Combination type installed shingle splicing structure

A wall panel and combined technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of single wall panel installation shape and affect the construction quality, so as to prevent wall panel damage, simplify construction steps, and expand the scope of application broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

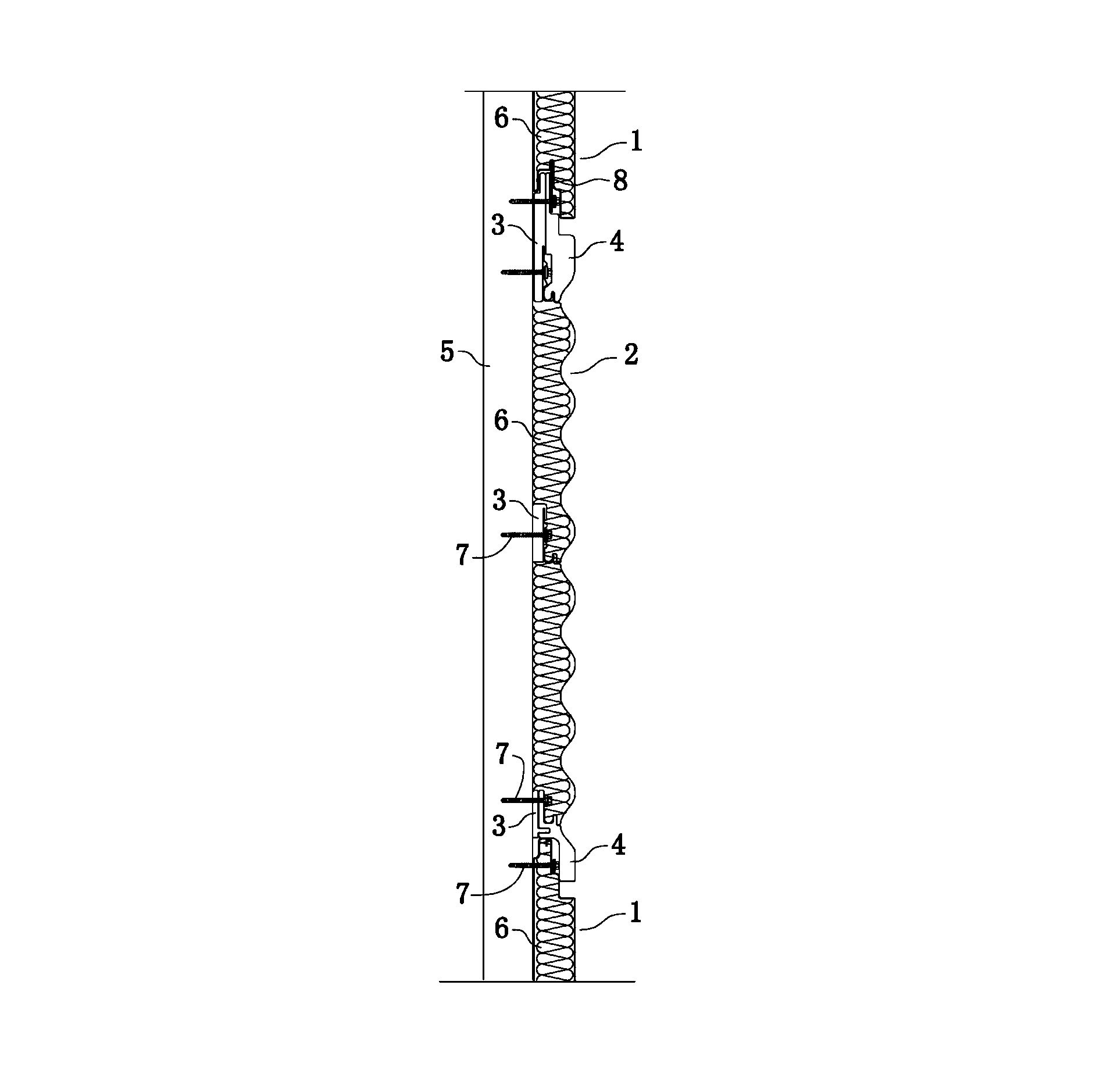

[0020] refer to figure 1 As shown, one embodiment of the present invention is a wall panel splicing structure for combined installation, and the splicing structure includes a first wall panel body 1 and a second wall panel body 2, and the first wall panel body 1 and the second wall panel body The ends of the second wall panel body 2 spliced with each other are provided with a socket, the bottom of the socket is provided with a pad 3, and the top is provided with a tongue and groove connector 4; the pad 3 is connected to the first wall panel body respectively. 1. The bottom of the socket of the second wall panel body 2 is compatible; one end of the tongue-and-groove connector 4 is compatible with the socket of the first wall panel body 1, and the other end is compatible with the socket of the second wall panel body 2 Engagement; the first wall panel body 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com