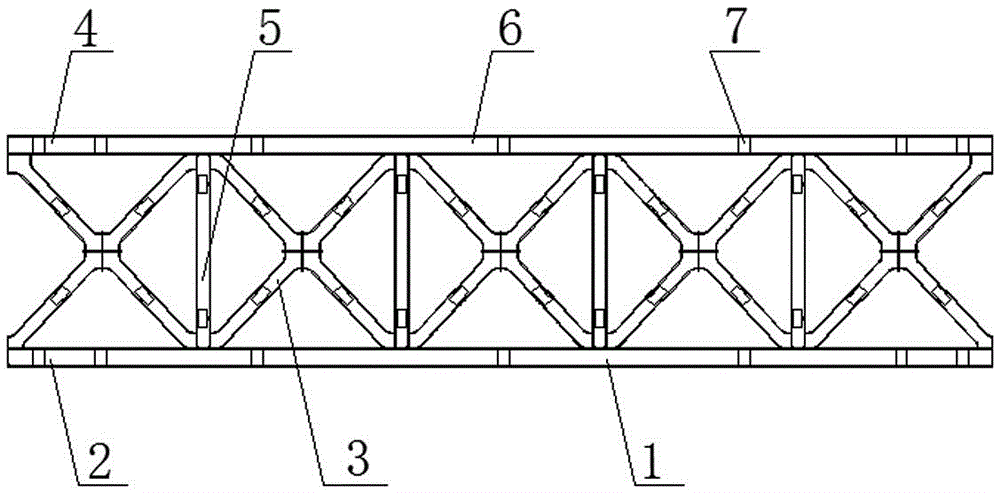

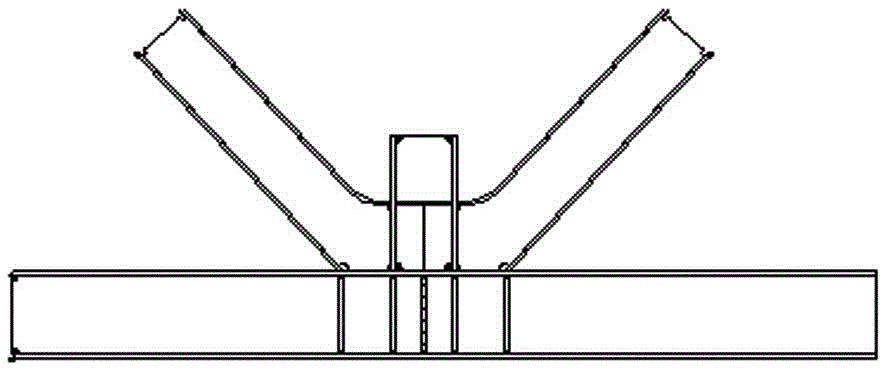

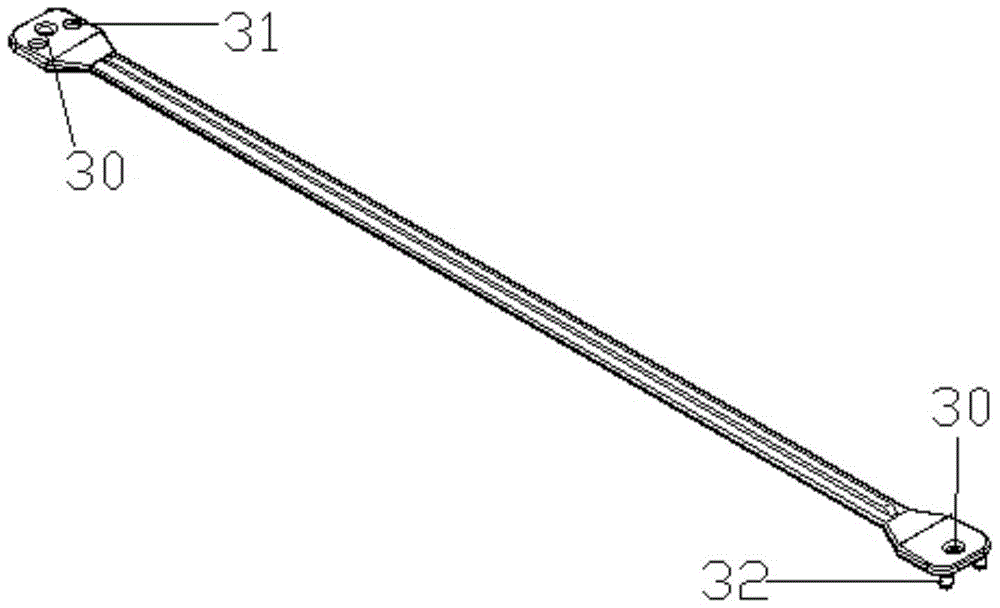

Splitting-type large-span steel truss

The invention discloses a splitting-type large-span steel truss. The splitting-type large-span steel truss consists of inner lower strings, side lower strings, cross joints, side upper strings, web members, inner upper strings and clamping plates. The side lower strings are positioned at the two ends; the inner lower strings are positioned between the side lower strings; components are split into a lower string through joints. The side upper strings are positioned at the two ends; the inner upper strings are positioned between the side upper strings; components are split into an upper string through joints. The cross joints are arranged between the lower string and the upper string which have the same length and opposite to each other in parallel; the outwards extending joints of the cross joints are respectively butted with the lower string and the upper string. The components are split by adopting connecting and welding the clamping plates; the joint strength is high; the safety is guaranteed. The components are dispersed when the splitting-type large-span steel truss is mounted; single components are small in size and light in weight, and are convenient to hang by using a tower crane configured at a construction site; the components are mounted without lifting obstacle in a project.

Owner:ZHENGTAI GRP

Housing, electronic device and manufacturing method of housing

ActiveCN108882580BAchieve relative lockingSimple splicing structureCasings/cabinets/drawers detailsEngineeringStructural engineering

The invention provides a shell, electronic equipment and a shell manufacturing method. The shell comprises a middle plate and a frame; the frame comprises a first segmented frame and a second segmented frame opposite to the first segmented frame; the two ends of the first segmented frame are buckled with the two ends of the second segmented frame respectively; the middle plate is clamped between the first segmented frame and the second segmented frame, and the middle plate has a first edge and a second edge opposite to the first edge; and the first edge abuts against the first segmented frame,and the second edge abuts against the second segmented frame. The splicing structure is simple, simplification of the splicing process is facilitated, and the processing cost is lowered.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A green and environmentally friendly concrete laminated floor slab

