Splitting-type large-span steel truss

A large-span, steel truss technology, applied in the field of steel trusses and metal components, can solve the problems of large-span steel trusses, such as large volume, inconvenient vertical lifting, heavy weight, etc., and achieve simple splicing structure, low construction supporting conditions, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

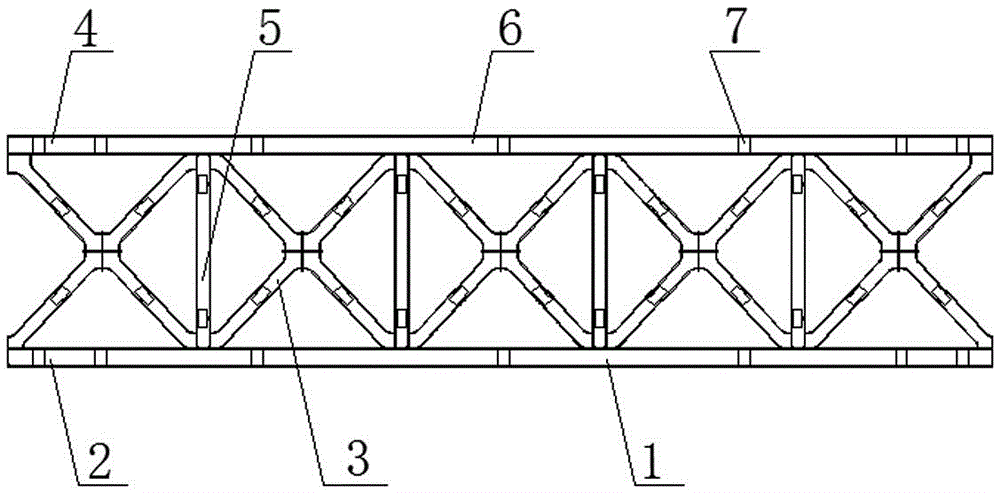

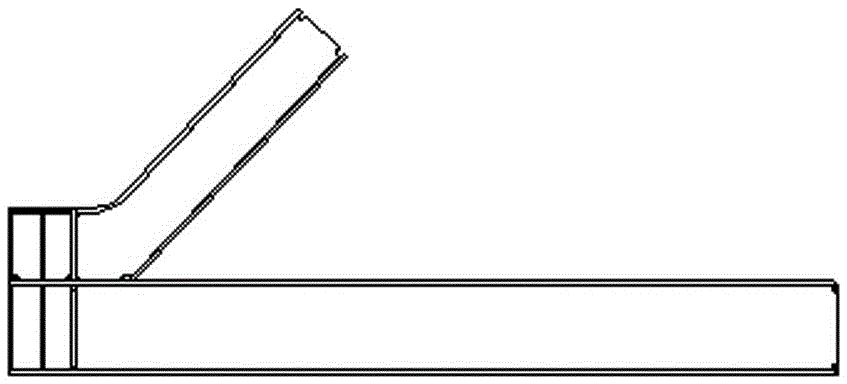

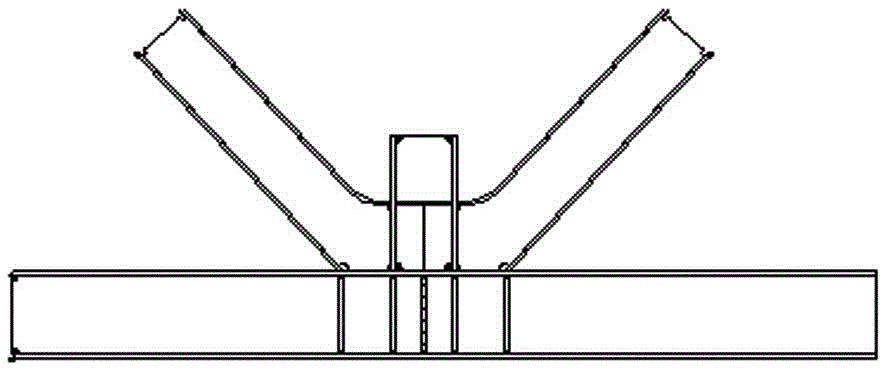

[0022] figure 1 The illustrated embodiment is a spliced long-span steel truss installed on the top floor of a 94.1-meter-high factory building, with a span of 38 meters and a weight of 37 tons per truss. Because the original design is a rectangular truss with an overall structure, the resulting product is large in size and heavy in weight, and cannot be lifted vertically with conventional lifting equipment at the construction site. In order to overcome the difficulty of hoisting large and super-heavy components to the top floor of super-high factory buildings for installation, the overall structural scheme of long-span steel trusses was abandoned, and a spliced long-span steel truss was adopted. The steel truss of this structure is in pieces before installation, so the individual components are small in size and light in weight, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com