Spliced 3D printing waterproof chassis

A 3D printing and splicing technology, which is applied to floors, insulation layers, buildings, etc., can solve the problems of weak seal, inability to realize chassis sealing connection, poor effect, etc., to achieve enhanced waterproof effect, improved fixing effect, and simple splicing structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

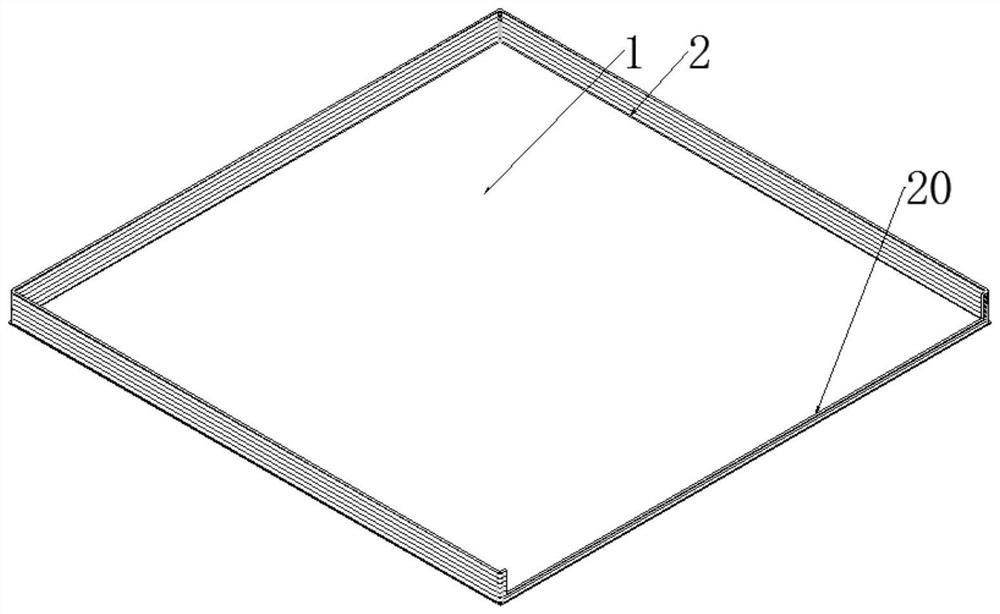

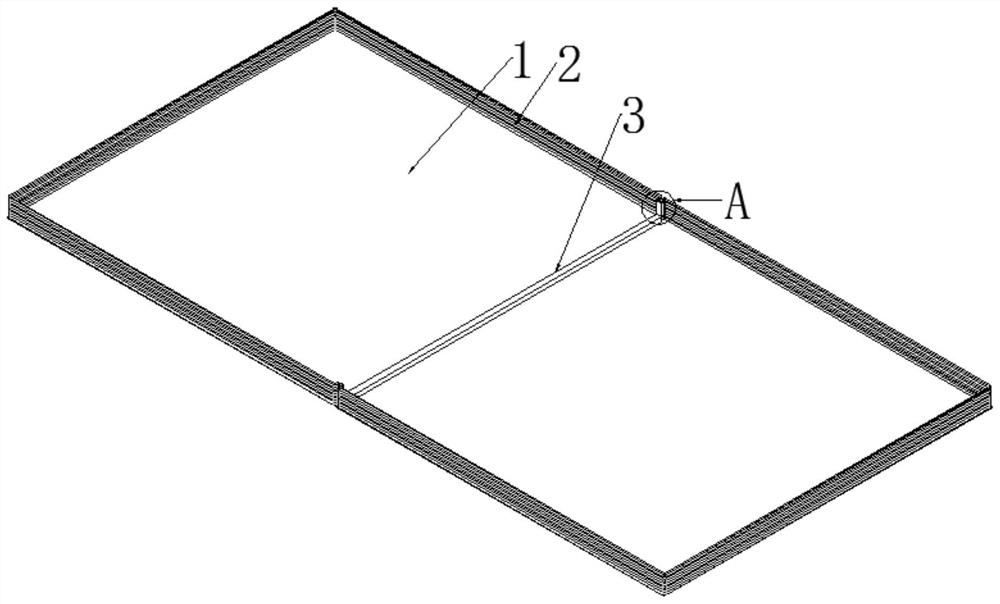

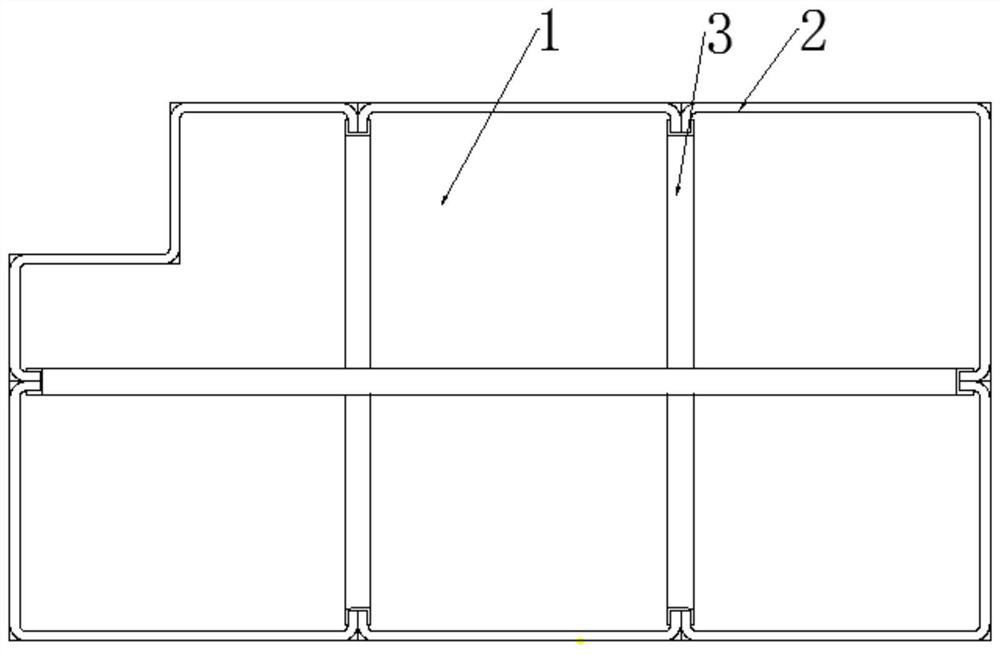

[0035] Such as Figure 1-9 As shown, the present invention provides a spliced 3D printing waterproof chassis, comprising:

[0036] At least two first bottom plate zero pieces 1, at least two first bottom plate zero pieces 1 are spliced to form the chassis body, wherein each first bottom plate zero piece 1 is 3D printed along the circumferential direction to set a first waterproof enclosure 2, the first bottom plate zero piece 1 A waterproof enclosure 2 has a bolt-shaped protrusion along the circumference, the splicing edge of the first waterproof enclosure 2 is cut to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com