ActiveCN109610710BConnection alignment is accurateSimple structureFloorsFloor slabArchitectural engineering

The invention provides an environment-friendly concrete composite floor slab. The environment-friendly concrete composite floor slab is characterized in that the environment-friendly concrete composite floor slab comprises a connecting steel bar support, a bottom plate steel bar support, four connecting steel bars, a bottom plate steel bar, a tie steel bar, a top steel bar, anti-shearing keys, anouter frame, positioning steel bars, positioning pipes, stirrups and a bottom plate steel bar casing pipe; outer frame connecting holes are formed in the two ends of the outer frame, outer frame positioning holes are formed in the two sides of the outer frame, and the anti-shearing keys are arranged on the inner sides of the connecting steel bars and the bottom plate steel bar; the bottom plate steel bar and the upper sides and the lower sides of the connecting steel bars are subjected to concrete pouring to form composite floor slab concrete layers; the positioning pipes penetrate into the space between the composite floor slab concrete layers through the positioning steel bars for fixed connection; the stirrups are arranged on the outer sides of the top ends of the four connecting steelbars in an embracing mode and fixedly connected with the connecting steel bars. Distributed bars in the composite floor slab are distributed evenly, the steel bars are aligned accurately, the structure is simple, the manufacturing process is easy and convenient, manufacturing is easy, the structure strength is high, and construction and mounting are easy.

Owner:中耕耘成建筑科技(镇江)有限公司

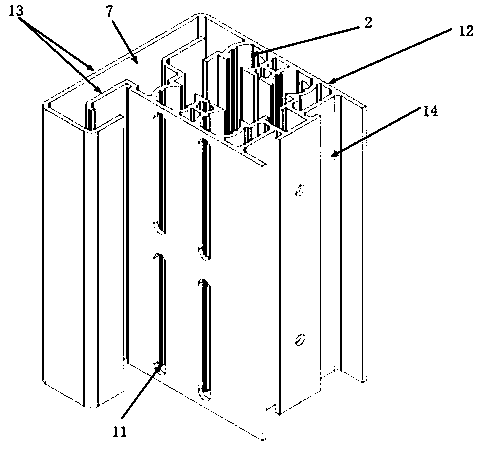

Precast concrete splicing component and preparation method thereof

ActiveCN106121058ASplicing speed is fastShorten the splicing construction periodMould auxillary partsBuilding constructionsPrecast concreteShear force

