Mortise and tenon building block and mortise and tenon building block system

A building block system and building block technology, applied in the field of mortise and tenon building blocks and mortise and tenon building block systems, can solve the problems of poor scalability and inability to become a system of mortise and tenon building blocks splicing, achieve beautiful appearance, increase diversity and flexibility, and expand The effect of imagination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] This embodiment is a preferred example of the present invention.

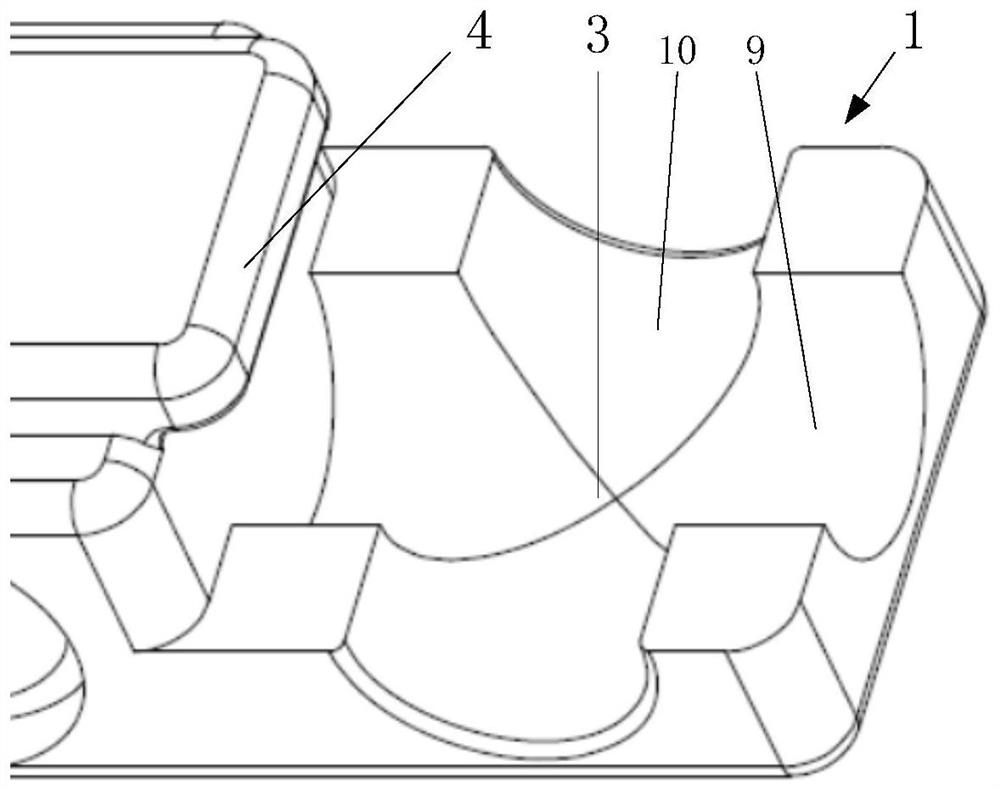

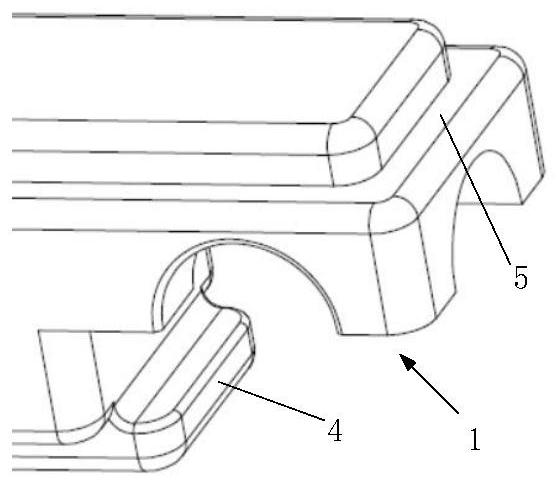

[0140] In this example, if image 3 , Figure 4 , Figure 5 , Image 6 As shown, the tongue and groove structure 3 on the building block body 1 can be spliced with the tongue and groove structure 3 of the other building block body 1 along the length direction of the building block body 1, and can also be spliced with the other building block body along the width direction. On the tongue-and-groove structure 3 of 1, different splicing structure styles are formed after splicing, and the first limiting edge 4 corresponding to the two splicing said tongue-and-groove structures 3 after splicing is crimped with the said limiting platform 5, and the first The limiting edge 4 has a limiting effect on the limiting platform 5 in the thickness direction, and two first splicing holes 6 are formed between the two tongue-and-groove structures 3 , and the first splicing holes 6 are round holes.

[0141] In this...

Embodiment 2

[0154] This embodiment is another preferred example of the present invention.

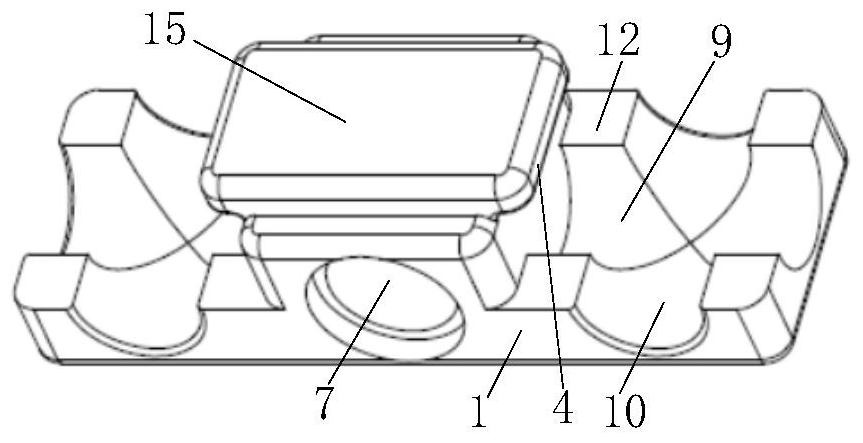

[0155] In this example, if Figure 7 , Figure 8 As shown, there are tongue-and-groove structures 3 along both ends of the building block body 1 and the fronts of the tongue-and-groove structures 3 face the same direction, and the structures of the tongue-and-groove structures 3 at both ends are not completely the same. The tongue-and-groove structure 3 is viewed as a square when viewed from above.

[0156] The building block body 1 has one or more second expansion holes 8, and the diameter of the second expansion hole 8 is larger than the diameter of the first splicing hole 6. In this embodiment, the building block body 1 has a second expansion hole parallel to the width direction. Two expansion holes 8.

[0157]There are bosses 11 along one or both sides of the second arc-shaped groove 10 and the bosses 11 match the first arc-shaped groove 9 or the second arc-shaped groove 10 on the other tong...

Embodiment 3

[0162] This embodiment is the third preferred example of the present invention.

[0163] In this example, if Figure 9 , Figure 10 As shown, there are tongue-and-groove structures 3 along both ends of the building block body 1 and the fronts of the tongue-and-groove structures 3 face the same direction, and the structures of the tongue-and-groove structures 3 at both ends are not completely the same. The tongue-and-groove structure 3 is viewed as a square when viewed from above.

[0164] In this embodiment, the building block body 1 has a second expansion hole 8, and the opening direction of the second expansion hole 8 is parallel to the thickness direction of the building block body 1. Through the second expansion hole 8, one expansion hole in the thickness direction of the building block body 1 can be realized. Side or both sides can be expanded to allow for fun building blocks.

[0165] In this embodiment, the two ends of the second expansion hole 8 along the length dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com