The invention discloses a precast concrete splicing component and a preparation method thereof. The precast concrete splicing component comprises a first splicing part provided with at least one first splicing face, a second splicing part provided with at least one second splicing face, connecting tenons with base bodies fixed into the first splicing part and the ends protruding out of the first splicing faces, isolation boards with one sides connected with anchor bars, and shearing force locking keys installed in first shearing force key installation cavities and second shearing force key installation cavities. No bolt hole or operation hole needs to be formed in the precast concrete splicing component, and the situation that the section of the precast component is weakened by various hole channels required for splicing and connecting construction of the precast concrete splicing component is eliminated. By the adoption of the precast concrete splicing component, under the condition that the section of the precast concrete component is not weakened, the highest splicing speed can be reached. The splicing accuracy of the precast concrete splicing component is high.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

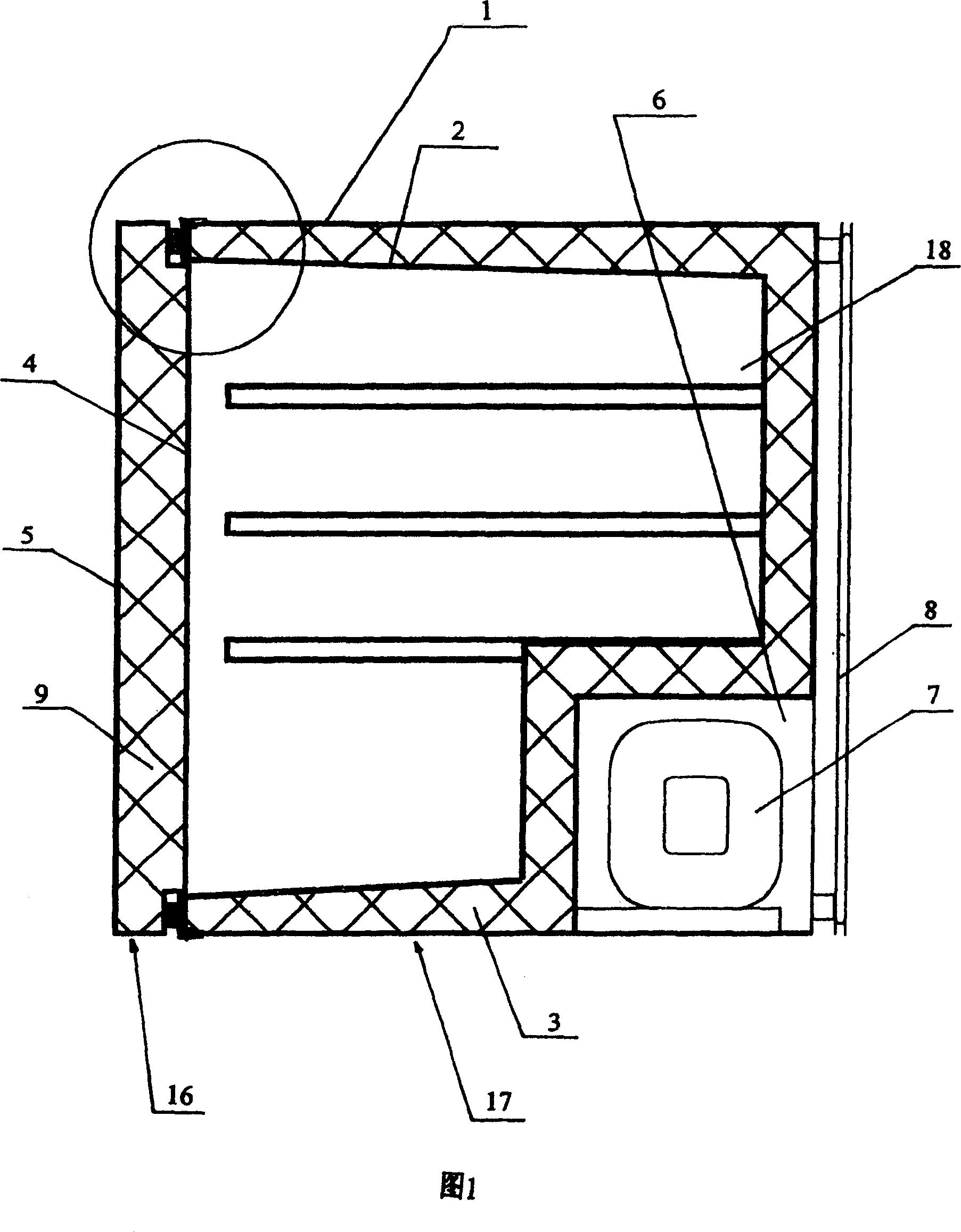

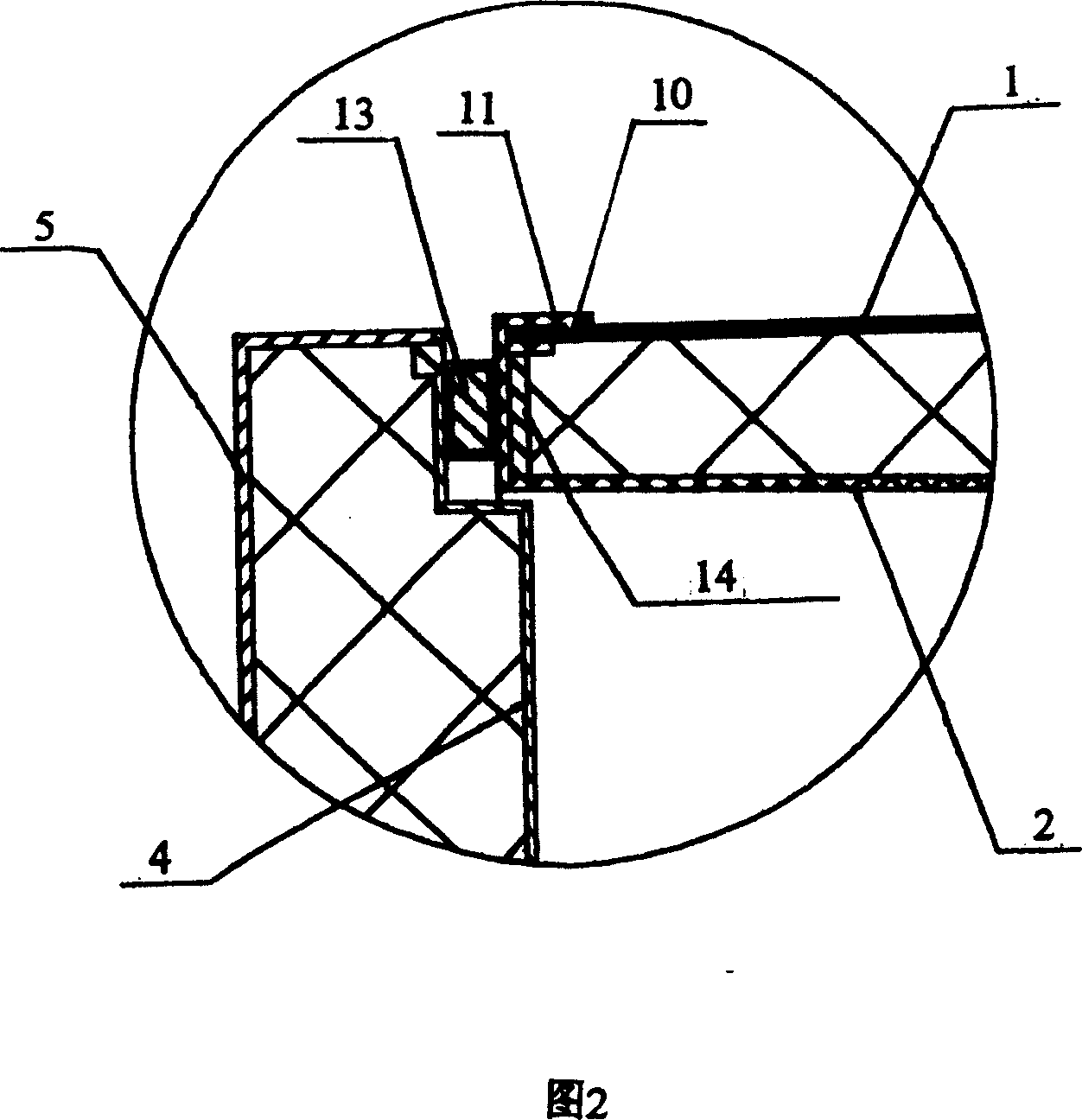

Refrigerator chamber and its manufacture

InactiveCN1303388CSimple and reasonable structureThe splicing structure is simple and reasonableDomestic cooling apparatusLighting and heating apparatusRefrigerator carRefrigerated temperature

The present invention relates to the field of refrigerator chamber producing method and technology via injection machine. The refrigerator chamber includes chamber and door and features that its integral heat insulating layer is one assembled plastic structure of injection molded plastic parts. The casing is divided into two or three plastic parts. It has the advantages of simple structure, easy assembly and low cost.

Owner:陈富定

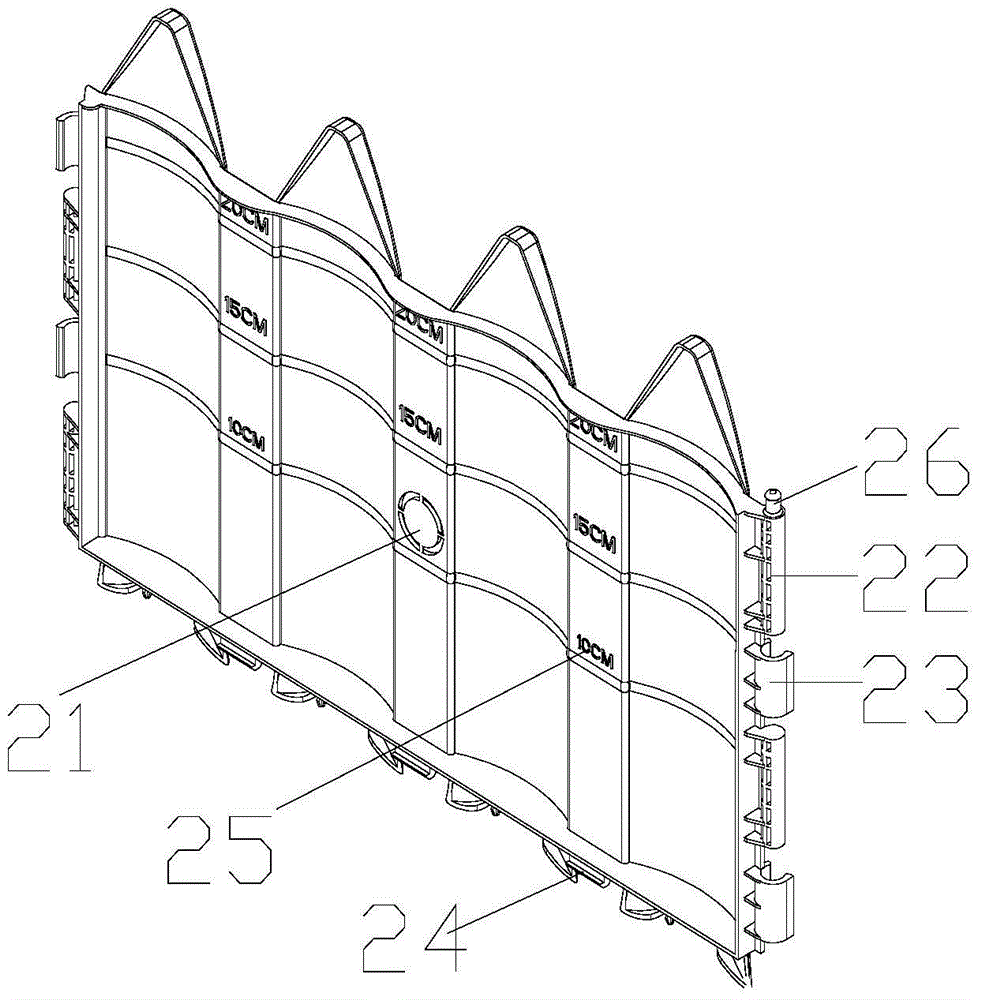

Storage and drainage planting tank

ActiveCN104115692BSimple splicing structureRealize automatic wateringSelf-acting watering devicesReceptacle cultivationWater storageEngineering

Owner:GUANGDONG WELL TECH

A pin bolt type cross mortise precast concrete component and its preparation method

ActiveCN106182361BSimple structureReduced precision requirementsCeramic shaping apparatusBuilding constructionsPrismTongue and groove

The invention discloses a bolt pin-type crossed tenon tooth precast concrete unit and a preparation method thereof. The bolt pin-type crossed tenon tooth precast concrete unit comprises a first splicing part, a second splicing part, segregation boards and shearing force locking bolt pins. Tenon teeth and mortises are arranged at the splicing ends of the first splicing part and the second splicing part at intervals. Each tenon tooth is a prism with the trapezoidal cross section. The segregation boards are provided with folding structures consistent with the tenon teeth and the mortises of the second splicing part. Bolt pin holes are formed in the positions, corresponding to bolt pin mounting cavities of the second splicing part, of the segregation boards. The shearing force locking bolt pins are mounted in the first bolt pin mounting cavities and the second bolt pin mounting cavities in a penetrating mode. The bolt pin-type crossed tenon tooth precast concrete unit is simple in structure. The precision requirement for formworks is low at the prefabrication stage. After prefabrication is completed, precision of joint cracks between precast parts is high, and no subsequent repairing treatment is required after splicing is completed. In addition, the highest splicing speed can be realized under the condition of not decreasing the cross section of the precast concrete unit.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com